0% found this document useful (0 votes)

560 views9 pagesMini Project Jib Crane Design

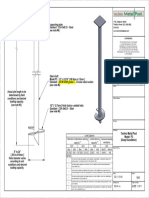

1) The author designs a jib crane beam made of S275 steel with cross section dimensions of 206mm height, 204mm width, and moment of inertia of 5268 x 10^4 mm^4. Static analysis shows maximum stresses of 40.4 MPa and dynamic analysis shows 135.5 MPa.

2) The author designs a cylindrical member AB with diameter of 30mm made of the same steel. Static analysis shows maximum stress of 59.3 MPa and dynamic analysis shows 164.5 MPa.

3) The author designs a pin connection and bracket to connect member AB to beam BC, with the pin made of stainless steel 303 and the bracket made of stainless steel 304.

Uploaded by

mohamed.hassan031Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

560 views9 pagesMini Project Jib Crane Design

1) The author designs a jib crane beam made of S275 steel with cross section dimensions of 206mm height, 204mm width, and moment of inertia of 5268 x 10^4 mm^4. Static analysis shows maximum stresses of 40.4 MPa and dynamic analysis shows 135.5 MPa.

2) The author designs a cylindrical member AB with diameter of 30mm made of the same steel. Static analysis shows maximum stress of 59.3 MPa and dynamic analysis shows 164.5 MPa.

3) The author designs a pin connection and bracket to connect member AB to beam BC, with the pin made of stainless steel 303 and the bracket made of stainless steel 304.

Uploaded by

mohamed.hassan031Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd