Professional Documents

Culture Documents

00-SAES-D-109 (7 Types Small Tanks at SA)

Uploaded by

Manoranjan NayakCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

00-SAES-D-109 (7 Types Small Tanks at SA)

Uploaded by

Manoranjan NayakCopyright:

Available Formats

Engineering Standard

SAES-D-109

29 December 2004

Design of Small Tanks (BLUE-LINED VERSION)

Vessels Standards Committee Members

Naffa'a, M.Y., Chairman

Al-Anizi, S.S.

Al-Gahtani, M.S.

Al-Musaiid, H.A.

Al-Sharhan, Z.S.

Jones, S.B.

Khanna, R.K.

Khouie, S.B.

Kim, S.U.

Muir, W.R.

Walsh, M.P.

Saudi Aramco DeskTop Standards

Table of Contents

1

Previous Issue: 30 November 2003

Scope.............................................................

Next Planned Update: 1 January 2006

Revised paragraphs are indicated in the right margin

Primary contact: Mahmoud Y. Naffa'a on 874-7263

Page 1 of 23

Document Responsibility: Vessels

SAES-D-109

Issue Date: 29 December 2004

Next Planned Update: 1 January 2006

Design of Small Tanks

Conflicts and Deviations................................

References.....................................................

Definitions......................................................

Responsibilities..............................................

Tank Selection...............................................

Materials........................................................

Design.........................................................

Appurtenances............................................

10 Coatings and Painting..................................

10

11 Insulation......................................................

10

12 Grounding....................................................

10

13 Cathodic Protection......................................

11

14 Foundations.................................................

11

15 Drawings, Calculations, and Data................

11

Appendix I..........................................................

12

Appendix II.........................................................

14

Appendix III........................................................

15

Appendix IV........................................................

17

Page 2 of 23

Document Responsibility: Vessels

SAES-D-109

Issue Date: 29 December 2004

Next Planned Update: 1 January 2006

Scope

1.1

Design of Small Tanks

This standard defines the minimum mandatory requirements governing the design

and selection of small atmospheric pressure storage tanks used in production,

process plant, bulk plant, building services, fuel dispensing, or community

facilities applications.

1.1.1

This standard shall not be attached to nor made a part of purchase orders.

1.1.2

The selection and design of field-erected atmospheric pressure storage

tanks in accordance with API STD 650, Appendix J shall be in accordance

with SAES-D-100.

1.2

This standard covers tanks used for the aboveground or underground storage of

flammable and combustible liquids. It also covers tanks used for the storage of

chemicals and water.

1.3

Tanks designed in accordance with this standard shall be limited to a maximum

capacity given by the relevant industry standards listed in Paragraph 3.2.

1.4

This standard shall be used by the Design Engineer to complete the tank data

sheets.

Conflicts and Deviations

2.1

Any conflicts between this standard and other Saudi Aramco Engineering

Standards (SAESs), Saudi Aramco Materials System Specifications (SAMSSs),

industry codes and standards, and Saudi Aramco Standard Drawings (SASDs) and

Forms shall be resolved in writing by the Company or Buyer Representative

through the Manager, Consulting Services Department of Saudi Aramco,

Dhahran.

2.2

Direct all requests to deviate from this standard in writing to the Company or

Buyer Representative, who shall follow internal company procedure SAEP-302

and forward such requests to the Manager, Consulting Services Department of

Saudi Aramco, Dhahran.

References

The selection and design of equipment and facilities covered by this standard shall comply

with the latest edition of the references listed below, unless otherwise noted.

3.1

Saudi Aramco References

Saudi Aramco Engineering Procedure

Page 3 of 23

Document Responsibility: Vessels

SAES-D-109

Issue Date: 29 December 2004

Next Planned Update: 1 January 2006

SAEP-302

Design of Small Tanks

Instructions for Obtaining a Waiver of a Mandatory

Saudi Aramco Engineering Requirement

Saudi Aramco Engineering Standards

SAES-A-005

Safety Instruction Sheets

SAES-A-112

Meteorological Data

SAES-B-005

Spacing and Diking For Atmospheric and LowPressure Tanks

SAES-B-054

Access, Egress, and Materials Handling for Plant

Facilities

SAES-B-055

Plant Layout

SAES-D-100

Design Criteria of Atmospheric and Low-Pressure

Tanks

SAES-H-001

Selection Requirements for Industrial Coatings

SAES-H-101

Approved Protective Coating System

SAES-J-300

Level

SAES-N-001

Insulation

SAES-P-111

Grounding

SAES-Q-005

Concrete Foundations

SAES-X-500

Cathodic Protection of Vessels and Tank Internals

SAES-X-600

Cathodic Protection of Plant Facilities

Saudi Aramco Materials System Specification

32-SAMSS-030

Manufacture of Small Tanks

Saudi Aramco Standard Drawings

AA-036355

Impressed Current Tank Bottom, Cathodic Protection

Details

AB-036387

Grounding

Saudi Aramco Forms and Data Sheets

2693-ENG

Tank Safety Instruction Sheet

Page 4 of 23

Document Responsibility: Vessels

SAES-D-109

Issue Date: 29 December 2004

Next Planned Update: 1 January 2006

2696-ENG

3.2

Design of Small Tanks

Appurtenance Schedule and Orientations

Industry Codes and Standards

(CO, LL) KNOW SMALL TANK SELECTION REQUIREMENTS AT SA (See Ch 6)

SEVEN TYPES OF SMALL TANKS EXIST AT SA FOR DESIGN PURPOSES

SEE SAES-D-100 for API 620 & 650 TANKS KNOW YOUR TANK SCOPE!!!

Page 5 of 23

Document Responsibility: Vessels

SAES-D-109

Issue Date: 29 December 2004

Next Planned Update: 1 January 2006

Design of Small Tanks

American Petroleum Institute

1-API STD 650

Welded Steel Tanks for Oil Storage

2-API SPEC 12F

Specification for Shop Welded Tanks for Storage of

Production Liquids

3-API SPEC 12P

Specification for Fiberglass Reinforced Plastic Tanks

American Water Works Association

4-AWWA D100

Welded Steel Tanks for Water Storage

5-AWWA D120

Thermosetting Fiberglass-Reinforced Plastic Tanks

Underwriters Laboratories, Inc.

6-UL 142

Steel Aboveground Tanks for Flammable and

Combustible Liquids

7-UL 1316

Glass-Fiber-Reinforced Plastic Underground Storage

Tanks for Petroleum Products, Alcohols, and

Alcohol-Gasoline Mixtures

Definitions

Atmospheric Pressure: Internal pressure that does not exceed the weight of the tank roof.

Design Engineer: The Engineering Company responsible for specifying, on the design

data sheet, the design requirements for tanks.

Combustible Liquid: A liquid that has a flash point greater than 54C and that is at a

temperature lower than 8C below its flash point.

Flammable liquid: A liquid that has a flash point equal to or less than 54C.

Saudi Aramco Engineer: The Supervisor of the Piping and Mechanical Unit, Consulting

Services Department, Dhahran.

Small Tanks: Shop fabricated or field erected atmospheric pressure storage tanks up to

1500 barrels capacity.

Tank Manufacturer: The Company responsible for the design and fabrication of tanks

Responsibilities

5.1

The Design Engineer is responsible for specifying the type, size and design

conditions for storage tanks, including the requirements for associated tank

appurtenances.

Page 6 of 23

Document Responsibility: Vessels

SAES-D-109

Issue Date: 29 December 2004

Next Planned Update: 1 January 2006

5.2

Design of Small Tanks

The Tank Manufacturer is responsible for the design, supply of materials,

fabrication, erection, inspection, testing, surface preparation and painting of tanks

in accordance with the Design Engineer's specification.

Tank Selection

6.1

6.2

6.3

Aboveground, vertical, cylindrical, steel tanks to be used for the storage of

production liquids and located within producing facilities shall be in accordance

with the following.

(1)

API SPEC 12F or UL 142 up to 750 barrels capacity.

(2)

API STD 650, Appendix J or UL 142 for over 750 and up to 1500 barrels

capacity.

(3)

The Design Engineer shall use the most economical selection from the

standards specified in each case.

API STD 650, Appendix J or UL 142, shall be used for aboveground, steel tanks

used for the storage of crude oil, hydrocarbon intermediates, chemicals, or final

products and located within process plants, bulk plants, buildings, fuel dispensing

or community facilities. The choice of the appropriate standard shall be based on

the following.

(1)

Either API STD 650 Appendix J or UL 142 may be used for tanks storing

liquids that have a specific gravity not greater than that of water. The

Design Engineer shall elect the more economical option between these

standards for each application.

(2)

API STD 650 Appendix J shall be used for tanks storing liquids that have a

specific gravity greater than that of water.

(3)

UL 142 shall be used for aboveground stainless steel tanks.

Underground, fiberglass reinforced plastic tanks to be used

for the storage of petroleum products shall be in accordance with UL 1316.

6.4

Aboveground, vertical, cylindrical, fiberglass reinforced plastic tanks to be used

for the storage of petroleum products, alcohol-gasoline mixtures, or corrosive

chemicals shall be in accordance with API SPEC 12P.

6.5

Aboveground steel tanks to be used for the storage of water shall be in accordance

with AWWA D100.

6.6

Aboveground fiberglass reinforced plastic tanks to be used for the storage of water

shall be in accordance with AWWA D120.

Page 7 of 23

Document Responsibility: Vessels

SAES-D-109

Issue Date: 29 December 2004

Next Planned Update: 1 January 2006

Design of Small Tanks

6.7

Fiberglass reinforced plastic tanks shall comply with the restrictions of

SAES-B-055, Section 8.7 on their use.

6.8

Steel tanks used for the storage of flammable or combustible liquids and located

within production facilities, process plants, or bulk plants shall be installed

aboveground.

6.9

Fiberglass reinforced plastic tanks used for the storage of flammable or

combustible liquids and located within fuel dispensing or community facilities

shall be located underground.

Materials

7.1

The Design Engineer shall specify material requirements based on the specific

tank service.

7.2

The Design Engineer shall specify a corrosion allowance for unlined carbon and

low-alloy steel tanks based on the anticipated service life and corrosivity of the

liquids to be stored.

7.3

Materials proposed by the Tank Manufacturer shall be selected in accordance with

32-SAMSS-030.

Design

8.1

General

8.1.1

The Design Engineer shall complete the Storage Tank Data Sheet for the

tank being purchased in accordance with this standard as follows:

(1)

API SPEC 12F tanks: Complete the Storage Tank Data Sheet in

Appendix I of this standard.

(2)

API STD 650 Appendix J tanks: Use the Storage Tank Data Sheet in

Appendix L of API STD 650 and provide the information as detailed

in Appendix II of this standard.

(3)

UL 142 tanks: Complete the Storage Tank Data Sheet provided in

Appendix III of this standard.

(4)

API SPEC 12P tanks: Use Data Sheet 1 of API SPEC 12P and

provide the information as detailed in Appendix IV of this standard.

(5)

UL 1316 tanks: Complete the Storage Tank Data Sheet provided in

Appendix III of this standard.

(6)

AWWA D100 tanks: Use Section III or Section IV in the Forward of

AWWA D100 as applicable and provide the required information.

Page 8 of 23

Document Responsibility: Vessels

SAES-D-109

Issue Date: 29 December 2004

Next Planned Update: 1 January 2006

(7)

8.2

Design of Small Tanks

AWWA D120 tanks: Complete the Storage Tank Data Sheet as

provided in Appendix III of this standard.

8.1.2

The Design Engineer shall complete Form SA 2696-ENG showing the tank

dimensions, appurtenance schedules, orientations and elevations.

8.1.3

The Design Engineer shall complete tank Safety Instruction Sheets in

accordance with SAES-A-005.

Design Criteria

Storage tanks within the scope of this standard shall be designed, fabricated,

inspected and tested in accordance with the applicable industry standard listed in

Paragraph 3.2 of this standard and 32-SAMSS-030.

8.3

8.4

Tank Dimensions and Capacity

8.3.1

The Design Engineer shall determine the initial tank dimensions based on

the most economical tank height (or length) versus diameter.

8.3.2

The Design Engineer shall verify that the Tank Manufacturer's design

proposal meets the specified dimensional requirements.

Design Conditions

The design temperature shall be the maximum operating temperature of the tank.

8.5

External Loads

8.5.1

The basic wind speed corresponding to the tank site shall be specified in

accordance with SAES-A-112.

8.5.2

The seismic zone factor, importance factor and the site coefficient

corresponding to the tank site shall be specified in accordance with SAESA-112.

8.5.3

Underground tanks shall be designed for soil, traffic and/or buoyancy

loads as applicable.

8.5.4

Loads superimposed by platforms and brackets and loads resulting from

connected piping shall be considered in the tank design.

Page 9 of 23

Document Responsibility: Vessels

SAES-D-109

Issue Date: 29 December 2004

Next Planned Update: 1 January 2006

8.6

Design of Small Tanks

Under-tank leak detection and sub-grade protection shall be provided for

aboveground, vertical flat bottom steel tank supported directly on soil foundation

according to API STD 650, Appendix I. Acceptable construction details are

Figures I-1, I-2, I-3, I-8, I-9 and I-10. Flexible membrane liner of minimum 1000

microns (40 mils) thickness compatible with the stored product shall be specified

under the tank bottom. The liner shall be placed at the bottom of the ring

foundation or minimum 1 meter below the top edge of the ring foundation

whichever is greater. The liner shall extend to the internal top edge of the ring

foundation. Alternative under-tank leak detection and sub-grade protection

systems shall not be permitted without the prior approval of the Saudi Aramco

Engineer.

Appurtenances

9.1

General

The type, quantity and layout of all appurtenances for storage tanks shall be

specified in accordance with this standard.

9.2

Nozzles and Manways

9.2.1

Nozzle and piping sizes 1- inch, 2- inch, 3- inch and 5 inch NPS shall

not be used.

9.2.2

Nozzles 2 inch NPS and larger shall be flanged.

9.2.3

Connections 1- inch NPS and smaller, other than welding outlets and

welding bosses, shall be Class 3000 minimum, either socket welded or

threaded couplings.

9.2.4

Connections 1- inch NPS and smaller shall be gusseted to prevent

potential physical damage during handling and shipping.

9.2.5

Manways for aboveground, vertical cylindrical tanks shall be specified as

follows.

9.2.6

(1)

One 24 inch NPS shell manway.

(2)

One 20 inch NPS roof manway for tanks larger than 10,000 gallons

capacity.

(3)

A cleanout opening, when provided in accordance with the

requirements of the relevant standard or specification, may be

substituted for the shell manway.

One 20 inch NPS manway shall be provided for aboveground or

underground horizontal cylindrical tanks.

Page 10 of 23

Document Responsibility: Vessels

SAES-D-109

Issue Date: 29 December 2004

Next Planned Update: 1 January 2006

9.3

Design of Small Tanks

Vents

The Design Engineer shall verify the adequacy of the number and size of the vents

proposed by the Tank Manufacturer. Provision of frangible joint at the shell-toroof juncture for aboveground vertical steel tanks for emergency venting is

prohibited.

9.4

9.5

9.6

9.7

Temperature Instruments

9.4.1

Dial thermometers shall be specified, when required by the Operating Unit

at the specific facility. The size and location of thermometers shall be

shown on Form SA 2696-ENG.

9.4.2

Tanks with heaters shall be equipped with a self-actuating temperature

controller, unless the inlet steam temperature is such that the condensing

temperature will not exceed the process needs. The location of the sensing

point for the controller shall be the same as for a dial thermometer.

Level Gauging Systems

9.5.1

Level gauging systems shall be specified in accordance with SAES-J-300.

9.5.2

A minimum of one level gauging instrument per tank, readable either from

grade or from an access platform, shall be specified.

9.5.3

Provisions for manual gauging shall be specified, even if the tank is

provided with an automatic gauging device.

Sample Connections

9.6.1

Sample connections shall be specified, when required by the Operating

Unit at the specific facility.

9.6.2

The number, size and location of sample connections shall be shown on

Form SA 2696-ENG.

Stairways, Ladders and Platforms

9.7.1

Stairways, ladders and platforms shall be specified in accordance with

SAES-B-054.

9.7.2

Access to the roof of aboveground, vertical, cylindrical, tanks shall be

provided as follows.

(1)

A spiral stairway shall be specified for tanks over 6 m in height and

for tanks requiring gauging or sampling from the roof. A platform

shall also be specified for access to the gauge or sampling hatch.

Page 11 of 23

Document Responsibility: Vessels

SAES-D-109

Issue Date: 29 December 2004

Next Planned Update: 1 January 2006

10

11

12

Design of Small Tanks

(2)

A vertical ladder shall be specified for tanks that do not require

spiral stairways.

(3)

Stairs shall be located on the upwind side with respect to the

prevailing wind direction of vertical tanks in hydrocarbon services,

and this shall be shown on Form SA 2696-ENG. However, where it is

impractical to meet this requirement, only the upper stairway

landing is required to be located upwind side of the tank.

Coatings and Painting

10.1

Surface preparation and painting specifications shall be selected in accordance

with SAES-H-001.

10.2

The Design Engineer shall specify all painting requirements on the Storage Tank

Data Sheet in accordance with SAES-H-101, including the Approved Protective

Coating Systems (APCS), surface preparation, primer type, number of coats, total

thickness and the areas or parts of the tank to be painted.

Insulation

11.1

The Design Engineer shall specify the type and thickness of external insulation for

above ground tanks in accordance with SAES-N-001, where required.

11.2

The Design Engineer shall specify whether aboveground tanks must be insulated

to protect them from fire exposure based on tank location or when required by the

Operating Unit.

Grounding

The Design Engineer shall specify the grounding requirements in accordance with SAESP-111 and standard drawing AB-036387.

13

Cathodic Protection

Cathodic protection requirements shall be in accordance with SAES-X-500 and

SAES-X-600.

14

Foundations

14.1

Spacing and diking of tanks shall be in accordance with SAES-B-005.

14.2

Concrete foundations for tanks shall be in accordance with SAES-Q-005.

14.3

Under Tank Leak Detection and Sub-grade Protection (CO, for AG Tanks)

Page 12 of 23

Document Responsibility: Vessels

SAES-D-109

Issue Date: 29 December 2004

Next Planned Update: 1 January 2006

15

Design of Small Tanks

14.3.1

Tanks in services other than water shall be provided with an under tank

leak detection and sub-grade protection according to API STD 650,

Appendix I. Acceptable construction details are Figures I-1, I-2, I-3, I-8,

I-9 and I-10.

14.3.2

Flexible membrane liner of minimum 1000 microns (40 mils) thickness

compatible with the stored product shall be specified under the tank

bottom. The liner shall be placed according to SASD AA-036355,

extending to the internal top edge of the ring foundation.

14.3.3

Joints in the liner shall satisfy the leak tightness, permeability, and

chemical resistance requirements for the liner material.

14.3.4

Alternative under-tank leak detection and sub-grade protection systems

shall not be permitted without the prior approval of the Saudi Aramco

Engineer.

Drawings, Calculations, and Data

15.1

The Design Engineer shall complete the Storage Tank Data Sheet and forms to the

extent specified in this standard.

15.2

The Design Engineer is responsible for completion of applicable portions of the

Tank Safety Instruction Sheet (Form SA 2693-ENG) in accordance with the data

provided by the Tank Manufacturer and SAES-A-005.

Revision Summary

29 December 2004 Revised the "Next Planned Update". Reaffirmed the contents of the document, and reissued with no other

changes.

Page 13 of 23

Document Responsibility: Vessels

SAES-D-109

Issue Date: 29 December 2004

Next Planned Update: 1 January 2006

Design of Small Tanks

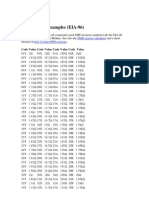

Appendix I

Data Sheet for Storage Tanks Designed

In Accordance with API SPEC 12F

1.

2.

3.

Tank Location:

Name of Plant:

__________________________

Location:

__________________________

Tank No.

_____________

Nominal Capacity

_____________ Gallons/Barrels

Outside Diameter

_____________ m

Height

_____________ m

Type of Bottom:

____________

Flat:

____________

Unskirted Cone:

____________

Skirted Cone:

____________

4.

Corrosion Allowance: ____________ mm

5.

Shell Plate Thickness: ____________ mm

Specify as 6 mm plus corrosion allowance in excess of 1.6 mm.

Page 14 of 23

Document Responsibility: Vessels

SAES-D-109

Issue Date: 29 December 2004

Next Planned Update: 1 January 2006

6.

7.

Maximum Pumping Rates:

In

______________ Barrels/Hour (Gallons/Hour)

Out

______________ Barrels/Hour (Gallons/Hour)

Liquid Stored ____________ Design S.G. _____ at _____ C

Is this a viscous oil service?

Yes

_____

No

_____

8.

Maximum Operating Temperature ___________ C

9.

Wind Velocity ______________ km/h(mph)

10.

Earthquake Zone ____________

Page 15 of 23

Design of Small Tanks

Document Responsibility: Vessels

SAES-D-109

Issue Date: 29 December 2004

Next Planned Update: 1 January 2006

Design of Small Tanks

Appendix I (Continued)

11.

12.

13.

No. and Size of Shell Manholes

_________________________

No. and Size of Roof Manholes

_________________________

Shell Nozzles:

Inlet:

No. __________

Size: ________________________

Outlet:

No. __________

Size ________________________

Instrument Connections:

Level:

14.

15.

No. ___________

Size ___________________

Temperature: No. ___________

Size ___________________

Sample:

Size ___________________

No. ___________

Is an anti-channel drain baffle required?

Yes

_____

No

_____

Is a downcomer pipe required?

Yes

_____

No

_____

16.

Insulation _____________________________________________

17.

Paint

______________________________________

Internal Coating

______________________________________

Page 16 of 23

Document Responsibility: Vessels

SAES-D-109

Issue Date: 29 December 2004

Next Planned Update: 1 January 2006

18.

Design of Small Tanks

Stairway: Circular __________

Straight __________

Ladder:

19.

20.

__________

Purchaser's Reference Documents:

SAMSSs

____________________________________________

SASDs

____________________________________________

Forms

____________________________________________

Others

____________________________________________

Remarks

_______________________________________________________

_______________________________________________________

Page 17 of 23

Document Responsibility: Vessels

SAES-D-109

Issue Date: 29 December 2004

Next Planned Update: 1 January 2006

Design of Small Tanks

Appendix II

Completion of API STD 650 Storage Tank Data Sheet

For Appendix J - Shop-Assembled Storage Tanks

The Design Engineer shall complete the following portions of the tank data sheet:

1.

2.

3.

Page 1 of Data Sheet

(1)

All items on Page 1. Add Appendix J to Items 9 and 10.

(2)

Item 5, the maximum pumping rates must be specified in order to properly

size the vents.

Page 2 of Data Sheet

(1)

Item 8, the details in API STD 650, Figure F-1, showing the horizontal leg

of the roof support angle turning inward for cone roof tanks.

(2)

Item 12, paint in accordance with Paragraph 10 of this standard

(3)

Item 13, tank bottom coating, if required

(4)

Item 18, mill test reports shall be required

(5)

Item 19, applicable Saudi Aramco Standard Drawings and Forms shall be

listed

(6)

Item 21, 32-SAMSS-030 shall also be listed

Page 3 of Data Sheet

(1)

Item 1, stairway style in accordance with this standard

(2)

Items 8, 9, 10 and 11, number and size of shell and roof manholes, and shell

and roof nozzles, in accordance with completed Form 2696-ENG for the

tank.

(3)

Other accessories, such as level gages, grounding lugs, etc., which are to be

supplied by the Tank Manufacturer, shall also be included on the Storage

Tank Data Sheet.

Page 18 of 23

Document Responsibility: Vessels

SAES-D-109

Issue Date: 29 December 2004

Next Planned Update: 1 January 2006

Design of Small Tanks

Appendix III

Data Sheet for Storage Tanks Designed

In Accordance with UL 142, UL 1316, or AWWA D120

1.

Tank Location: ____________________________________________

Name of Plant: ____________________________________________

Location:

2.

4.

5.

____________________________________________

Applicable Industry Standard:

UL 1316

__________

UL 142

__________

__________

AWWA D120

__________

Tank Material (For UL 142 tanks)

Carbon Steel

_________

Stainless Steel

_________

Tank No.

____________

Nominal Capacity

____________ Gallons/Barrels

Diameter

____________ m

Height (Length):

____________ m

Page 19 of 23

Document Responsibility: Vessels

SAES-D-109

Issue Date: 29 December 2004

Next Planned Update: 1 January 2006

6.

Design of Small Tanks

Tank Geometry

Cylindrical:

_________

Spherical:

_________

Rectangular: _________

7.

Tank Orientation:

Vertical:

__________

Horizontal: __________

8.

Maximum Pumping Rates:

In

9.

_________________

Barrels/Hour (Gallons/Hour)

Out _________________

Barrels/Hour (Gallons/Hour)

Liquid Stored _____________ Design S.G. _____ at _____ C

Corrosion Allowance _____________ mm

10.

Wind Velocity

______________

Earthquake Zone ______________

Page 20 of 23

km/h (mph)

Document Responsibility: Vessels

SAES-D-109

Issue Date: 29 December 2004

Next Planned Update: 1 January 2006

Design of Small Tanks

Appendix III (Continued)

Maximum Operating Temperature ___________ C

11.

For UL 142 Tanks Only

Is Secondary Containment Required?

Yes

_____

No

_____

Stairway:

Circular __________

Straight __________

Ladder: __________

12.

No. and Size of Manholes

13.

Shell Nozzles:

14.

_________________________

Inlet:

No. __________

Size _______________________

Outlet:

No. __________

Size _______________________

Instrument Connections:

Level:

No. ___________

Size _______________________

Temperature: No. ___________

Size _______________________

Sample:

Size _______________________

No. ___________

Page 21 of 23

Document Responsibility: Vessels

SAES-D-109

Issue Date: 29 December 2004

Next Planned Update: 1 January 2006

Design of Small Tanks

15.

Insulation ________________________________________________

16.

Paint ___________________________________________________

Internal Coating ___________________________________________

17.

18.

Purchaser's Reference Documents:

SAMSSs

________________________________________________

SASDs

________________________________________________

Forms

________________________________________________

Others

________________________________________________

Remarks

_________________________________________________________

_________________________________________________________

Page 22 of 23

Document Responsibility: Vessels

SAES-D-109

Issue Date: 29 December 2004

Next Planned Update: 1 January 2006

Design of Small Tanks

Appendix IV

Completion of API SPEC 12P

Storage Tank Data Sheet

The Design Engineer shall complete Design Data Sheet 1 of API SPEC 12P as necessary

for the particular tank application. The entries noted below shall be completed as follows

for all applications.

1.

An API SPEC 12P Monogram is required.

2.

If a ladder is required, it must be caged when required by SAES-B-054.

Page 23 of 23

You might also like

- Saudi Aramco Engineering Standard - Safety Identification and Safety ColorsDocument17 pagesSaudi Aramco Engineering Standard - Safety Identification and Safety ColorsRiaz Rashid67% (3)

- SAES B 055 Plant LayoutDocument34 pagesSAES B 055 Plant Layoutnavaronefra100% (1)

- The Family Handyman - October 2020 PDFDocument86 pagesThe Family Handyman - October 2020 PDFFabian MaunaNo ratings yet

- Materials System SpecificationDocument6 pagesMaterials System SpecificationCherukunnon JubuNo ratings yet

- Coating InspectionDocument11 pagesCoating InspectionManoranjan Nayak100% (1)

- Saes B 005Document13 pagesSaes B 005Karu 2100% (1)

- SMD Resistor ExamplesDocument5 pagesSMD Resistor Examplesmarcbuss100% (1)

- Saes S 020Document27 pagesSaes S 020Gutaiba Almasri100% (2)

- Sae 44Document26 pagesSae 44Anonymous 4IpmN7OnNo ratings yet

- Saudi Arabian Engineering Standardssaes J 002Document49 pagesSaudi Arabian Engineering Standardssaes J 002explosionproofNo ratings yet

- 32 Samss 005Document33 pages32 Samss 005Selvakpm06No ratings yet

- 100 Yer Pe Yss 0438Document36 pages100 Yer Pe Yss 0438Mohammad Aamir PerwaizNo ratings yet

- Saep 27Document14 pagesSaep 27Abdul Ahad LoneNo ratings yet

- Saep 201Document5 pagesSaep 201brecht1980No ratings yet

- AE-036411-001 INDEX For Drawing and EquipmentDocument1 pageAE-036411-001 INDEX For Drawing and Equipmentnarutothunderjet216No ratings yet

- How To Build Pyramids and Other Orgone GeneratorsDocument6 pagesHow To Build Pyramids and Other Orgone GeneratorsGuy Jones100% (2)

- Bsee201 B - Fluid MechanicsDocument150 pagesBsee201 B - Fluid MechanicsMarvin GagarinNo ratings yet

- B747F 400Document2 pagesB747F 400Nadeem100% (1)

- 17 Samss 006Document13 pages17 Samss 006Ahamedulla KhanNo ratings yet

- Saes B 014Document39 pagesSaes B 014Ahmed100% (2)

- Saes D 100 PDFDocument22 pagesSaes D 100 PDFShajin Mohammed Shamsudhin0% (1)

- Gi-1782 001Document7 pagesGi-1782 001malika_00No ratings yet

- Storage Tanks (API 650 / 620) : Presented By: Manoranjan Nayak Static Mech - Inspector CP1, CP2 & UO1Document18 pagesStorage Tanks (API 650 / 620) : Presented By: Manoranjan Nayak Static Mech - Inspector CP1, CP2 & UO1Manoranjan Nayak100% (1)

- Saudi Aramco Inspection Checklist: Hood Installation SAIC-K-4036 25-Apr-18 HvacDocument3 pagesSaudi Aramco Inspection Checklist: Hood Installation SAIC-K-4036 25-Apr-18 HvacjunaidNo ratings yet

- 32 Samss 006Document22 pages32 Samss 006Vajid MadathilNo ratings yet

- Engineering Department ProcedureDocument29 pagesEngineering Department ProcedureOmar Ahmed Elkhalil100% (1)

- SAIC-K-2026 Rev 0Document2 pagesSAIC-K-2026 Rev 0philipyapNo ratings yet

- 32 Samss 030Document28 pages32 Samss 030naruto256No ratings yet

- SAEP 1610 (Oct 2017)Document9 pagesSAEP 1610 (Oct 2017)nadeem shaikhNo ratings yet

- Saes B 055Document33 pagesSaes B 055Tarek Mustafa100% (1)

- Franchise PresentationDocument23 pagesFranchise PresentationManoranjan NayakNo ratings yet

- Artificial Intelligence Questions&Ans Uninformed SearchDocument5 pagesArtificial Intelligence Questions&Ans Uninformed Searchjaijohnk83% (6)

- Bgas 1Document25 pagesBgas 1Manoranjan Nayak60% (5)

- Sabp A 012Document92 pagesSabp A 012sethu1091No ratings yet

- Sabp D 002Document16 pagesSabp D 002engforever AdnanNo ratings yet

- Schedule B - Attachment IVDocument41 pagesSchedule B - Attachment IVwangruiNo ratings yet

- Schedule B - Job SepcificationsDocument129 pagesSchedule B - Job SepcificationsKalpana SrinivasNo ratings yet

- Saep 14 PDFDocument48 pagesSaep 14 PDFRami Elloumi100% (1)

- Saes B 058Document15 pagesSaes B 058Rashid ArshadNo ratings yet

- Building Siting StudyDocument12 pagesBuilding Siting Studyminah22No ratings yet

- Saes G 006Document4 pagesSaes G 006AdnanAtifNo ratings yet

- Wood Magazine Issue #189Document96 pagesWood Magazine Issue #189bangbang63100% (1)

- Saep 42 PDFDocument11 pagesSaep 42 PDFRami ElloumiNo ratings yet

- Ac 036660 004Document1 pageAc 036660 004narutothunderjet216No ratings yet

- Saep 121Document6 pagesSaep 121Demac SaudNo ratings yet

- Principles of Heat TreatmentDocument17 pagesPrinciples of Heat TreatmentManoranjan Nayak100% (2)

- Electromagnetic CompatibilityDocument12 pagesElectromagnetic Compatibilityoadipphone7031No ratings yet

- 32 Samss 005Document33 pages32 Samss 005naruto256100% (1)

- Saep 110Document6 pagesSaep 110brecht1980No ratings yet

- 10040 00 133 ES 0003 - rev01保温保冷手册指南 PDFDocument25 pages10040 00 133 ES 0003 - rev01保温保冷手册指南 PDFJimlemonNo ratings yet

- Saep 125Document9 pagesSaep 125Demac SaudNo ratings yet

- 32 Samss 005Document34 pages32 Samss 005ரமேஷ் பாலக்காடுNo ratings yet

- SAES-Q-010 Cement Based, Non-Shrink GroutDocument8 pagesSAES-Q-010 Cement Based, Non-Shrink GroutWaqar AhmedNo ratings yet

- Risk Based SpacingDocument14 pagesRisk Based SpacingNaresh NutakkiNo ratings yet

- CSG CMT CalculationsDocument5 pagesCSG CMT Calculationsfrancisryan4519No ratings yet

- Deaton FE Slab DesignDocument57 pagesDeaton FE Slab DesignMohamed AliNo ratings yet

- Saep 1661Document7 pagesSaep 1661Shahul Hameed RazikNo ratings yet

- Saep 42Document11 pagesSaep 42munnaNo ratings yet

- MC20005-WHP-WI-P-0118 Corrosion PR & Erosion PR Datasheet WI - Rev.D1Document18 pagesMC20005-WHP-WI-P-0118 Corrosion PR & Erosion PR Datasheet WI - Rev.D1nguyenmainamNo ratings yet

- Chemical Process Retrofitting and Revamping: Techniques and ApplicationsFrom EverandChemical Process Retrofitting and Revamping: Techniques and ApplicationsGade Pandu RangaiahNo ratings yet

- Plant LayoutDocument8 pagesPlant Layoutrsmallwood395895100% (1)

- Saes B 055 PDFDocument33 pagesSaes B 055 PDFSajid HussainNo ratings yet

- USS ProtocolDocument77 pagesUSS Protocolreza2131No ratings yet

- Client: BMT India Document: Terms of References For Quantitative Risk Assessment StudyDocument10 pagesClient: BMT India Document: Terms of References For Quantitative Risk Assessment StudyAnurag BholeNo ratings yet

- Saep 342Document5 pagesSaep 342munnaNo ratings yet

- Saes B 060Document17 pagesSaes B 060laudivelNo ratings yet

- Saep 303Document59 pagesSaep 303Demac SaudNo ratings yet

- Saes S 040Document22 pagesSaes S 040Mohammed YousufNo ratings yet

- Fundaments of Chemical Engineering Process Equipment DesignDocument7 pagesFundaments of Chemical Engineering Process Equipment DesignAgung Priambodho100% (1)

- Saep 3101DDocument14 pagesSaep 3101DKhaja MoinNo ratings yet

- 015-FH-1002 (Rev.1) PDFDocument8 pages015-FH-1002 (Rev.1) PDFarjun PV RaoNo ratings yet

- SATIP-K-001-11 - AC Split Systems DX TypeDocument3 pagesSATIP-K-001-11 - AC Split Systems DX TypeRAMAKRISHNANo ratings yet

- Ns GroutDocument2 pagesNs Groutpravi343450% (2)

- Aspen ZyqadDocument4 pagesAspen ZyqadsckanyiNo ratings yet

- Cleaning Gauging Hydrautesting and Chemical CleaningDocument2 pagesCleaning Gauging Hydrautesting and Chemical CleaningJosephKaren LorzanoIlaganNo ratings yet

- SAES-D-109 - Design of Small Metallic Atmospheric StorageDocument24 pagesSAES-D-109 - Design of Small Metallic Atmospheric StorageGaurav BedseNo ratings yet

- Saes D 110Document22 pagesSaes D 110senthilkumarNo ratings yet

- X-GSU-UO1-GD00-0833 - Request Approval For WPS & PQR (Civil Piling Work For Berth #4) PDFDocument18 pagesX-GSU-UO1-GD00-0833 - Request Approval For WPS & PQR (Civil Piling Work For Berth #4) PDFManoranjan Nayak100% (1)

- Career Changer Cover LetterDocument1 pageCareer Changer Cover LetterManoranjan NayakNo ratings yet

- Fire Fighting PDFDocument1 pageFire Fighting PDFManoranjan NayakNo ratings yet

- Parallel Park / ConventionalDocument8 pagesParallel Park / ConventionalManoranjan NayakNo ratings yet

- Business Dynamics in The 21st CenturyDocument270 pagesBusiness Dynamics in The 21st CenturyskilmagNo ratings yet

- How To Fix - External Disk Drive Suddenly Became RAWDocument96 pagesHow To Fix - External Disk Drive Suddenly Became RAWAntonio Marcano0% (1)

- EWF2703 TV EmersonDocument57 pagesEWF2703 TV EmersonEriksson Miguel Tapia SolisNo ratings yet

- MV Reg CleanDocument32 pagesMV Reg CleanJose Alberto CostaNo ratings yet

- Pre - Use Inspection Qualification: Date: Equipment Welding Machine Serial Number Model: LocationDocument3 pagesPre - Use Inspection Qualification: Date: Equipment Welding Machine Serial Number Model: LocationEugenio Jr. MatesNo ratings yet

- Opus UserguideDocument313 pagesOpus UserguideMoez EssafiNo ratings yet

- WPH02 01 Que 20150604Document28 pagesWPH02 01 Que 20150604ArnieNo ratings yet

- E-Line DLDocument21 pagesE-Line DLiulian17dNo ratings yet

- L19 External DiffusionDocument30 pagesL19 External DiffusionEga NabellaNo ratings yet

- Pavement Evaluation and Overlay Des - DR MSA - LatestDocument103 pagesPavement Evaluation and Overlay Des - DR MSA - LatestSreedhar BhuduruNo ratings yet

- OML Section CDocument3 pagesOML Section Cمهند ستارNo ratings yet

- EN 61000 3-2 GuideDocument19 pagesEN 61000 3-2 Guideyunus emre KılınçNo ratings yet

- People Soft Bundle Release Note 9 Bundle9Document29 pagesPeople Soft Bundle Release Note 9 Bundle9rajiv_xguysNo ratings yet

- Debug 1214Document3 pagesDebug 1214Anonymous B4WiRjNo ratings yet

- 02 - Student Lesson 2 Pile Driving SystemDocument91 pages02 - Student Lesson 2 Pile Driving SystemdannyzuanNo ratings yet

- Below Which Not More Than 5 Percent of The Test Results Are Expected To Fall"Document13 pagesBelow Which Not More Than 5 Percent of The Test Results Are Expected To Fall"shravan iitmNo ratings yet

- VORON2.2 ManualDocument120 pagesVORON2.2 ManualSsZzliMmNo ratings yet

- Tools of BiotechnologyDocument10 pagesTools of Biotechnologyiamforu1No ratings yet