0% found this document useful (0 votes)

259 views1 page3D Connection Design for Structural Stability

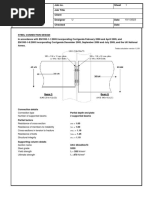

The stability of a structure depends mainly on its connections, which often fail due to shear forces at joints. The document provides a simple 5-step design procedure for 3D structural connections: (1) determine member end forces, (2) calculate connection forces, (3) design bolts for tension and shear capacity, (4) ensure combined capacity is less than 1, and (5) ensure plate thickness is greater than bolt diameter. It also defines notations for the various forces, dimensions, bolt properties, and number of bolts.

Uploaded by

Mahaveer JanapalaCopyright

© Attribution Non-Commercial (BY-NC)

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

259 views1 page3D Connection Design for Structural Stability

The stability of a structure depends mainly on its connections, which often fail due to shear forces at joints. The document provides a simple 5-step design procedure for 3D structural connections: (1) determine member end forces, (2) calculate connection forces, (3) design bolts for tension and shear capacity, (4) ensure combined capacity is less than 1, and (5) ensure plate thickness is greater than bolt diameter. It also defines notations for the various forces, dimensions, bolt properties, and number of bolts.

Uploaded by

Mahaveer JanapalaCopyright

© Attribution Non-Commercial (BY-NC)

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd