Professional Documents

Culture Documents

32 Samss 030

Uploaded by

naruto256Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

32 Samss 030

Uploaded by

naruto256Copyright:

Available Formats

Materials System Specification

32-SAMSS-030 Manufacture of Small Tanks Vessels Standards Committee Members

Naffaa, Mahmoud Youniss, Chairman Sudairy, Jaralla Ali, Vice Chairman Gahtani, Moraya Saif Kim, Steve Un Anizi, Salamah Salem Niemeyer, Dennis Charles Anezi, Mohammed Ali Sharhan, Ziyad Sharhan Muir, William Rhodes

4 January 2006

Saudi Aramco DeskTop Standards

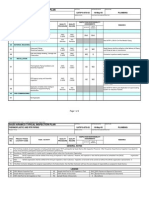

Table of Contents 1 2 3 4 5 6 7 8 9 10 Scope............................................................. 2 Materials......................................................... 6 Design............................................................ 7 Fabrication.................................................... 10 Inspection and Testing................................. 10 Nondestructive Examination......................... 11 Documentation............................................. 11 Disinfection................................................... 11 Shipping Requirements................................ 12 Tank Labeling............................................... 13 14 17 20 26 28

Appendix I Supplement to API SPEC 12F...... Appendix II Supplement to API STD 650 Appendix J............................................ Appendix III Supplement to UL 142................ Appendix IV Supplement to UL 1316.............. Appendix V Supplement to API SPEC 12P.....

Previous Issue: 29 December 2004 Next Planned Update: 4 January 2011 Revised paragraphs are indicated in the right margin Primary contact: Naffaa, Mahmoud Youniss on 966-3-8747263 CopyrightSaudi Aramco 2005. All rights reserved.

Page 1 of 28

Document Responsibility: Vessels Issue Date: 4 January 2006 Next Planned Update: 4 January 2011

32-SAMSS-030 Manufacture of Small Tanks

Scope 1.1 General 1.1.1 This Saudi Aramco Materials System Specification (SAMSS) defines the minimum mandatory requirements governing material, design, fabrication, inspection, and testing of small, atmospheric pressure storage tanks used in production, process plant, bulk plant, building services, fuel dispensing, or community facilities applications. This specification covers tanks used for the aboveground or underground storage of flammable and combustible liquids. It also covers tanks used for the storage of chemicals or water. Tanks purchased in accordance with the various industry standards and specifications shall also meet the requirements contained within the body of this specification, plus the supplementary requirements contained in the appendices of this specification as follows.

Standard or Specification API SPEC 12F API STD 650, Appendix J UL 142 UL 1316 API SPEC 12P Appendix I II III IV V

1.1.2

1.1.3

Appendices are not provided for tanks purchased in accordance with AWWA D100 and AWWA D120. 1.1.4 1.1.5 This specification may be attached to and form an integral part of a purchase order. Proposals The Tank Manufacturer may offer an alternative design, but must quote on the base inquiry documents. The proposal shall include a detailed description of any exceptions to the requirements of this specification. 1.2 Compliance 1.2.1 Conflicts and Deviations 1.2.1.1 Any conflict between this specification and other Saudi Aramco Materials System Specifications (SAMSSs), Saudi Aramco Engineering Standards (SAESs), industry codes and

Page 2 of 28

Document Responsibility: Vessels Issue Date: 4 January 2006 Next Planned Update: 4 January 2011

32-SAMSS-030 Manufacture of Small Tanks

standards, and Saudi Aramco Standard Drawings (SASDs) and Forms shall be resolved in writing by the Company or Buyer Representative through the Manager, Consulting Services Department of Saudi Aramco, Dhahran. 1.2.1.2 Direct all requests to deviate from this specification in writing to the Company or Buyer Representative, who shall follow internal company procedure SAEP-302 and forward such requests to the Manager, Consulting Services Department of Saudi Aramco, Dhahran.

1.3

Referenced Publications Materials or equipment supplied to this specification shall comply with the latest edition of the references listed below, unless otherwise noted. 1.3.1 Saudi Aramco References Saudi Aramco Engineering Procedures SAEP-302 Instructions for Obtaining a Waiver of a Mandatory Saudi Aramco Engineering Requirement Qualification of non-Saudi Aramco NDT Personnel

SAEP-1142

Saudi Aramco Engineering Standards SAES-H-001 SAES-W-017 SAES-X-500 SAES-X-600 Coating Selection & Application Welding Requirements for Tanks Cathodic Protection of Vessels and Tank Internals Cathodic Protection of Plant Facilities

Saudi Aramco Materials System Specification 09-SAMSS-107 Fluoropolymer/Ceramic Coatings to Fasteners

Saudi Aramco Inspection Requirements Form 175-325100 Steel Tanks Aboveground or Underground to UL Specifications Form 175-325200 Fiberglass Tanks Underground to UL Specifications

Page 3 of 28

Document Responsibility: Vessels Issue Date: 4 January 2006 Next Planned Update: 4 January 2011

32-SAMSS-030 Manufacture of Small Tanks

Form 175-325300 Fiberglass Tanks Aboveground to AWWA Specifications Saudi Aramco Forms and Data Sheets SA 2696-ENG SA NMR-7918-1 Appurtenance Schedule and Orientations Nonmaterial Requirements for Tanks

Saudi Aramco Standard Drawings AB-036003 AD-036061 AA-036355 AB-036387 1.3.2 Manholes and Vents for Tanks Roof Center Vents for Cone-Roof Tanks Impressed Current Tank Bottom, Cathodic Protection Details Grounding

Industry Codes and Standards American Petroleum Institute API SPEC 12F API SPEC 12P API STD 650 API STD 2000 API RP 2003 Specification for Shop Welded Tanks for Storage of Production Liquids Specification for Fiberglass Reinforced Plastic Tanks Welded Steel Tanks for Oil Storage Venting Atmospheric and Low-Pressure Storage Tanks Protection Against Ignitions Arising Out of Static, lightning, and Stray Currents

American Society of Civil Engineers ASCE 7 Minimum Design Loads for Buildings and Other Structures

American Society of Mechanical Engineers ASME B16.11 Forged Steel Fittings, Socket-Welding and Threaded

American Society of Mechanical Engineers/Boiler and Pressure Vessel Code ASME SEC V Nondestructive Examination

Page 4 of 28

Document Responsibility: Vessels Issue Date: 4 January 2006 Next Planned Update: 4 January 2011

32-SAMSS-030 Manufacture of Small Tanks

American Society for Testing and Materials ASTM A193 ASTM A307 ASTM D1418 Alloy Steel and Stainless Steel Bolting Materials for High Temperature Services Carbon Steel Externally Threaded Standard Fasteners Rubber and Rubber Lattices

American Water Works Association AWWA C652 AWWA D100 AWWA D120 Military Specifications MIL C16173 Corrosion Preventive Compound, Solvent Cutback, Cold-Application Disinfection of Water Storage Facilities Welded Steel Tanks for Water Storage Thermosetting Fiberglass-Reinforced Plastic Tanks

National Fire Protection Association NFPA 68 Guides for Venting of Deflagration

Underwriters Laboratories, Inc. UL 142 UL 1316 Steel Aboveground Tanks for Flammable and Combustible Liquids Glass-Fiber-Reinforced Plastic Underground Storage Tanks for Petroleum Products, Alcohols, and Alcohol-Gasoline Mixtures

Process Industry Practices VEFV1100 1.4 Definitions Design Engineer: The Engineering Company responsible for specifying, on the design data sheet, the design requirements for tanks. Low-Flash Liquids: Hydrocarbon liquids with a flash point equal to or less than 54C. Saudi Aramco Engineer: The Supervisor of Process Equipment Unit, Consulting Services Department, Dhahran. Vessel/S&T Heat Exchanger Standard Details

Page 5 of 28

Document Responsibility: Vessels Issue Date: 4 January 2006 Next Planned Update: 4 January 2011

32-SAMSS-030 Manufacture of Small Tanks

Saudi Aramco Inspector: The person or company authorized by the Saudi Aramco Inspection Department to inspect tanks to the requirements of this specification. Small Tanks: Shop fabricated or field erected atmospheric pressure storage tanks up to 1500 barrels capacity. Tank Manufacturer: The Company responsible for the design and fabrication of tanks. Flammable liquid: A liquid that has a flash point equal to or less than 54C. Combustible Liquid: A liquid that has a flash point greater than 54C and that is at a temperature lower than 8C below its flash point. 2 Materials 2.1 General 2.1.1 2.1.2 The Tank Manufacturer shall submit a complete material specification with the proposal. The Tank Manufacturer may propose the use of alternative materials to those that are specified in the relevant industry standard. The alternative materials shall comply with all the other requirements of that standard and this specification. The chemical compositions and mechanical properties of non-ASTM materials shall be submitted for evaluation by the Saudi Aramco Engineer.

2.1.3 Materials proposed by the Tank Manufacturer that are equivalent to those specified in the relevant industry standard shall be approved by the Saudi Aramco Engineer. 2.1.4 2.2 All materials shall be clearly identified and provided with supplier test certificates.

Bolting 2.2.1 Flange bolting material shall conform to ASTM A193 Grade B7 bolts with ASTM A194 Grade 2H nuts except for the following. 1) 2) Low carbon steel machine bolts conforming to ASTM A307 Grade A or B may be used on nonmetallic flanges. Stud bolts conforming to ASTM A193 Grade B7M with ASTM A194 Grade 2HM nuts shall be used when the tank is in wet sour service and buried.

Page 6 of 28

Document Responsibility: Vessels Issue Date: 4 January 2006 Next Planned Update: 4 January 2011

32-SAMSS-030 Manufacture of Small Tanks

2.2.2 2.3

All bolting shall be coated by fluoropolymer coating per 09-SAMSS-107.

Gasketing Gasket materials shall be non-asbestos, conforming to Johns Manville JM 960 or Garlock 3000 except for the following. 1) Synthetic rubber gasket, ASTM D1418 Class CSM, shall be used for all acid services except nitric acid and oleum. For nitric acid and oleum, ASTM D1418 Class FKM elastomer shall be used for flat face flanges or spiral wound Type 304 stainless steel, PTFE filled gaskets shall be used for raised face flanges. Elastomeric material, 3 mm thick with a Shore A Durometer hardness of between 50 and 60, shall be used for full face gaskets for plastic flanges. For wet chlorine service and hypochlorite service the elastomer shall be ASTM D1418 Class CSM.

2)

Design 3.1 Design Considerations 3.1.1 Information provided by the Design Engineer on the Storage Tank Data Sheet and a completed Form SA 2696-ENG shall be used for the tank design in accordance with the relevant industry standard and this specification. Wind and seismic design criteria shall be in accordance with the information provided by the Design Engineer on the Storage Tank Data Sheet. Aboveground, vertical, cylindrical tanks shall be designed for wind and earthquake loads in accordance with ASCE 7. 3.1.3 3.2 Underground tanks shall be designed for soil, traffic and/or buoyancy loads as applicable.

3.1.2

Openings The number, size, type, and orientation of nozzles and manholes shall be in accordance with that specified on the Storage Tank Data Sheet.

3.3

Venting 3.3.1 Normal and emergency venting requirements shall be specified in accordance with API STD 2000, SAES-J-600, SASD AB-036003 and AD-036061 and the requirements of this specification.

Page 7 of 28

Document Responsibility: Vessels Issue Date: 4 January 2006 Next Planned Update: 4 January 2011

32-SAMSS-030 Manufacture of Small Tanks

3.3.2

Maximum filling and emptying rates specified on the Storage Tank Data Sheet shall be used as a basis for determining the normal venting capacity. All open vents shall be protected by bird screens. The need to protect fixed roof tanks against internal deflagration shall be determined by the design engineer according to NFPA 68. The design of deflagration venting shall be submitted to the Chief Fire Prevention Engineer and CSD for review.

3.3.3 3.3.4

3.4

Platforms, Walkways, and Stairways 3.4.1 3.4.2 3.4.3 The type and location of stairway shall be as specified on the Storage Tank Data Sheet and Form SA 2696-ENG. Platforms, walkways, and stairways shall be fabricated of open grating. Checker-plate grating is not permitted. Stairways on insulated tanks shall be provided with stringers on both sides.

3.5

Foundations Aboveground, vertical flat bottom steel tank supported directly on soil foundation shall meet the following requirements: 3.5.1 A foundation drip ring shall be provided in order to prevent the ingress of rainwater or condensation between the tank bottom and foundation. The ring shall meet the following requirements: 1) 2) Material shall be carbon steel, 3 mm thick. Continuously seal welded to the edge of the tank bottom or annular plate. All radial joints between the drip ring sections shall also be seal welded. Extend at least 75 mm beyond the outer periphery of the concrete ring wall. Turn down at its outer diameter at a 45 degree angle. The top of the drip ring and a 75 mm height of the tank shell shall be painted with a 250-300 microns (10-12 mils) thick epoxy coating in accordance with SAES-H-001, APCS-1.

3) 4) 5)

3.5.2

Tank's bottom shall be coated with APCS-3 or APCS-113, as applicable, on its soil side leaving minimum 2.5 cm wide strip of uncoated steel

Page 8 of 28

Document Responsibility: Vessels Issue Date: 4 January 2006 Next Planned Update: 4 January 2011

32-SAMSS-030 Manufacture of Small Tanks

along the underside of the floor plate, centered on, and directly below the weld seam. This will typically require masking a strip along the underside of each end (edge) of each bottom plate approximately 5 cm wide. Cathodic protection for the soil side of tank bottoms shall be provided according to SAES-X-600. APCS-3 shall be specified for tank with maximum operation temperature of 70C, while APCS-113 shall be specified for higher operation temperatures. 3.5.3 The top fill layer shall be a mixture of sweet sand and cement (33:1 ratio, i.e., 3% cement). The material specifications and mixing requirements shall be as follows: 1) The maximum permissible salt content is 0.1%. Sand shall be dried to a free-moisture content of not more than 2.0% by weight of dry soil. The dry sand must be screened through 6 mm mesh (maximum). Care must be taken in using clean mixing and handling equipment to ensure mixture remains free from foreign matter. The sand shall then be thoroughly mixed with cement in a 33:1 ratio by weight in a concrete mixer. After laying the mixture shall be rolled a minimum six times by a 3 ton roller. Vibratory plate tampers may be used in lieu of rollers for areas where a roller cannot reach and/or cover.

2)

3)

3.5.4

Under Tank Leak Detection and Sub-grade Protection 3.5.4.1 Tanks in services other than water shall be provided with an under tank leak detection and sub-grade protection according to API STD 650, Appendix I. Acceptable construction details are Figures I-1, I-2, I-3, I-6, I-7, I-8, I-9 or I-10. Flexible membrane liner of minimum 1000 microns (40 mils) thickness compatible with the stored product shall be specified under the tank bottom. The liner shall be placed according to SASD AA-036355, extending to the internal top edge of the ring foundation. Joints in the liner shall satisfy the leak tightness, permeability, and chemical resistance requirements for the liner material. Alternative under-tank leak detection and sub-grade protection systems shall not be permitted without the prior approval of the Saudi Aramco Engineer.

3.5.4.2

3.5.4.3 3.5.4.4

Page 9 of 28

Document Responsibility: Vessels Issue Date: 4 January 2006 Next Planned Update: 4 January 2011

32-SAMSS-030 Manufacture of Small Tanks

Fabrication 4.1 General All flange bolt holes shall straddle the axial centerline of the tank. 4.2 Marking 4.2.1 Marking shall be done with water soluble materials that contain no substances that would attack or harmfully affect the tank at both ambient and operating temperature. Marking materials shall be free of lead, sulfur, zinc, cadmium, mercury, chlorine, or any other halogens. Export packaging, marking, and shipping shall be in accordance with the purchase order.

4.2.2 4.2.3 4.3

The soil side of the bottom plates shall be cleaned of all foreign matter and gritblast cleaned prior to being coated and placed in position for welding. The topside surface of bottom plates that are not internally coated shall also be gritblast cleaned prior to welding. Surface preparation shall be according to APCS-3 or APCS-113, as applicable.

Inspection and Testing 5.1 Inspection 5.1.1 Inspection shall be in accordance with Saudi Aramco Inspection Requirements Forms 175-325100, 175-325200, and, 175-325300 the relevant industry standard, this specification and the following additional requirements. Saudi Aramco shall have the right to inspect the fabrication at any state and to reject material or workmanship, which does not conform to the specified requirements. Inspection procedures shall be established in accordance with ASME SEC V. A written procedure for each inspection method and technique, including acceptance criteria to be used, shall be submitted to the Saudi Aramco Inspector for approval. Qualification of the procedure may be required, as determined by the Saudi Aramco Inspector. Inspection procedures in conformance with other standards are acceptable only with the approval of the Saudi Aramco Inspector.

5.1.2

5.1.3

Page 10 of 28

Document Responsibility: Vessels Issue Date: 4 January 2006 Next Planned Update: 4 January 2011

32-SAMSS-030 Manufacture of Small Tanks

5.1.4 5.1.5

Written reports and evaluations of all inspections performed shall be submitted to the Saudi Aramco Inspector. Prior to final inspection and pressure testing, the inside and outside of the tank shall be thoroughly cleaned of all slag, scale, dirt, grit, weld spatter, paint, oil, etc.

5.2

Testing 5.2.1 After completion of all external and internal welding, nondestructive examination, as applicable, and prior to coating, tanks shall be pressure tested using water as the testing media in accordance with the applicable Saudi Aramco Inspection Requirements Forms 175-325100, 175-325200, and, 175-325300, the relevant industry standard and this specification. Water used for pressure testing shall be potable. For metallic tanks manufactured from stainless steel, the water shall not contain more than 50 ppm chlorides with pH value of 10 to 11 at the time of filling the tank.

5.2.2

Nondestructive Examination 6.1 6.2 All Non-destructive Testing (NDT) shall be in accordance with the requirements of the relevant industry standard and this specification. All NDT shall be done by personnel certified to SAEP-1142 or approved equivalent for the particular method or technique to be used.

Documentation 7.1 7.2 The Tank Manufacturer shall prepare drawings, calculations, and data in accordance with Form SA NMR-7918-1, Non-Material Requirements. Drawings and calculations that are approved by the Design Engineer shall not relieve the Tank Manufacturer of the responsibility to comply with the relevant industry standard and this specification. All approved data sheets, drawings and forms are to be submitted to Engineering Drawings Services Division (EDSD) for inclusion into Corporate Drawings Management System.

7.3

Disinfection All potable water storage tanks shall be disinfected in accordance with AWWA C652.

Page 11 of 28

Document Responsibility: Vessels Issue Date: 4 January 2006 Next Planned Update: 4 January 2011

32-SAMSS-030 Manufacture of Small Tanks

The chlorine and bacteriological tests shall be approved by the Environmental Health Department of Saudi Aramco. 9 Shipping Requirements 9.1 General 9.1.1 9.1.2 Prior to shipping tanks are to be completely and thoroughly dried after testing and cleaned to the satisfaction of the Saudi Aramco Inspector. The Tank Manufacturer is responsible for ensuring that the tanks which are completely shop fabricated are adequately braced and shall provide temporary supports where appropriate to ensure adequate supporting of the tank during shipment.

9.1.3 Tanks partially shop fabricated and/or liable to suffer distortion during transit and erection shall be suitably braced. All ends that will be open during shipment shall be covered to prevent ingress of dirt and other foreign matters. The Tank Manufacturer shall provide the Saudi Aramco Engineer of the method of protection for review and approval. 9.2 Internal Protection The following internal protection measures are applicable to metallic tanks only. 9.2.1 Tank internals shall be protected by use of a nontoxic vapor phase corrosion inhibitor such as COTEC VCI-309 or 307 or equivalent, applied at a rate of 100 g/m. The inhibitor selected must be appropriate for the metallurgy of the tank. Tanks must be sealed vapor tight using metallic or wooden covers, for inhibitors to be effective. Alternatively, temporary coatings in accordance with MIL C6173 Grade IV (example Tectyl 846) or equivalent or a vapor proof bag with moisture control may be used. Temporary coatings for use on stainless steel tanks must be chloride free, suitable for its intended use and not result in crevice corrosion. Where permanent internal coatings are specified, the Tank Manufacturer shall contact the Saudi Aramco Engineer for any corrosion protection required.

9.2.2 9.2.3

9.2.4 9.2.5

9.3

External Protection

Page 12 of 28

Document Responsibility: Vessels Issue Date: 4 January 2006 Next Planned Update: 4 January 2011

32-SAMSS-030 Manufacture of Small Tanks

9.3.1

Solid stainless steel tanks, which are to be shipped via ocean freight, protect using a temporary protective system compatible with stainless steel and suitable for outdoor exposure in accordance with MIL C16173 Grade IV. Threaded nozzle connections, shall be protected with threaded plugs. However, telltale holes in reinforcing pads shall be protected with wooden plugs or packed with a rust preventative grease such as Denso paste. Flanged connections and all other machined surfaces shall be protected by a coating such as MIL C16173 Grade IV, which is easily removed in the field and fitted with a steel or wood cover, 3 mm thick and neoprene gaskets. Covers shall be securely attached by a minimum of four bolts equally spaced. For ocean shipment, flanged connections shall also be covered with heavy duty plastic bags securely taped to the nozzles. Flanges with permanent blind flanges or covers shall be secured with the gaskets and bolting required for service.

9.3.2

9.3.3

9.3.4

9.3.5

10

Tank Labeling 10.1 10.2 10.3 For aboveground tanks, the tank number and content shall be painted in both Arabic and English at 180 degree intervals around the tank. Marking shall be done with materials containing no substances that would attack or harmfully affect the tank at both ambient and operating temperature. For metallic tanks, marking materials shall be free of lead, sulfur, zinc, cadmium, mercury, chlorine, or any other halogens.

Revision Summary Major revision.

4 January 2006

Page 13 of 28

Document Responsibility: Vessels Issue Date: 4 January 2006 Next Planned Update: 4 January 2011

32-SAMSS-030 Manufacture of Small Tanks

Appendix I Supplement to API SPEC 12F The following paragraph numbers refer to API SPEC 12F, Eleventh Edition, November 1994, which is part of this specification. The text in each paragraph below is an addition to API SPEC 12F unless it is noted as an exception. Paragraph numbers not appearing in API SPEC 12F are new paragraphs to be inserted in numerical order. 2 2.2 Material Plates (Exception) Rimmed and capped steels are not permitted. 2.3 2.8 Delete this paragraph. Couplings (Exception) Threaded and socket welded connections shall be in accordance with ASME B16.11. 2.9 Bolting (Exception) Bolting shall be in accordance with Paragraph 2.2 of this specification. 3 3.6 Design Type The tank bottom type shall be in accordance with that specified on the Storage Tank Data Sheet. 3.9 3.10 (Exception) The tank bottom shall be attached to the tank shell, if the bottom is flanged by a double-welded butt joint with complete penetration. Thickness The nominal thickness of shell plates shall be 6 mm, including a corrosion allowance of 1.6 mm. Corrosion allowance in excess of 1.6 mm shall be added when specified on the Storage Tank Data Sheet. 3.15 3.15.1 Shell Attachment For insulated tanks, the design of the deck-to-shell attachment shall prevent the infiltration of rainwater into the insulation.

Page 14 of 28

Document Responsibility: Vessels Issue Date: 4 January 2006 Next Planned Update: 4 January 2011

32-SAMSS-030 Manufacture of Small Tanks

3.15.2 3.17

The tank deck shall be attached to the tank shell if the deck is flanged by a double-welded butt joint with complete penetration. Connections All connections 3 inch NPS and larger that are used to support piping loads shall be reinforced.

3.20

Anchoring Anchoring shall be provided as required to prevent tank overturning due to wind loads.

3.21

Grounding Tanks in hydrocarbon services shall be provided with grounding lugs in accordance with SASD AB-036387 and API RP 2003 requirements.

Venting Requirements (Exception) Normal and emergency venting requirements shall be specified in accordance with paragraph 3.3 of the body of 32-SAMSS-030. Provision of frangible joint at the shell-to-roof juncture is prohibited.

5 5.1

Fabrication, Testing, and Painting Fabrication Reinforcing pads and all other external attachment pads shall have rounded corners of minimum 50 mm radius. Pads shall be provided with a 6 mm telltale hole.

5.2 5.2.1 5.2.2 5.2.3 5.2.4 5.3

Welding All welding procedures and procedure qualifications shall be in accordance with SAES-W-017 and be submitted for review by Saudi Aramco. Weld hardness testing requirements and acceptance criteria shall be in accordance with SAES-W-017. All structural attachment welds to the tank shell, bottom, deck, and appurtenances shall be continuously seal welded. All welds shall be free from coarse ripples, undercuts, grooves, overlaps, abrupt ridges and valleys. Testing

Page 15 of 28

Document Responsibility: Vessels Issue Date: 4 January 2006 Next Planned Update: 4 January 2011

32-SAMSS-030 Manufacture of Small Tanks

5.3.1 5.3.2

The tank shall be tested by filling it with water to 50 mm (2 in.) above the weld connecting the roof plate or compression bar to the top angle or shell. All reinforcing pads shall be tested by applying pneumatic pressure between the shell and pad and checking for leaks using a soap film. Pneumatic testing pressure, depending on opening diameter and/or shell plate thickness, shall be as follows: For openings with diameter up to and including 20 inches, irrespective of shell plate thickness: 15 psig (103 kPa) For larger openings (normally not exceeding 24 inches): a) b) 10 psig (69 kPa) for shell plate thickness less than 3/16 inch or 5 mm. 15 psig (103 kPa) for thicker shell plates.

5.3.2.1 5.3.2.2

5.3.3

Upon completion of the test and where it is required to have gas-tight all roof weld joints shall be tested for leakage using the vacuum box method test with a soap solution before any surface coating is applied. Coatings and Painting The type of coating and painting systems to be applied shall be as specified on the Storage Tank Data Sheet. Prior to coating or painting, internal and external surfaces shall be cleaned to remove all scale, rust, grease dirt, weld spatter and foreign objects. Gasket contact surfaces shall not be coated or painted. Markings All tanks with internal coatings shall have the Saudi Aramco's Approved Protective Coating Specification number (APCS number) marked on the nameplate.

5.6 5.6.1 5.6.2 5.6.3 6

Page 16 of 28

Document Responsibility: Vessels Issue Date: 4 January 2006 Next Planned Update: 4 January 2011

32-SAMSS-030 Manufacture of Small Tanks

Appendix II Supplement to API STD 650 Appendix J The following paragraph numbers refer to API STD 650 Appendix J, Tenth Edition, November 1998, which is part of this specification. The text in each paragraph below is an addition to API STD 650 Appendix J unless it is noted as an exception. Paragraph numbers not appearing in API STD 650 Appendix J are new paragraphs to be inserted in numerical order. J.2 Materials (Exceptions) a) b) J.3 J.3.1 J.3.1.6 J.3.3 Bolting shall be in accordance with Paragraph 2 of 32-SAMSS-030. Rimmed and capped steels are not permitted.

Design Joints For insulated tanks, the design of the roof-to-shell junction shall prevent the infiltration of rainwater into the insulation. Shells (Exception) The nominal thickness of shell plates shall not be less than 6 mm, including a corrosion allowance of 1.6 mm. Corrosion allowance in excess of 1.6 mm shall be added when specified on the Storage Tank Data Sheet.

J.3.5 J.3.5.1 J.3.5.1 J.3.5.5 J.3.6 J.3.6.3

Roofs General (Exception) Roof plate lap joints shall have a minimum of 25 mm overlap. When an internal coating is specified, the roof lap joints shall be continuously welded on both sides. Tank Connections and Appurtenances Threaded Connections Threaded and socket welded connections shall be in accordance with ASME B16.11.

Page 17 of 28

Document Responsibility: Vessels Issue Date: 4 January 2006 Next Planned Update: 4 January 2011

32-SAMSS-030 Manufacture of Small Tanks

J.3.6.4

Grounding Tanks in hydrocarbon services shall be provided with grounding lugs in accordance with SASD AB-036387 and API RP 2003 requirements.

J.3.10

Venting Normal and emergency venting requirements shall be specified in accordance with paragraph 3.3 of the body of 32-SAMSS-030. Provision of frangible joint at the shell-to-roof juncture is prohibited.

J.4 J.4.1.4

Fabrication and Construction Shaping of Shell Plates Reinforcing pads and all other external attachment pads shall have rounded corners of minimum 50 mm radius. Pads shall be provided with a 6 mm tapped hole.

J.4.2 J.4.2.2

Testing, Repairs, and Inspection Testing The tank shall be tested by filling it with water to 50 mm (2 in.) above the weld connecting the roof plate or compression bar to the top angle or shell. All reinforcing pads shall be tested by applying a pressure up to 103 kPa (15 psig) pneumatic pressure between the shell and pad and checking for leaks using a soap film. Upon completion of the test, all roof weld joints shall be tested for leakage using the vacuum box method test with a soap solution.

J.6 J.6.1 J.6.2 J.6.3 J.6.4

Welding Procedure and Welder Qualifications All welding procedures and procedure qualifications shall be in accordance with SAES-W-017 and be submitted for review by Saudi Aramco. Weld hardness testing requirements and acceptance criteria shall be in accordance with SAES-W-017. All structural attachment welds to the tank shell, bottom, roof, and appurtenances shall be continuously seal welded. All welds shall be free from coarse ripples, undercuts, grooves, overlaps, abrupt ridges and valleys.

Page 18 of 28

Document Responsibility: Vessels Issue Date: 4 January 2006 Next Planned Update: 4 January 2011

32-SAMSS-030 Manufacture of Small Tanks

J.7

Marking All tanks with internal coatings shall have the Saudi Aramco's Approved Protective Coating Specification number (APCS number) marked on the nameplate.

J.8 J.8.1 J.8.2

Non-destructive Testing Procedures Personnel responsible for or affecting the results of Non-destructive Testing (NDT) shall be certified at least Level II In the method being used. Radiographic Standards Tungsten inclusions in gas tungsten arc welds shall be evaluated as individual rounded indications. Clustered or aligned tungsten inclusions shall be removed and repaired.

J.9 J.9.1 J.9.2 J.9.3 J.9.4

Coatings and Painting The type of coating and painting systems to be applied shall be as specified on the Storage Tank Data Sheet. Prior to coating or painting, internal and external surfaces shall be cleaned to remove all scale, rust, grease dirt, weld spatter and foreign objects. Application of primers prior to hydrostatic testing is acceptable. Gasket contact surfaces shall not be coated or painted.

Page 19 of 28

Document Responsibility: Vessels Issue Date: 4 January 2006 Next Planned Update: 4 January 2011

32-SAMSS-030 Manufacture of Small Tanks

Appendix III Supplement to UL 142 The following paragraph numbers refer to UL 142, Seventh Edition, April 1993, including revisions through and up to July 1998, which is part of this specification. The text in each paragraph below is an addition to UL 142 unless it is noted as an exception. Paragraph numbers not appearing in UL 142 are new paragraphs to be inserted in numerical order. 1 1.5 1.8 Scope The tank shall be designed for seismic loading in accordance with ASCE 7. These requirements cover single wall tanks, secondary containment tanks, multiple compartments single and multiple compartment secondary containment tanks. Multiple wall tanks shall be such that the outer tank is physically separated from the inner primary containment tank by standoffs; where the inner tank is completely contained within the outer tank. Materials (Exception) Rimmed and capped steels are not permitted. Construction Joints Figure 6.1 (Exception). Only shell joint numbers 1 and 2 shall be used. Figure 6.2 (Exception). Only head joint numbers 1 and 2 shall be used. Figure 6.3 (Exception). Only bottom joint numbers 1 and 5 shall be used. Figure 6.4 (Exception). Only roof joint numbers 5, 6, 7 and 9 shall be used. For insulated tanks, the design of the roof-to-shell junction shall prevent the infiltration of rainwater into the insulation. Figure 6.5 (Exception). Only corner joint numbers 7 through 9 shall be used. 6.2 Reinforcing pads and all other external attachment pads shall have rounded corners of minimum 50 mm radius. Pads shall be provided with a 6 mm tapped hole.

5 5.2 6 6.1

Page 20 of 28

Document Responsibility: Vessels Issue Date: 4 January 2006 Next Planned Update: 4 January 2011

32-SAMSS-030 Manufacture of Small Tanks

6.3 6.4 6.5 6.6 6.7 6.7.1 6.7.2 6.7.3 6.7.4 6.8 6.8.1

All structural attachment welds to the tank shell and appurtenances shall be continuously seal welded. All welds shall be free from coarse ripples, undercuts, grooves, overlaps, abrupt ridges and valleys. All welding procedures and procedure qualifications shall be in accordance with SAES-W-017 and be submitted for review by Saudi Aramco. Weld hardness testing requirements and acceptance criteria shall be in accordance with SAES-W-017. Coatings and Painting The type of coating and painting systems to be applied shall be as specified on the Storage Tank Data Sheet. Prior to coating or painting, internal and external surfaces shall be cleaned to remove all scale, rust, grease dirt, weld spatter and foreign objects. Application of primers prior to testing is acceptable. Gasket contact surfaces shall not be coated or painted. Non-destructive Testing All reinforcing pads shall be tested by applying up to 103 kPa pneumatic pressure between the shell and the pad and checking for leaks using a soap film. All lap-welded bottom joints in vertical cylindrical tanks shall be tested for leakage by using the vacuum box method test with soap solution before any surface coating is applied. Grounding Vertical tanks in hydrocarbon services shall be provided with grounding lugs in accordance with SASD AB-036387 and API RP 2003 requirements. Horizontal and rectangular tanks in hydrocarbon services shall be provided with a grounding lug connection welded to the tank support in accordance with PIP VEFV1100. Tank Connections (Exception) All connections 2 inch NPS and larger shall be attached by fullpenetration welds. A fillet weld is acceptable to join the reinforcing pad to

Page 21 of 28

6.8.2

6.9 6.9.1 6.9.2

7 7.1, 7.2

Document Responsibility: Vessels Issue Date: 4 January 2006 Next Planned Update: 4 January 2011

32-SAMSS-030 Manufacture of Small Tanks

the nozzle neck and to the shell or roof. All connections 3 inch NPS and larger that are used to support piping loads shall be reinforced. 8 Venting (Exception) Normal and emergency venting requirements shall be specified in accordance with paragraph 3.3 of the body of 32-SAMSS-030. Provision of frangible joint at the shell-to-roof juncture is prohibited. 11 11.1 11.2 11.3 11.4 Painting The type of coating and painting systems to be applied shall be as specified on the Storage Tank Data Sheet. Prior to coating or painting, internal and external surfaces shall be cleaned to remove all scale, rust, grease, dirt, weld spatter and foreign objects. Application of primers prior to hydrostatic testing is acceptable. Gasket contact surfaces shall not be coated or painted.

PART I PRIMARY CONTAINMENT TANKS HORIZONTAL CYLINDRICAL TANKS 13 13.2 Construction Steel Thickness (Exception) In Table 13.1, the minimum thickness for carbon steel tanks shall not be less than 6 mm, and the minimum thickness for stainless steel tanks shall not be less than 4 mm. 13.3 13.4 13.4.1 13.4.2 Heads and head joints joint numbers 3 through 6 of Figure 6.1 shall not be used. Compartment tank construction (Exception) Compartment tanks shall be of double-head construction as in detail number 1 in Figure 13.2. Delete this paragraph.

VERTICAL CYLINDRICAL TANKS 15 Construction

Page 22 of 28

Document Responsibility: Vessels Issue Date: 4 January 2006 Next Planned Update: 4 January 2011

32-SAMSS-030 Manufacture of Small Tanks

15.2

Steel Thickness (Exception) In Table 15.1, the minimum thickness shall be as follows:

Carbon Steel Shell Bottom Top 6 mm 6 mm 4 mm Stainless Steel 4 mm 4 mm 3 mm

15.3 15.3.1 15.3.4 15.3.5 15.4 15.4.1 15.4.2 15.5

Tank Top (Roof) If two or more pieces are required, joints shall be one of the shell joint constructions details 1 or 2 numbers of Figure 1. Roof plate lap joints shall have a minimum of 25 mm overlap. When an internal coating is specified, the roof lap joints shall be continuously welded on both sides. Tank Bottom (Floor) (Exception) Bottom plates shall be butt welded in accordance with Figure 6.1, joint number 1 or 2. Anchoring shall be provided as required to prevent tank overturning due to wind and/or seismic loads. Weak Shell-to-Roof Joint Construction. Provision of weak shell-to-roof joint construction for emergency venting is prohibited.

RECTANGULAR CONSTRUCTION 17.2 The minimum thickness for carbon steel tanks shall not be less than 6 mm, and the minimum thickness for stainless steel tanks shall not be less than 4 mm.

PART II - SECONDARY CONTAINMENT TANKS ALL SECONDARY CONTAINMENT TANK CONSTRUCTIONS 20 20.1 General Secondary containment horizontal cylindrical tanks shall comply with the construction requirements for all tanks in Sections 4 11 of UL 142 with the exceptions, additions or deletion stipulated in 32-SAMSS-030.

Page 23 of 28

Document Responsibility: Vessels Issue Date: 4 January 2006 Next Planned Update: 4 January 2011

32-SAMSS-030 Manufacture of Small Tanks

21.1

The primary containment tank shell and heads of a secondary containment tank shall meet the requirements of Sections 12 and 13 of UL 142 including the exceptions, additions or deletion stipulated in 32-SAMSS-030. The outer shell and head of a secondary containment tank shall meet the requirements of Sections 12 and 13 of UL 142 with the exceptions, additions or deletion stipulated in 32-SAMSS-030. Delete this paragraph. (Exception) The minimum thickness for the outer carbon steel tanks shall not be less than 6 mm, and the minimum thickness for stainless steel tanks shall not be less than 4 mm. Delete this paragraph.

21.2

21.5 21.6

21.8

VERTICAL CYLINDRICAL CONSRUCTIONS 22 22.1 General Secondary containment horizontal cylindrical tanks shall comply with the construction requirements for all tanks in Sections 4 11 of UL 142 with the exceptions, additions or deletion stipulated in 32-SAMSS-030. The primary containment tank shell and heads of a secondary containment tank shall meet the requirements of Sections 14 and 15 of UL 142 including the exceptions, additions or deletion stipulated in 32-SAMSS-030. The outer shell and head of a secondary containment tank shall meet the requirements of Sections 14 and 15 of UL 142 with the exceptions, additions or deletion stipulated in 32-SAMSS-030. Delete this paragraph.

23.1.1

23.1.2

23.1.4

RECTANGULAR CONSTRUCTIONS 24 24.1 General Secondary containment horizontal cylindrical tanks shall comply with the construction requirements for all tanks in Sections 4 11 of UL 142 with the exceptions, additions or deletion stipulated in 32-SAMSS-030. The primary containment tank shell and heads of a secondary containment tank shall meet the requirements of Sections 16 and 17 of UL 142 including the exceptions, additions or deletion stipulated in 32-SAMSS-030.

25.1

Page 24 of 28

Document Responsibility: Vessels Issue Date: 4 January 2006 Next Planned Update: 4 January 2011

32-SAMSS-030 Manufacture of Small Tanks

25.2

The outer shell and head of a secondary containment tank shall meet the requirements of Sections 16 and 17 of UL 142 with the exceptions, additions or deletion stipulated in 32-SAMSS-030. Tank Leakage Test Primary Containment Tanks The leakage test shall be conducted in accordance with the method described in Paragraph 39.2.1b. All reinforcing pads shall be tested by applying pneumatic pressure between the shell and pad and checking for leaks using a soap film. Pneumatic testing pressure, depending on opening diameter and/or shell plate thickness, shall be as follows: a) b) For openings with diameter up to and including 20 inches, irrespective of shell plate thickness: 15 psig (103 kPa) For larger openings (normally not exceeding 24 inches): i) ii) 10 psig (69 kPa) for shell plate thickness less than 3/16 inch or 5 mm. 15 psig (103 kPa) for thicker shell plates.

39 39.2 39.2.1 39.2.3

48 48.1 48.1.1(f)

Marking Elements All Tanks All tanks with internal coatings shall have the Saudi Aramco's Approved Protective Coating Specification number (APCS number) marked on the nameplate.

Page 25 of 28

Document Responsibility: Vessels Issue Date: 4 January 2006 Next Planned Update: 4 January 2011

32-SAMSS-030 Manufacture of Small Tanks

Appendix IV Supplement to UL 1316 The following paragraph numbers refer to UL 1316, April 2, 1996, which is part of this specification. The text in each paragraph below is an addition to UL 1316 unless it is noted as an exception. Paragraph numbers not appearing in UL 1316 are new paragraphs to be inserted in numerical order. CONSTRUCTION 3 3.3 General One piece construction heads shall be only used. Heads shall be either hemispherical or dished. Head radius shall be equal to or less than the head diameter. Dished heads shall have a knuckle with a radius equal to or greater than 0.03 times the head diameter, but not less than 1 inch. The minimum cylinder wall thickness and minimum head thickness shall be 0.20 in. (5 mm). Inside diameter tolerances shall be 1 % of nominal inside diameter. The cylinder wall of the tank may be tapered but shall not exceed 0.5 per side. The taper, if any, shall be additive to the nominal inside diameter. Workmanship The tank interior surface shall have no non-wetted or exposed reinforcements, no cracks or crazing, and no blisters. Additionally, no pits, surface porosity, pin holes, pores, chips, or scratches greater than 1/16 in. in depth are permitted. Maximum frequency for these visual observations less than 1/16 in. deep shall be less than 20/ft. No voids (entrapped air or bubbles) or encapsulated foreign matter greater than 1/16 in. in depth or greater than in. in diameter are allowed. The tank exterior surface shall have no cracks, crazes greater than 1 in., blisters greater than in. in diameter, sharp projections, non-wetted or exposed reinforcement. Additionally, no pits, surface porosity, pin holes, chips, scratches, or foreign greater than 1/16 in. in depth are permitted. Maximum frequency for these visual observations less than 1/16 in. deep shall be less than 20/ft. No voids (entrapped air or bubbles) or encapsulated foreign matter greater than 1/16 in. in depth or greater than in. in diameter are allowed.

Page 26 of 28

3.4 3.5 3.6 3.7 3.8 3.8.1

3.8.2

Document Responsibility: Vessels Issue Date: 4 January 2006 Next Planned Update: 4 January 2011

32-SAMSS-030 Manufacture of Small Tanks

3.9 4 4.1 4.2 4.3 4.4 5 5.3 12 12.2

Any tank may be repaired prior to shipment, provided the repaired tank meets all requirements of this specification. Pipe Connections Steel threaded fittings shall be in accordance with ASME B16.11. All nozzles NPS 3 and larger that are subject to piping loads shall be reinforced. For tanks equipped with agitators, the shell shall be reinforced in order to provide sufficient rigidity. (Exception) Fitting sizes 1- in and 2- in NPS shall not be used Manways (Exception) Manways shall be circular and a minimum size of NPS 20. External pressure test (Exception) The empty tank shall be subjected to an external hydrostatic pressure as specified in the following table:

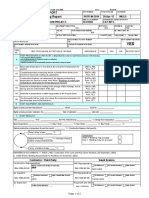

Applied External Water Pressure (D + 914 76) mm of water [(D + 36 3) in of water] (D + H 76) mm of water [(D + H 3) in of water] Or (D + 914 76) in of water + 9.78 [(H/1000)-0.914]kPa superimposed negative internal pressure [(D + 36 3) in of water + 0.8826 [(H/12)-3] in of Hg] Holding Time 24 hours 24 hours Additional Superimposed Internal Pressure 18 kPa (5.3 in Hg) 18 kPa (5.3 in Hg) Holding Time 1 minute 1 minute

Depth of Cover 0-914 76 mm (036 3 in) > 914 76 mm (036 3 in)

D: Tank Diameter in mm [in] H: Desired depth of cover in mm [in])

15 15.2

Earth Load Test (Exception) While the tank is still buried, it is to be subjected to a concentrated load of 22,400 lb (10,168 kg) applied to a load-bearing plate 20 by 20 in. (500 by 500 mm) at the top of the cover material.

Page 27 of 28

Document Responsibility: Vessels Issue Date: 4 January 2006 Next Planned Update: 4 January 2011

32-SAMSS-030 Manufacture of Small Tanks

Appendix V Supplement to API SPEC 12P The following paragraph numbers refer to API SPEC 12P, Second Edition, January 1995, which is part of this specification. The text in each paragraph below is an addition to API SPEC 12P unless it is noted as an exception. Paragraph numbers not appearing in API SPEC 12P are new paragraphs to be inserted in numerical order. 4 4.1 4.7 Design General Bottom Strength The type of tank bottom shall be as specified on the Storage Tank Data Sheet. 4.8 Geometry The type of deck shall be as specified on the Storage Tank Data Sheet. 4.13 Nozzles (Exception) Steel threaded connections shall be in accordance with ASME B16.11. 4.20 Wind Load on Tanks (Overturning Stability) Anchoring shall be provided as required to prevent tank overturning due to wind loads. 4.21 Stiffeners For tanks equipped with agitators, the shell shall be reinforced in order to provide sufficient rigidity. 4.21.2 All nozzles NPS 3 and larger that are used to support piping loads shall be reinforced.

Page 28 of 28

You might also like

- 45 Samss 005Document45 pages45 Samss 005Mohammed Ishaq AamerNo ratings yet

- (Compare Report) SAES-B-005Document14 pages(Compare Report) SAES-B-005kartik_harwani4387No ratings yet

- 32 Samss 020Document18 pages32 Samss 020naruto256No ratings yet

- 34 Samss 716Document12 pages34 Samss 716naruto256No ratings yet

- 34 Samss 718Document14 pages34 Samss 718naruto256No ratings yet

- Saes A 007Document29 pagesSaes A 007NagarjunNo ratings yet

- 34 Samss 830Document18 pages34 Samss 830naruto256No ratings yet

- 34 Samss 711Document25 pages34 Samss 711naruto256No ratings yet

- Materials System SpecificationDocument6 pagesMaterials System SpecificationCherukunnon JubuNo ratings yet

- 01 Samss 035Document28 pages01 Samss 035Cherukunnon Jubu100% (2)

- PME Engineering ReportDocument28 pagesPME Engineering Reportnaruto256100% (2)

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistphilipyapNo ratings yet

- Api PR586-1Document46 pagesApi PR586-1Woodrow Fox100% (2)

- SAES Engineering Standards and Specifications OverviewDocument13 pagesSAES Engineering Standards and Specifications OverviewRiyaz BasheerNo ratings yet

- List of SAESDocument8 pagesList of SAESSyed NaseemuddinNo ratings yet

- sp001 5thedition ChecklistsDocument14 pagessp001 5thedition ChecklistsJavier Mauricio Higuera MoraNo ratings yet

- 45 Samss 006Document8 pages45 Samss 006naruto256No ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PerAbu Anas M.SalaheldinNo ratings yet

- 34 Samss 821Document9 pages34 Samss 821naruto256No ratings yet

- 32 Samss 005Document33 pages32 Samss 005Selvakpm06No ratings yet

- 34 Samss 624Document23 pages34 Samss 624Hemac Hander100% (1)

- 34 Samss 717Document19 pages34 Samss 717naruto256No ratings yet

- 34 Samss 634Document13 pages34 Samss 634naruto256No ratings yet

- 34 Samss 820Document21 pages34 Samss 820naruto2560% (1)

- SAES-N-001 PDF Download - Basic Criteria, Industrial Insulation - PDFYARDocument7 pagesSAES-N-001 PDF Download - Basic Criteria, Industrial Insulation - PDFYARZahidRafique100% (1)

- SAES-L-133 PDF Download - Corrosion Protection Requirements - PDFYARDocument6 pagesSAES-L-133 PDF Download - Corrosion Protection Requirements - PDFYARZahidRafique100% (1)

- 34 Samss 913Document22 pages34 Samss 913naruto256No ratings yet

- 31 Samss 004 离心泵Document22 pages31 Samss 004 离心泵zhang100% (1)

- Agitator DesignDocument2 pagesAgitator Designnaruto256100% (1)

- Materials System Specification: Saudi Aramco Desktop StandardsDocument14 pagesMaterials System Specification: Saudi Aramco Desktop StandardsMoustafa Bayoumi100% (1)

- Ad 036821 001Document1 pageAd 036821 001AmolNo ratings yet

- Stair Pressurization CalculationDocument2 pagesStair Pressurization Calculationnaruto256100% (1)

- 100 Yer Pe Yss 0438Document36 pages100 Yer Pe Yss 0438Mohammad Aamir PerwaizNo ratings yet

- 34 Samss 841Document68 pages34 Samss 841naruto256No ratings yet

- PipingDocument16 pagesPipingraja11185100% (1)

- Saes A 005 PDFDocument32 pagesSaes A 005 PDFAdnanAtifNo ratings yet

- Active Doc ListDocument360 pagesActive Doc ListLeo NunnikhovenNo ratings yet

- 32 Samss 005Document34 pages32 Samss 005ரமேஷ் பாலக்காடுNo ratings yet

- Engineering Procedure: SAEP-310 13 January 2008 Piping and Pipeline Repair Piping Standards Committee MembersDocument39 pagesEngineering Procedure: SAEP-310 13 January 2008 Piping and Pipeline Repair Piping Standards Committee Membersbrecht1980100% (4)

- 34-Samss-010 2018Document9 pages34-Samss-010 2018asimazami69No ratings yet

- Saudi Aramco piping inspection planDocument2 pagesSaudi Aramco piping inspection planMuhammad Farukh Manzoor100% (1)

- Saudi Aramco Typical Inspection PlanDocument3 pagesSaudi Aramco Typical Inspection PlanOmer aliNo ratings yet

- SAUDIPIPINGMATTRACEDocument9 pagesSAUDIPIPINGMATTRACEMAZHARULNo ratings yet

- Saep 119Document12 pagesSaep 119brecht1980No ratings yet

- 01 Samss 016 PDFDocument15 pages01 Samss 016 PDFFlorin Daniel AnghelNo ratings yet

- Saep 327Document11 pagesSaep 327brecht1980100% (2)

- 32 Samss 005Document33 pages32 Samss 005naruto256100% (1)

- TPS QA KA AA 001 (C01) Welding Tank ProcedureDocument10 pagesTPS QA KA AA 001 (C01) Welding Tank ProcedureTouil HoussemNo ratings yet

- SAES-L-450 PDF Download - On-Land and Near-Shore Pipelines - PDFYARDocument5 pagesSAES-L-450 PDF Download - On-Land and Near-Shore Pipelines - PDFYARZahidRafiqueNo ratings yet

- 34 Samss 846Document35 pages34 Samss 846naruto256No ratings yet

- SAEP-35-N - Valves Handling, Hauling, Receipt Tests and StorageDocument8 pagesSAEP-35-N - Valves Handling, Hauling, Receipt Tests and StorageMuhammad Farukh Manzoor0% (1)

- Materials System SpecificationDocument7 pagesMaterials System Specificationaanouar77No ratings yet

- SAES X 500 Cathodic ProtectionDocument8 pagesSAES X 500 Cathodic ProtectionAbdul Khader HassanNo ratings yet

- 1 SATIP-E-004-01 H Exc Installation-Shell and Tube-Rev1Document2 pages1 SATIP-E-004-01 H Exc Installation-Shell and Tube-Rev1Anonymous S9qBDVkyNo ratings yet

- 32 Samss 005Document34 pages32 Samss 005jagp_24No ratings yet

- 00-SAES-D-109 (7 Types Small Tanks at SA)Document23 pages00-SAES-D-109 (7 Types Small Tanks at SA)Manoranjan NayakNo ratings yet

- 34 Samss 625Document18 pages34 Samss 625naruto256100% (1)

- 32 Samss 006Document22 pages32 Samss 006Vajid MadathilNo ratings yet

- Saes H 204Document34 pagesSaes H 204heartbreakkid132No ratings yet

- Saep 318 PDFDocument49 pagesSaep 318 PDFRami Elloumi0% (1)

- 34 Samss 815Document9 pages34 Samss 815naruto256No ratings yet

- Saes H 200 PDFDocument9 pagesSaes H 200 PDFSohail Aziz Ahmad Malik100% (1)

- 01-SAMSS-049 Reinforced Thermoset Resin (RTR) Pipe, Fittings and Adhesive Packing, Handling, Transportation and Storage 21-FEB-2012 PDFDocument8 pages01-SAMSS-049 Reinforced Thermoset Resin (RTR) Pipe, Fittings and Adhesive Packing, Handling, Transportation and Storage 21-FEB-2012 PDFasiqnaNo ratings yet

- API 653 Above Ground Storage Tanks Inspector 08-July-2023Document8 pagesAPI 653 Above Ground Storage Tanks Inspector 08-July-2023RAVI0% (1)

- New Revision of SAES-S-040Document22 pagesNew Revision of SAES-S-040luke luckyNo ratings yet

- Materials System SpecificationDocument9 pagesMaterials System SpecificationFAPM1285No ratings yet

- Saudi Aramco Test Report Temperature Tie-In Welding ReportDocument2 pagesSaudi Aramco Test Report Temperature Tie-In Welding ReportManoj Kumar100% (2)

- Saes A 208Document14 pagesSaes A 208nadeemNo ratings yet

- Saudi Aramco Typical Inspection PlanDocument2 pagesSaudi Aramco Typical Inspection PlanMAZHARULNo ratings yet

- Saes W 011Document2 pagesSaes W 011hendraox3996No ratings yet

- Cathodic ProtectionDocument5 pagesCathodic ProtectionFaseen ibnu Ameer AhasenNo ratings yet

- 01 Samss 010Document11 pages01 Samss 010doyenofcastleNo ratings yet

- Coating Procedure - Shuqaiq Desalination PJT - Rev.2Document19 pagesCoating Procedure - Shuqaiq Desalination PJT - Rev.2ABAID ULLAHNo ratings yet

- Saudi Aramco Inspection Checklist: Preliminary / Final Alignment of Pump & Driver SAIC-G-2022 30-Apr-17 MechDocument23 pagesSaudi Aramco Inspection Checklist: Preliminary / Final Alignment of Pump & Driver SAIC-G-2022 30-Apr-17 Mechkarthi51289No ratings yet

- Saudi Aramco Test Report: DC Rectifier Testing 24-Jul-18 CP-SATR-X-3202Document7 pagesSaudi Aramco Test Report: DC Rectifier Testing 24-Jul-18 CP-SATR-X-3202nadeem shaikhNo ratings yet

- Saes B 063Document6 pagesSaes B 063Cherukunnon JubuNo ratings yet

- 00 Saip 08 - 03142016Document9 pages00 Saip 08 - 03142016PandhuNo ratings yet

- 01 Samss 031Document3 pages01 Samss 031Awais CheemaNo ratings yet

- 74 Samss 001Document7 pages74 Samss 001getravi1886No ratings yet

- Stud For Slid StripDocument1 pageStud For Slid Stripnaruto256No ratings yet

- Crossed Roller DesignGuideDocument17 pagesCrossed Roller DesignGuidenaruto256No ratings yet

- Flexibility - Analysis Check - Sheet by AnasDocument1 pageFlexibility - Analysis Check - Sheet by AnasojaudoNo ratings yet

- 45 Samss 009Document6 pages45 Samss 009naruto256No ratings yet

- 45 Samss 008Document7 pages45 Samss 008naruto256No ratings yet

- 45 Samss 009Document6 pages45 Samss 009naruto256No ratings yet

- 45 Samss 013Document23 pages45 Samss 013naruto256No ratings yet

- 34 Samss 851Document82 pages34 Samss 851naruto256100% (1)

- 36 Samss 001Document78 pages36 Samss 001naruto256No ratings yet

- 34 Samss 847Document22 pages34 Samss 847naruto256100% (1)