Professional Documents

Culture Documents

Hydraulic Machinery

Uploaded by

getsweetOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hydraulic Machinery

Uploaded by

getsweetCopyright:

Available Formats

Monroe L.

Weber-Shirk

School of Civil and

Environmental Engineering

Hydraulic Machinery

Pumps, Turbines...

Hydraulic Machinery Overview

Types of Pumps

Dimensionless Parameters for Turbomachines

Power requirements

Head-discharge curves

Pump Issues

Cavitation

NPSH

Priming

Pump selection

Types of Pumps

Positive displacement

piston pump

peristaltic pump

gear pump

two-lobe rotary pump

screw pump

Jet pumps

Turbomachines

axial-flow (propeller pump)

radial-flow (centrifugal pump)

mixed-flow (both axial and radial flow)

Positive Displacement Pumps

Piston pump

Diaphragm pump

Peristaltic pump

Rotary pumps

gear pump

two-lobe rotary pump

screw pump

Reciprocating action pumps

Piston pump

can produce very high pressures

hydraulic fluid pump

high pressure water washers

diaphragm pump

Peristaltic Pump

Fluid only contacts tubing

Tubing ___ and roller

_______ with respect to the

tubing determine flow rate

Tubing eventually fails

from fatigue and abrasion

Fluid may leak past roller at

high pressures

Viscous fluids may be

pumped more slowly

ID

velocity

Rotary Pumps

Gear Pump

fluid is trapped between gear teeth and the

housing

Two-lobe Rotary Pump

(gear pump with two teeth on each gear)

same principle as gear pump

fewer chambers - more extreme pulsation

trapped fluid

Rotary Pumps

Disadvantages

precise machining

abrasives wear surfaces rapidly

pulsating output

Uses

vacuum pumps

air compressors

hydraulic fluid pumps

food handling

Screw Pump

Can handle debris

Used to raise the

level of wastewater

Abrasive material

will damage the

seal between screw

and the housing

Grain augers use

the same principle

Positive Displacement Pumps

What happens if you close a valve on the

effluent side of a positive displacement pump?

What does flow rate vs. time look like for a

piston pump?

0

0.2

0.4

0.6

0.8

1

1.2

0 2 4 6 8 10

rads

t

o

t

a

l

f

l

o

w

1st piston

2nd piston

3rd piston

3 pistons

Thirsty Refugees

Jet Pump

eductor

A high pressure, high velocity jet discharge is

used to pump a larger volume of fluid.

Advantages

no moving parts

self priming

handles solids easily

Disadvantage

inefficient

Uses

deep well pumping

pumping water mixed with solids

(inefficient process)

Turbomachines

impeller

casing housing

( ) ( )

2 1

2 1 z t t

T Q r V rV r

= -

Demours centrifugal pump - 1730

Theory

conservation of angular momentum

conversion of kinetic energy to potential energy in flow

expansion ___________ ________

Pump components

rotating element - ___________

encloses the rotating element and seals the pressurized

liquid inside - ________ or _________

Pressure Developed by

Centrifugal Pumps

g

V

H

2

2

= velocity head

Centrifugal pumps accelerate a liquid

The maximum velocity reached is the velocity of the

periphery of the impeller

The kinetic energy is converted into potential energy

as the fluid leaves the pump

The potential energy developed is approximately

equal to the ________ ____ at the periphery of the

impeller

A given pump with a given impeller diameter and

speed will raise a fluid to a certain height regardless

of the fluid density

Radial Pumps

Impeller

Vanes

Casing

Suction Eye Impeller

Discharge

centrifugal

Flow Expansion

diameter

rotational speed

also called _________ pumps

broad range of applicable flows and heads

higher heads can be achieved by increasing the

_______ or the ________ ______ of the impeller

Axial Flow

propeller

also known as

__________ pumps

low head (less than 12

m)

high flows (above 20

L/s)

Dimensionless Parameters for

Turbomachines

We would like to be able to compare pumps with

similar geometry. Dimensional analysis to the

rescue...

To use the laws of similitude to compare

performance of two pumps we need

exact geometric similitude

all linear dimensions must be scaled identically

roughness must scale

homologous - streamlines are similar

constant ratio of dynamic pressures at corresponding

points

also known as kinematic similitude

3

D

Q

e

same

Kinematic Similitude:

Constant Force Ratio

VD

gl

V

2

gl

V

o

l V

2

V

c

viscous

gravity

surface-tension

elastic

Reynolds

ratio of inertial to _______ forces

Froude

ratio of inertial to ________ force

Weber

ratio of inertial to _______ ______ forces

Mach

ratio of inertial to _______ forces

Turbomachinery Parameters

2

2

C

V

p

p

A

=

2

C

V

Hg

H

A

=

2

flow

D

Q

A

Q

V =

2

4

C

Q

HgD

flow

H

A

=

4

2 3

, , ,

flow flow

H

impeller flow flow

HgD D

Q

C f Re

Q D D D

e

w

D

= =

impeller

(Impeller is better defined)

3

, , , , , ,

flow

p

impeller flow flow

D

Q

C f Re F W M

D D D

e

w

=

Where is the fluid?

Shape Factor

Related to the ratio of flow passage

diameter to impeller diameter

Defined for the point of best efficiency

What determines the ideal shape for a

pump?

) ( f S = e , , , p Q A

Exercise

Impeller Geometry:

Shape Factor

0.18

0.37

1.25

2.33

3.67

axial: high _______, low _______

mixed

radial

mixed

S =

e Q

gH

p

( )

3 4

pressure flow

pressure flow

S

500

1000

3400

6400

10000

N

( )

4 3

p

sp

H

Q N

N =

*

N in rpm, Q in gpm, H in ft

*

Impeller

diameter

N

sp

= 2732S

Radial: high _______, low ____

Use of Shape Factor:

Specific Speed

The maximum efficiencies for all pumps occurs

when the Shape Factor is close to 1!

Flow passage dimension is close to impeller diameter!

Low expansion losses!

There must be an optimal shape factor given a

discharge and a head.

Double suction (like two pumps in parallel)

Multistage (pumps in series)

Use Q and H for each stage

S =

e Q

gH

p

( )

3 4

Additional Dimensionless

Parameters

C

H

=

AHg

e

2

D

2

5 3

D

P

C

P

e

=

C

Q

=

Q

eD

3

S =

C

Q

1 2

C

H

3 4

impeller

power

Alternate equivalent way

to calculate S.

D is the _______ diameter

P is the _____

(defined at max efficiency)

H Q P

w

A =

Head-Discharge Curve

Theoretical

head-discharge

curve

Actual head-

discharge curve

Q

H

circulatory flow -

inability of finite

number of blades to

guide flow

friction - ____

shock - incorrect angle

of blade inlet ___

other losses

bearing friction

packing friction

disk friction

internal leakage

V

2

AV

2

Pump Power Requirements

H Q P

w

A =

s

w

P

P

P

e =

m

s

m

P

P

e =

m P

m

e e

H Q

P

A

=

water

pump

shaft

motor

Water power

Subscripts

w = _______

p = _______

s = _______

m = _______

Impeller Shape vs. Power Curves

S

1 - O.33

2 - 0.81

3 - 1.5

4 - 2.1

5 - 3.4

Discharge (% of design)

P

o

w

e

r

(

%

o

f

d

e

s

i

g

n

)

axial

radial

Implications

http://www.mcnallyinstitute.com/

Affinity Laws

With speed, e, held constant:

3

2

1

2

1

|

|

.

|

\

|

=

e

e

P

P

2

2

1

2

1

|

|

.

|

\

|

=

A

A

e

e

H

H

2

1

2

1

e

e

=

Q

Q

With diameter, D, held constant:

5

1 1

2 2

P D

P D

=

2

2

1

2

1

|

|

.

|

\

|

=

A

A

D

D

H

H

3

1 1

2 2

Q D

Q D

=

C

H

=

AHg

e

2

D

2

C

Q

=

Q

eD

3

H Q P A =

5 3

D

P

C

P

e

=

0

0.01

0.02

0.03

0.04

0.05

0.06

0.07

0.08

0 0.02 0.04 0.06 0.08 0.1

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

D=0.366 m

Dimensionless Performance

Curves

C

H

=

AHg

e

2

D

2

3

D

Q

C

Q

e

=

Efficiency

(defined at max efficiency)

4 3

2 1

H

Q

C

C

S =

Curves for a particular pump

____________ of the fluid! Independent

( )

( )

3 . 4

027 . 0

083 . 0

75 . 0

5 . 0

=

Pump Example

Given a pump with shape factor of 4.57, a

diameter of 366 mm, a 2-m head, a speed of

600 rpm, and dimensionless performance

curves (previous slide).

What will the discharge be?

How large a motor will be needed if motor

efficiency is 95%?

Exercise

0

0.01

0.02

0.03

0.04

0.05

0.06

0.07

0.08

0 0.02 0.04 0.06 0.08 0.1

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

D=0.366 m

C

H

=

AHg

e

2

D

2

3

D

Q

C

Q

e

=

E

f

f

i

c

i

e

n

c

y

0

0.01

0.02

0.03

0.04

0.05

0.06

0.07

0.08

0 0.02 0.04 0.06 0.08 0.1

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

D=0.366 m

C

H

=

AHg

e

2

D

2

3

D

Q

C

Q

e

=

E

f

f

i

c

i

e

n

c

y

Pumps in Parallel or in Series

Parallel

Flow ________

Head ________

Series

Flow ________

Head ________

Multistage

adds

same

same

adds

Cavitation in Water Pumps

water vapor bubbles

form when the pressure

is less than the vapor

pressure of water

very high pressures

(800 MPa or 115,000

psi) develop when the

vapor bubbles collapse

0

1000

2000

3000

4000

5000

6000

7000

8000

0 10 20 30 40

Temperature (C)

V

a

p

o

r

p

r

e

s

s

u

r

e

(

P

a

)

Net Positive Suction Head

NPSH

R

- absolute pressure in excess of vapor

pressure required at pump inlet to prevent

cavitation

given by pump manufacturer

determined by the water velocity at the entrance to the

pump impeller

NPSH

A

- pressure in excess of vapor pressure

available at pump inlet

determined by pump installation (elevation above

reservoir, frictional losses, water temperature)

If NPSH

A

is less than NPSH

R

cavitation will occur

Net Positive Suction Head

1

2

2

2

s s v

R

p V p

NPSH

g g g

= + -

s = suction

Total head -p

v

!

NPSH

R

increases with Q

2

!

Elevation datum

Absolute pressure

2

2

eye eye

v

R

p V

p

NPSH

g g g

= - + At cavitation!

Az

How much total head in excess of vapor pressure is available?

NPSH

R

2

2

atm v s s v

L

p p p V p

z h

g g g g g

- D - - = + -

2

2

atm s s

reservoir L

p p V

z h

g g g

+ = + +

2

2

atm s s

L

p p V

z h

g g g

- D - = +

atm v

L A

p p

z h NPSH

g g

- D - - =

Subtract vapor pressure

2 2

1 1 2 2

1 2

2 2

L

p V p V

z z h

g g g g

+ + = + + +

NPSH problem

Determine the minimum

reservoir level relative to the

pump centerline that will be

acceptable. The NPSH

r

for

the pump is 2.5 m. Assume

you have applied the energy

equation and found a head

loss of 0.5 m.

18C

?

Exercise

Pumps in Pipe Systems

60 m

1 km

Pipe diameter is 0.4 m

and friction factor is

0.015. What is the pump

discharge?

h

p

= z

2

z

1

+ h

l

h

p

= f (Q)

1 m 1 m

2

p

h a bQ = -

often expressed as

p

1

+

V

1

2

2g

+ z

1

+ h

p

=

p

2

+

V

2

2

2g

+ z

2

+ h

l

Pumps in Pipe Systems

0

20

40

60

80

100

120

0 0.2 0.4 0.6 0.8

Discharge (m

3

/s)

H

e

a

d

(

m

)

system operating point

Static head

Head vs. discharge

curve for ________

pump

What happens as the static head changes (a tank fills)?

Priming

C

H

=

Ap

e

2

D

2

Ap = C

H

e

2

D

2

C

H

=

AHg

e

2

D

2

density

1.225 kg/m

3

The pressure increase created is

proportional to the _______ of the fluid

being pumped.

A pump designed for water will be

unable to produce much pressure

increase when pumping air

Density of air at sea level is __________

Change in pressure produced by pump is

about 0.1% of design when pumping air

rather than water!

Priming Solutions

Applications with water at less than atmospheric

pressure on the suction side of the pump require a

method to remove the air from the pump and the

inlet piping

Solutions

foot valve

priming tank

vacuum source

self priming

foot valve

to vacuum pump

priming tank

Self-Priming Centrifugal Pumps

Require a small volume of liquid in the

pump

Recirculate this liquid and entrain air from

the suction side of the pump

The entrained air is separated from the

liquid and discharged in the pressure side of

the pump

Variable Flows?

How can you obtain a wide range of flows?

__________________________

__________________________

__________________________

__________________________

__________________________

Why is the flow from two identical pumps

usually less than the 2x the flow from one

pump?

Valve

Multiple pumps (same size)

Multiple pumps (different sizes)

Variable speed motor

Storage tank

RPM for Pumps

60 cycle

variable speed

belt drive

number of

poles sync full load rad/sec

2 3600 3500 367

4 1800 1750 183

6 1200 1167 122

8 900 875 92

10 720 700 73

12 600 583 61

14 514 500 52

16 450 438 46

18 400 389 41

20 360 350 37

22 327 318 33

24 300 292 31

26 277 269 28

28 257 250 26

30 240 233 24

Estimate of Pump rpm

The best efficiency is obtained when S=1

Given a desired flow and head the

approximate pump rpm can be estimated!

S =

e Q

gH

p

( )

3 4

( )

3 4

p

gH

Q

w

Pump Selection

Material Compatibility

Solids

Flow

Head

NPSH

a

Pump Selection software

A finite number of pumps will come close to

meeting the specifications!

Pump Selection Chart

Model X

Model M

http://www.pricepump.com/

End of Curve Operation

Right of the BEP

is sufficient NPSH available for the pump to operate

properly?

fluid velocities through the suction and discharge

nozzles of the pump could be extremely high, resulting

in increased pump and system noise

Left of BEP operation

high thrust loads on the pump bearings and mechanical

face seals result in premature failure.

The pump is oversized, resulting in lower efficiency

and higher operating and capital costs.

Goulds Pump Curves

BEP = 1836 L/s

S =

e Q

gH

p

( )

3 4

Splitcase double suction

890 rpm = 93.2 rad/s

S=0.787

Check the Power!

Pump Installation Design

Why not use one big pump?

Can the system handle a power failure?

Can the pump be shut down for

maintenance?

How is the pump primed?

Are there enough valves so the pump can be

removed for service without disabling the

system?

Pump Summary

Positive displacement vs. turbomachines

Dimensional analysis

Useful for scaling

Useful for characterizing full range of pump

performance from relatively few data points

Turbomachines convert shaft work into increased

pressure (or vice versa for turbines)

The operating point is determined by where the

pump and system curves intersect

NPSH

Water problem?

Early in my college days I took a break and spent 17 months in Salvadoran

refugee camps in Honduras. The refugee camps were located high in the

mountains and for several of the camps the only sources of water large enough

to sustain the population of 6-10,000 were located at much lower elevations. So

it was necessary to lift water to the camps using pumps.

When I arrived at the camps the pumps were failing frequently and the pipes

were bursting frequently. Piston pumps were used. The refugees were

complaining because they needed water. The Honduran army battalion was

nervous because they didnt want any refugees leaving the camp. There was

only one set of spare parts (valve springs and valves) for the pump and the last

set of parts only lasted a few days. The pump repair crew didnt want to start

using the pump until the real cause of the problem was fixed because spare

parts have to be flown in from Miami.

Water problem:

proposed solutions?

piston pump (80 L/min)

2 km pipeline (2

galvanized and then

3 PVC) with rise of

100 m

Shape Factor Solution

Create a dimensionless grouping

Ap

Ap

Q

2 3

Ap

Q

2 3

e

4 3

Eliminate ______

Eliminate _______

Eliminate ______

S =

e Q

Ap

|

\

|

.

|

3 4

S =

e Q

gH

p

( )

3 4

mass

length

time

) ( f S = e , , , p Q A

Pump Curve Solution

2 2

D

Hg

C

H

e

A

=

C

Q

=

Q

eD

3

s

rev s

rev

/ 8 . 62

2

60

min 1

min

600

=

|

|

.

|

\

|

|

|

.

|

\

|

|

|

.

|

\

|

=

t

e

( )( )

( ) ( )

037 . 0

366 . 0 / 8 . 62

/ 8 . 9 2

2 2

2

= =

m s

s m m

C

H

068 . 0 =

Q

C

3

D C Q

Q

e =

( )( )( ) s m m s Q / 21 . 0 366 . 0 / 8 . 62 068 . 0

3

3

= =

( )( )

( )

( )( )

3 3

9800 / 0.21 / 2

5.55

0.78 0.95

N m m s m

P kW = =

m P

m

e e

H Q

P

A

=

Pump Curve Solution

0

0.01

0.02

0.03

0.04

0.05

0.06

0.07

0.08

0 0.02 0.04 0.06 0.08 0.1

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

D=0.366 m

C

H

=

AHg

e

2

D

2

C

Q

=

Q

eD

3

Efficiency

NPSH solution

18C

?

A R

NPSH NPSH =

atm v

l R

p p

z h NPSH

g

-

D = - -

Pa p

v

2000 =

3

/ 9789 m N =

101300

atm

p Pa =

( ) ( )

m m

m N

Pa Pa

z 5 . 2 5 . 0

/ 9789

2000 101300

3

= A

m z 14 . 7 = A

atm v

A L

p p

NPSH z h

g

-

= - D -

Implications of Power Curves

You are going to start a radial flow pump

powered by an electric motor. You want to

reduce the starting load on the motor. What

can you do?

What would you do if you were starting an

axial flow pump?

How could reducing the head on a radial

flow pump result in motor failure?

Find Q

( ) ( )

2 1

2 1 z t t

T Q r V rV r

= -

2

2 z t

T QV r r =

p

1

+

V

1

2

2g

+ z

1

+ h

p

=

p

2

+

V

2

2

2g

+ z

2

+ h

l

2

2 z t

T Q V r w r w =

2

2 t

z

p

V r

T

h

Q g

w

w

g

= =

2

2

2

2

2

2

t

V r

V

z

g g

w

= +

work

Dimensional analysis

Neglect head loss

Datum is reservoir level

Let A = 10 cm

2

2

2 t

z

V r

T

VA g

w

w

g

=

How could we lift water more

efficiently?

2

2

2

2

2

t

V r

V

z

g g

w

= + D

2

2 2

2 2

t

Q A V r g z AV w = - D =

Solve for Q=AV

Decrease V without decreasing Q! (

v

t

e

r

cs

2

p

z

h

T

z Q z

w

g

=

D D

2

2

2 2

t

p z

A z V r g z

z

h T

g w

w

D - D

D

=

2

2 z t

T Q V r w r w =

Lost energy

2

2

2

2

2

t

V r

V

z

g g

w

= + D

2

2

2

2

2

t

V r

V

z

g g

w

= + D

0.1

1

10

100

1000

0.0001 0.001 0.01 0.1 1 10

Flow (m

3

/s)

P

u

m

p

i

n

g

h

e

a

d

(

m

)

Axial

Mixed

Radial

Positive

displacement

20

40

60

10

200

400

600

100

2000

4000

6000

1000

1 2 4 6

Selection of Pump Type

P

o

w

e

r

(

k

W

)

You might also like

- Southern Marine Engineering Desk Reference: Second Edition Volume IiFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IiNo ratings yet

- How To Design Solar PV System - Guide For Sizing Your Solar Photovoltaic SystemDocument2 pagesHow To Design Solar PV System - Guide For Sizing Your Solar Photovoltaic Systemgetsweet100% (1)

- Centrifugal Pump Design GuideDocument44 pagesCentrifugal Pump Design Guidedinsha100% (1)

- Rotating Equipment Interview QuestionsDocument5 pagesRotating Equipment Interview QuestionsSud100% (1)

- Southern Marine Engineering Desk Reference: Second Edition Volume IFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume INo ratings yet

- Control of DC Motor Using Different Control StrategiesFrom EverandControl of DC Motor Using Different Control StrategiesNo ratings yet

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Centrifugal PumpDocument42 pagesCentrifugal PumpKautilyaChennaNo ratings yet

- Understanding Centrifugal PumpDocument7 pagesUnderstanding Centrifugal PumpjokishNo ratings yet

- Pump Basics1Document34 pagesPump Basics1Surendra ReddyNo ratings yet

- 3.6 Pumps - Revised (Table Format)Document11 pages3.6 Pumps - Revised (Table Format)mtpiping2572No ratings yet

- Clickable List: E - HydraulicsDocument9 pagesClickable List: E - Hydraulicssaeed65No ratings yet

- Modern Borehole Analytics: Annular Flow, Hole Cleaning, and Pressure ControlFrom EverandModern Borehole Analytics: Annular Flow, Hole Cleaning, and Pressure ControlNo ratings yet

- Centrifugal Pump - HandbookDocument26 pagesCentrifugal Pump - HandbookPrafull Dhakate100% (2)

- Pumps and Compressors: Week 7Document20 pagesPumps and Compressors: Week 7ednsmnNo ratings yet

- PumpsDocument115 pagesPumpsMehmet Yılmaz100% (1)

- Jet PumpDocument21 pagesJet Pumpdewidar1234100% (2)

- Chapter 5 Pump and Control Devices PDFDocument68 pagesChapter 5 Pump and Control Devices PDFRana G100% (2)

- How VFD Speed Affects Centrifugal Pump HydraulicsDocument6 pagesHow VFD Speed Affects Centrifugal Pump HydraulicsAudrey Patrick KallaNo ratings yet

- How to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesFrom EverandHow to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesRating: 5 out of 5 stars5/5 (1)

- PumpDocument116 pagesPumpV Dhinakaran67% (3)

- Chapter 7Document28 pagesChapter 7lockas222No ratings yet

- Centrifugal Pump Sizing, Selection and Design Practices (Hay)Document77 pagesCentrifugal Pump Sizing, Selection and Design Practices (Hay)Scribd_del75% (8)

- Pump Selection and Design GuideDocument175 pagesPump Selection and Design Guidecheckmeout803100% (1)

- Pumps PresentationDocument44 pagesPumps Presentationoida_adNo ratings yet

- How to find pump size and pump head calculationDocument8 pagesHow to find pump size and pump head calculationprosperNo ratings yet

- Prevention of Actuator Emissions in the Oil and Gas IndustryFrom EverandPrevention of Actuator Emissions in the Oil and Gas IndustryNo ratings yet

- Pump FundamentalsDocument127 pagesPump FundamentalsSheik Mohd50% (2)

- How To Size A Pump Blackmonk Engineering PDFDocument9 pagesHow To Size A Pump Blackmonk Engineering PDFRajesh KrishnamoorthyNo ratings yet

- Mechanical - Pumps KSB Centrifugal Pump DesignDocument44 pagesMechanical - Pumps KSB Centrifugal Pump DesignkichasNo ratings yet

- Hydraulic MachineryDocument60 pagesHydraulic MachinerySushil Kumar Singh100% (1)

- Hydraulic Machinery: Pumps, Turbines..Document60 pagesHydraulic Machinery: Pumps, Turbines..shunmugaNo ratings yet

- Hydraulic Machines ChapterDocument15 pagesHydraulic Machines Chapterحيدر محمدNo ratings yet

- ChE354 PumpsDocument36 pagesChE354 PumpsFA AyNo ratings yet

- Pump ExpDocument14 pagesPump ExpBIPIN SHARMANo ratings yet

- ChE354 PumpsDocument23 pagesChE354 Pumpsfahad670No ratings yet

- Fluid Mechanics II (Chapter 4)Document20 pagesFluid Mechanics II (Chapter 4)sarmadNo ratings yet

- Centrifugal Pump Performance TestDocument10 pagesCentrifugal Pump Performance TestAnurag KashyapNo ratings yet

- PumpDocument71 pagesPumpfacebookshopNo ratings yet

- 2,4 Pipes&PumpsDocument226 pages2,4 Pipes&PumpsShankar Angappan100% (1)

- (Jet Pump) Spe 191382 PaDocument12 pages(Jet Pump) Spe 191382 PaFaysal MalikNo ratings yet

- Performance and Experimentation On Centrifugal PumpDocument10 pagesPerformance and Experimentation On Centrifugal PumpLohith AcharyaNo ratings yet

- Libro de BombasDocument260 pagesLibro de BombasBoris SalazarNo ratings yet

- Centrifugal Pump Performance AnalysisDocument8 pagesCentrifugal Pump Performance AnalysisFaiz AkbarsyahNo ratings yet

- Lab 5 - Operating Characteristics of A Centrifugal PumpDocument9 pagesLab 5 - Operating Characteristics of A Centrifugal PumpGianne Nigelle DoriaNo ratings yet

- GPM RevDocument138 pagesGPM RevJuan Cortes TorizNo ratings yet

- Piston PumpDocument7 pagesPiston Pumpmohanadymt100% (1)

- Pumps Chapter 11Document91 pagesPumps Chapter 11Muhammad Usman100% (1)

- Hydraulic PumpsDocument63 pagesHydraulic PumpsSergio Juan67% (6)

- ERT 205 Lab 5Document14 pagesERT 205 Lab 5Ang Kien HauNo ratings yet

- Pump Efficiency - Lab 3Document8 pagesPump Efficiency - Lab 3KhalilHussainNo ratings yet

- Fluid Lecture - Chapter - 3present - EEDocument31 pagesFluid Lecture - Chapter - 3present - EEGebeyaw DemekeNo ratings yet

- Experiment No 7+8+9Document32 pagesExperiment No 7+8+9Muhammad kamran AmjadNo ratings yet

- Hydraulic Pumps ExplainedDocument33 pagesHydraulic Pumps ExplainedNebiyou KorraNo ratings yet

- Centifugal PumpDocument8 pagesCentifugal PumpTinaaTinyNo ratings yet

- Dynamic (Nonpositive Displacement) Pumps. This Type Is Generally UsedDocument12 pagesDynamic (Nonpositive Displacement) Pumps. This Type Is Generally Usedalqad.mohamdNo ratings yet

- TurbomachineDocument41 pagesTurbomachineshailendra_236No ratings yet

- Solar 2 - Solar Power PlantsDocument60 pagesSolar 2 - Solar Power PlantsgetsweetNo ratings yet

- Review Problems Soln PDFDocument10 pagesReview Problems Soln PDFgetsweetNo ratings yet

- Review Problems Soln PDFDocument10 pagesReview Problems Soln PDFgetsweetNo ratings yet

- Renewable Theoretical Summary - Mona - MidtermDocument11 pagesRenewable Theoretical Summary - Mona - MidtermgetsweetNo ratings yet

- Review ProblemsDocument5 pagesReview ProblemsgetsweetNo ratings yet

- Review ProblemsDocument5 pagesReview ProblemsgetsweetNo ratings yet

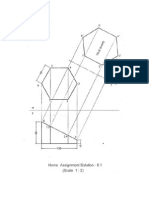

- Bearing Housing: 1. All Unspecified Radii To Be 0.5 MM 2. All Unspecified Chamfers To Be 0.5/45°Document1 pageBearing Housing: 1. All Unspecified Radii To Be 0.5 MM 2. All Unspecified Chamfers To Be 0.5/45°getsweetNo ratings yet

- Curriculum Vitae Replace With First Name(s) Surname(s)Document2 pagesCurriculum Vitae Replace With First Name(s) Surname(s)Valentina100% (1)

- Review ProblemsDocument5 pagesReview ProblemsgetsweetNo ratings yet

- Curriculum Vitae Replace With First Name(s) Surname(s)Document2 pagesCurriculum Vitae Replace With First Name(s) Surname(s)Valentina100% (1)

- Lesson 4 XPDocument30 pagesLesson 4 XPmaglalang_dexter_024No ratings yet

- General Overview Boilers and FlowDocument22 pagesGeneral Overview Boilers and FlowLiam MoylanNo ratings yet

- ITEC Application Form 2014-15Document8 pagesITEC Application Form 2014-15Mangalah Gauari MahaletchnanNo ratings yet

- Media Lecture Notes S5B1C6Document17 pagesMedia Lecture Notes S5B1C6getsweetNo ratings yet

- NEWChapter - 3-Mass Balance PDFDocument10 pagesNEWChapter - 3-Mass Balance PDFAbdelhaleem KhaderNo ratings yet

- Problem 01 Problem 02: Community College of Allegheny CountyDocument1 pageProblem 01 Problem 02: Community College of Allegheny CountygetsweetNo ratings yet

- Sustainable BackgroundDocument111 pagesSustainable BackgroundgetsweetNo ratings yet

- Proposal Tips HintsDocument4 pagesProposal Tips HintsAravindan NatarajanNo ratings yet

- Oblique Projection Worksheet - Draw Cylinder & Shapes in 2 ViewsDocument2 pagesOblique Projection Worksheet - Draw Cylinder & Shapes in 2 ViewsgetsweetNo ratings yet

- Air Pollution Examples Stability Classes ConcentrationsDocument50 pagesAir Pollution Examples Stability Classes ConcentrationsgetsweetNo ratings yet

- Home Soln 8Document4 pagesHome Soln 8getsweetNo ratings yet

- ST RD: Engineering Drawing & CAD Page 1 of 2 Sanjay SharmaDocument2 pagesST RD: Engineering Drawing & CAD Page 1 of 2 Sanjay SharmagetsweetNo ratings yet

- CCAC Mechanical Drawing Worksheet 01 ProblemsDocument1 pageCCAC Mechanical Drawing Worksheet 01 ProblemsgetsweetNo ratings yet

- Chapter 08 2Document64 pagesChapter 08 2Subhi MohamadNo ratings yet

- Worksheet Week7Document2 pagesWorksheet Week7getsweet0% (1)

- Engineering Drawing & CAD Page 1 of 2 Sanjay SharmaDocument2 pagesEngineering Drawing & CAD Page 1 of 2 Sanjay SharmagetsweetNo ratings yet

- Multi-view drawing with dimensions of given objectDocument3 pagesMulti-view drawing with dimensions of given objectgetsweetNo ratings yet

- U U U P T: Quick Visit To Bernoulli LandDocument9 pagesU U U P T: Quick Visit To Bernoulli LandAkash SodhaNo ratings yet

- Create The Following Solid Models Using Solidworks.: ExerciseDocument1 pageCreate The Following Solid Models Using Solidworks.: ExercisegetsweetNo ratings yet