Professional Documents

Culture Documents

Vessel DRG

Vessel DRG

Uploaded by

jemunozs4328Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Vessel DRG

Vessel DRG

Uploaded by

jemunozs4328Copyright:

Available Formats

8

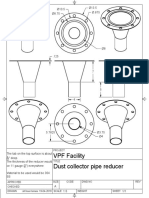

28 TYP 16 TYP 90 3/4"

F

Nozzle #

A B C D E

Hole Schedule Service Description

Inlet Outlet Vent Drain Instrument 24" Sch40 12" Sch40 2" Sch160 2" Sch160 2" Sch160

Edition: 2004

Location

270 Top Head Top Head 90 Bottom Head Shell 0

Addenda: 2006

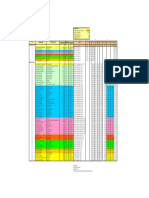

ITEM NO. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

DESCRIPTION Shell 3/4" x 42" OD x 72" lg 4x4x0.625 Leg 42InchRFWN 300# B16.47 HHJNUT 1.5000-12-D-N Studs ASME SE Head 3/4" Nominal thk, 0.698 A.F. x 42" OD c/w 1-1/2" Straight Skirt 300 lb. - 24.000" NPS (SCH. 40) B16.5 300 lb. - 2.000" NPS (SCH. 160) B16.5 300 lb. - 2.000" NPS (SCH. 80) B16.5 300 lb. - 12.000" NPS (SCH. 40) B16.5 Nozzle A pipe Nozzle D Pipe Nozzle E Pipe Nozzle B Pipe Nozzle C Pipe Lifting Lugs 1" thk Nozzle A Repad 3/4" thk x 30" OD x 24.0625" ID Nozzle B Repad 1/2" thk x 16" OD x 12-13/16" ID

MATERIAL SA-240 304 Plate SA/CSA-G40.21 44 W SA-182 F304 SA-194 2H SA-193 B8 SA-240 304 SA-182 F304 SA-182 F304 SA-182 F304 SA-182 F304 SA-312 TP304 SA-312 TP304 SA-312 TP304 SA-312 TP304 SA-312 TP304 SA-240 304 SA-240 304 SA-240 304

QTY. 1 4 2 64 32 2 1 2 1 1 1 1 1 1 1 2 1 1

Design Code & Conditions

Code: ASME Section VIII Division 1 Impact Test: Not Required per UHA-51(d) Radiography: None MAWP Internal: 350 psi at: 650 F Maximum Working Pressure MAWP External: 7. psi at: 650 F Maximum Working Pressure 5 350 psi Minimum Design Metal Temperature MDMT: -20 F at: Design Temp: 650 F at: 350 psi Minimum Design Metal Temperature Test Pressure: 455 psi at: 55 F with: Water Exterior Finish: lbs For: 30 min. Minimum TBA lbs Corrosion Allowance: 0" Interior Finish: None

5.63 180

11.25 0

31.625

E

Volume: Weights -

cuft Dry:

Operating Fluid: Compressed Air Service: lbs Test:

Certified by

(Name of Manufacturer)

6 TYP

BOTTOM VIEW

270 18 0.698 0.500 16 0.500 0.375

D

U

B 48.90 12 8 15 C

W (if arc or gas welded) RT (if radiographed) HT (if postweld heat treated) CRN

CRN

350 psi (kPa) at

650 F (C)

Max. allowable working pressure (MAWP)

No. A

7.5

psi (kPa) at

650 F (C)

Max. allowable external working pressure

Forces and Moments - Operating Load Size FX FY FZ Mx My (Inches) (lbs) (lbs) (lbs) (ft-lbs) (ft-lbs) 24 6475 6475 4856 38206 25520

Mz (ft-lbs) 33117

14

10

-20

F (C) at

350 psi (kPa)

NOTES:

Loads are defined at the Shell-Nozzle intersection. All welds should be neat in appearance, free of slag and other defects. Vessel shall be clean of scale, oil, weld splatter and all other foreign matter before hydrostatic testing. Remove all sharp edgeson nozzles - 1/8" radius minimum. This vessel will be bolted to the floor. All nozzles are to support nominal loads only.

D

Minimum Design Metal Temperature (MDMT)

Construction:

Manufacturer's serial number Year built

0.438 6 A 27.62

Conditions:

3 TYP

C

42 O.D. Full Pen

C

25

4.000 Ref 135.5 E 17 11 7

22.50 1 72 9 13 R2 1/4" 1 1/2"

B

A

B

35 24

1/4 NPT TellTale Hole 0.500 0.500 0.563 0.688 28 TYP 0.250 12

DETAIL A SCALE 1 : 8

UNLESS OTHERWISE SPECIFIED

DO NOT SCALE DRAWING INTERPRET DIMENSIONS AND TOLERANCES PER ASME Y14.5M-1994 DIMENSIONS ARE IN INCHES SolidWorks MAINTAINED DATA CHANGES SHALL BE INCORPORATED ELECTRONICALLY BY THE DESIGN ACTIVITY

Pressure Vessel Engineering Ltd.

155 Frobisher Drive, Unit F-220, Waterloo, ON, N2V 2E1, Canada

TITLE

PROPRIETARY

NO PART OF THIS DOCUMENT MAY BE REPRODUCED, STORED IN A RETRIEVAL SYSTEM, OR TRANSMITTED IN ANY FORM, WITHOUT THE WRITTEN PERMISSION OF Pressure Vessel Engineering Ltd.

CUSTOMER

.5 D 0.375

8 7

Nozzles C, D & E

12

TOLERANCES APPLY AS SHOWN BELOW 0 PL DEC 0.2 1 PL DEC 0.1 2 PL DEC 0.01 3 PL DEC 0.005 .1 ANGLES 32 in SURFACE ROUGHNESS

XYZ Vessel Inc.

PROJECT

Sample Vessel # 8

SIZE DRAWING NO

Sample Vessel

DRAWN BY DATE

THIRD ANGLE PROJECTION

RTS

CHECKED BY

Dec 21, 2005

DATE

X

APPROVED

X

DATE

C

SCALE

PVE-Sample # 8

WEIGHT

REVISION

1:1

2

PVE Sample 8

1

SHEET 1 OF 1

You might also like

- 7.5 Tons Overhead CraneDocument1 page7.5 Tons Overhead CraneGnabBangNo ratings yet

- Cargo Sampling On Chemical Tankers What When and How To DoDocument23 pagesCargo Sampling On Chemical Tankers What When and How To DoKunal SinghNo ratings yet

- Trailer EbsDocument28 pagesTrailer EbsFahmi Khaibara100% (1)

- Sample Section Modulas CalculationDocument18 pagesSample Section Modulas CalculationShamik ChowdhuryNo ratings yet

- API RP 4G InspectionDocument7 pagesAPI RP 4G InspectionChandrasekhar Sonar100% (2)

- New Storage Tanks Design GuidelinesDocument6 pagesNew Storage Tanks Design GuidelineschrisevabNo ratings yet

- Spreaer Beam&Lifting Line Beam p5Document2 pagesSpreaer Beam&Lifting Line Beam p5Sabrang LorNo ratings yet

- Tank Drawings Example PDFDocument2 pagesTank Drawings Example PDFMiguel OrhlNo ratings yet

- Calculation Software of WeldingDocument1 pageCalculation Software of WeldinghaharameshNo ratings yet

- Fasteners WeightDocument4 pagesFasteners Weightpbp2956No ratings yet

- Astm E1806-23Document22 pagesAstm E1806-23zuqin bianNo ratings yet

- Cog CalculationDocument152 pagesCog CalculationSiva ShankarNo ratings yet

- Design and Verification of Lifting LugsDocument3 pagesDesign and Verification of Lifting LugsFabio Okamoto100% (1)

- Skid LiftDocument2 pagesSkid LiftAmi PutraNo ratings yet

- Lifting Lug Calculation: Equipment: Housing Gas Filter (Simplex)Document1 pageLifting Lug Calculation: Equipment: Housing Gas Filter (Simplex)Tejas ShahNo ratings yet

- API 650 Pipe Column DesignDocument4 pagesAPI 650 Pipe Column DesignJoselito CalagosNo ratings yet

- Sample2 DrawingDocument1 pageSample2 DrawingganeshNo ratings yet

- Buckling and Postbuckling of Beams, Plates, and ShellsDocument8 pagesBuckling and Postbuckling of Beams, Plates, and Shellslalo198No ratings yet

- WPS ExampleDocument2 pagesWPS ExampleMarcio Jr.No ratings yet

- Sample Seal Pot DWGDocument1 pageSample Seal Pot DWGsandesh sadvilkarNo ratings yet

- 1967 Skid Design ReviewDocument15 pages1967 Skid Design ReviewmirraoNo ratings yet

- Sample3 Drawing PDFDocument2 pagesSample3 Drawing PDFMas Arman TewoNo ratings yet

- 050 0160 A (Main Frame Assembly)Document3 pages050 0160 A (Main Frame Assembly)Miltongrimi GrimilNo ratings yet

- Vertical Compress DrawingDocument1 pageVertical Compress DrawingFaull JackmanNo ratings yet

- Sample13 DrawingDocument2 pagesSample13 DrawingSourav HaitNo ratings yet

- Copper Concentrate Leaching in Chloride-Jpibañez-JipinzaDocument12 pagesCopper Concentrate Leaching in Chloride-Jpibañez-JipinzaFelipe GuerreroNo ratings yet

- 185-170-5-300-M44-0055 RevBDocument1 page185-170-5-300-M44-0055 RevBVashish RamrechaNo ratings yet

- Cooling Tower Selection CriteriaDocument5 pagesCooling Tower Selection CriteriaPrashant Suvarna100% (1)

- DWG 415-019 REV 0Document7 pagesDWG 415-019 REV 0jonodo89No ratings yet

- Data Sheet Fuel Gas Filter Rev 0Document22 pagesData Sheet Fuel Gas Filter Rev 0Bowo Edhi WibowoNo ratings yet

- Sample Design Calculation - Vessel Supported On LugsDocument11 pagesSample Design Calculation - Vessel Supported On Lugsandry4jc100% (1)

- Option-2-Piping Support Structural BOQDocument12 pagesOption-2-Piping Support Structural BOQMaqsood Ibn Shaikhul ArfeenNo ratings yet

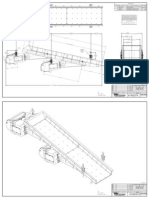

- Dust Collector Pipe Reducer Drawing v0Document1 pageDust Collector Pipe Reducer Drawing v0itsmelalithNo ratings yet

- Sp-210-E-103 Rev 0Document7 pagesSp-210-E-103 Rev 0Natarajan RavisankarNo ratings yet

- Sample2 DrawingDocument1 pageSample2 DrawingSourav HaitNo ratings yet

- Skid 1 - Foundation Load Table: Dead Weight (LB) Wind Load (120 MPH) Load (LBF) Load (LBF) S 0.825gDocument3 pagesSkid 1 - Foundation Load Table: Dead Weight (LB) Wind Load (120 MPH) Load (LBF) Load (LBF) S 0.825gomarNo ratings yet

- Purchase Spec. For Nozzles Swage (Sa106b)Document4 pagesPurchase Spec. For Nozzles Swage (Sa106b)Daison PaulNo ratings yet

- Cone Weight CalculationDocument10 pagesCone Weight CalculationRajesh OwaiyarNo ratings yet

- A-344, A-347 Master LinkDocument1 pageA-344, A-347 Master LinkAekJayNo ratings yet

- Approval Required: Material ListDocument2 pagesApproval Required: Material ListJorge VarelaNo ratings yet

- Tor. Dish EndDocument4 pagesTor. Dish EndSiva ShankarNo ratings yet

- Binder1 PDFDocument43 pagesBinder1 PDFKyNo ratings yet

- Plate & RectangularDocument7 pagesPlate & RectangularibicengNo ratings yet

- Tank Level Calculator Storage Tank: Head Related Size DiagramDocument29 pagesTank Level Calculator Storage Tank: Head Related Size DiagramDHAVALESH AMNo ratings yet

- Telescopic Spreader BeamsDocument3 pagesTelescopic Spreader BeamsAlmir PendekNo ratings yet

- Transmittal - KTA - TB-PAC03-AECC-PVG-104Document2 pagesTransmittal - KTA - TB-PAC03-AECC-PVG-104Lê Đức ThiệnNo ratings yet

- How To Order Alfa ValveDocument0 pagesHow To Order Alfa ValveZoebairNo ratings yet

- Sheet For Calculation of Welding ElectrodesDocument4 pagesSheet For Calculation of Welding ElectrodesthehraoNo ratings yet

- BuoyancyDocument1 pageBuoyancyLcm TnlNo ratings yet

- A554 y 730 HV DWG Hva 300Document1 pageA554 y 730 HV DWG Hva 300josephNo ratings yet

- Legend: Marine Energy Sdn. Bhd. SapurakencanaDocument1 pageLegend: Marine Energy Sdn. Bhd. SapurakencananamasralNo ratings yet

- Customer: Ge Packaged Power PROJECT PO: 411513279 PROJECT NO.: 1370344 Project Name: Termoyopal Project Location: Yopal, ColombiaDocument2 pagesCustomer: Ge Packaged Power PROJECT PO: 411513279 PROJECT NO.: 1370344 Project Name: Termoyopal Project Location: Yopal, ColombiaomarNo ratings yet

- As Built: Rfso, C/W Dip PipeDocument18 pagesAs Built: Rfso, C/W Dip Piperomeo112976No ratings yet

- Pveng: Vessel With Large Opening Pve Sample VesselDocument1 pagePveng: Vessel With Large Opening Pve Sample VesselSivateja NallamothuNo ratings yet

- Tail Lifting Lug Calculation MS WordDocument11 pagesTail Lifting Lug Calculation MS WordWijayanto BekasiNo ratings yet

- Nalco Idler-S409/1 - 37870/8200004980/IDLERS&ROLLERSDocument2 pagesNalco Idler-S409/1 - 37870/8200004980/IDLERS&ROLLERSAlok NayakNo ratings yet

- Peract Pi Q23 DW 0004 PDFDocument5 pagesPeract Pi Q23 DW 0004 PDFGNo ratings yet

- Tbe For Osbl (SBS)Document5 pagesTbe For Osbl (SBS)benidbb100% (3)

- L-CV-155-VA-24XX01 Nitrogen: ASME Sec VIII Div 1+ PED97/23/ECDocument1 pageL-CV-155-VA-24XX01 Nitrogen: ASME Sec VIII Div 1+ PED97/23/ECevrim77No ratings yet

- Finned Tube Heat ExchangerDocument4 pagesFinned Tube Heat ExchangerneelNo ratings yet

- Tube Bundle DrawingDocument1 pageTube Bundle DrawingVeera ManiNo ratings yet

- SC20 Sample CoolerDocument3 pagesSC20 Sample CoolerjdanastasNo ratings yet

- FEA Report Piping Saddle PDFDocument7 pagesFEA Report Piping Saddle PDFalprieto2003No ratings yet

- Drawing No. ATD: 000-000-000-4000 - 2.dgn 2011/10/31 01:08:29 PMDocument1 pageDrawing No. ATD: 000-000-000-4000 - 2.dgn 2011/10/31 01:08:29 PMjonodo89No ratings yet

- Another DWG of Vessel No 3Document1 pageAnother DWG of Vessel No 3Nomi KhanNo ratings yet

- MPVN BrochureDocument32 pagesMPVN Brochurefernando_naciamentNo ratings yet

- Sample11 DrawingDocument1 pageSample11 DrawingSidra KhanNo ratings yet

- Fabrication of Process Analyzer Packages-MSDocument24 pagesFabrication of Process Analyzer Packages-MSAhmed ElghmatiNo ratings yet

- Monitoring ReportDocument40 pagesMonitoring ReportAngelika CalingasanNo ratings yet

- Carrier 58cta070Document14 pagesCarrier 58cta070ITLHAPNNo ratings yet

- Ruler Technical DocumentDocument7 pagesRuler Technical DocumentNestorRinconMallo100% (1)

- Ethyl AlcoholDocument5 pagesEthyl AlcoholTamil kumaranNo ratings yet

- Resume ProcessEngr SemiconductorsDocument2 pagesResume ProcessEngr Semiconductorssamy512No ratings yet

- Cygnus 2 Hands Free ManualDocument43 pagesCygnus 2 Hands Free ManualwarshipvnNo ratings yet

- Lexpure (Techsheet My)Document1 pageLexpure (Techsheet My)DigitalVault EnterpriseNo ratings yet

- Proheat 35 Manual PDFDocument82 pagesProheat 35 Manual PDFrafaeldctNo ratings yet

- Manual ViscometersDocument62 pagesManual ViscometersArvin Singh100% (1)

- TRE 145-185 (1995) 29-2-99 Service Descarga Derecho Ingles PDFDocument49 pagesTRE 145-185 (1995) 29-2-99 Service Descarga Derecho Ingles PDFManuelNo ratings yet

- Catalogue of RC140-50 Toroidal Core Winding MachineDocument8 pagesCatalogue of RC140-50 Toroidal Core Winding MachineSoham ShahNo ratings yet

- Chapter 14 - WaterDocument55 pagesChapter 14 - WaterSamnang HangNo ratings yet

- HBA Juli 2010Document1 pageHBA Juli 2010Ichsan NNNo ratings yet

- Unit 24: Applications of Pneumatics and HydraulicsDocument15 pagesUnit 24: Applications of Pneumatics and HydraulicsEmad ElsaidNo ratings yet

- Denso Valve Flange Tape Wrapping SpecDocument3 pagesDenso Valve Flange Tape Wrapping SpecNaufal Firmansyah100% (1)

- Howo Maintenance InstructionsDocument7 pagesHowo Maintenance InstructionsSimon EllyNo ratings yet

- Saneeksha Final ThesisDocument51 pagesSaneeksha Final ThesisCyPherNo ratings yet

- Taushunaev 2018 IOP Conf. Ser. Mater. Sci. Eng. 365 062013Document7 pagesTaushunaev 2018 IOP Conf. Ser. Mater. Sci. Eng. 365 062013juan castiblancoNo ratings yet

- BA - BV Series Air Hammer Pneumatic Vibrator - B0Document16 pagesBA - BV Series Air Hammer Pneumatic Vibrator - B0Nguyễn Ngọc Phước VươngNo ratings yet

- Kenmore 385.15202 Sewing Machine Instruction ManualDocument65 pagesKenmore 385.15202 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Dyeing & PrintingDocument33 pagesDyeing & Printingyuganshu_soni100% (1)

- Data SheetDocument5 pagesData Sheetyilo2000No ratings yet