Professional Documents

Culture Documents

G Funkcije

Uploaded by

Semsudin HabibovicOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

G Funkcije

Uploaded by

Semsudin HabibovicCopyright:

Available Formats

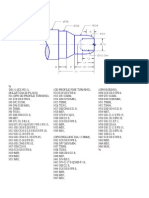

G FUNKCIJE

G00 G01 G02 G03 G04 G05 G09 G10 G14 G15 G17 G18 G19 G20 G21 G28 G29 G31 G32 G40 G41 G42 G50 G51 G52 Modal G53 G54 G55 G56 G57 G58 G59 G61 G64 G65 G70 G71 G72 G73 Machine Zero Positioning Coordinate Work Offset Positioning Coordinate #1 Work Offset Positioning Coordinate #2 - Modal Work Offset Positioning Coordinate #3 - Modal Work Offset Positioning Coordinate #4 - Modal Work Offset Positioning Coordinate #5 - Modal Work Offset Positioning Coordinate #6 - Modal Exact Stop - Modal Exact Stop G61 Cancel Macro Sub-Routine Call - Optional Finishing Cycle O.D. / I.D. Stock Removal Cycle Example End Face Stock Removal Cycle Irregular Path Stock Removal Cycle Rapid Position Motion Linear Interpolation Motion OR Linear Motion, Chamfer and Corner Rounding - Modal CW Circulation Interpolation Motion - Modal CCW Circular Interpolation Motion - Modal Dwell (P) P=Seconds. Milliseconds Fine Spindle Control Motion (Live Tooling) - Optional Exact Stop Programmable Offset Setting Main-Spindal / Sub-Spindle Swap - Optional Main-Spindal / Sub-Spindle Swap Cancel - Optional Circular Motion XYZ Plane Selection Live Tooling (G02, G03) - Modal, Optional Circular Motion ZX Plane Selection (G02, G03) Circular Motion YZ Plane Selection Live Tooling (G02, G03) - Modal/Optional Verify Inch Coordinate Positioning Verify Metric Coordinate Positioning - Modal Rapid to machine zero return through Ref. Point Move to Location Through G29 Ref. Point Feed Until skip Function - Optional Thread cutting path - Modal Tool Nose Compensation Cancel G41/G42 Tool Nose Compensation, Left - Modal Tool Nose Compensation, Right - Modal Spindle Speed Maximum RPM Limit (S) - Modal Rapid to Machine zero, Cancel offset Work offset Positioning Coordinate OR Global Work Offset Coordinate System Shift -

G74 G75 G76 G77 G80 G81 G82 G83 G84 G85 G86 G87 G88 G89 G90 G92 G94 G95 G96 G97 G98 G99 G100 G101 G102 G103 G105 G112 G113 G154 G159 G160 G161 G184 G186 G187 G194 G195 G196 G200

Face Grooving OR High Speed Peck Drill Cycle Peck Grooving Cycle O.D. or I.D. Threading Cycle, Multiple Pass O.D. / I.D. Live Tooling Flatting Cycle - Optional Cancel Canned Cycle Drill Canned Cycle - Modal Spot Drill / Counterbore Canned Cycle - Modal Peck Drill Deep Hole Canned Cycle - Modal Tapping Canned Cycle - Modal Bore In-Bore Out Canned Cycle - Modal Bore In-Stop-Rapid Out Canned Cycle - Modal Bore In-Stop-Manual Retract Canned Cycle - Modal Bore In-Dwell-Manual Retract Canned Cycle - Modal Bore In-Dwell-Bore-out Canned Cycle - Modal O.D. / I.D. Turning Cycle - Modal Threading Cycle - Modal End Facing Cycle - Modal Live Tooling End Face Rigid Tap - Modal/Optional Constant Surface speed, CSS On - Modal Constant Non-Varying Spindle Speed, CSS Off (S) Feed Per Minute (F) - Modal Feed Per Revolution (F) Mirror Image Cancel G101 Mirror Image Programmable Output to RS-232 Limit Block Lookahead Servo Bar Command - Optional Cartesian to Polar Transformation - Optional Cartesian to Polar Transformation Cancel - Optional Select Work Offset Positioning Coordinate P1-99 (P) - Modal Background Pickup / Part Return - Optional APL Axis Command On - Optional APL Axis Command Off - Optional Reverse Tapping Canned Cycle - Modal Live Tooling Reverse Rigid Tap - Optional Accuracy Control for High Speed Machining (E) Sub-Spindle / Tapping Canned Cycle - Modal Live Tooling Radial Tapping - Optional Live Tooling Radial Tapping Reverse - Optional Index on the Fly

G110-G111 Work Offset-positioning Coordinate #7-#8 - Modal

G114-G129 Work Offset Positioning Coordinate #9-#24 - Modal

You might also like

- How to Rebuild & Modify Rochester Quadrajet CarburetorsFrom EverandHow to Rebuild & Modify Rochester Quadrajet CarburetorsRating: 5 out of 5 stars5/5 (2)

- Mori Seiki G Codes and M CodesDocument9 pagesMori Seiki G Codes and M CodesAsh BetchumNo ratings yet

- G & M Codes (All CNC)Document24 pagesG & M Codes (All CNC)Fanuc21T100% (4)

- Complete G Code ListDocument7 pagesComplete G Code ListRevolusiSoekarno100% (2)

- MachineMate Inc - Full List of CNC CodesDocument6 pagesMachineMate Inc - Full List of CNC CodesDejan StalovicNo ratings yet

- G - Code M - CodeDocument3 pagesG - Code M - CodeblashkogNo ratings yet

- Standard CNC G Codes - Vertical and Horizontal MillsDocument3 pagesStandard CNC G Codes - Vertical and Horizontal Millschubby_hippoNo ratings yet

- Haas CNC Lathe and Mill G Codes ListDocument51 pagesHaas CNC Lathe and Mill G Codes ListpptmnltNo ratings yet

- Code G FanucDocument3 pagesCode G FanucSanchai Progaeew100% (1)

- Standard CNC G Codes and M Codes ReferenceDocument4 pagesStandard CNC G Codes and M Codes ReferenceLuis Enrique Pichardo100% (1)

- G-Codes and M-Functions - MillingDocument1 pageG-Codes and M-Functions - MillingJuan Carlos Cárdenas TufiñoNo ratings yet

- Mitsubishi ManualsDocument4 pagesMitsubishi ManualsRevolusiSoekarnoNo ratings yet

- CNC CodeDocument9 pagesCNC CodeMochammad Karim Al AminNo ratings yet

- Machine Mate Inc - Full List of CNC CodesDocument5 pagesMachine Mate Inc - Full List of CNC CodesEr Zorawar SinghNo ratings yet

- Machinist'S Reference GuideDocument52 pagesMachinist'S Reference Guidedelta toNo ratings yet

- NC Programming Codes NC Programming As Per ISO DIN 66025 and RS274Document14 pagesNC Programming Codes NC Programming As Per ISO DIN 66025 and RS274Silva JoãoNo ratings yet

- Common G-Codes For CNC Machining CentersDocument2 pagesCommon G-Codes For CNC Machining CentersivtrubeljaNo ratings yet

- G CodeDocument5 pagesG CodeScott NorvaisaNo ratings yet

- Fanuc G CodeDocument3 pagesFanuc G CodeRevolusiSoekarno100% (1)

- GcodeDocument3 pagesGcodeMohammad Syafly ZulkifliNo ratings yet

- Program structure of CNC machines according to PALDocument16 pagesProgram structure of CNC machines according to PALmanuel_plfNo ratings yet

- G M Codes All CNCDocument24 pagesG M Codes All CNCParveen Kumar0% (1)

- Mori Seiki GM CodeDocument10 pagesMori Seiki GM CodevusvusNo ratings yet

- Mitsubishi CNC ManualsDocument5 pagesMitsubishi CNC ManualsRevolusiSoekarnoNo ratings yet

- Sinumerik 808D G Codes and M CodesDocument4 pagesSinumerik 808D G Codes and M CodesIvica GelemanovicNo ratings yet

- Master List of CNC G and M CodesDocument2 pagesMaster List of CNC G and M CodesChong Yee HowNo ratings yet

- Funkcije Za GlodaliceDocument10 pagesFunkcije Za GlodaliceSelvedin GudicNo ratings yet

- NC Programming CodesDocument9 pagesNC Programming CodesSasa MilosavljevicNo ratings yet

- Fanuc CodeDocument11 pagesFanuc CoderlwersalNo ratings yet

- 808D GM Codes QuickDocument5 pages808D GM Codes QuickrianrureNo ratings yet

- FANUC G Code of LatheDocument25 pagesFANUC G Code of LatheHùng LêNo ratings yet

- CNC Programming 1of1 G-CodesDocument1 pageCNC Programming 1of1 G-CodesVinod BhaskarNo ratings yet

- CNC CodexDocument10 pagesCNC CodexAmar AshrafNo ratings yet

- G-Codes and M-Functions - MillingDocument1 pageG-Codes and M-Functions - MillingBilal IbrahimNo ratings yet

- G-Code & M-Code Reference GuideDocument6 pagesG-Code & M-Code Reference GuideSayeed AndrabiNo ratings yet

- CNC Torna KodlarıDocument5 pagesCNC Torna KodlarıKamil SakarNo ratings yet

- M Ang G Code Mesin CNC Mori SeikiDocument13 pagesM Ang G Code Mesin CNC Mori SeikiWirdiIanNo ratings yet

- CNCConfigGcode Mcode ChartDocument2 pagesCNCConfigGcode Mcode ChartAlvaro PNo ratings yet

- G-Codes Simple DefinitionDocument5 pagesG-Codes Simple DefinitiontedulNo ratings yet

- (SN) G-C Codes PDFDocument24 pages(SN) G-C Codes PDFSebastianAndrade13No ratings yet

- Milling CodesDocument2 pagesMilling CodesYousuf A. AjabshahNo ratings yet

- Turning Centers Machine Code GlossaryDocument3 pagesTurning Centers Machine Code GlossaryLaura BNo ratings yet

- CNC Machine Language G Code ListDocument3 pagesCNC Machine Language G Code ListJules OlivierNo ratings yet

- FME CNC Unit 5Document78 pagesFME CNC Unit 5B30parvej arif shahNo ratings yet

- Return To Reference PositionDocument4 pagesReturn To Reference PositionAshish MishraNo ratings yet

- NC Programming Codes: Power Automation America, IncDocument6 pagesNC Programming Codes: Power Automation America, IncTejaPhanipavan SunkaraNo ratings yet

- Full List of CNC CodesDocument5 pagesFull List of CNC CodesanoofmxNo ratings yet

- Linuxcnc GcodeDocument1 pageLinuxcnc Gcodekk_kamalakkannanNo ratings yet

- G-codes and M-codes for CNC lathesDocument2 pagesG-codes and M-codes for CNC latheskirankuma.jagtapNo ratings yet

- CNC G-codes and M-codes guideDocument16 pagesCNC G-codes and M-codes guideNavneet JamwalNo ratings yet

- G-Codes and M-Functions - Turning: © Peter Smid CNC Programming HandbookDocument1 pageG-Codes and M-Functions - Turning: © Peter Smid CNC Programming HandbookAmutha SaravananNo ratings yet

- G Codes Thermwood CNCDocument2 pagesG Codes Thermwood CNCgriffin.ramseyNo ratings yet

- Speed Changers, Drives & Gears World Summary: Market Values & Financials by CountryFrom EverandSpeed Changers, Drives & Gears World Summary: Market Values & Financials by CountryNo ratings yet

- Advanced AutoCAD® 2017: Exercise WorkbookFrom EverandAdvanced AutoCAD® 2017: Exercise WorkbookRating: 1 out of 5 stars1/5 (1)

- Engine, Turbine & Power Transmission Equipment World Summary: Market Values & Financials by CountryFrom EverandEngine, Turbine & Power Transmission Equipment World Summary: Market Values & Financials by CountryNo ratings yet

- Krovni Paneli-NosivostDocument1 pageKrovni Paneli-NosivostSemsudin HabibovicNo ratings yet

- Sky 001Document68 pagesSky 001Semsudin HabibovicNo ratings yet

- m10800 Skylight 2Document23 pagesm10800 Skylight 2Semsudin HabibovicNo ratings yet

- Powerpoint Kursevi 2013 Početni Nivo Powerpoint 2010 Ima Poboljšan Interfejs I Selekciju Novih Funkcija Za Prezentaciju - KursDocument2 pagesPowerpoint Kursevi 2013 Početni Nivo Powerpoint 2010 Ima Poboljšan Interfejs I Selekciju Novih Funkcija Za Prezentaciju - KursSemsudin HabibovicNo ratings yet

- m10800 Skylight 1Document5 pagesm10800 Skylight 1Semsudin HabibovicNo ratings yet

- G FunkcijeDocument3 pagesG FunkcijeSemsudin HabibovicNo ratings yet

- M FunkcijeDocument2 pagesM FunkcijeSemsudin HabibovicNo ratings yet

- CNC Program 1Document2 pagesCNC Program 1Semsudin HabibovicNo ratings yet

- Optical Fiber Communication Case Study on Material DispersionDocument5 pagesOptical Fiber Communication Case Study on Material DispersionAyush SharmaNo ratings yet

- CBK Test QuestionsDocument2 pagesCBK Test QuestionsMehul GuptaNo ratings yet

- Constructivism improves a lesson on nounsDocument6 pagesConstructivism improves a lesson on nounsOlaniyi IsaacNo ratings yet

- Retaining Wall DetailsDocument1 pageRetaining Wall DetailsWilbert ReuyanNo ratings yet

- Thesis Hakonen Petri - Detecting Insider ThreatsDocument72 pagesThesis Hakonen Petri - Detecting Insider ThreatsalexandreppinheiroNo ratings yet

- Tutorial Task 3 - A C P I WK 2Document8 pagesTutorial Task 3 - A C P I WK 2BM70621 Alya Zahirah Binti AziziNo ratings yet

- 2014 01 RappTrans - Weight Sensors ReportDocument51 pages2014 01 RappTrans - Weight Sensors Reportsuraj dhulannavarNo ratings yet

- Reporte Corporativo de Louis Dreyfus Company (LDC)Document21 pagesReporte Corporativo de Louis Dreyfus Company (LDC)OjoPúblico Periodismo de InvestigaciónNo ratings yet

- Red Lion Edict-97 - Manual PDFDocument282 pagesRed Lion Edict-97 - Manual PDFnaminalatrukNo ratings yet

- DataSheet IMA18-10BE1ZC0K 6041793 enDocument8 pagesDataSheet IMA18-10BE1ZC0K 6041793 enRuben Hernandez TrejoNo ratings yet

- 2.2valves, Alarm - Ul Product IqDocument1 page2.2valves, Alarm - Ul Product Iqbhima irabattiNo ratings yet

- 0520 Int OTG P4 MSDocument12 pages0520 Int OTG P4 MSTrévina JosephNo ratings yet

- IEC61508 GuideDocument11 pagesIEC61508 Guidesrbehera1987No ratings yet

- GMS175CSDocument4 pagesGMS175CScorsini999No ratings yet

- Inna Phos Diammonium Phosphate MSDSDocument9 pagesInna Phos Diammonium Phosphate MSDSjosephNo ratings yet

- Public OpinionDocument7 pagesPublic OpinionSona Grewal100% (1)

- Major Project Report - Template 2021Document18 pagesMajor Project Report - Template 2021vamkrishnaNo ratings yet

- RTR Piping Inspection GuideDocument17 pagesRTR Piping Inspection GuideFlorante NoblezaNo ratings yet

- Manual PDFDocument9 pagesManual PDFRuth ResuelloNo ratings yet

- Password ManagementDocument7 pagesPassword ManagementNeerav KrishnaNo ratings yet

- Mercury Poisoning Symptoms and TreatmentsDocument1 pageMercury Poisoning Symptoms and TreatmentsRakheeb BashaNo ratings yet

- Unit 1Document50 pagesUnit 1vaniphd3No ratings yet

- Financial ManagementDocument2 pagesFinancial ManagementSanna KazmiNo ratings yet

- 06 Dielectrics Capacitance 2018mkDocument41 pages06 Dielectrics Capacitance 2018mkTrần ĐứcAnhNo ratings yet

- Dedicated Teacher ResumeDocument2 pagesDedicated Teacher ResumeLei Pitallano ComboyNo ratings yet

- Lecture Euler EquationDocument33 pagesLecture Euler EquationYash RajNo ratings yet

- Sem Iii Sybcom Finacc Mang AccDocument6 pagesSem Iii Sybcom Finacc Mang AccKishori KumariNo ratings yet

- Dream Life - Allan HobsonDocument307 pagesDream Life - Allan HobsonJose MuñozNo ratings yet

- The Beggar's Opera by Gay, John, 1685-1732Document50 pagesThe Beggar's Opera by Gay, John, 1685-1732Gutenberg.orgNo ratings yet

- Cisco Series SWCFG Xe 16 12 XDocument416 pagesCisco Series SWCFG Xe 16 12 XWagner SantiagoNo ratings yet