Professional Documents

Culture Documents

Long seam weld estimation

Uploaded by

mhsalihOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Long seam weld estimation

Uploaded by

mhsalihCopyright:

Available Formats

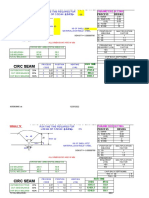

LONG SEAM/CIRC SEAM WELD KG & RUN TIME ESTIMATION

SINGLE 'V' RUN TIME TIME REQUIRED FOR PARAMETERS SETTING

L/SEAM OR C/SEAM (LS/CS)= LS PROCESS KG/SHIFT HRS/KG

1). SMAW 1.6 5.00

2). SAW (C/S) 25 0.32

q= 60 (L/S) 15 0.53

8

THK= 10 3).FCAW (1.2 ) 4.5 1.78

4). GTAW 0.8 10.00

R.F.= 2 LG OF LONG SEAM= 600

MATERIAL (SS/STEEL)= STEEL

R.G.= 2 POSITION OF MULTIPLICATION

DENSITY= 0.00000785 WELDING FACTOR

1). 1G 1

2). 2G 1.6

3). 3G 1.3

4). 4G 1.8

ALL DIMENSIONS ARE IN MM

LESS- MULTIPLICATION

CROSS SEC. AREA TOTAL WELD KG ACCESSIBLE FACTOR

ROOT RUN= 36.8 0.2 YES 2

O/S WELDING= 52.0 0.2 NO 1

C/B WELDING= 104.5 0.5

TOTAL WELDING= 156.6 0.7 CHIP BACK DEPTH(MM)

THK <= 30 6

THK > 30 12

PROCESS POSITION ACCESSIBLE LESSCALCULATED RUN TIME TO BE CONSIDERED

LONG SEAM CODE CODE (Y/N) (min) (Hrs) (Hrs)

OUTSIDE ROOT RUN 100% 1 5 1 1.0 Y 2 104.0 1.7 2.0

OUT SIDE BALANCE 100% 2 0.53 1 1.0 Y 2 15.7 0.3 2.0

CHIP BACK WELDING 100% 1 5 2 1.6 Y 2 472.7 7.9 7.9

TOTAL = 592.4 9.9 11.9

151198161.xls.ms_office, LSSINGLEV, 6/11/2013 PAGE 1 OF 14

LONG SEAM/CIRC SEAM WELD KG & RUN TIME ESTIMATION

SINGLE 'V' RUN TIME TIME REQUIRED FOR PARAMETERS SETTING

L/SEAM OR C/SEAM (LS/CS)= ls PROCESS KG/SHIFT HRS/KG

1). SMAW 1.6 5.00

q= 2). SAW (C/S) 25 0.32

45 (L/S) 15 0.53

6

THK= 6 3).FCAW (1.2 ) 4.5 1.78

4). GTAW 0.8 10.00

R.F.= 0 LG OF LONG SEAM= 3200

MATERIAL (SS/STEEL)= STEEL

R.G.= 1 POSITION OF MULTIPLICATION

DENSITY= 0.00000785 WELDING FACTOR

1). 1G 1

2). 2G 1.6

3). 3G 1.3

4). 4G 1.8

ALL DIMENSIONS ARE IN MM

LESS- MULTIPLICATION

CROSS SEC. AREA TOTAL WELD KG ACCESSIBLE FACTOR

ROOT RUN= 21.3 0.5 YES 2

O/S WELDING= 28.2 0.7 NO 1

C/B WELDING= 104.5 2.6

TOTAL WELDING= 132.8 3.3 CHIP BACK DEPTH(MM)

THK <= 30 6

THK > 30 12

PROCESS POSITION ACCESSIBLE LESSCALCULATED RUN TIME TO BE CONSIDERED

LONG SEAM CODE CODE (Y/N) (min) (Hrs) (Hrs)

OUTSIDE ROOT RUN 100% 1 5 1 1.0 Y 2 320.4 5.3 5.3

OUT SIDE BALANCE 100% 2 0.53 1 1.0 Y 2 45.4 0.8 2.0

CHIP BACK WELDING 100% 1 5 2 1.6 Y 2 2521.2 42.0 42.0

TOTAL = 2887.0 48.1 49.4

151198161.xls.ms_office, LSSINGLEV (2), 6/11/2013 PAGE 2 OF 14

LONG SEAM/ CIRC SEAM WELD KG & RUN TIME ESTIMATION

DOUBLE 'V' RUN TIME TIME REQUIRED FOR PARAMETERS SETTING

L/SEAM OR C/SEAM (LS/CS)= LS PROCESS KG/SHIFT HRS/KG

q= 45 1). SMAW 1.6 5.00

2). SAW (C/S) 25 0.32

(L/S) 15 0.53

60.0

3).FCAW (1.2 ) 4.5 1.78

THK= 90 4). GTAW 0.8 10.00

R.F.= 2 LG OF LONG SEAM= 995

MATERIAL (SS/STEEL)= STEEL

28.0

POSITION OF MULTIPLICATION

= 60 DENSITY= 0.00000785 WELDING FACTOR

1). 1G 1

R.G.= 3 2). 2G 1.6

ALL DIMENSIONS ARE IN MM 3). 3G 1.3

3). 4G 1.3

LESS- MULTIPLICATION

CROSS SEC. AREA TOTAL WELD KG ACCESSIBLE FACTOR

ROOT RUN= 38.9 0.3 YES 2

O/S WELDING= 1732.3 13.5 NO 1

C/B WELDING= 746.8 5.8

TOTAL WELDING= 2479.2 19.4 CHIP BACK DEPTH(MM)

THK <= 30 6

THK > 30 12

PROCESS POSITION CALCULATED

ACCESSIBLE LESS RUN TIME TO BE CONSIDERED

LONG SEAM CODE CODE (Y/N) (min) (Hrs) (Hrs)

OUTSIDE ROOT RUN 100% 1 5 2 1.6 Y 2 291.8 4.9 4.9

OUT SIDE BALANCE 100% 1 5 1 1.0 Y 2 8118.4 135.3 135.3

CHIP BACK WELDING 100% 1 5 1 1.0 Y 2 3500.0 58.3 58.3

TOTAL = 11910.2 198.5 198.5

151198161.xls.ms_office, LSDOUBLEV, 6/11/2013 PAGE 3 OF 14

LONG SEAM/CIRC SEAM WELD KG & RUN TIME ESTIMATION

COMPOUND 'V' RUN TIME TIME REQUIRED FOR PARAMETERS SETTING

L/SEAM OR C/SEAM (LS/CS)= CS PROCESS KG/SHIFT HRS/KG

= 10 1). SMAW 1.6 5.00

2). SAW (C/S) 25 0.32

56 (L/S) 15 0.53

3).FCAW (1.2 ) 4.5 1.78

q= 45 THK= 70 4). GTAW 0.8 10.00

I/D OF SHELL 2600

12 MATERIAL (SS/STEEL)= STEEL

POSITION OF MULTIPLICATION

R.F.= 2 DENSITY= 0.00000785 WELDING FACTOR

1). 1G 1

R.G.= 3 2). 2G 1.6

ALL DIMENSIONS ARE IN MM 3). 3G 1.3

4). 4G 1.8

LESS- MULTIPLICATION

CROSS SEC. AREA TOTAL WELD KG ACCESSIBLE FACTOR

ROOT RUN= 38.9 2.5 YES 2

O/S WELDING= 1110.9 73.1 NO 1

C/B WELDING= 259.2 17.1

TOTAL WELDING= 1370.1 90.2 CHIP BACK DEPTH(MM)

THK <= 30 6

THK > 30 12

PROCESS POSITION ACCESSIBLE LESSCALCULATED RUN TIME TO BE CONSIDERED

CIRC SEAM CODE CODE (Y/N) (min) (Hrs) (Hrs)

OUTSIDE ROOT RUN 100% 1 5 1 1.0 Y 2 1497.0 25.0 25.0

OUT SIDE BALANCE 100% 2 0.32 1 1.0 Y 2 2808.9 46.8 46.8

CHIP BACK WELDING 100% 2 0.32 1 1.0 Y 2 655.4 10.9 10.9

TOTAL = 4961.3 82.7 82.7

151198161.xls.ms_office, LSCOMPOUND, 6/11/2013 PAGE 4 OF 14

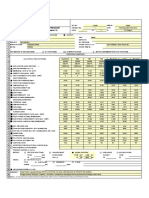

NOZZLE WELD KG & RUN TIME ESTIMATION

SINGLE 'V' NOZZLE ON SHELL/DEND) (D/S) ? S PARAMETERS SETTING

PROCESS KG/SHIFT HRS/KG

CFW= 10 MATERIAL (SS/STEEL)= STEEL 1). SMAW 1.6 5.00

INC. ANG=45 2). SAW 15 0.53

DENSITY= 7.85E-06 3). FCAW (1.2 ) 4.5 1.78

4). GTAW 0.8 10.00

NOZZLE O/D= OFF SET=

60 0

POSITION OF MULTIPLICATION

THK= 26

WELDING FACTOR

R.F.= 2 1). 1G 1

2). 2G

SHELL I/D=

1.6

R.G= 3). 3G 1.3

4300

4 NOZ O/D

60 LESS MULTIPLICATION

ACCESSIBLE FACTOR

YES 2

ELLIPSE DIMENSION NO 1

WEIGHT CROSS SEC. WELD KG

MAJOR AXIS= 64.0 CALCULATION AREA ON SHELL ON D/END CHIP BACK DEPTH(MM)

MINOR AXIS= 64 ROOT RUN= 39.5 0.06 0.06 THK <= 30 6

LG. OF WELDING= 201.07 O/S WELDING= 298.54 0.47 0.47 THK > 30 12

C/B WELDING= 56.55 0.09 0.09

TOTAL WELDING= 0.56 0.56

PROCESS POSITION CALCULATED RUN TIME TO BE CONSIDERED

ON SHELL CODE CODE ACCESSIBLE LESS (Y/N) (min) (Hrs) (Hrs)

OUTSIDE ROOT RUN 100% 1 5 1 1.0 Y 2 282.7 4.7 4.7

OUT SIDE BALANCE 100% 1 5 1 1.0 Y 2 282.7 4.7 4.7

CHIP BACK WELDING 100% 1 5 1 1.0 Y 2 53.6 0.9 2.0

TOTAL = 619.0 10.3 11.4

151198161.xls.ms_office, NOZSINGLEV, 6/11/2013 PAGE 5 OF 14

NOZZLE WELD KG & RUN TIME ESTIMATION

DOUBLE 'V' NOZZLE ON SHELL/DEND) (D/S) ? D PARAMETERS SETTING

50 PROCESS KG/SHIFT HRS/KG

MATERIAL (SS/STEEL)= STEEL 1). SMAW 1.6 5.00

INC. ANG= 60 2). SAW 15 0.53

50 DENSITY= 7.85E-06 3).FCAW (1.2 ) 4.5 1.78

4). GTAW 0.8 10.00

NOZZLE O/D= OFF SET=

60 653 500

POSITION OF MULTIPLICATION

THK= 90 R.F.= 2 WELDING FACTOR

1). 1G 1

28

2). 2G 1.6

10 3). 3G 1.3

SHELL I/D=

10 NOZ O/D

2450

R.G= 653 LESS MULTIPLICATION

3 ACCESSIBLE FACTOR

INC. ANG= 45 YES 2

ELLIPSE DIMENSION NO 1

WEIGHT WELD KG

MAJOR AXIS= 736.6 CALCULATION CROSS SEC. AREA ON SHELL ON D/END CHIP BACK DEPTH(MM)

MINOR AXIS= 656 ROOT RUN= 34.4 1.18 0.56 THK <= 30 6

LG. OF WELDING= 4382.427 O/S WELDING= 4519.30 155.47 73.11 THK > 30 12

C/B WELDING= 752.19 25.88 12.17

TOTAL WELDING= 181.35 85.28

PROCESS POSITION ACCESSIBLE LESS CALCULATED RUN TIME TO BE CONSIDERED

ON D/END CODE CODE (Y/N) (min) (Hrs) (Hrs)

OUTSIDE ROOT RUN 100% 2 0.53 1 1.0 Y 2 4679.2 78.0 78.0

OUT SIDE BALANCE 100% 1 5 2 1.6 Y 2 70188.5 1169.8 1169.8

CHIP BACK WELDING 100% 1 5 2 1.6 Y 2 11682.2 194.7 194.7

TOTAL = 86549.9 1442.5 1442.5

151198161.xls.ms_office, NOZDOUBLEV (2), 6/11/2013 PAGE 6 OF 14

NOZZLE WELD KG & RUN TIME ESTIMATION

SET ON NOZZLE IN SHELL/DEND) (D/S) ? S PARAMETERS SETTING

PROCESS KG/SHIFT HRS/KG

60 19.5 NOZ I/D MATERIAL (SS/STEEL)= STEEL 1). SMAW 1.6 5.00

2). SAW 15 0.53

19.5 DENSITY= 0.00000785 3).FCAW (1.2 ) 4.5 1.78

` 4). GTAW 0.8 10.00

INC. ANG.= 10 OFFSET=

R.F.= 1 0

CFW= 9 POSITION OF MULTIPLICATION

INC. ANG.= 60 WELDING FACTOR

R.G.= 3 1). 1G 1

2). 2G 1.6

THK= 60

NOZ I/D 3). 3G 1.3

21

SHELL

1776

NOZ O/D

I/D=

60 LESS MULTIPLICATION

ACCESSIBLE FACTOR

YES 2

ELLIPSE DIMENSION CROSS SEC. AREA WELD KG NO 1

WEIGHT CALCULATION ON SHELL ON D/END

MAJOR AXIS= 40.5 ROOT RUN= 38.15 0.04 0.04

MINOR AXIS= 40.5 O/S WELDING= 357.25 0.36 0.36

LG. OF WELDING= 127.2 TOTAL WELDING= 0.36 0.36

PROCESS POSITION ACCESSIBLE LESS CALCULATED RUN TIME TO BE CONSIDERED

ON SHELL CODE CODE (Y/N) (min) (Hrs) (Hrs)

OUTSIDE ROOT RUN 100% 1 5 2 1.6 Y 2 342.6 5.7 5.7

OUT SIDE BALANCE 100% 1 5 1 1.0 y 2 214.1 3.6 3.6

TOTAL = 556.7 9.3 9.3

151198161.xls.ms_office, NOZSETON, 6/11/2013 PAGE 7 OF 14

FILLET WELD KG & RUN TIME ESTIMATION

SINGLE SIDE FILLET JOINT

PARAMETERS SETTING

PROCESS KG/SHIFT HRS/KG

1). SMAW 1.6 5.00

LENGTH OF WELDING(MM)= 10000.000 2). SAW 15 0.53

3).FCAW (1.2 ) 4.5 1.78

MATERIAL (SS/STEEL)= STEEL

DENSITY= 0.00000785

6

FOR CALCULATING WELD LENGTH

RADIUS OF WELDING(MM)= 1000 POSITION OF MULTIPLICATION

INCLUDED ANGLE OF WELDING(DEG)= 60 WELDING FACTOR

6 LENGTH OF WELDING(MM)= 1047.198 1). 1F/2F 1

2) 3F 1.1

WELD CALCULATION CROSS SEC. AREA TOTAL WELD KG LESS- MULTIPLICATION

TOTAL WELDING 18.00 1.41 ACCESSIBLE FACTOR

YES 2

NO 1

PROCESS POSITION ACCESSIBLE LESS CALCULATED RUN TIME TO BE CONSIDERED

CODE CODE (Y/N) (min) (Hrs) (Hrs)

FILLET WELD 1 5.00 1 1.0 Y 2 847.8 14.1 14.1

TOTAL = 847.8 14.1 14.1

151198161.xls.ms_office, FILLETSINGLE, 6/11/2013 PAGE 8 OF 14

FILLET WELD KG & RUN TIME ESTIMATION

DOUBLE SIDE FILLET JOINT

PARAMETERS SETTING

WELDING BY SINGLE OPERATOR/ PROCESS KG/SHIFT HRS/KG

DOUBLE OPERATOR(S/D)? S 1). SMAW 1.6 5.00

LENGTH OF WELDING(MM)= 785.000 2). SAW 15 0.53

3).FCAW (1.2 ) 4.5 1.78

MATERIAL (SS/STEEL)= STEEL

DENSITY= 0.00000785

6 10

FOR CALCULATING WELD LENGTH

RADIUS OF WELDING(MM)= 1000 POSITION OF MULTIPLICATION

INCLUDED ANGLE OF WELDING(DEG)= 60 WELDING FACTOR

6 6 LENGTH OF WELDING(MM)= 1047.198 1). 1F/2F 1

2) 3F 1.1

WELD CALCULATION CROSS SEC. AREA TOTAL WELD KG LESS- MULTIPLICATION

FIRST SIDE WELDING 18.00 0.11 ACCESSIBLE FACTOR

SECOND SIDE WELDING 30.00 0.18 YES 2

TOTAL WELDING= 48.00 0.30 NO 1

PROCESS POSITION ACCESSIBLE LESS CALCULATED RUN TIME TO BE CONSIDERED

SINGLE OPERATOR CODE CODE (Y/N) (min) (Hrs) (Hrs)

FIRST SIDE 100% 1 5.00 1 1.0 Y 2 66.6 1.1 2.0

SECOND SIDE SIDE 100% 1 5.00 1 1.0 Y 2 110.9 1.8 2.0

TOTAL= 177.5 3.0 4.0

151198161.xls.ms_office, FILLETDOUBLE, 6/11/2013 PAGE 9 OF 14

FILLET WELD KG & RUN TIME ESTIMATION

DOUBLE SIDE + FULL PENETATION JOINT

PARAMETERS SETTING

PROCESS? (DOT / WITH CHIP BACK / PROCESS KG/SHIFT

FIRST SIDE 20 SECOND SIDE TIG+SMAW) (D/C/T) ? D 1). SMAW 1.6

LENGTH OF WELDING(MM)= 1047.198 2). SAW (TWIN HEAD) 14 28

3).FCAW (1.2 ) 4.5

MATERIAL (SS/STEEL)= STEEL 4). GTAW+SMAW 0.8

9.5

70 DEG DENSITY= 7.85E-06

FOR CALCULATING WELD LENGTH

RADIUS OF WELDING(MM)= 1000 POSITION OF MULTIPLICATION

20 70 deg 20 INCLUDED ANGLE OF WELDING(DEG)= 60 WELDING FACTOR

LENGTH OF WELDING(MM)= 1047.198 1). 1F/2F 1

RG= 2 2) 3F 1.1

CHIP BACK DEPTH(MM)= 6

20 1 20

1+D,2 1+C,3+C 4

76 39 26

WELD CALCULATION CROSS SEC. AREA TOTAL WELD KG MULTIPLICATION

ROOT RUN (BOTH SIDE) 76 0.62 LESS-ACCESSIBLE FACTOR

FIRST SIDE WELDING 305.16 2.51 (INCLUDING CHIP BACK) YES 2

SECOND SIDE WELDING 305.16 2.51 NO 1

TOTAL WELDING= 610.32 5.02

PROCESS POSITION ACCESSIBLE LESS CALCULATED RUN TIME TO BE CONSIDERED

DOT CODE CODE (Y/N) (min) (Hrs) (Hrs)

ROOT RUN (BOTH SIDE) 100% 2 0.57 1 1.0 Y 2 42.6 0.7 2.0

FIRST SIDE 100% 2 0.57 1 1.0 Y 2 172.0 2.9 2.9

SECOND SIDE SIDE 100% 2 0.57 1 1.0 Y 2 172.0 2.9 2.9

TOTAL= 193.3 6.4 5.7

151198161.xls.ms_office, FILLETDOUBLEVFP, 6/11/2013 PAGE 10 OF 14

FILLET WELD KG & RUN TIME ESTIMATION

G

HRS/KG

5.00

0.570.29

1.78

10.00

FOR TIG

MULTIPLICATION

FACTOR

1

1.1

MULTIPLICATION

FACTOR

2

1

BE CONSIDERED

(Hrs)

2.0

2.9

2.9

5.7

151198161.xls.ms_office, FILLETDOUBLEVFP, 6/11/2013 PAGE 11 OF 14

FILLET WELD KG & RUN TIME ESTIMATION

SINGLE SIDE + FULL PENETATION JOINT

PARAMETERS SETTING

PROCESS? (WITH OUT CHIPBACK / WITH CHIP PROCESS KG/SHIFT HRS/KG

SECOND SIDE FIRST SIDE BACK / TIG+SMAW) (W/C/T) ? W 1). SMAW 1.6 5.00

20 LENGTH OF WELDING(MM)= 52000.000 2). SAW 20 0.40

3).FCAW (1.2 ) 4.5 1.78

60 DEG MATERIAL (SS/STEEL)= STEEL 4). GTAW+SMAW 0.8 10.00

FOR TIG

DENSITY= 7.85E-06

FOR CALCULATING WELD LENGTH

10 50 RADIUS OF WELDING(MM)= 1000 POSITION OF MULTIPLICATION

INCLUDED ANGLE OF WELDING(DEG)= 60 WELDING FACTOR

3 LENGTH OF WELDING(MM)= 1047.198 1). 1F/2F 1

15 15 2) 3F 1.1

CHIP BACK DEPTH(MM)= 6

2

WELD CALCULATION CROSS SEC. AREA TOTAL WELD KG MULTIPLICATION

FIRST SIDE WELDING 715.59 292.10 LESS-ACCESSIBLE FACTOR

SECOND SIDE WELDING 75.00 30.62 (INCLUDING CHIP BACK) YES 2

TOTAL WELDING= 790.59 322.72 NO 1

PROCESS POSITION ACCESSIBLE LESS CALCULATED RUN TIME TO BE CONSIDERED

WITH OUT C/B CODE CODE (Y/N) (min) (Hrs) (Hrs)

FIRST SIDE 100% 4 5.00 1 1.0 N 1 87631.4 1460.5 1460.5

SECOND SIDE SIDE 100% 4 5.00 1 1.0 N 1 9184.5 1460.5 1460.5

TOTAL= 96815.9 2921.0 2921.0

151198161.xls.ms_office, FILLETSINGLEVFP, 6/11/2013 PAGE 12 OF 14

FILLET WELD KG & RUN TIME ESTIMATION

CORNER JOINT

PARAMETERS SETTING

PROCESS? (WITH OUT CHIPBACK / WITH CHIP PROCESS KG/SHIFT HRS/KG

SECOND SIDE FIRST SIDE BACK / TIG+SMAW) (W/C/T) ? W 1). SMAW 1.6 5.00

20 LENGTH OF WELDING(MM)= 1047.198 2). SAW 20 0.40

3).FCAW (1.2 ) 4.5 1.78

60 DEG MATERIAL (SS/STEEL)= STEEL 4). GTAW+SMAW 0.8 10.00

FOR TIG

DENSITY= 7.85E-06

FOR CALCULATING WELD LENGTH

10 RADIUS OF WELDING(MM)= 1000 POSITION OF MULTIPLICATION

INCLUDED ANGLE OF WELDING(DEG)= 60 WELDING FACTOR

3 LENGTH OF WELDING(MM)= 1047.198 1). 1F/2F 1

15 15 2) 3F 1.1

CHIP BACK DEPTH(MM)= 6

2

WELD CALCULATION CROSS SEC. AREA TOTAL WELD KG MULTIPLICATION

FIRST SIDE WELDING 464.12 3.82 LESS-ACCESSIBLE FACTOR

SECOND SIDE WELDING 75.00 0.62 (INCLUDING CHIP BACK) YES 2

TOTAL WELDING= 539.12 4.43 NO 1

PROCESS POSITION ACCESSIBLE LESS CALCULATED RUN TIME TO BE CONSIDERED

WITH OUT C/B CODE CODE (Y/N) (min) (Hrs) (Hrs)

FIRST SIDE 100% 4 5.00 1 1.0 Y 2 2289.2 38.2 38.2

SECOND SIDE SIDE 100% 4 5.00 1 1.0 Y 2 369.9 38.2 38.2

TOTAL= 2659.1 76.3 76.3

151198161.xls.ms_office, CORNER JOINT, 6/11/2013 PAGE 13 OF 14

FILLET WELD KG & RUN TIME ESTIMATION

CORNER JOINT

PARAMETERS SETTING

PROCESS? (WITH OUT CHIPBACK / WITH CHIP PROCESS KG/SHIFT HRS/KG

SECOND SIDE FIRST SIDE BACK / TIG+SMAW) (W/C/T) ? W 1). SMAW 1.6 5.00

20 LENGTH OF WELDING(MM)= 1047.198 2). SAW 20 0.40

3).FCAW (1.2 ) 4.5 1.78

60 DEG MATERIAL (SS/STEEL)= STEEL 4). GTAW+SMAW 0.8 10.00

FOR TIG

DENSITY= 7.85E-06

10 FOR CALCULATING WELD LENGTH

RADIUS OF WELDING(MM)= 1000 POSITION OF MULTIPLICATION

INCLUDED ANGLE OF WELDING(DEG)= 60 WELDING FACTOR

3 LENGTH OF WELDING(MM)= 1047.198 1). 1F/2F 1

15 2) 3F 1.1

CHIP BACK DEPTH(MM)= 6

2

WELD CALCULATION CROSS SEC. AREA TOTAL WELD KG MULTIPLICATION

FIRST SIDE WELDING 490.59 4.03 LESS-ACCESSIBLE FACTOR

SECOND SIDE WELDING 39.00 0.32 (INCLUDING CHIP BACK) YES 2

TOTAL WELDING= 529.59 4.35 NO 1

PROCESS POSITION ACCESSIBILITY CALCULATED RUN TIME TO BE CONSIDERED

WITH OUT C/B CODE CODE (Y/N) (min) (Hrs) (Hrs)

FIRST SIDE 100% 4 5.00 1 1.0 Y 2 2419.7 40.3 40.3

SECOND SIDE SIDE 100% 4 5.00 1 1.0 Y 2 192.4 40.3 40.3

TOTAL= 2612.1 80.7 80.7

151198161.xls.ms_office, CORNER JOINT (2), 6/11/2013 PAGE 14 OF 14

You might also like

- Long seam weld estimationDocument16 pagesLong seam weld estimationTiago FerreiraNo ratings yet

- Weld WeightDocument6 pagesWeld WeightDesaiNo ratings yet

- Double V Weld CalculationDocument8 pagesDouble V Weld CalculationHgagselim SelimNo ratings yet

- Weld WeightDocument10 pagesWeld WeightDivyesh PatelNo ratings yet

- Weld Weight 1Document2 pagesWeld Weight 1francisco zepedaNo ratings yet

- Circ Seam: Long Seam/ Circ Seam Weld KG & Run Time EstimationDocument10 pagesCirc Seam: Long Seam/ Circ Seam Weld KG & Run Time EstimationpelotoNo ratings yet

- Welding CalculationDocument5 pagesWelding CalculationMohamad FadelNo ratings yet

- Circ Seam: Run Time Time Required For L/Seam or C/Seam (LS/CS) CsDocument5 pagesCirc Seam: Run Time Time Required For L/Seam or C/Seam (LS/CS) CsMina RemonNo ratings yet

- Welding CalculationDocument5 pagesWelding CalculationBWQNo ratings yet

- Observations: Current Sensitivity For IDocument3 pagesObservations: Current Sensitivity For IwksudeeraNo ratings yet

- OVERLAY WELD KG & RUN TIME ESTIMATIONDocument32 pagesOVERLAY WELD KG & RUN TIME ESTIMATIONDenial Basanovic100% (1)

- Comparative Analysis Effect of Operating Time On Loss and Gain Characteristics of Quantum Dot Laser Using Group Iii NitridesDocument18 pagesComparative Analysis Effect of Operating Time On Loss and Gain Characteristics of Quantum Dot Laser Using Group Iii NitridesMd. Nawab Siraj Ud DaulaNo ratings yet

- Long Seam Weld EstimationDocument5 pagesLong Seam Weld EstimationalokbdasNo ratings yet

- Welding CalculationsDocument16 pagesWelding Calculationsmt92606222100% (2)

- Welding CalculationsDocument14 pagesWelding Calculationsjitulpatil100% (6)

- 4011 Breaker Timing & CRM 01.09.2021Document1 page4011 Breaker Timing & CRM 01.09.2021msantosh1965No ratings yet

- Plumbing Calculation Sheet: Storm Drainage LoadDocument1 pagePlumbing Calculation Sheet: Storm Drainage LoadJohn ANo ratings yet

- Stochastic in Highway EngineerDocument38 pagesStochastic in Highway EngineerDonlot DonlotanNo ratings yet

- I-2 Actual Con PropuestaDocument1 pageI-2 Actual Con PropuestaAlejandro VargasNo ratings yet

- Weld CalculationDocument34 pagesWeld CalculationAshwani DograNo ratings yet

- Aritra MTPDocument39 pagesAritra MTPsohamNo ratings yet

- Centrifugal and Axial Compressor DATA SHEET (API 617-7TH Chapter 2) SI UNITS (1-1.6.5)Document4 pagesCentrifugal and Axial Compressor DATA SHEET (API 617-7TH Chapter 2) SI UNITS (1-1.6.5)Carlos Felipe Reyes MartínezNo ratings yet

- Prepared By: - Yasmeen Bsharat - Abeer Saleh: Dr. Abdul Razzaq TouqanDocument49 pagesPrepared By: - Yasmeen Bsharat - Abeer Saleh: Dr. Abdul Razzaq Touqanvuxuandung84No ratings yet

- Model 6240M4/5/6X: High Temperature Gas Turbine AccelerometerDocument3 pagesModel 6240M4/5/6X: High Temperature Gas Turbine AccelerometerUsman AliNo ratings yet

- Numerical RelayDocument7 pagesNumerical RelayRiyah_Rae100% (1)

- Red Dist. PamparqueDocument5 pagesRed Dist. PamparqueAnonymous XdrDJANo ratings yet

- Lanes, Volumes, Timings Av. GullmanDocument2 pagesLanes, Volumes, Timings Av. GullmandanielscaresNo ratings yet

- Stability analysis of powerhouse structuresDocument46 pagesStability analysis of powerhouse structuresAkshay DuggalNo ratings yet

- Soil Resistivity Calculation for Substation Earth Mat DesignDocument8 pagesSoil Resistivity Calculation for Substation Earth Mat DesignVivek ShambharkarNo ratings yet

- Bus Protection Device Coordination ReportDocument6 pagesBus Protection Device Coordination ReportMichael S. NuezNo ratings yet

- Okaya LE SpecDocument1 pageOkaya LE SpecDino KaoNo ratings yet

- Packed Bed+ HetpDocument10 pagesPacked Bed+ HetpganeswNo ratings yet

- Bridge PortionDocument16 pagesBridge PortionNagara SelvarajNo ratings yet

- DDR N°40 Omf-50 TP202 Du 05092021Document3 pagesDDR N°40 Omf-50 TP202 Du 05092021Mohamed SouidiNo ratings yet

- CBR Test ResultsDocument1 pageCBR Test ResultsFariha Azad100% (3)

- Share EXCEL SHEET FOR CBR TESTDocument1 pageShare EXCEL SHEET FOR CBR TESTTarun100% (1)

- Contoh Perhitungan Holtrop Riska-1Document23 pagesContoh Perhitungan Holtrop Riska-1Riska AmaliyahNo ratings yet

- Lanes, Volumes, Timings Av. GullmanDocument2 pagesLanes, Volumes, Timings Av. GullmandanielscaresNo ratings yet

- Design of SlabsDocument59 pagesDesign of SlabsSam OlarteNo ratings yet

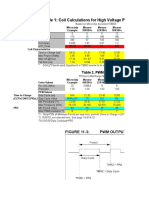

- Table 1: Coil Calculations For High Voltage Power SupplyDocument6 pagesTable 1: Coil Calculations For High Voltage Power Supplynaveen reddyNo ratings yet

- SAG-TENSION COMPUTATIONS FOR TRANSMISSION LINESDocument37 pagesSAG-TENSION COMPUTATIONS FOR TRANSMISSION LINESSmtakalkar TakalkarNo ratings yet

- ELP303 Expt3Document7 pagesELP303 Expt3Neelkanth KunduNo ratings yet

- APC materials piezoelectric propertiesDocument1 pageAPC materials piezoelectric propertiesnamyefNo ratings yet

- LAS Webinar PresentationDocument35 pagesLAS Webinar PresentationAbhinay KumarNo ratings yet

- Common P141Document5 pagesCommon P141Abdul KhaliqNo ratings yet

- Valve pressure drop and stream propertiesDocument1 pageValve pressure drop and stream propertieskara_25No ratings yet

- Step (1) : Determine Storage Volume RequiredDocument12 pagesStep (1) : Determine Storage Volume RequiredYANIshaNo ratings yet

- Đánh giá hệ thống hiện hữu tăng công suất khí Saint-GobainDocument1 pageĐánh giá hệ thống hiện hữu tăng công suất khí Saint-GobainDuy Nguyễn VănNo ratings yet

- 13SMD0084-13SMD0096 HAWK UPH#LinkDesign20230412-172416Document5 pages13SMD0084-13SMD0096 HAWK UPH#LinkDesign20230412-172416Adiin 102No ratings yet

- Wind Turbine Airfoil CatalogueDocument150 pagesWind Turbine Airfoil CatalogueMihaela IleniNo ratings yet

- Rigging DesignDocument8 pagesRigging DesignDurgesh HingnekarNo ratings yet

- Spinning mill production report with cotton counts and productivity dataDocument15 pagesSpinning mill production report with cotton counts and productivity dataMukesh Kumar100% (1)

- AVO and Lamé Constants For Rock Parameterization and Fluid DetectionDocument1 pageAVO and Lamé Constants For Rock Parameterization and Fluid Detectionpetro AliNo ratings yet

- Beam warping and shear calculationsDocument1 pageBeam warping and shear calculationsTruong Phuoc TriNo ratings yet

- Newnes Circuit Calculations Pocket Book: with Computer ProgramsFrom EverandNewnes Circuit Calculations Pocket Book: with Computer ProgramsNo ratings yet

- Transistor Electronics: Use of Semiconductor Components in Switching OperationsFrom EverandTransistor Electronics: Use of Semiconductor Components in Switching OperationsRating: 1 out of 5 stars1/5 (1)

- Computer Techniques for Electromagnetics: International Series of Monographs in Electrical EngineeringFrom EverandComputer Techniques for Electromagnetics: International Series of Monographs in Electrical EngineeringR. MittraRating: 3 out of 5 stars3/5 (1)

- Electronics – From Theory Into Practice: Applied Electricity and Electronics DivisionFrom EverandElectronics – From Theory Into Practice: Applied Electricity and Electronics DivisionRating: 5 out of 5 stars5/5 (1)

- Rectangular Tank DesignDocument35 pagesRectangular Tank Designfaizal91% (11)

- ZR28 01 PDFDocument16 pagesZR28 01 PDFsathishNo ratings yet

- Sara E. F. Gensburg, Ltd. Architecture/Design: Type S.F. Rate Minimum Fee Size S.F. Rate Minimum FeeDocument1 pageSara E. F. Gensburg, Ltd. Architecture/Design: Type S.F. Rate Minimum Fee Size S.F. Rate Minimum FeemhsalihNo ratings yet

- 1" Rotogages For Large Mobile and Stationary Containers A9090 SeriesDocument2 pages1" Rotogages For Large Mobile and Stationary Containers A9090 Seriesmhsalih100% (1)

- Idoc - Pub Welding-TransformerDocument38 pagesIdoc - Pub Welding-TransformermhsalihNo ratings yet

- Suction PipelineDocument4 pagesSuction PipelinemhsalihNo ratings yet

- 1980 National Waste Processing Conference 34Document11 pages1980 National Waste Processing Conference 34premNo ratings yet

- Elliptical Head Design ToolDocument1 pageElliptical Head Design ToolMohammad Kamal HabbabaNo ratings yet

- Rectangular Tank-Data SheetDocument1 pageRectangular Tank-Data Sheetmhsalih100% (1)

- ANSI FlangeDocument10 pagesANSI FlangemechftpNo ratings yet

- Bearing Load CalculationDocument16 pagesBearing Load CalculationmhsalihNo ratings yet

- Structural Shape PDFDocument18 pagesStructural Shape PDFtienNo ratings yet

- Guide to Welded Steel Pipe Design, Properties, Installation & StandardsDocument93 pagesGuide to Welded Steel Pipe Design, Properties, Installation & StandardsfileseekerNo ratings yet

- Basic Rigging Work BookDocument45 pagesBasic Rigging Work BookJohn Henry Sinurat100% (1)

- Separation Technologies in Oil and Gas Production: Sebastian Osvaldo Zuniga BenavidesDocument40 pagesSeparation Technologies in Oil and Gas Production: Sebastian Osvaldo Zuniga BenavidesCarlos SalazarNo ratings yet

- Guide to Welded Steel Pipe Design, Properties, Installation & StandardsDocument93 pagesGuide to Welded Steel Pipe Design, Properties, Installation & StandardsfileseekerNo ratings yet

- Water Level BookletDocument20 pagesWater Level BookletmhsalihNo ratings yet

- 09 Lad CalculationoDocument2 pages09 Lad CalculationomhsalihNo ratings yet

- Guide to Welded Steel Pipe Design, Properties, Installation & StandardsDocument93 pagesGuide to Welded Steel Pipe Design, Properties, Installation & StandardsfileseekerNo ratings yet

- Hammer Mill Design Mini ProjectDocument46 pagesHammer Mill Design Mini Projectmasthan31686% (7)

- Engineering Design Guideline Separator Vessel Rev01Document28 pagesEngineering Design Guideline Separator Vessel Rev01Yan Laksana50% (4)

- Sugar HandlingDocument1 pageSugar HandlingmhsalihNo ratings yet

- Masonry Design GuideDocument60 pagesMasonry Design GuidemhsalihNo ratings yet

- Water Level BookletDocument20 pagesWater Level BookletmhsalihNo ratings yet

- Designing For Truck MovementsDocument69 pagesDesigning For Truck MovementsWaruna JayasooriyaNo ratings yet

- Compressor SitesDocument26 pagesCompressor SitesRandall WestNo ratings yet

- Metric FastenersDocument28 pagesMetric Fastenersmhsalih100% (1)

- Sihi lph55000Document10 pagesSihi lph55000mhsalihNo ratings yet

- Business Letter English PDFDocument2 pagesBusiness Letter English PDFmhsalihNo ratings yet

- Sand CastingDocument7 pagesSand CastingNajwa MNoorNo ratings yet

- Rate Analysis For ShutteringDocument2 pagesRate Analysis For ShutteringSarin100% (2)

- Sample BQ For WBLFFDocument4 pagesSample BQ For WBLFFUmmi Hanie100% (2)

- Estimation Name of Work: Construction of Toilets For Logistic and VigilanceDocument12 pagesEstimation Name of Work: Construction of Toilets For Logistic and Vigilancepviccu100% (1)

- Aluminum TempersDocument5 pagesAluminum TempersLeonard ChoNo ratings yet

- ASTM A351 Grade CF8 Heat-Treated Chemical PropertiesDocument6 pagesASTM A351 Grade CF8 Heat-Treated Chemical PropertiesRajnish KumarNo ratings yet

- CATALOGO DE CONECTORES BC-LOK - CompressedDocument71 pagesCATALOGO DE CONECTORES BC-LOK - Compressedleopoldo cobosNo ratings yet

- Interpipe CatalogDocument3 pagesInterpipe CatalogUmmes AhmedNo ratings yet

- Pavement Design Report (PK 50 - PK 61.3) - Rev.1 05 May 2021Document94 pagesPavement Design Report (PK 50 - PK 61.3) - Rev.1 05 May 2021Adrian FrantescuNo ratings yet

- Fast-curing epoxy mortar repairs concreteDocument4 pagesFast-curing epoxy mortar repairs concreteBalasubramanian AnanthNo ratings yet

- IJEDR1904037Document5 pagesIJEDR1904037Arun anandNo ratings yet

- Alfa Laval M6: Gasketed Plate Heat Exchanger For A Wide Range of ApplicationsDocument2 pagesAlfa Laval M6: Gasketed Plate Heat Exchanger For A Wide Range of ApplicationsCyrilDepalomaNo ratings yet

- Calculation Chek - CorrectionDocument37 pagesCalculation Chek - Correctiondebashish sarkarNo ratings yet

- Notice No.1 Rules For The Manufacture Testing and Certification of Materials July 2Document5 pagesNotice No.1 Rules For The Manufacture Testing and Certification of Materials July 2taddeoNo ratings yet

- Derakane - Tech SupportDocument32 pagesDerakane - Tech SupportJainam ShahNo ratings yet

- Perimeter Fence Rev 02-6Document1 pagePerimeter Fence Rev 02-6Victorino SantosNo ratings yet

- Procedure For Positive Material Identification at Vendor'S WorksDocument7 pagesProcedure For Positive Material Identification at Vendor'S WorksAjay BaggaNo ratings yet

- Siemens Selection GuideDocument21 pagesSiemens Selection GuidefredyNo ratings yet

- NORSOK Structural Steel Fabrication M-101Document67 pagesNORSOK Structural Steel Fabrication M-101Agnes Chong80% (5)

- Flexural design calculation sheetDocument41 pagesFlexural design calculation sheetBranko ĐokovićNo ratings yet

- Info@posiflex - Co.uk - Tel: +44 (0) 1462 443131 - WWW - Posiflex.co - UkDocument45 pagesInfo@posiflex - Co.uk - Tel: +44 (0) 1462 443131 - WWW - Posiflex.co - UkThái Mai ĐìnhNo ratings yet

- Compressive Strength of Hydraulic Cement Mortars (Using 2-In. or (50-mm) Cube Specimens)Document10 pagesCompressive Strength of Hydraulic Cement Mortars (Using 2-In. or (50-mm) Cube Specimens)anant11235100% (1)

- Standard Pipe Sizes and PropertiesDocument64 pagesStandard Pipe Sizes and PropertiesLipika GayenNo ratings yet

- J Conbuildmat 2017 02 107Document7 pagesJ Conbuildmat 2017 02 107Jerson SotoNo ratings yet

- Composite Precast Beam DesignDocument47 pagesComposite Precast Beam DesignfarahazuraNo ratings yet

- Equivalencia de AcerosDocument8 pagesEquivalencia de AcerosTúlio Barata FrançaNo ratings yet

- Building and Construction MaterialsDocument121 pagesBuilding and Construction MaterialsElena NoveskaNo ratings yet

- Mục 64 Keo dán nguội băng tải Devcon R flex 15565Document2 pagesMục 64 Keo dán nguội băng tải Devcon R flex 15565Việt Hùng NghiêmNo ratings yet

- The Durability of Cement-Treated Clay Granite Powder and Slag-Treated Clay Granite Powder Composites Under Seawater ExposureDocument1 pageThe Durability of Cement-Treated Clay Granite Powder and Slag-Treated Clay Granite Powder Composites Under Seawater ExposureJoyce Persie SilverNo ratings yet

- W Rly Ussor 2011Document301 pagesW Rly Ussor 2011pandeydb69% (26)