Professional Documents

Culture Documents

IsoTherm Mixing Module Installation Manual

IsoTherm Mixing Module Installation Manual

Uploaded by

Jean-Jacques LobOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IsoTherm Mixing Module Installation Manual

IsoTherm Mixing Module Installation Manual

Uploaded by

Jean-Jacques LobCopyright:

Available Formats

Installation # 05-0507-02

IsoTherm Installation

Product Details

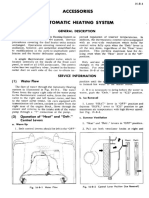

The IsoTherm utilizes both a Mixing Valve and the Law of Tees to control temperature to the zone. Boiler water enters the IsoTherm at point 1 where it passes through the mix valve, mixing with tempered zone water (point 3), and exits at point 2. Water then undergoes another mixing phase before entering the pump at point 5. Discharge water (point 6) is diverted based on flow conditions into the manifold supply and mix valve. Remaining flow is returned to the boiler loop (point 8). Flow across the manifold (points 7 and 4) is controlled via the individual circuit balancing valves located on the stainless steel manifold. Individual thermal actuators may be used with each circuit for additional control. The boiler supply temperature must be at least 158F to obtain the full heat capacity of the 51,000 BTU/hr.

4500 E. Progress Place Springfield, MO 65803 ph: 417.864.6108 fax: 417.864.8161

www.wattsradiant.com

5 3

Installation & Operation

The IsoTherm attaches directly to the 1 stainless steel manifold. If using a Watts Radiant manifold box, it may be necessary to rotate the pump head and pump housing, depending on which side the IsoTherm is to mount to the Stainless Steel manifold. To rotate the pump head, remove the four allen screws located on the pump base. Rotate the head to the desired position and re-attach the allen screws. The pump needs to be installed on its side, as illustrated, to adequately fit inside the box enclosure. Low profile conduit adapters may be required to connect power to the pump. IsoTherm must be installed using a Primary/Secondary piping format, as shown below. A circulator is provided on the IsoTherm. Field installing an additional/secondary circulator is not required or recommended. Mix Points 2 4 5 Return

Mix Valve

The mix valve is equipped with a visual indicator pin, designed to indicate mix temperature setting based on pin location. Pilot pin flush with the surface is 131F. Each click CW (pilot pin rises, temp decreases) or CCW (pilot pin drops, temp increases)is a 3 increase or decrease in temperature. 1

Supply Allen Screws Remove allen screws to rotate pump head. Should only be done if necessary to fit an enclosure.

Temp Decrease

Temp Increase 8 6 7

Primary/Secondary Piping

To ensure proper operation and to prevent any ghost flow conditions, a primary/secondary piping arrangement is required off the the main boiler loop with a check valve installed on the supply and return leg to the IsoTherm. Supply/return tees feeding the IsoTherm should be a maximum of 24 apart. A second circulator is not required and is not recommended; the IsoTherm provides its own circulation. Check Valve (field installed) 24 Max Primary Loop By-pass

Accessory Items

Accessory items include trunk isolation valves, Stainless to NPT and Stainless to sweat transition fittings. 1. Ball Valve with Temperature Gauge 2. BSP to 3/4 NPT 3. BSP to 1 NPT 4. BSP to 1 Sweat 1

1"NPT

2&3 4

Check Valve (field installed)

25

Pump Curve

Technical Details

Min. Supply Temperature . . . . . . . . . . . . . . . 113F Max. Supply Temperature. . . . . . . . . . . . . . . 140F Max. Heat Output . . . . . . . . . . . . . . . . . . . . 51 MBH Point 1 2 3 4 5 6 7 8 Flow (gpm) 3 5 2 3 8 3 5 3 Temp (F) 180 132 120 100 120 120 120 120

Head (ft) 20

Product Options

Qty. Description IsoTherm, 1 Mixing Module Isolation Ball Valve, Red Handle Isolation Ball Valve, Blue Handle SS Manifold Adapter, 1 NPT SS Manifold Adapter, 1 Sweat SS Manifold Adapter, 3/4 Sweat Part # D3803995 D4201720-NR D4201720-NB D4201480 D0505 D0504 Order # 81005361 81001995 81001994 81001989 81005367 81005366

15

10

Special Cautions

0 2 4 6 8 10 12 14 16 18 20

0 Flow (gpm)

Supply temperature from the boiler to the IsoTherm must be at least 158F for the IsoTherm to operate correctly. Install a spring check on both supply and return lines feeding the IsoTherm. Supply/return lines must be plumbed no farther than 24 apart off of the primary loop. Do not use a secondary circulator to feed the IsoTherma circulator is provided with the IsoTherm unit. Do not wire the IsoTherm circulator to run continuously. Watts Radiant 2005 9/05

Installation # 05-0507-02

You might also like

- Atlas Copco Xas 400 CD Inst 2012Document70 pagesAtlas Copco Xas 400 CD Inst 2012german gualavisi50% (2)

- Flanders Commercial Replacement Air Filter CatalogDocument121 pagesFlanders Commercial Replacement Air Filter Cataloge-ComfortUSANo ratings yet

- MoogDocument4 pagesMoogHamzaKadNo ratings yet

- Manual DestiladorDocument28 pagesManual DestiladorMaritza Josefina Colina RamonesNo ratings yet

- Piston Check Valve: Installation, Operation & Maintenance ManualDocument12 pagesPiston Check Valve: Installation, Operation & Maintenance ManualJoseph Samir EshakNo ratings yet

- Rtts PackerDocument2 pagesRtts Packersaeed65100% (2)

- Catalog Produk PT Dipa Puspa LabsainsDocument1,798 pagesCatalog Produk PT Dipa Puspa LabsainsMuh SyahrulNo ratings yet

- Technical Instructions: Form TI410-5 v3Document8 pagesTechnical Instructions: Form TI410-5 v3薛泽绵No ratings yet

- Opa 960RKTB Im 0514Document4 pagesOpa 960RKTB Im 0514Analiza BariaNo ratings yet

- Apollo Valves: 94A / 95A SeriesDocument1 pageApollo Valves: 94A / 95A Seriesmaruthappan sundaramNo ratings yet

- Series EMVII-6400SS Installation InstructionsDocument4 pagesSeries EMVII-6400SS Installation InstructionsWattsNo ratings yet

- Manual BOOK AR SERIESDocument4 pagesManual BOOK AR SERIESchandra atmaNo ratings yet

- Honeywell V4043H Motorised Zone ValveDocument2 pagesHoneywell V4043H Motorised Zone Valvetfs2006No ratings yet

- Kidde Natura™ Inert Gas System IG-541 Nitrogen Agent Cylinder AssemblyDocument4 pagesKidde Natura™ Inert Gas System IG-541 Nitrogen Agent Cylinder AssemblyJoseph HoNo ratings yet

- Circuit Setter Plus Model MC: Instruction ManualDocument4 pagesCircuit Setter Plus Model MC: Instruction Manualmacanipharoldf6220No ratings yet

- Aqua Heat Pumpn ManualDocument38 pagesAqua Heat Pumpn Manualmk saravananNo ratings yet

- Bell & Gossett: Circuit Setter Balance Valves 4" Thru 12" SizesDocument4 pagesBell & Gossett: Circuit Setter Balance Valves 4" Thru 12" SizessamNo ratings yet

- Circuit Setter ManualDocument4 pagesCircuit Setter ManualAnonymous 7xHNgoKE6eNo ratings yet

- Application Drawings RBIDocument40 pagesApplication Drawings RBIR Proyectos PueblaNo ratings yet

- Watts 500800 User-Manual PDFDocument8 pagesWatts 500800 User-Manual PDFfogdartNo ratings yet

- L4006A, B, E, H Aquastat® Controllers: ApplicationDocument8 pagesL4006A, B, E, H Aquastat® Controllers: ApplicationJimy Antony Perez CubaNo ratings yet

- Moog ServoValves G761and761Series InstallationInstructions enDocument4 pagesMoog ServoValves G761and761Series InstallationInstructions entetsa zangetsuNo ratings yet

- V5013PDocument8 pagesV5013PAudi eko susatyoNo ratings yet

- Basic English Manual 2Document2 pagesBasic English Manual 2Iulian ZidaritaNo ratings yet

- Instructional Model of Basic Rankine Cycle: User'S ManualDocument4 pagesInstructional Model of Basic Rankine Cycle: User'S ManualJoseph DavidNo ratings yet

- M30 CalorifierDocument29 pagesM30 CalorifierAlexNo ratings yet

- 450 PumpDocument15 pages450 PumpJader David Rocha MoralesNo ratings yet

- Manual W94 Valv. Autopiloteada Watson MC DanielDocument20 pagesManual W94 Valv. Autopiloteada Watson MC Danieldyca.produccionNo ratings yet

- Motorised Mid-Position Diverter Valve: FeaturesDocument2 pagesMotorised Mid-Position Diverter Valve: FeaturesHazem HassonNo ratings yet

- Im 306Document10 pagesIm 306Iwan SetiawanNo ratings yet

- AHU CHW Coil ConnectionDocument1 pageAHU CHW Coil ConnectionMULTIKARTHI07100% (1)

- Steam Water - Washdown - Unit TI 11 002 USDocument2 pagesSteam Water - Washdown - Unit TI 11 002 USMiltonNo ratings yet

- EnergyMaster Thermal Store ManualDocument16 pagesEnergyMaster Thermal Store ManualandrewsheldonNo ratings yet

- Uai B 0214Document4 pagesUai B 0214Jose Puc ManzanillaNo ratings yet

- Vaq RaqDocument4 pagesVaq RaqgreismarNo ratings yet

- MN 03006Document2 pagesMN 03006hyarub9No ratings yet

- Temperature Rise Test Procedure - Rev-01Document3 pagesTemperature Rise Test Procedure - Rev-01Soumya ranjan BasuriNo ratings yet

- Manual Merit Water Still W4000 and W4000EURODocument28 pagesManual Merit Water Still W4000 and W4000EUROgunawanNo ratings yet

- Kospel EKCO.R2 Electric Boilers Manual EngDocument12 pagesKospel EKCO.R2 Electric Boilers Manual EngSh KNo ratings yet

- V4073A Installation GuideDocument2 pagesV4073A Installation GuidemohamednavaviNo ratings yet

- E Plus Sizing Guidelines HE 2040 - 230808 - 084821Document35 pagesE Plus Sizing Guidelines HE 2040 - 230808 - 084821Kyriakos MichalakiNo ratings yet

- O&m RGVDocument7 pagesO&m RGVNur NaziraNo ratings yet

- CAT - Feedwater Protection SystemDocument11 pagesCAT - Feedwater Protection SystemMurli RamchandranNo ratings yet

- Circuit SetterDocument4 pagesCircuit SetterHVACRNIC2005No ratings yet

- Versaflo Ups: Grundfos InstructionsDocument23 pagesVersaflo Ups: Grundfos InstructionsCoordinador LaboratorioNo ratings yet

- Electric Mini Tank Water Heaters GL 2.5 - GL 4 - GL 6+: Downloaded From Manuals Search EngineDocument13 pagesElectric Mini Tank Water Heaters GL 2.5 - GL 4 - GL 6+: Downloaded From Manuals Search EngineKerwin CastañedaNo ratings yet

- Servo Electrohydraulic760 - CDS6541 - GDocument4 pagesServo Electrohydraulic760 - CDS6541 - GGuillermoNo ratings yet

- Isotherm Boiler ManualDocument5 pagesIsotherm Boiler ManualWillem LindenNo ratings yet

- Manual AW Remote KecilDocument32 pagesManual AW Remote KecilBambang PriyambodoNo ratings yet

- GravesDocument15 pagesGravessrikanthNo ratings yet

- Air Booster: Model: KS-4,5,6,8Document12 pagesAir Booster: Model: KS-4,5,6,8Esteban Jose De VirgilioNo ratings yet

- Industrial Chiller User ManualDocument15 pagesIndustrial Chiller User ManualJose Morillo CheoNo ratings yet

- De Esfera0-Instalação e ManutençãoDocument2 pagesDe Esfera0-Instalação e ManutençãoHélder SilvaNo ratings yet

- CW 5000 ManualDocument13 pagesCW 5000 ManualPARTHIBAN RETECHNo ratings yet

- TA168 100 InstallDocument2 pagesTA168 100 InstallLucas SantosNo ratings yet

- 771 772 773seriesvalves-ImDocument4 pages771 772 773seriesvalves-Imza3amNo ratings yet

- Circuit Setter Bell & GrossetDocument6 pagesCircuit Setter Bell & GrossetKevinCostasCaceresNo ratings yet

- Steam Generator Steam Generator: Quality of LifeDocument29 pagesSteam Generator Steam Generator: Quality of LifeMiguel DexsNo ratings yet

- Reliable Technology For Continuous Operation: Technical DescriptionDocument12 pagesReliable Technology For Continuous Operation: Technical DescriptionPaola Armas100% (1)

- PJDX ManualDocument9 pagesPJDX Manualshaft181No ratings yet

- 16 NaDocument7 pages16 NaZain ShariffNo ratings yet

- Accessories Automatic Heating System: General DescriptionDocument4 pagesAccessories Automatic Heating System: General DescriptionLuis Fernando ZampieriNo ratings yet

- Watts63C Yerden Isitma Icin Termostatik Karisim VanasiDocument4 pagesWatts63C Yerden Isitma Icin Termostatik Karisim VanasiErdinc KlimaNo ratings yet

- Comfort Star MPK12-410 BrochureDocument2 pagesComfort Star MPK12-410 Brochuree-ComfortUSANo ratings yet

- Schluter Kerdi Line Data SheetDocument8 pagesSchluter Kerdi Line Data Sheete-ComfortUSANo ratings yet

- PAW Heating Components and Solar Systems BrochureDocument56 pagesPAW Heating Components and Solar Systems Brochuree-ComfortUSANo ratings yet

- ComfortStar CCH/CHH Series MiniSplit Air Conditioners BrochureDocument16 pagesComfortStar CCH/CHH Series MiniSplit Air Conditioners Brochuree-ComfortUSA50% (2)

- Comfort Star EAC-900R BrochureDocument2 pagesComfort Star EAC-900R Brochuree-ComfortUSANo ratings yet

- Daikin Split Systems BrochureDocument32 pagesDaikin Split Systems Brochuree-ComfortUSA100% (1)

- Aspen Pumps Operation ManualDocument4 pagesAspen Pumps Operation Manuale-ComfortUSA100% (1)

- Venmar IAQ Products BrochureDocument12 pagesVenmar IAQ Products Brochuree-ComfortUSANo ratings yet

- Mitsubishi System CatalogDocument76 pagesMitsubishi System Cataloge-ComfortUSANo ratings yet

- Samsung Wall Mouted Classic Heat PumpsDocument6 pagesSamsung Wall Mouted Classic Heat Pumpse-ComfortUSANo ratings yet

- Haier Air Conditioners Owners ManualDocument24 pagesHaier Air Conditioners Owners Manuale-ComfortUSANo ratings yet

- Multiaqua Products CatalogDocument418 pagesMultiaqua Products Cataloge-ComfortUSANo ratings yet

- Branch Box Installation ManualDocument4 pagesBranch Box Installation Manuale-ComfortUSANo ratings yet

- Navien CH Combi Heater BrochureDocument4 pagesNavien CH Combi Heater Brochuree-ComfortUSANo ratings yet

- Samsung Vivace Wall Mounted Heat PumpsDocument3 pagesSamsung Vivace Wall Mounted Heat Pumpse-ComfortUSANo ratings yet

- Fujitsu AOU48RLXFZ Design and Technical ManualDocument312 pagesFujitsu AOU48RLXFZ Design and Technical Manuale-ComfortUSA100% (2)

- Samsung Concealed Heat Pump Ceiling CassetesDocument3 pagesSamsung Concealed Heat Pump Ceiling Cassetese-ComfortUSANo ratings yet

- Samsung Neo Forte Wall Mounted Heat PumpsDocument5 pagesSamsung Neo Forte Wall Mounted Heat Pumpse-ComfortUSANo ratings yet

- Fujitsu AOU24RLXFZ Indoor Design and Technical ManualDocument209 pagesFujitsu AOU24RLXFZ Indoor Design and Technical Manuale-ComfortUSANo ratings yet

- Samsung Multi Zone System ComponentsDocument8 pagesSamsung Multi Zone System Componentse-ComfortUSANo ratings yet

- Samsung Floor Standing Heat PumpDocument1 pageSamsung Floor Standing Heat Pumpe-ComfortUSA100% (1)

- Steamview Radiator BrochureDocument2 pagesSteamview Radiator Brochuree-ComfortUSANo ratings yet

- SpacePak BrochureDocument7 pagesSpacePak Brochuree-ComfortUSANo ratings yet

- Samsung Concealed Heat Pump Ceiling CassetesDocument3 pagesSamsung Concealed Heat Pump Ceiling Cassetese-ComfortUSANo ratings yet

- Sanyo Air Conditioners Sell SheetDocument2 pagesSanyo Air Conditioners Sell Sheete-ComfortUSANo ratings yet

- Samsung Wall Mouted Classic Heat PumpsDocument6 pagesSamsung Wall Mouted Classic Heat Pumpse-ComfortUSANo ratings yet

- Charleston Steam Radiator BrochureDocument2 pagesCharleston Steam Radiator Brochuree-ComfortUSANo ratings yet

- Sanyo Air Conditioners Sell SheetDocument2 pagesSanyo Air Conditioners Sell Sheete-ComfortUSANo ratings yet

- Sanyo HVAC CatalogDocument28 pagesSanyo HVAC Cataloge-ComfortUSANo ratings yet

- Sistema de Operacion 14G HidraulicaDocument25 pagesSistema de Operacion 14G Hidraulicayeison100% (3)

- Typical Laboratory VFX Submittal REV BDocument48 pagesTypical Laboratory VFX Submittal REV BERIK FLOREZ MALDONADONo ratings yet

- B2 B3 Series Catalog PageDocument4 pagesB2 B3 Series Catalog PageJorge Manuel MezaNo ratings yet

- Process Piping Design & EngineeringDocument4 pagesProcess Piping Design & Engineeringtibi1000No ratings yet

- Mueller DrumTec Company BrochureDocument11 pagesMueller DrumTec Company BrochureXavierNo ratings yet

- A6 VDocument40 pagesA6 VWesame Shnoda100% (1)

- All Engine Manual (OCR)Document580 pagesAll Engine Manual (OCR)Alberto Mansilla Tejeda100% (1)

- Parts Manual: CMP20-30L FX20-30L SF20-30LDocument117 pagesParts Manual: CMP20-30L FX20-30L SF20-30LLuiz SchwindenNo ratings yet

- 8 Power PackDocument66 pages8 Power PackElber Luis Chavez BarriosNo ratings yet

- Lincoln SL1 - SLV ComparisonDocument4 pagesLincoln SL1 - SLV ComparisonJed MayNo ratings yet

- JG7000 (3.5m) Manual & Parts List ENG (Backward, Nord VV) (201812)Document118 pagesJG7000 (3.5m) Manual & Parts List ENG (Backward, Nord VV) (201812)Yosy PrastiyoNo ratings yet

- Roll Crusher For REPOL® POLYTRACK®Document54 pagesRoll Crusher For REPOL® POLYTRACK®Rahmat Hidayat100% (1)

- Globe ValveDocument17 pagesGlobe Valveachmad firmanyahNo ratings yet

- Fuel Delivery ComponentsDocument4 pagesFuel Delivery ComponentsSirleh Saleh100% (1)

- Manual FrigidaireDocument30 pagesManual FrigidaireYimy Yecitd Gonzalez MirandaNo ratings yet

- 01.0 - 22146.002E - Hydraulic SystemDocument126 pages01.0 - 22146.002E - Hydraulic SystemShariq Khan100% (1)

- Data Sheet: Actuators For Modulating or 3-Point ControlDocument8 pagesData Sheet: Actuators For Modulating or 3-Point ControlandreiterenteNo ratings yet

- P3 Duplex AGSS Plant O&M Manual Rev 5Document23 pagesP3 Duplex AGSS Plant O&M Manual Rev 5anfalapNo ratings yet

- Model m75 Service ManualDocument40 pagesModel m75 Service ManualMuhamad Sharif Bin ZainudinNo ratings yet

- CLSS: Load Sensing CirkuitDocument18 pagesCLSS: Load Sensing CirkuitMuhammad DaniNo ratings yet

- PWHT Requirement (Rev.3)Document6 pagesPWHT Requirement (Rev.3)Oliver SanvictoresNo ratings yet

- Piping Training Course - Part - 1Document162 pagesPiping Training Course - Part - 1Ibrahim Braneci100% (1)

- Batu Pig Valve Brochure v4Document16 pagesBatu Pig Valve Brochure v4Tariq NbsNo ratings yet

- Penlon EMO Franks Service Instruction PDFDocument21 pagesPenlon EMO Franks Service Instruction PDFluisNo ratings yet

- Manual Pinch Valve BrochureDocument8 pagesManual Pinch Valve BrochureCarlos Manuel AcostaNo ratings yet

- Check List For Third Party Conformity Assessment Section-A. The Information To Be Provided by The EntityDocument11 pagesCheck List For Third Party Conformity Assessment Section-A. The Information To Be Provided by The EntityDeepak DubeyNo ratings yet

- D&E MINIATURES 2000 Model Submarine CatalogDocument26 pagesD&E MINIATURES 2000 Model Submarine CatalogDUNCAN0420100% (1)