Professional Documents

Culture Documents

Lifting Eye Bolts: Steel / Stainless Steel

Lifting Eye Bolts: Steel / Stainless Steel

Uploaded by

kraikaroOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lifting Eye Bolts: Steel / Stainless Steel

Lifting Eye Bolts: Steel / Stainless Steel

Uploaded by

kraikaroCopyright:

Available Formats

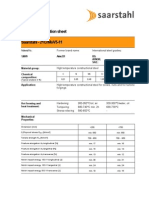

DIN 580

Steel / Stainless Steel

Lifting eye bolts

d1

Steel ST St. Steel NI St. Steel A4

d2 M8 M 10 M 12 M 16 M 20 M 24 M 10 M 12 M 16 M 20 M 24 20 25 30 35 40 50 65 75

d3 36 45 54 63 72 90 108 126

d4 20 25 30 35 40 50 60 70

e 6 8 10 12 14 18 22 26

h 36 45 53 62 71 90 109 128

k 8 10 12 14 16 20 24 28

l 13 17 20,5 27 30 36 45 54

m 10 12 14 16 19 24 28 32

F1 max. in N

F 2 max. in N

F 3 max. in N

M8 M 10 M 12 M 16 M 20 M 24 M 30 M 36

1400 1000 700 2300 1700 1150 3400 2400 1700 7000 5000 3500 12000 8600 6000 18000 12900 9000 32000 23000 16000 46000 33000 23000

Specication

Information

The following guidelines of lifting eye bolts DIN 580 have to be observed in addition to the load values given in the above table: The eye bolt must be of fully screwed in to achieve a perfect contact between the two mating faces. Both threads must be of a equal length and the base material of equal strength to that of the bolt. Operating instructions with more details and specications are included with every delivery (see also www.ganter-griff.com/service). The official DIN standard sheet species the additional sizes M42, M48, M56, M64, M72 x 6, M80 x 6 und M100 x 6. see also... Lifting eye bolts (rotating) GN 581 Page 612

Steel C 15 E ST -- drop-forged -- annealed -- contact face machined -- zinc plated, blue passivated Stainless Steel A2 NI -- drop-forged -- contact face machined Stainless Steel A4 A4 -- drop-forged -- contact face machined Stainless Steel characteristics Page 1144 RoHS compliant

Lifting eye bolt

1 2

1 2

d1 Material

DIN 580-M20-NI

Page 610 | 2.2 Screws and Nuts, Washers, Lifting accessories

You might also like

- Iso 14582 - Hexalobular Socket Countersunk Flat Head Screws, High Head PDFDocument5 pagesIso 14582 - Hexalobular Socket Countersunk Flat Head Screws, High Head PDFMitesh MakvanaNo ratings yet

- SAE J518-1993 液压分体法兰 PDFDocument13 pagesSAE J518-1993 液压分体法兰 PDFliu zhao liu zhaoNo ratings yet

- BS en 755-7 PDFDocument6 pagesBS en 755-7 PDFRok HermanNo ratings yet

- Polymer CompositeDocument65 pagesPolymer Compositeamor20006100% (2)

- Iso-10664 PDFDocument10 pagesIso-10664 PDFPrabu ArNo ratings yet

- ISO 2338 B / SN 212771 B: Dowel Pins, SteelDocument8 pagesISO 2338 B / SN 212771 B: Dowel Pins, SteelSirbu Vasile Liviu100% (1)

- DIN 7060 Curcular Sight Glass PDFDocument14 pagesDIN 7060 Curcular Sight Glass PDFalathekoala100% (2)

- Mil H 25579Document22 pagesMil H 25579Senthil KumarNo ratings yet

- Din1688 1 PDFDocument4 pagesDin1688 1 PDFFelipe FernandesNo ratings yet

- Coefficient of Friction Reference Table - Engineer's HandbookDocument4 pagesCoefficient of Friction Reference Table - Engineer's Handbooksafaozhan100% (1)

- DIN 7349 - Arruela Plana PDFDocument1 pageDIN 7349 - Arruela Plana PDFpierocarnelociNo ratings yet

- Iso 228 1 2000Document9 pagesIso 228 1 2000Ulvi NebiyevNo ratings yet

- 2 Frequency Geodesic Silo Dome Assembly Manual: Zip Tie DomesDocument34 pages2 Frequency Geodesic Silo Dome Assembly Manual: Zip Tie DomesHamid ZankaNo ratings yet

- Din 7991Document5 pagesDin 7991mohamadreza bagheriNo ratings yet

- Iso 4162Document2 pagesIso 4162Guillermo TorresNo ratings yet

- BS en 729-1 - 1995Document1 pageBS en 729-1 - 1995Syed Waqar Hussain ZahidyNo ratings yet

- Scaffolding DetailsDocument8 pagesScaffolding DetailsGopal Sudhir100% (1)

- Iso 4161 1999Document9 pagesIso 4161 1999lokesh prakash100% (1)

- ISO 14583-01 - Hexalobular Socket Pan Head ScrewsDocument8 pagesISO 14583-01 - Hexalobular Socket Pan Head ScrewsGuillermo TorresNo ratings yet

- Asme B18.18.2M R1999Document16 pagesAsme B18.18.2M R1999Gerardo Rivera100% (1)

- Food Packaging TechniquesDocument35 pagesFood Packaging TechniquesMadhu ShaliniNo ratings yet

- Refractory ProcedureDocument13 pagesRefractory ProcedureArunachalam Avanashi100% (3)

- 25CrMo4 (EN 10083 3)Document2 pages25CrMo4 (EN 10083 3)mohsen_267No ratings yet

- Din 7977Document1 pageDin 7977zorghi1No ratings yet

- Jis D 0201-1995 PDFDocument23 pagesJis D 0201-1995 PDFALEX MURPHYNo ratings yet

- Din en 10132-4Document14 pagesDin en 10132-4Guilherme MendesNo ratings yet

- Smarter Materials Selection For Corrosion Control PDFDocument12 pagesSmarter Materials Selection For Corrosion Control PDFAsyraf Nordin100% (1)

- DIN 915 EN-1980 Hexagon Socket Set Screws With Dog PointDocument4 pagesDIN 915 EN-1980 Hexagon Socket Set Screws With Dog Pointthachpn100% (1)

- Hexagon Head Screws With Metric Fine Pitch Thread - Product Grades Aandb (First Revision)Document15 pagesHexagon Head Screws With Metric Fine Pitch Thread - Product Grades Aandb (First Revision)kumar QANo ratings yet

- Iso 8734 1997Document8 pagesIso 8734 1997edNo ratings yet

- Steel Standard DIN ISO EN 10088-3Document55 pagesSteel Standard DIN ISO EN 10088-3Laukik FegdeNo ratings yet

- BS ISO 5455 Scale PDFDocument8 pagesBS ISO 5455 Scale PDFaikalessNo ratings yet

- Asme B18 2 1 1996Document61 pagesAsme B18 2 1 1996Daniyal EzaziNo ratings yet

- BS-970!3!1991-Specification For Wrought Steels For Mechanical and Allied Engineering PurposesDocument38 pagesBS-970!3!1991-Specification For Wrought Steels For Mechanical and Allied Engineering PurposesEric Mellier100% (1)

- Din 267-3 - 08.83Document2 pagesDin 267-3 - 08.83gkhnNo ratings yet

- Iso 4017 2014Document9 pagesIso 4017 2014Ravi KumarNo ratings yet

- Iso 6157-1-1988Document12 pagesIso 6157-1-1988Djaffar SalahouiNo ratings yet

- Hollow Bars (ISO2938)Document8 pagesHollow Bars (ISO2938)suku maranNo ratings yet

- Din 1705Document2 pagesDin 1705Anurag Jain50% (2)

- Din en 1561 - en - 1997-08Document21 pagesDin en 1561 - en - 1997-08AlissonFernandes17No ratings yet

- BS en 10087-1999 (2006)Document18 pagesBS en 10087-1999 (2006)Martijn GrootNo ratings yet

- DIN125ADocument1 pageDIN125AManoj PatilNo ratings yet

- Iso 7040Document1 pageIso 7040serzo75No ratings yet

- ISO - FDIS - 6848-2004-Clasificação Eléctrodos de Tungsténio PDFDocument16 pagesISO - FDIS - 6848-2004-Clasificação Eléctrodos de Tungsténio PDFRicardo FernandesNo ratings yet

- High Tensile: Hexagon Head Setscrews Fine Pitch EN ISO 8676 (DIN 961)Document2 pagesHigh Tensile: Hexagon Head Setscrews Fine Pitch EN ISO 8676 (DIN 961)jaison jacobNo ratings yet

- Din 6915 PDFDocument3 pagesDin 6915 PDFa.tabkhi1980100% (3)

- Din 975 PDFDocument1 pageDin 975 PDFThiago CurvoNo ratings yet

- Din 444Document1 pageDin 444joseocsilvaNo ratings yet

- Asm Metals - Stainless Steel and Nickel Alloys PDFDocument33 pagesAsm Metals - Stainless Steel and Nickel Alloys PDFFernandoiNo ratings yet

- Din 7623Document2 pagesDin 7623Racha Amel100% (1)

- Metric DIN 434 Square Taper Washers: Visit Our For Product AvailabilityDocument4 pagesMetric DIN 434 Square Taper Washers: Visit Our For Product AvailabilityRodrigoNo ratings yet

- Material Specifications Forged Products Manufactured With The Forging Rev.04Document13 pagesMaterial Specifications Forged Products Manufactured With The Forging Rev.04Emre TekinNo ratings yet

- Asme Sec II Part B 2017Document1 pageAsme Sec II Part B 2017Lipika Gayen0% (1)

- Din 8140 AmecoilDocument1 pageDin 8140 Amecoiljuanpalomo74No ratings yet

- BS en 10003-3-1995 (1998)Document12 pagesBS en 10003-3-1995 (1998)Sainath AmudaNo ratings yet

- FW F436 P PDFDocument2 pagesFW F436 P PDFLuis CarlosNo ratings yet

- Sae J200-Epdm-Ts5 - Google SearchDocument2 pagesSae J200-Epdm-Ts5 - Google SearchJessica ApalinNo ratings yet

- BS3076 Na18Document4 pagesBS3076 Na18BHARGAVNo ratings yet

- Normazione 52861: Cold Rolled Steels Cold Worked Strips and PlatesDocument5 pagesNormazione 52861: Cold Rolled Steels Cold Worked Strips and PlatesRizwanAliNo ratings yet

- Iso 12151 5 2007Document9 pagesIso 12151 5 2007Jackson PhinniNo ratings yet

- Sae.j995.1967 Mechanical and Quality Requirements For Steel Nuts PDFDocument5 pagesSae.j995.1967 Mechanical and Quality Requirements For Steel Nuts PDFAlonso Enrique Peña ReyesNo ratings yet

- Din 1681-GS 60Document9 pagesDin 1681-GS 60Vishnu AgawaneNo ratings yet

- 21 CR Mo V511Document1 page21 CR Mo V511uksrajNo ratings yet

- Din 928 en PDFDocument1 pageDin 928 en PDFroyroverNo ratings yet

- Din 580-Lifting Eye Bolts PDFDocument1 pageDin 580-Lifting Eye Bolts PDFAntohi CatalinNo ratings yet

- Lifting Eye Bolts Steel Stainless Steel Din 580 PDFDocument1 pageLifting Eye Bolts Steel Stainless Steel Din 580 PDFheitormartNo ratings yet

- Lifting Eye Nuts: Steel / Stainless SteelDocument1 pageLifting Eye Nuts: Steel / Stainless SteelMalik Uzair ZafarNo ratings yet

- VDI 3842 - Vibrations in Piping System PDFDocument44 pagesVDI 3842 - Vibrations in Piping System PDFsafaozhan88% (8)

- Steam Tables and ChartsDocument9 pagesSteam Tables and ChartsjpnaveenNo ratings yet

- 10 0 Driveline Dynamics NotesDocument19 pages10 0 Driveline Dynamics NotessafaozhanNo ratings yet

- MC Design Engineers Guide PDFDocument19 pagesMC Design Engineers Guide PDFgovindsrNo ratings yet

- Mohr's CircleDocument5 pagesMohr's CircleKoustav SarkarNo ratings yet

- Mechanical DesignDocument51 pagesMechanical DesignsafaozhanNo ratings yet

- Daiko SF 82: Data Sheet N. 1011 Mig, Tig & Saw WireDocument1 pageDaiko SF 82: Data Sheet N. 1011 Mig, Tig & Saw WireRhyan EdwinNo ratings yet

- MDS Y20Document1 pageMDS Y20von18No ratings yet

- Rubber Mastic and Sealant Tapes PDFDocument18 pagesRubber Mastic and Sealant Tapes PDFNikhil MathewNo ratings yet

- Manpower Deployment Plan Ot2499Document1 pageManpower Deployment Plan Ot2499becemNo ratings yet

- Unconventional Machining Process - Unit 4 Chemical and Electrochemical Energy Based ProcessesDocument31 pagesUnconventional Machining Process - Unit 4 Chemical and Electrochemical Energy Based Processesanon_185555118No ratings yet

- OPS. Monitoring - Bolo Parallel Bridge (23A00075) As of 07.03.23Document10 pagesOPS. Monitoring - Bolo Parallel Bridge (23A00075) As of 07.03.23mj macaspacNo ratings yet

- Piping Materials Specification Class D15KdDocument3 pagesPiping Materials Specification Class D15KdQeyratNo ratings yet

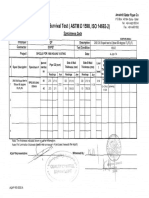

- 1000 Hrs Survival Test (ASTM D 1598, ISO 14692-2) : Specimens DataDocument24 pages1000 Hrs Survival Test (ASTM D 1598, ISO 14692-2) : Specimens DataNADEEM AHMEDNo ratings yet

- Name: - : Industrial Materials and ProcessesDocument3 pagesName: - : Industrial Materials and ProcessesSheryll PascobilloNo ratings yet

- 04 Strainer (24-64) PDFDocument41 pages04 Strainer (24-64) PDFDavid Gustavo Duran TangoNo ratings yet

- Repair and Maintenance of Berth No 6, Port of PortlandDocument5 pagesRepair and Maintenance of Berth No 6, Port of Portlandmehdi_hoseineeNo ratings yet

- Div15-4 Swimming PoolDocument14 pagesDiv15-4 Swimming Poolmohamed nizmyNo ratings yet

- Wattyl Killrust Brochure 2Document6 pagesWattyl Killrust Brochure 2Tech 84No ratings yet

- Doors and AccessoriesDocument54 pagesDoors and AccessoriesSelvin GalindoNo ratings yet

- Quality Systems Manual Method StatementDocument8 pagesQuality Systems Manual Method StatementLloyd MariNo ratings yet

- 03 Christoph MuellerDocument55 pages03 Christoph MuellerKaren LimNo ratings yet

- Mechanical Test Codes and Standards ListDocument6 pagesMechanical Test Codes and Standards ListIsmail TpNo ratings yet

- 2000-Behavior of Fe-Mn-Al-C Steels During Cyclic TestsDocument4 pages2000-Behavior of Fe-Mn-Al-C Steels During Cyclic TestsJaime Andres CastañedaNo ratings yet

- TDS - Biocomp BF 7210 - EngDocument3 pagesTDS - Biocomp BF 7210 - EngAldo EspinozaNo ratings yet

- Chapter 5 - Roofing & False CeilingDocument22 pagesChapter 5 - Roofing & False CeilingsaravananNo ratings yet

- Alloy Steel Pipe Price List IndonesiaDocument14 pagesAlloy Steel Pipe Price List Indonesiaiandegs2010No ratings yet

- Materials Varieties and ApplicationsDocument2 pagesMaterials Varieties and ApplicationsHossein GhazinezhadNo ratings yet

- 5 Drawing ZTT Line HardwareDocument2 pages5 Drawing ZTT Line HardwareVictor DoyoganNo ratings yet

- Interpipe - Global Steel Pipe ProducerDocument19 pagesInterpipe - Global Steel Pipe ProducerAlexandruVerdesNo ratings yet