Professional Documents

Culture Documents

Weldkg

Uploaded by

alokbdas0 ratings0% found this document useful (0 votes)

142 views5 pagesThe document provides information for estimating welding times and weights for various welding processes, materials, and joint configurations including long seam, circular seam, single V, compound V, backing strip, and J-groove welds. Parameters specified include welding process, material type, dimensions, thickness, welding positions, and whether preheating is required. Charts provide welding time estimates in minutes for various welding configurations based on these parameters.

Original Description:

weld

Original Title

weldkg

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides information for estimating welding times and weights for various welding processes, materials, and joint configurations including long seam, circular seam, single V, compound V, backing strip, and J-groove welds. Parameters specified include welding process, material type, dimensions, thickness, welding positions, and whether preheating is required. Charts provide welding time estimates in minutes for various welding configurations based on these parameters.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

142 views5 pagesWeldkg

Uploaded by

alokbdasThe document provides information for estimating welding times and weights for various welding processes, materials, and joint configurations including long seam, circular seam, single V, compound V, backing strip, and J-groove welds. Parameters specified include welding process, material type, dimensions, thickness, welding positions, and whether preheating is required. Charts provide welding time estimates in minutes for various welding configurations based on these parameters.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

You are on page 1of 5

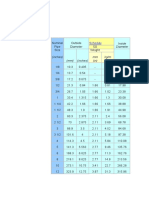

LONG SEAM/ CIRC SEAM WELD KG & RUN TIME ESTIMATION

DOUBLE 'V' PARAMETERS SETTING

PROCESS HRS/KG

q= 45 1). SMAW 2.67

2). SAW (C/S) 0.44

(L/S) 0.53

3). FCAW 2

4). GTAW 10

R.F.= 2

LG OF LONG SEAM= 3000

MATERIAL (SS/STEEL)= STEEL

= 60 DENSITY= 0.00000785 1). 1G

2). 2G

3 3). 3G

ALL DIMENSIONS ARE IN MM

CROSS SEC. AREA TOTAL WELD KG

YES

O/S WELDING= NO

C/B WELDING=

TOTAL WELDING=

THK <= 30 6

THK > 30 12

RUN TIME

(min)

20% 1 2.67 1 1.0 Y 1.5 1015.4

80% 2 0.53 1 1.0 Y 1.5 806.2

100% 2 0.53 1 1.0 N 1 362.9

RUN TIME TIME REQUIRED FOR

L/SEAM OR C/SEAM (LS/CS)= LS

40.0

18

THK= 60

1381.8

POSITION

MULTIPLICATION

FACTOR

OUTSIDE ROOT RUN

CHIP BACK WELDING

POSITION OF

WELDING

MULTIPLICATION

FACTOR

OUT SIDE BALANCE

CODE CODE

897.2

484.6

1 21.1

11.4

CHIP BACK DEPTH(MM) 32.5

R.G.=

LONG SEAM

1

1.1

1.6

1.5

HEATING

(Y/N)

PREHEATING

REQUIRED? (Y/N)

PROCESS

228378000.xls.ms_office 5/14/2014

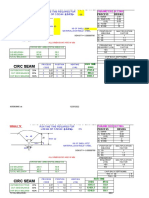

LONG SEAM/CIRC SEAM WELD KG & RUN TIME ESTIMATION

SINGLE 'V' PARAMETERS SETTING

PROCESS HRS/KG

1). SMAW 2.67

2). SAW (C/S) 0.44

q= 70 (L/S) 0.53

3). FCAW 2

4). GTAW 10

R.F.= 2

I/D OF SHELL 1000

MATERIAL (SS/STEEL)= STEEL

R.G.= 3

DENSITY= 0.00000785 1). 1G

2). 2G

3). 3G

ALL DIMENSIONS ARE IN MM

CROSS SEC. AREA TOTAL WELD KG

YES

O/S WELDING= NO

C/B WELDING=

TOTAL WELDING=

THK <= 30 6

THK > 30 12

(min) (Hrs)

20% 1 2.67 1 1.0 Y 1.5 449.1 7.5

80% 1 2.67 1 1.0 Y 1.5 1796.4 29.9

100% 1 2.67 1 1.0 Y 1.5 559.4 9.3

TOTAL WELDING= 46.7

RUN TIME TIME REQUIRED FOR

L/SEAM OR C/SEAM (LS/CS)= CS

371.5

1.6

PREHEATING

REQUIRED?

MULTIPLICATION

FACTOR

1.5

MULTIPLICATION

FACTOR

1

THK= 20

18

9.3

1.1

PROCESS POSITION

11.7 464.0

92.5 2.3

1

RUN TIME

POSITION OF

WELDING

CHIP BACK DEPTH(MM)

OUT SIDE BALANCE

CHIP BACK WELDING

CIRC SEAM CODE

OUTSIDE ROOT RUN

CODE (Y/N)

HEATING

228378000.xls.ms_office 5/14/2014

LONG SEAM/CIRC SEAM WELD KG & RUN TIME ESTIMATION

COMPOUND 'V' PARAMETERS SETTING

PROCESS HRS/KG

= 10 1). SMAW 2.67

2). SAW (C/S) 0.44

(L/S) 0.53

3). FCAW 2

q= 45 4). GTAW 10

I/D OF SHELL 2600

MATERIAL (SS/STEEL)= STEEL

R.F.= 2

DENSITY= 0.00000785 1). 1G

2). 2G

R.G.= 3 3). 3G

ALL DIMENSIONS ARE IN MM

CROSS SEC. AREA TOTAL WELD KG

YES

O/S WELDING= NO

C/B WELDING=

TOTAL WELDING=

THK <= 30 6

THK > 30 12

RUN TIME

(min)

20% 1 2.67 1 1.0 Y 1.5 3699.2

80% 2 0.44 1 1.0 Y 1.5 2438.4

100% 2 0.44 1 1.0 Y 1.5 482.6

OUTSIDE ROOT RUN

OUT SIDE BALANCE

CHIP BACK WELDING

77.0 1168.9

185.1

1354.0

12.2

89.2

CIRC SEAM

PROCESS POSITION

1.5

1

HEATING

CODE CODE (Y/N)

CHIP BACK DEPTH(MM)

RUN TIME TIME REQUIRED FOR

L/SEAM OR C/SEAM (LS/CS)= CS

POSITION OF

WELDING

MULTIPLICATION

FACTOR

THK= 70

56

12

1

1.1

1.6

PREHEATING

REQUIRED?

MULTIPLICATION

FACTOR

228378000.xls.ms_office 5/14/2014

LONG SEAM/CIRC SEAM WELD KG & RUN TIME ESTIMATION

BACKING STRIP PARAMETERS SETTING

PROCESS HRS/KG

q= 2 1). SMAW 2.67

2). SAW (C/S) 0.44

(L/S) 0.53

3). FCAW 2

LG OF LONG SEAM= 2600

R.G.= MATERIAL (SS/STEEL)= STEEL

18

DENSITY= 0.00000785 1). 1G

2). 2G

3). 3G

ALL DIMENSIONS ARE IN MM

YES

O/S WELDING= NO

C/B WELDING=

TOTAL WELDING=

THK <= 30 6

THK > 30 12

RUN TIME

(min)

0% 1 2.67 1 1.0 Y 1.5 0.0

100% 2 0.53 1 1.0 Y 1.5 1369.7

100% 2 0.53 1 1.0 Y 1.5 1551.6

TOTAL WELD KG CROSS SEC. AREA

28.7

1406.9

1593.7

1406.9

28.7

32.5

OUTSIDE ROOT RUN

OUT SIDE BALANCE

CHIP BACK WELDING

1

LONG SEAM

PROCESS POSITION HEATING

CODE CODE (Y/N)

1.6

PREHEATING

REQUIRED?

MULTIPLICATION

FACTOR

1.5

CHIP BACK DEPTH(MM)

RUN TIME TIME REQUIRED FOR

L/SEAM OR C/SEAM (LS/CS)= ls

POSITION OF

WELDING

MULTIPLICATION

FACTOR

1

1.1

70 THK=

228378000.xls.ms_office 5/14/2014

LONG SEAM/CIRC SEAM WELD KG & RUN TIME ESTIMATION

J GROOVE

HRS/KG

= 1 2.67

0.44

0.53

2

10

I/D OF SHELL 2600

R= 12 MATERIAL (SS/STEEL)= STEEL

R.F.= 0

DENSITY= 0.00000785 1). 1G

2). 2G

R.G.= 2 3). 3G

ALL DIMENSIONS ARE IN MM

TOTAL WELD KG

YES

O/S WELDING= NO

C/B WELDING=

TOTAL WELDING=

THK <= 30 6

THK > 30 12

RUN TIME

(min)

20% 1 2.67 1 1.0 Y 1.5 7694.7

80% 2 0.44 1 1.0 Y 1.5 5072.2

100% 2 0.44 1 1.0 Y 1.5 783.4

160.1

OUT SIDE BALANCE

CHIP BACK WELDING

HEATING

CODE CODE (Y/N)

POSITION

2413.4

OUTSIDE ROOT RUN

2711.6

CIRC SEAM

PROCESS

179.9

11.9

THK= 90

19.8

PROCESS

1). SMAW

2). SAW (C/S)

(L/S)

298.2

RUN TIME TIME REQUIRED FOR

L/SEAM OR C/SEAM (LS/CS)= CS

CROSS SEC. AREA

CHIP BACK DEPTH(MM)

POSITI

ON OF

MULTIPLICATION

FACTOR

1

1.1

PARAMETERS SETTING

78.1

1.6

PREHE

ATING

MULTIPLICATION

FACTOR

1.5

1

3). FCAW

4). GTAW

228378000.xls.ms_office 5/14/2014

You might also like

- Welding CalculatorDocument10 pagesWelding Calculatorneel0% (2)

- Sa 516 GR 70 WPSDocument5 pagesSa 516 GR 70 WPSRajesh Owaiyar71% (7)

- Welding CalculationsDocument14 pagesWelding Calculationsjitulpatil100% (6)

- Pressure Vessel CertificationDocument4 pagesPressure Vessel CertificationalokbdasNo ratings yet

- Inspection and Test Plan For Shell and Tube Heat ExchangerDocument6 pagesInspection and Test Plan For Shell and Tube Heat ExchangertomychalilNo ratings yet

- Report Mig 23DKM12F1022 ShammirDocument16 pagesReport Mig 23DKM12F1022 ShammirMuhd Shammir86% (14)

- Weld WeightDocument10 pagesWeld WeightDivyesh PatelNo ratings yet

- Welding CalculationDocument32 pagesWelding CalculationDenial Basanovic100% (1)

- Long Seam/Circ Seam Weld KG & Run Time EstimationDocument16 pagesLong Seam/Circ Seam Weld KG & Run Time EstimationTiago FerreiraNo ratings yet

- Weld CalculationDocument34 pagesWeld CalculationAshwani DograNo ratings yet

- How To Calculate Filler MetalDocument3 pagesHow To Calculate Filler MetalEdgar Coavas PérezNo ratings yet

- Weld CostsDocument2 pagesWeld CostsJina Chandran100% (1)

- Double V Weld CalculationDocument8 pagesDouble V Weld CalculationHgagselim SelimNo ratings yet

- Electrodes CalculatorDocument2 pagesElectrodes CalculatorAsebaho Badr100% (1)

- Weld Cost CalculationDocument15 pagesWeld Cost CalculationMustafa KaramürselNo ratings yet

- Determining The Cost of WeldingDocument22 pagesDetermining The Cost of WeldingSanjay J NNo ratings yet

- 07 Piping BOQDocument54 pages07 Piping BOQHRK65No ratings yet

- Weld Consumable CalculatorDocument7 pagesWeld Consumable CalculatoretienetergolinoNo ratings yet

- Weld Metal Cost Calculator 3Document1 pageWeld Metal Cost Calculator 3Naresh Tammineedi100% (1)

- Welding Cost Estimation For 12 Joints in 8 NPS SCH 80 PDFDocument1 pageWelding Cost Estimation For 12 Joints in 8 NPS SCH 80 PDFAnonymous VRspXsmNo ratings yet

- Cross Section Area in MM: Enter The THK-T in MM Enter The Deg-DDocument7 pagesCross Section Area in MM: Enter The THK-T in MM Enter The Deg-DAnas MaliyekkalNo ratings yet

- Electrode CalculationDocument2 pagesElectrode CalculationKenshin HimuraNo ratings yet

- Introduction To Cost EstimatingDocument22 pagesIntroduction To Cost EstimatingArwa HusseinNo ratings yet

- ANSI B36.10 Steel PipesDocument8 pagesANSI B36.10 Steel Pipesphoneme79No ratings yet

- Operating FactorDocument9 pagesOperating Factormekhman mekhtyNo ratings yet

- Welding CalculationDocument16 pagesWelding CalculationbrintopvNo ratings yet

- Welding Rod Cal (1) .Document7 pagesWelding Rod Cal (1) .hakr5100% (1)

- Imperial Piping Weight Load Calculation WorkbookDocument13 pagesImperial Piping Weight Load Calculation WorkbookKakoDa100% (1)

- Weld CalculationsDocument12 pagesWeld Calculationshakr5100% (1)

- Fasteners WeightDocument4 pagesFasteners Weightpbp2956No ratings yet

- Weld Metal Calculation 1Document6 pagesWeld Metal Calculation 1Nabihah NurulhudaNo ratings yet

- Weld Consumable Calculator ComDocument7 pagesWeld Consumable Calculator Comchetan85No ratings yet

- A Guide To Estimating The Consumption of Welding Consumables-NADocument1 pageA Guide To Estimating The Consumption of Welding Consumables-NAManuel Antonio Santos VargasNo ratings yet

- Demo Weld Cost Calc XLDocument10 pagesDemo Weld Cost Calc XLKhalid Ahmod ShibleeNo ratings yet

- Weld CalculationDocument7 pagesWeld CalculationDenny Syamsuddin100% (1)

- Weld Consumable CalculatorDocument3 pagesWeld Consumable CalculatorramausNo ratings yet

- QAQC References 2Document138 pagesQAQC References 2Mohd SharainiNo ratings yet

- Welding and Fabrication NoteDocument54 pagesWelding and Fabrication NoteluminiousNo ratings yet

- Fit-Up Inspection Report: Location: Weld Type Equipment Description: Date: Report No.: SystemDocument1 pageFit-Up Inspection Report: Location: Weld Type Equipment Description: Date: Report No.: SystemAnonymous 0rt9KWmNNo ratings yet

- Welding Cost, Economics - GMAW & MMAW Process & QualityDocument6 pagesWelding Cost, Economics - GMAW & MMAW Process & Qualityratneshkumar2004No ratings yet

- Weld Cost Calc XLDocument63 pagesWeld Cost Calc XLRobert WhitakerNo ratings yet

- Cost Calculation Program For Productivity in WeldingDocument20 pagesCost Calculation Program For Productivity in WeldingiyigunNo ratings yet

- Weld Metal CalculationDocument1 pageWeld Metal CalculationKiukStaksNo ratings yet

- Pipe Schedule Reference ChartDocument10 pagesPipe Schedule Reference ChartRamadossK100% (1)

- Weight CalculatorDocument2 pagesWeight CalculatorenjoygurujiNo ratings yet

- Determinacion de Los Costos de Soldadura para Union de FileteDocument26 pagesDeterminacion de Los Costos de Soldadura para Union de Filetegraci2828No ratings yet

- Mild Steel Welding ElectrodeDocument12 pagesMild Steel Welding ElectrodeVĩnh NguyễnNo ratings yet

- Pipe DataDocument1 pagePipe Dataakhilsyam21No ratings yet

- Machining Symbol 1Document8 pagesMachining Symbol 1Prasanna RajaNo ratings yet

- Welding CalculationsDocument16 pagesWelding Calculationsmt92606222100% (2)

- Dynamic Behavior of Jack-Up ISOPE10Document36 pagesDynamic Behavior of Jack-Up ISOPE10Imran Siddiqui100% (1)

- Long Seam: Long Seam/Circ Seam Weld KG & Run Time EstimationDocument14 pagesLong Seam: Long Seam/Circ Seam Weld KG & Run Time EstimationmhsalihNo ratings yet

- Circ Seam: Long Seam/ Circ Seam Weld KG & Run Time EstimationDocument10 pagesCirc Seam: Long Seam/ Circ Seam Weld KG & Run Time EstimationpelotoNo ratings yet

- Weld Weight 1Document2 pagesWeld Weight 1francisco zepedaNo ratings yet

- EISA504 IMO9471886 Preliminary Test ConditionsRev2 57334319 57226253Document93 pagesEISA504 IMO9471886 Preliminary Test ConditionsRev2 57334319 57226253islimaNo ratings yet

- Lifting LugDocument24 pagesLifting LugMas Arman Tewo100% (6)

- Lifting LugDocument8 pagesLifting LugAzwan ShahNo ratings yet

- Gantry Girder UnprotectedDocument95 pagesGantry Girder Unprotectedjignesh14283% (12)

- Welding CalculationDocument5 pagesWelding CalculationBWQNo ratings yet

- Mk2+ Dual Wallform To Retaining Wall: Shade CorporationDocument15 pagesMk2+ Dual Wallform To Retaining Wall: Shade CorporationJuan Dela CruzNo ratings yet

- Padeye Calculation For Anchor Block R0 20140722Document3 pagesPadeye Calculation For Anchor Block R0 20140722subucwiNo ratings yet

- Connection Foot Bridge 44.5m Mail 1Document42 pagesConnection Foot Bridge 44.5m Mail 1Er Navneet JassiNo ratings yet

- Ice Loading Effect - Sag TensionDocument32 pagesIce Loading Effect - Sag TensionAnupam0103100% (1)

- Skirt Support TrialDocument11 pagesSkirt Support TrialAbhishek Nag50% (2)

- Vessel Pressure TestingDocument3 pagesVessel Pressure Testingalokbdas100% (1)

- ASME Pressure Vessel Joint EfficienciesDocument5 pagesASME Pressure Vessel Joint EfficienciesalokbdasNo ratings yet

- Spherical Pressure VesselDocument4 pagesSpherical Pressure VesselalokbdasNo ratings yet

- Inspection and Test Plan For Pressure VesselDocument2 pagesInspection and Test Plan For Pressure Vesselalokbdas50% (2)

- Pressure Vessel RT TestDocument4 pagesPressure Vessel RT TestalokbdasNo ratings yet

- Pressure Vessel DefinitionDocument3 pagesPressure Vessel DefinitionalokbdasNo ratings yet

- Pressure VesselDocument16 pagesPressure VesselAzhar AliNo ratings yet

- Saddle AnalysisDocument17 pagesSaddle AnalysisAntonio Perez Zornoza100% (1)

- Dimensions of Welded and Seamless Pipe: Nominal Wall ThicknessDocument2 pagesDimensions of Welded and Seamless Pipe: Nominal Wall ThicknessalokbdasNo ratings yet

- Pressure Vessel Dimension InspectionDocument12 pagesPressure Vessel Dimension Inspectionalokbdas100% (3)

- Inspection and Test Plan For Shell and Tube Heat ExchangerDocument2 pagesInspection and Test Plan For Shell and Tube Heat Exchangeralokbdas100% (1)

- Equipment Design (Week 5) : Dr. H.B. VuthaluruDocument146 pagesEquipment Design (Week 5) : Dr. H.B. Vuthalurualokbdas100% (2)

- Heat Exchanger InspectionDocument11 pagesHeat Exchanger InspectionVivek Bhangale100% (1)

- Calculation Is Based On ASME Section VIII Division 2 Part 4 - 2011 EditionDocument1 pageCalculation Is Based On ASME Section VIII Division 2 Part 4 - 2011 EditionvpjagannaathNo ratings yet

- Test Ring Calculation (Based On L&T Std. (6249-Lt-Eq-00-Od-0004 - Rev-1) )Document7 pagesTest Ring Calculation (Based On L&T Std. (6249-Lt-Eq-00-Od-0004 - Rev-1) )alokbdasNo ratings yet

- API 650 Tank Shell Evaluation Rev 3Document31 pagesAPI 650 Tank Shell Evaluation Rev 3alokbdasNo ratings yet

- MIG Welding: Lab Report ME-223 Advance Workshop PracticeDocument2 pagesMIG Welding: Lab Report ME-223 Advance Workshop PracticeMomina ShakeelNo ratings yet

- WIS5 (Sept 19) - NotesDocument321 pagesWIS5 (Sept 19) - NotesRodrigo CelesNo ratings yet

- Cblm-Smaw-Nc IiDocument80 pagesCblm-Smaw-Nc IiERIC NARAGANo ratings yet

- (Welding) ANSI-AWS Standard A5.9-1993 - Specification For Bare Stainless Steel Welding ElectrodDocument33 pages(Welding) ANSI-AWS Standard A5.9-1993 - Specification For Bare Stainless Steel Welding ElectrodAna Quintana100% (1)

- NTTC R3 PDFDocument72 pagesNTTC R3 PDFAJ AcuñaNo ratings yet

- Resistance Welding ProcessesDocument63 pagesResistance Welding ProcessesJay DaveNo ratings yet

- AHU ManualDocument17 pagesAHU ManualwolfzemunNo ratings yet

- Aws Form E-9 Stud Welding Procedure Specification (WPS) or Procedure Qualification Record (PQR) or Welder Qualification Record (WQR) 000 PDFDocument1 pageAws Form E-9 Stud Welding Procedure Specification (WPS) or Procedure Qualification Record (PQR) or Welder Qualification Record (WQR) 000 PDFrajNo ratings yet

- Saudi Aramco Inspection Checklist: Inprocess Welding Inspection - Offshore Structures SAIC-W-1313 WeldDocument1 pageSaudi Aramco Inspection Checklist: Inprocess Welding Inspection - Offshore Structures SAIC-W-1313 Weldkartik_harwani4387No ratings yet

- Presentation Induction Heater Plant in Moscow Russia 2020Document21 pagesPresentation Induction Heater Plant in Moscow Russia 2020HIRENNo ratings yet

- Long Test in SmawDocument4 pagesLong Test in SmawTeacher Ronel SDO NavotasNo ratings yet

- Aws QCDocument111 pagesAws QCPIERRONNo ratings yet

- LG WiredController PREMTB10UDocument76 pagesLG WiredController PREMTB10UJay SmetanaNo ratings yet

- Gedik Kaynak - Gedik WeldingDocument4 pagesGedik Kaynak - Gedik Weldinga4140110No ratings yet

- Chapter 8 AISC05 11192018Document18 pagesChapter 8 AISC05 11192018saiye.w58 RSUNo ratings yet

- Btu Room 2 TuvDocument13 pagesBtu Room 2 TuvmsharoookNo ratings yet

- ACCORDING TO EN ISO 9606-1:2013: ISO 9606-1 Ss NB 141 T BW Fm4 S s3.6 D60 PHDocument1 pageACCORDING TO EN ISO 9606-1:2013: ISO 9606-1 Ss NB 141 T BW Fm4 S s3.6 D60 PHAnup SharmaNo ratings yet

- December 2013 Registry of Competent Worker of Sultan Kudarat ProvinceDocument24 pagesDecember 2013 Registry of Competent Worker of Sultan Kudarat Provincetesdaro12No ratings yet

- EH Manual EnglishDocument6 pagesEH Manual EnglishHasan CosalevNo ratings yet

- Form Welding Summary and Material Traceability Record - Piping TuhupDocument6 pagesForm Welding Summary and Material Traceability Record - Piping TuhupYuwantoniAlNo ratings yet

- Soldadura y WEDM y SEDMDocument7 pagesSoldadura y WEDM y SEDMdestroy4679No ratings yet

- Welding Presentation AESDocument31 pagesWelding Presentation AEScharlessimoNo ratings yet

- Shielded Metal Arc WeldingDocument4 pagesShielded Metal Arc WeldingLloyd AlmonteNo ratings yet

- Aws A5.5 - 96 PDFDocument55 pagesAws A5.5 - 96 PDFRichard Nelson Antonio EspinozaNo ratings yet

- Weld Imperfection Examination StandardDocument4 pagesWeld Imperfection Examination StandardMohd Akmal ShafieNo ratings yet

- WPS PQR-02Document8 pagesWPS PQR-02Ranjan Kumar100% (1)

- Grove WeldDocument12 pagesGrove WeldPratamaditya DiditNo ratings yet

- Welding 2 PDFDocument7 pagesWelding 2 PDFPratyush BhattacharyaNo ratings yet