Professional Documents

Culture Documents

Whittle MultiMineGeitaGold

Whittle MultiMineGeitaGold

Uploaded by

Mditsa1991Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Whittle MultiMineGeitaGold

Whittle MultiMineGeitaGold

Uploaded by

Mditsa1991Copyright:

Available Formats

Development and Application of Whittle Multi-Mine at Geita Gold

Mine, Tanzania

T Joukoff

1

, D Purdey

2

and C Wharton

3

ABSTRACT

In the past, life of mine scheduling at Geita Gold Mine, Tanzania, has

been a largely manual process involving the optimisation and scheduling

of each mine as a separate entity. The scheduling has been a

time-consuming process undertaken using spreadsheets. Recent advances

in the Whittle software have enabled multiple mines to be optimised and

scheduled simultaneously, so that the mining sequence that maximises the

NPV (net present value) for the entire set of mines as a whole can be

determined. This case study presents the results of the collaboration

between Gemcom Africa (Pty) Ltd and Geita Gold Mining Limited to

develop and apply the Whittle Multi-Mine module at Geita Gold Mine. It

shows how improvements to the NPV of the life of mine schedule were

achieved by using Whittle Multi-Mine as a tool to help guide the

preferred order of mining. It highlights the contributions from each of the

mines to the overall cash flow of the project and investigates the effect of

time on the NPVs from each mine. The cost of deferring production from

certain mines has become plainly evident, whilst for others there is little

impact. Furthermore, Whittle Multi-Mine has identified areas requiring

more focus in terms of the life of mine plan.

INTRODUCTION

Geita Gold Mine is situated in northwest Tanzania,

approximately 25 km from the southern shores of Lake Victoria.

Historical mining in the area has taken place for many years,

with the last major operation being the Geita Underground Mine,

which operated from the 1930s through to the 1960s and

produced almost 1 Moz of gold. Ongoing small scale mining

continues to this day.

The modern Geita mine has been operating since mid-1999,

with processing of ore commencing in mid-2000. To date, 48

Mbcm of material has been mined from three open pits; 14 Mt of

ore, grading 3.8 g/t, has been processed and 1.5 Moz recovered.

The current Life of Mine Plan indicates a mine life in excess of

ten years and entails the mining of ten individual pits, several of

which are multi-stage. Total mining is expected to exceed 320

Mbcm, producing more than 80 Mt of high-grade ore and

yielding more than 10 Moz of recovered gold.

The open pit mines are operated with conventional techniques

using excavators and trucks on flitches up to 3.5 m high. Most

material requires blasting, ranging from paddock blasting in

soft laterites and oxides, to hard rock blasting in sulfides.

Pit optimisation at Geita has been an ongoing process,

predominantly undertaken using the NPV Scheduler software,

however; from early 2003 Whittle software has been used in

parallel. Although techniques to evaluate multiple orebodies have

existed for some time (Tulp, 1997), each open pit has been

optimised and scheduled as a separate entity rather than

consideration given to whole of mine optimisation and

scheduling. Estimates of the mill throughput likely to be required

from each pit were used to guide the pit life and net present value

(NPV) calculation. Since the ore delivery rate required was

generally not known until the whole mine schedule was finalised

using all the pits, this was obviously a flawed process.

Once the optimal pit for each mine was decided, pit designs

were undertaken, reserves calculated and the entire data set

exported to a spreadsheet for manual scheduling. Various

guidelines and comparisons between the pits and stages were

used to assist with the manual scheduling process, such as strip

ratio, profit per tonne milled, cash cost per ounce, profit per

ounce and break-even time. This introduced another flaw in the

process, where the optimal extraction sequence was not

necessarily followed during the manual scheduling process.

It became apparent that this trial and error scheduling method

was time-consuming and limited the number of alternate life of

mine scenarios that could be evaluated. A need for a technique to

optimise the extraction sequence in this multiple mine scenario

was identified. Such a tool was available as part of the Whittle

suite of mine planning software, but was still in its infant stages,

requiring rigorous testing on a real life scenario. This paper

describes Whittle Multi-Mine and its application at Geita, but

first briefly reviews the traditional and widely applied MOBS

technique.

MOBS

A technique known as MOBS (Multiple Ore Body Systems,

Tulp, 1997) has existed for some time now and has been widely

applied in situations where multiple orebody deposits exist in

proximity. In short, the technique involves agglomerating block

models representing each of these deposits into one super model

(Figure 1), and optimising and scheduling using Whittle

software. The limitations of this method are described following.

To enable the identification of material selected for mining by

Whittle from the different deposits, it was necessary to assign

unique rock codes that were reflective of the different deposit

areas. Furthermore, the rock codes used for Whittle also needed

to capture the actual rock type, so that different mining and

processing costs could be defined if necessary. This required the

assignation of many rock codes and sometimes resulted in the

loss of geological definition due to the restriction in the number

of codes that could be handled by Whittle.

Once the optimisations had been completed and the pit shells

generated, it was necessary to cut up the super model results file

to separate the individual mines, using the polygon intersection

Orebody Modelling and Strategic Mine Planning Perth, WA, 22 - 24 November 2004 267

1. MAusIMM, C/- Gemcom Africa (Pty) Ltd, PO Box 411689,

Craighall 2024 Gauteng, Republic of South Africa.

2. MAusIMM, C/- MRM Mining Services, PO Box 3193, Halfway

House 1685 Gauteng, Republic of South Africa.

3. 66 Rathmullen Quadrant, Doncaster Vic 3108.

NORTH PIT

WEST PIT

MAIN PIT

SATELLITE 1 SATELLITE 2

FIG 1 - Example super model constructed by merging

MOBS in Whittle.

functionality in Whittle, so that the results could be exported

from Whittle back to a general mining package (GMP). This was

because the original coordinates of the individual deposits were

lost when they were combined into the super model.

Issues arose when scheduling MOBS, since it was not possible

to control the order that the deposits were mined in without

creating complex pit list files with GMPs or by writing scripts

with programming packages. Furthermore, it was necessary to

ensure that the top surface of all of the models lay on the same

Whittle bench level in the combined super model, requiring the

user to offset each individual block model so as to create a

regular surface over the entire model. This meant that when

simulating the mining of a bench in Whittle, the bench was

mined from all of the mines in the super model. It was also not

possible to have different cut-backs in each mine, nor was it

possible to have different final pits per mine. This reduced the

effectiveness of the scheduling and did not allow areas of higher

value to be deliberately targeted.

For more advanced scheduling using the Whittle Milawa

scheduling algorithm, it was necessary to stack groups of pit

shells, representing the nested pits derived for each mine, for

Milawa to work effectively (Figure 2). This was difficult to set up

and comparatively inflexible when evaluating many alternate

mining sequences.

Whilst the technique described above generated results that

added value to mining operations; it was tedious and much time

was spent on manipulating models and data files, thus limiting

the amount of time that could be spent on actually evaluating

different scheduling sequences and the consequent impact on

NPV.

MULTI-MINE

Whittle Multi-Mine provides a much more sophisticated and

flexible means of optimising and scheduling in a multiple mine

situation, as was proven by its successful application at Geita

Gold Mine. The different techniques applied at Geita are

described following, using examples (Joukoff and Purdey, 2004)

to illustrate the results.

With Whittle Multi-Mine it is no longer necessary to use rock

codes to identify material from different deposits. It is now

possible for Whittle model files to carry a mine name, so the

issue of running out of rock codes is no longer a problem. This

allows greater geological detail to be modelled, leading to

increased flexibility and detail when modelling costs, recoveries

and slopes in Whittle, if desired. Furthermore, because each

model can be associated with a mine name, it is possible to view

and export results for individual mines. This reduces the amount

of time required to be spent on data manipulation and provides

more time to deal with strategic issues.

It is possible to optimise all the mines under consideration

either simultaneously or individually, because the Whittle model

files carry a mine name. The advantage of optimising them

together is that the impact of each mine on the combined cash

flows of all the mines can be examined and reported.

Scheduling with Multi-Mine is now also much more

sophisticated than the MOBS technique previously applied. It is

possible to vary the mining rates in different mines and also to

control when mining can occur in a particular mine. This

functionality proved particularly useful at Geita because some of

the mines were remote from the processing plant and ore

production from these mines was limited by the long distance

haulage capacity (Figure 3). Also, due to Geitas environmental

commitment to backfilling completed pits to minimise

disturbance caused by the construction of waste dumps, some

mines were not able to commence until adjacent mines were

completed. Furthermore, either of the Fixed Lead or Milawa

scheduling algorithms can be applied as described following.

268 Perth, WA, 22 - 24 November 2004 Orebody Modelling and Strategic Mine Planning

T JOUKOFF, D PURDEY and C WHARTON

FIG 2 - Stacked pit shells to enable Milawa to operate

independently on each mine before the development of Whittle

Multi-Mine.

Roberts

Ridge 8

Star/Comet

Geita Hill Pits

Nyankanga

Chipaka

Matandani

Kukuluma

Lone Cone Pits

Legend

Haul Road

Pit

Plant

Schematic of Geita Gold Mine

(Not to scale)

~5 km

~20 km

~19 km

FIG 3 - Schematic of Geita Gold Mine.

Fixed lead

Fixed lead scheduling can operate with or without precedence

controls. By establishing mining precedence rules, different

orders of mining the individual mines can be simulated, making

it possible to investigate which order maximises the NPV to the

company. This technique is particularly applicable in situations

where only one mine will operate at a time, such as when the

mines are very large and where ore control issues can be handled

sufficiently by manipulating the mining sequence within each

mine, without the need to blend material from different mines.

Each mine may have its own process plant and associated

infrastructure but logistically, mining equipment may need to

move from one mine to another. The order of mines to which

equipment moves can be optimised using this functionality.

Alternately, when no particular precedence is required and

mining can occur simultaneously in all mines following the same

bench lead constraints, fixed lead scheduling can also be applied.

These two alternate concepts are illustrated in Figure 4.

Fixed lead scheduling was tried at Geita but with limited

effectiveness because the site wanted to be able to mine from

many pits simultaneously, rather than mine them sequentially.

Although this was possible as described previously, it was not

practical in Geitas case because several of the mines were

already in production and operating on different bench levels.

Furthermore, within the constraints of the existing cut-back

designs at Geita, using fixed lead scheduling did not provide an

optimal mill feed schedule. Geita needed to be able to draw

material from multiple sources to feed the mill, to meet the

appropriate oxide/sulfide blend requirements and also to make

better use of the available mill capacity. Greater flexibility was

required, and to overcome these issues it was necessary to apply

the Milawa algorithm.

Milawa

The majority of the Geita scheduling work in Multi-Mine was

undertaken using the Milawa scheduling algorithm. This was

because Milawa allowed material to be mined from different

mines simultaneously, applying different lead and lag constraints

to the different mines (as opposed to fixed lead scheduling,

which uses the same lead constraint for each mine). There was a

requirement at Geita to limit the maximum highwall height

between cut-backs to 150 m, for geotechnical reasons. The

maximum vertical advance in each mine was also restricted to

either 50 m or 100 m per year, depending on the size of the mine.

For this reason it was necessary to define different constraints for

different mines and this was easily achieved with Multi-Mine.

It would be prudent at this stage to briefly explain the

differences between the various Milawa scheduling algorithms.

In NPV mode, Milawa will seek to maximise the NPV of the

schedule, taking into consideration the number of benches,

cut-backs and time periods in the life of the mine (Wharton,

2000). Milawa NPV schedules generally mine just enough waste

to uncover the ore required to fill the mill and tend to defer waste

stripping as much as possible. Logically, this will lead to

increased NPVs. However, this waste deferral may result in

insufficient ore availability at some time in the schedule, but only

if the cut-backs have not been selected appropriately or if the

mining capacity is not well matched to the selected cut-backs.

The Milawa algorithm in balanced mode provides a solution to

this problem by producing a schedule that completely utilises all

of the available mining and milling capacity where possible. The

general effect of such a schedule is to mine more waste than is

needed to uncover the ore necessary to feed the mill, hence

bringing costs forward and resulting in a reduced NPV. However,

both the mill feed schedule and the total mining schedule will be

well balanced. A diagrammatic sketch of a Milawa mining

sequence is included in Figure 5.

APPLICATION AT GEITA GOLD MINE, TANZANIA

Geita Gold Mining Limited provided a data set representing nine

of the mines planned as at November 2003 (Nyankanga, Lone

Cone, Geita Hill, Kukuluma, Matandani, Chipaka, Ridge 8,

Star/Comet and Roberts). Each model was exported from a GMP

with pre-defined rock types that allowed unique costs and

process recoveries to be assigned to each rock type. Although it

is possible to model costs in Multi-Mine using a Mine variable,

a cost model reflecting the different long distance haulage costs,

defined for different rock types, already existed. As well as this,

the existing cut-back positions were exported as pit list models,

allowing the cut-backs within each mine to be differentiated

during subsequent analysis. These pit lists were agglomerated in

Whittle to create a results file suitable for use with the

Multi-Mine scheduling tools. Some of the required operational

constraints have already been described previously in this paper.

Before undertaking any further scheduling in Whittle, a

baseline schedule was developed with Multi-Mine that mimicked

the existing Life of Mine (LoM) Plan as much as possible. This

was so that subsequent NPV calculations for alternate mining

sequences would be comparable. An iterative process was used

in defining this baseline schedule, using modifications to the

min/max lead and max benches constraints to force Multi-Mine

to mine in a similar sequence and with similar quantities as

defined in the LoM Plan. Concurrent with this work in

Multi-Mine was the recalculation of the LoM Plan NPV because

this included the effects of many cash outflows that were not

applicable in pit optimisation.

Once the Multi-Mine baseline schedule was constructed, the

constraints were selectively relaxed to allow Multi-Mine to begin

to optimise the schedule. Alternate orders of mining were tested

by simply adjusting the preferred order of mining and the mine

start and stop times, and the resultant NPV, ore delivery schedule

and total mining schedule evaluated.

Orebody Modelling and Strategic Mine Planning Perth, WA, 22 - 24 November 2004 269

DEVELOPMENT AND APPLICATION OF WHITTLE MULTI-MINE AT GEITA GOLD MINE, TANZANIA

M1 M2

M3

M1 M2

M3 M1

M2 M3

M1

M2 M3

A. B.

FIG 4 - Diagrammatic representation of two different fixed lead scheduling sequences in Whittle Multi-Mine. A. Mining precedence applies

and equipment moves from one mine to another on completion of each mine (Wharton, 2000). B. No mining precedence applies and all

mining occurs simultaneously in all mines, following specified bench lag constraints (Wharton, 2000).

In total, twenty-four different LoM scheduling scenarios for

Geita were considered using the Milawa algorithm in

conjunction with Multi-Mine. Comparison of the NPV of each of

these schedules with the baseline schedule showed that the NPVs

ranged from 87 per cent to 103 per cent of the baseline NPV.

Whilst a three per cent improvement in NPV may seem small, in

Geitas case it represented an increase in NPV in excess of 1500

times the cost of undertaking the Multi-Mine work. An ore

schedule representative of the results generated with Multi-Mine

is displayed in Figure 6.

The most significant difference between the Whittle

Multi-Mine results and the existing site LoM Plan was that the

Milawa algorithm preferred to mine Star/Comet as early as

possible, rather than later in the project life as had been

previously scheduled. This gave some indication as to the

significance of the Star/Comet mine to the overall project NPV.

When run unconstrained, Multi-Mine also preferred to mine

Matandani in early years, but this was not a favoured option as

the waste from Matandani was planned to be backfilled into the

Kukuluma mine.

Investigation of the contribution to NPV from each mine for

each scheduling scenario helped to determine which mines the

overall NPV was most sensitive to. Table 1 contains a

representative set of results showing these cash flow

contributions for various scenarios. It is clear that for some of the

mines changes to the order of mining had little or no effect on

their contribution to total NPV, whilst for others the change in

contribution to NPV was considerable.

The effect of delaying production from any mine can be seen.

The cost of deferring Nyankanga is very evident; the NPV

contribution being as much as 67 per cent (Scenario 14) or as

little as 46 per cent (Scenario 3). This represents a 21 per cent

improvement in cash flow contribution from Nyankanga for

Scenario 14 compared with Scenario 3. In fact, in Scenario 3 the

NPV from Nyankanga approaches that of worst case mining.

As a further example consider Chipaka mine; if this is mined last

(Scenario 14) the NPV contribution erodes to just 0.5 per cent,

but if it is mined first (Scenario 17), the NPV contribution can be

as much as two per cent. However, when considering the NPV of

all of the mines concurrently, delaying Chipaka gives the project

a better overall NPV. This clearly demonstrated how the order of

mining can have a serious impact on the value of the project.

It was concluded from all of the scenarios that the NPV was

relatively insensitive to changes in the order of mining from the

Chipaka, Kukuluma and Ridge 8 mines. This suggested that it

was not worthwhile to further optimise the timing of these mines.

Conversely, there was substantial gain to be made by optimising

the mining sequence from Nyankanga, Geita Hill, Matandani and

Star/Comet. For this reason, the order of mining from these

mines was the focus for the remainder of the scenarios and

yielded higher value schedules.

Examination of the bench schedules produced by Whittle

Multi-Mine helped to understand how much material was mined

from each bench, each cut-back and each mine in each period

and hence made it possible to determine whether Multi-Mine

was adhering to the required operational constraints. The

resultant schedules were both safe and practical. Furthermore, by

making comparisons between the benches mined in different

scheduling scenarios it was possible to understand where the

material was being mined from, and the subsequent contribution

of that material to the overall value of the schedule. An example

bench schedule is given in Table 2.

CONCLUSIONS

This paper has reviewed the techniques available in Whittle to

optimise and schedule multiple orebody models and multiple

mines. The application of Whittle Multi-Mine at Geita Gold

Mine, Tanzania, has demonstrated how improvements to the

NPV of the life of mine schedule were achieved, using

Multi-Mine to help optimise the mining sequence. The Milawa

algorithm in both NPV and balanced mode was able to guide the

order of mining benches from the various cut-backs of the

various pits, within the operational constraints at Geita.

270 Perth, WA, 22 - 24 November 2004 Orebody Modelling and Strategic Mine Planning

T JOUKOFF, D PURDEY and C WHARTON

M1

M2 M3

M1

M2 M3

FIG 5 - Diagrammatic sketch of a Milawa mining sequence in

Whittle Multi-Mine (Wharton, 2000).

MILL FEED SCHEDULE

T

O

N

N

A

G

E

G

R

A

D

E

YEAR

FIG 6 - Representative ore schedule, Geita Gold Mine case study. Different shades represent different mines.

Many alternate scheduling sequences were very quickly

investigated using Whittle Multi-Mine. This process identified

which mines demonstrated greater sensitivity to the order in

which they were extracted and subsequently stressed the effect of

time on the cash flow contribution of these mines to the overall

project NPV. It also assisted in highlighting a potential mismatch

between the required material movement and the available

mining capacity. If the mining capacity is well matched to the

selected cut-backs then it will be possible to achieve a balanced

schedule together with an improved NPV.

ACKNOWLEDGEMENTS

This paper describes work undertaken by co-author David

Purdey whilst employed as Chief Mining Engineer Geita Gold

Mining Limited and is presented with Geita Gold Mining

Limiteds permission. The authors would like to thank Geita

Gold Mining Limiteds management for their permission to

present this paper and also thank the members of the Mining

Department at Geita who contributed to the preparation of the

data used in the Multi-Mine analyses.

The opinions expressed in this paper are not necessarily those

of Geita Gold Mining Limited.

REFERENCES

Joukoff, T and Purdey, D P, 2004.

http://www.whittle.ca/whittle-multimine.asp Improved life of mine

scheduling with Gemcom Whittle Multi-Mine at Geita Gold Mine,

Tanzania (Gemcom Software International Inc: Vancouver).

Tulp, T, 1997. Multiple Ore Body Systems (MOBS), in Proceedings

Optimising with Whittle, Perth, pp 149-163 (Whittle Programming

Pty Ltd: Melbourne).

Wharton, C, 2000. Add value to your mine through improved long term

scheduling, in Proceedings Whittle North American Strategic Mine

Planning Conference, Breckenridge, Colorado.

Wharton, C, 2003. Multi-pit analysis and advanced pit scheduling,

Development notes (unpublished), Melbourne.

Orebody Modelling and Strategic Mine Planning Perth, WA, 22 - 24 November 2004 271

DEVELOPMENT AND APPLICATION OF WHITTLE MULTI-MINE AT GEITA GOLD MINE, TANZANIA

Pit Bench Total Year 1 Year 2 Year 3

Tonnes Ore t Waste t Ore t Waste t Ore t Waste t

Kukuluma 69 1496 - - 341 1155 - -

Kukuluma 68 1131 - - 306 825 - -

Kukuluma 67 772 - - 244 527 - -

Kukuluma 66 453 - - 194 259 - -

Kukuluma 65 20 - - 12 9 - -

Kukuluma 64 142 - - - - 105 37

Kukuluma 63 56 - - - - 44 12

Kukuluma 62 11 - - - - 9 2

Subtotal

Lone Cone 66 1266 161 1105 - - - -

Lone Cone 65 1176 201 975 - - - -

Lone Cone 64 1015 154 861 - - - -

Lone Cone 63 901 111 789 - - - -

Lone Cone 62 788 - - 73 715 - -

Lone Cone 61 653 - - 44 609 - -

Lone Cone 60 532 - - 37 495 - -

Lone Cone 59 401 - - 43 358 - -

Subtotal

TABLE 2

Example extract from bench schedule generated using Whittle Multi-Mine.

Matan' Chipaka Geita Hill Kuk' Lone Cone Ridge 8 Roberts Star Comet Nyank' Total

Scenario 2 5% 1% 17% 4% 3% 1% 1% 4% 63% 100%

Scenario 3 5% 2% 28% 5% 4% 1% 3% 6% 46% 100%

Scenario 7 5% 1% 17% 4% 3% 1% 1% 9% 57% 100%

Scenario 14 3% 0% 16% 4% 2% 1% 2% 6% 67% 100%

Scenario 15 3% 1% 18% 4% 3% 1% 1% 8% 60% 100%

Scenario 16 4% 1% 17% 4% 3% 1% 2% 8% 60% 100%

Scenario 17 3% 2% 16% 4% 3% 1% 1% 6% 65% 100%

Scenario 19 4% 1% 18% 4% 4% 1% 2% 8% 59% 100%

Scenario 21 5% 1% 22% 5% 4% 1% 2% 7% 55% 100%

Scenario 23 5% 1% 20% 5% 1% 1% 3% 9% 56% 100%

TABLE 1

NPV contributions by pit by scenario, Geita Gold Mine case study.

272 Perth, WA, 22 - 24 November 2004 Orebody Modelling and Strategic Mine Planning

You might also like

- Long Hole Stoping With Short Interval ControlDocument30 pagesLong Hole Stoping With Short Interval ControlMimi SegoviaNo ratings yet

- Simulation Techniques in Oyu Tolgoi Underground Development SchedulingDocument9 pagesSimulation Techniques in Oyu Tolgoi Underground Development SchedulingNIEVES MORALES SUBIABRENo ratings yet

- Short Term Mine Planning ChallengesDocument27 pagesShort Term Mine Planning ChallengesRene MoraNo ratings yet

- Oil Filtration in MiningDocument50 pagesOil Filtration in MiningJon CarbonNo ratings yet

- Whittle MultiMineBetterMultipleMines PDFDocument14 pagesWhittle MultiMineBetterMultipleMines PDFCristian' Berrios SalasNo ratings yet

- 05 Morrison PDFDocument12 pages05 Morrison PDFFrancisco CabreraNo ratings yet

- Large-Scale Mine Production Scheduling Optimisation With Mill Blending Constraints at Newmont's Twin Creeks OperationDocument7 pagesLarge-Scale Mine Production Scheduling Optimisation With Mill Blending Constraints at Newmont's Twin Creeks OperationRosdian AriefNo ratings yet

- Pit Planing and DesignDocument6 pagesPit Planing and DesignKeiko Uriol ReyesNo ratings yet

- Pillars. During The Hand-Loading Period, The Process Consisted of Five Sequential and Labor-Intensive UnitDocument29 pagesPillars. During The Hand-Loading Period, The Process Consisted of Five Sequential and Labor-Intensive UnitZeph roxNo ratings yet

- Whittle SplitShellDocument8 pagesWhittle SplitShellWashington BobadillaNo ratings yet

- Menabde Et Al - 2019 - MineoptimisationofConditionalsimulatedmodelsDocument18 pagesMenabde Et Al - 2019 - MineoptimisationofConditionalsimulatedmodelsJorge ValencaNo ratings yet

- An EDP-Model of Open Pit Short Term Production Scheduling Optimization For Stratiform OrebodiesDocument10 pagesAn EDP-Model of Open Pit Short Term Production Scheduling Optimization For Stratiform OrebodiesrannscribdNo ratings yet

- MSIP Scheduler RescheduledDocument19 pagesMSIP Scheduler RescheduledRCBNo ratings yet

- Simultaneous Destination and Schedule Optimization With Minemax Scheduling Technology at NewmontDocument44 pagesSimultaneous Destination and Schedule Optimization With Minemax Scheduling Technology at Newmontraymond.jyl6807No ratings yet

- Computers and Operations Research: Navid Seyed Hosseini, Eugene Ben-Awuah, Yashar PourrahimianDocument15 pagesComputers and Operations Research: Navid Seyed Hosseini, Eugene Ben-Awuah, Yashar PourrahimiansouzamfabianoNo ratings yet

- Underground Mine Planning: Stope Layout Optimisation Under Grade Uncertainty Using Genetic AlgorithmsDocument19 pagesUnderground Mine Planning: Stope Layout Optimisation Under Grade Uncertainty Using Genetic AlgorithmsCecilia Obregón RiveraNo ratings yet

- An Improved Formulation of The Underground Mine Scheduling Optimisation Problem When Considering Selective MiningDocument16 pagesAn Improved Formulation of The Underground Mine Scheduling Optimisation Problem When Considering Selective MiningAxel Godoy QueratNo ratings yet

- 2008 Developing An Optimised Production Forecast at Northparkes E48 Mine Using MILP - Rahal Et AlDocument10 pages2008 Developing An Optimised Production Forecast at Northparkes E48 Mine Using MILP - Rahal Et AlgertvanhoutNo ratings yet

- Ejor KirunaDocument14 pagesEjor Kirunahehusa25No ratings yet

- Case Studies in Open Pit Design Using Lerchs-Grossman Pit OptimizationDocument8 pagesCase Studies in Open Pit Design Using Lerchs-Grossman Pit OptimizationTerry ChongNo ratings yet

- Development of A Mathematical Programming Model To Support The Planning of Short-Term MiningDocument15 pagesDevelopment of A Mathematical Programming Model To Support The Planning of Short-Term MiningJhol Dueñas GutierrezNo ratings yet

- Blast Fragmentation For Maximising The Sag Mill Throughput at Porgera Gold MineDocument17 pagesBlast Fragmentation For Maximising The Sag Mill Throughput at Porgera Gold MineElías Bravo CortésNo ratings yet

- Open Pit Optimisation and Design of Tabakoto Pit at Anglogold Ashanti Sadiola Mine Using Surpac and Whittle SoftwareDocument12 pagesOpen Pit Optimisation and Design of Tabakoto Pit at Anglogold Ashanti Sadiola Mine Using Surpac and Whittle SoftwareBoukaré OUEDRAOGONo ratings yet

- Cutt Off SynopsisDocument13 pagesCutt Off SynopsisDhruv ChatterjeeNo ratings yet

- Open Pit OptimizationDocument6 pagesOpen Pit Optimizationdeim0No ratings yet

- Production SchedulingDocument35 pagesProduction SchedulingRohit Kumar100% (2)

- DagdelenDocument4 pagesDagdelenWashington BobadillaNo ratings yet

- 108 Yashar BlockCaveLiteratureReviewDocument19 pages108 Yashar BlockCaveLiteratureReviewAlexander ArdilesNo ratings yet

- Grasberg Block Cave Mine Cave Planning and UndercutDocument12 pagesGrasberg Block Cave Mine Cave Planning and Undercutalvaroaac4No ratings yet

- Cut-Off Grade Optimisation To Maximise The Net Present Value Using Whittle 4XDocument16 pagesCut-Off Grade Optimisation To Maximise The Net Present Value Using Whittle 4XMinangkabau BreederNo ratings yet

- 51 BellDocument12 pages51 BellBrian ChitemereNo ratings yet

- Resue Firing and Dilution Control in Narrow Vein MiningDocument3 pagesResue Firing and Dilution Control in Narrow Vein MiningMostafaOmid0% (1)

- Digitization of Long Hole StopingDocument15 pagesDigitization of Long Hole StopingkhaireddineNo ratings yet

- Mine PlanningDocument4 pagesMine PlanningDowney NaVithraNo ratings yet

- M2M Toromocho Site SAG Conference 2023 1699484174Document22 pagesM2M Toromocho Site SAG Conference 2023 1699484174vladimirNo ratings yet

- Chadwick 2011 MDocument5 pagesChadwick 2011 MalinoriNo ratings yet

- 2 PBDocument8 pages2 PBNaufal AgilNo ratings yet

- Mine Access Development Simulation Through Direct Mine Design Data IntegrationDocument12 pagesMine Access Development Simulation Through Direct Mine Design Data Integrationabercon mbedziNo ratings yet

- Increasing Underground Coal Mine Productivity Through A Training ProgramDocument10 pagesIncreasing Underground Coal Mine Productivity Through A Training ProgramDirceu NascimentoNo ratings yet

- 2019 11+Blast+Induced+Ore+Movement Poupeau+and+Hunt Mining+GeologyDocument23 pages2019 11+Blast+Induced+Ore+Movement Poupeau+and+Hunt Mining+GeologyJaime Francisco Aranibar LaguaNo ratings yet

- An Application of Branch and Cut To Open Pit Mine SchedulingDocument27 pagesAn Application of Branch and Cut To Open Pit Mine SchedulingALBERTUSNo ratings yet

- Open Cast Method and Its Application Prospect in Chinese Surface MinesDocument4 pagesOpen Cast Method and Its Application Prospect in Chinese Surface Minesrongow titoNo ratings yet

- Maptek Forge 3 2008Document6 pagesMaptek Forge 3 2008Kenny CasillaNo ratings yet

- Case Study - MineSched at SebukuDocument27 pagesCase Study - MineSched at SebukuBlank Kusuma100% (1)

- Pit To Plant - Current TrendsDocument6 pagesPit To Plant - Current Trendsretrospect1000No ratings yet

- The Application of Ipcc at The Moatize Coal Project: Rmccarthy@snowdengroup - CaDocument12 pagesThe Application of Ipcc at The Moatize Coal Project: Rmccarthy@snowdengroup - CaManuel Montenegro Pérez100% (1)

- Design and Dimensioning of Sublevel Stoping For ExDocument7 pagesDesign and Dimensioning of Sublevel Stoping For ExBwalya BwalyaNo ratings yet

- Design and Dimensioning of Sublevel Stoping For ExDocument6 pagesDesign and Dimensioning of Sublevel Stoping For ExJóse AntonioNo ratings yet

- 04 Application of The Minnovex Sag Power Index at Five Canadian PlantsDocument12 pages04 Application of The Minnovex Sag Power Index at Five Canadian PlantsPablo PapcNo ratings yet

- SPE 185420 MS Operational ExcellenceDocument14 pagesSPE 185420 MS Operational ExcellenceDeepak RanaNo ratings yet

- A Ventilation System For Large Block Cave MinesDocument7 pagesA Ventilation System For Large Block Cave MinesYojan Ccoa CcopaNo ratings yet

- Pit OptimisationDocument6 pagesPit OptimisationJuan Pablo Henríquez ValenciaNo ratings yet

- Paper 4 FaltaDocument11 pagesPaper 4 FaltaAntoni Carlos Castillo RodilNo ratings yet

- Enterprise OptimisationDocument13 pagesEnterprise OptimisationMarcos BuenoNo ratings yet

- SPE/IADC 67823 Through Tubing Well ConstructionDocument10 pagesSPE/IADC 67823 Through Tubing Well ConstructionzainalNo ratings yet

- A New Algorithm For Stope Boundary OptimizationDocument7 pagesA New Algorithm For Stope Boundary OptimizationMartin Pavez KentNo ratings yet

- Max OpenDocument16 pagesMax OpenSelamet ErçelebiNo ratings yet

- Activity 6 - DAHUYLADocument14 pagesActivity 6 - DAHUYLAJef Michael L. DahuylaNo ratings yet

- BOCCOST Data ModelingDocument6 pagesBOCCOST Data Modelingboanerges wino pattyNo ratings yet

- Integrated Sand Management For Effective Hydrocarbon Flow AssuranceFrom EverandIntegrated Sand Management For Effective Hydrocarbon Flow AssuranceNo ratings yet

- Minemax Scheduler White Paper PDFDocument12 pagesMinemax Scheduler White Paper PDFjaja_543No ratings yet

- Blending Module PDFDocument2 pagesBlending Module PDFjaja_543No ratings yet

- Quick Start Tutorial: Example - Dip FileDocument29 pagesQuick Start Tutorial: Example - Dip Filejaja_543No ratings yet

- Outotec en MMH PDFDocument24 pagesOutotec en MMH PDFjaja_543No ratings yet

- METSIM Brochure2 2009 PDFDocument40 pagesMETSIM Brochure2 2009 PDFjaja_5430% (1)

- Slope Stability Problem Session PDFDocument31 pagesSlope Stability Problem Session PDFjaja_543No ratings yet

- Diggability Assessment in Open Pit Mines: A Review: Mohammad Babaei KhorzoughiDocument29 pagesDiggability Assessment in Open Pit Mines: A Review: Mohammad Babaei KhorzoughiZuhaib ShaikhNo ratings yet

- MassMin 2008 PDFDocument1,159 pagesMassMin 2008 PDFCristobalNo ratings yet

- Geotechnical Aspects of Open Stope Design at BHP Cannington: G C StreetonDocument7 pagesGeotechnical Aspects of Open Stope Design at BHP Cannington: G C StreetonJuan PerezNo ratings yet

- April July LaycansDocument1 pageApril July LaycansKumar Jagannath SNo ratings yet

- Estimating Flyrock Distance in Bench Blasting Through Blast Induced Pressure Measurements in RockDocument8 pagesEstimating Flyrock Distance in Bench Blasting Through Blast Induced Pressure Measurements in RockM Arif Satrio AgungNo ratings yet

- Moncayo Integrated Small-Scale Mining Association vs. South East Mindanao Gold Mining CorporationDocument2 pagesMoncayo Integrated Small-Scale Mining Association vs. South East Mindanao Gold Mining CorporationJug HeadNo ratings yet

- Optimum Location and Relocation Plan of Semi-Mobile In-Pit Crushing and Conveying Systems in Open-Pit Mines by Transportation ProblemDocument22 pagesOptimum Location and Relocation Plan of Semi-Mobile In-Pit Crushing and Conveying Systems in Open-Pit Mines by Transportation ProblemMorteza ParichehNo ratings yet

- Analyses of Non Fatal Accidents in An Opencast Mine by Logistic Regression Model A Case Study PDFDocument11 pagesAnalyses of Non Fatal Accidents in An Opencast Mine by Logistic Regression Model A Case Study PDFDr-Rabia AlmamalookNo ratings yet

- Heat Treatment Online Notes PDFDocument10 pagesHeat Treatment Online Notes PDFSandeep KadamNo ratings yet

- Handbook To The New Gold-Fields by Ballantyne, R. M. (Robert Michael), 1825-1894Document56 pagesHandbook To The New Gold-Fields by Ballantyne, R. M. (Robert Michael), 1825-1894Gutenberg.orgNo ratings yet

- R. F. J. Jones and D. G. Bird - Roman Gold-Mining in North-West Spain, II Workings On The Rio DuernaDocument21 pagesR. F. J. Jones and D. G. Bird - Roman Gold-Mining in North-West Spain, II Workings On The Rio DuernaLuciusQuietusNo ratings yet

- EVA1 Javier RiveraDocument3 pagesEVA1 Javier RiveraJavier RiveraNo ratings yet

- Gold Dore BarsDocument2 pagesGold Dore BarsdaelingNo ratings yet

- Mine Planning and Mine Design, Consulting - RungePincockMinarco PDFDocument2 pagesMine Planning and Mine Design, Consulting - RungePincockMinarco PDFJenrykeCVNo ratings yet

- 047 Innovative Mining at GarpenbergDocument6 pages047 Innovative Mining at GarpenbergKenny CasillaNo ratings yet

- Daily Report - 280223 PDFDocument2 pagesDaily Report - 280223 PDFFeri Febrianas FeriNo ratings yet

- 28 Sme Mining Engineering HandbookDocument1 page28 Sme Mining Engineering HandbookYeimsNo ratings yet

- Sampling PDFDocument30 pagesSampling PDFNikhil SubarnoNo ratings yet

- บทที่ 3 Heat treatmentDocument24 pagesบทที่ 3 Heat treatmentParas gurungNo ratings yet

- 782-LS-M-001 A Equipment ListDocument2 pages782-LS-M-001 A Equipment ListSai krishnaNo ratings yet

- Improving Management of Potentially Acid Generating Waste RockDocument16 pagesImproving Management of Potentially Acid Generating Waste RockLuthfie QNo ratings yet

- December 2015Document92 pagesDecember 2015Kartik MorpariyaNo ratings yet

- The BHP Billiton Way April 2012Document16 pagesThe BHP Billiton Way April 2012mario5681100% (1)

- Tembang Operations Update: Sumatra Copper & Gold PLCDocument2 pagesTembang Operations Update: Sumatra Copper & Gold PLCAkhmedov CkhasanovNo ratings yet

- Saxon Miners in Serbian Medieval Laws and Written Textx StojkovicDocument6 pagesSaxon Miners in Serbian Medieval Laws and Written Textx Stojkovicgeorgeszs100% (1)

- BCG Report On Steel IndustryDocument40 pagesBCG Report On Steel IndustryAtif Ahmad Khan0% (1)

- Entire en SVK Ar22Document160 pagesEntire en SVK Ar22Gerardo MarquezNo ratings yet

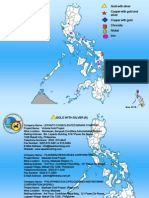

- Gold With Silver Copper With Gold and Silver Copper With Gold Chromite Nickel IronDocument17 pagesGold With Silver Copper With Gold and Silver Copper With Gold Chromite Nickel IronTin ReyesNo ratings yet

- San Nicolas 43-101 Report Dec 28 2005 Roscoe PostleDocument74 pagesSan Nicolas 43-101 Report Dec 28 2005 Roscoe PostleYvan Rolando Hurtado GuerreroNo ratings yet