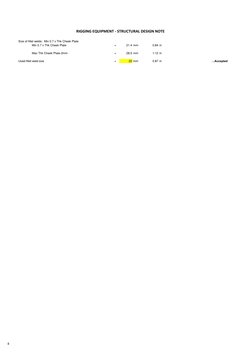

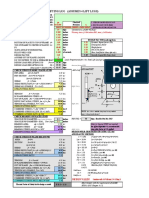

RIGGING EQUIPMENT - STRUCTURAL DESIGN NOTE

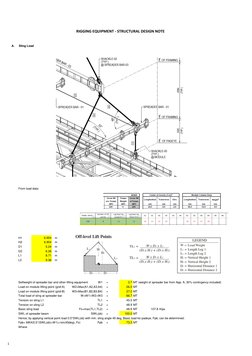

A. Sling Load

From load data:

H1 6.954 m

H2 6.954 m

D1 5.24 m

D2 6.26 m

L1 8.71 m

L2 9.36 m

Selfweight of spreader bar and other lifting equipment W1 = 3.7 MT (weight of spreader bar from App. A, 30% contingency included)

Load on module lifting point (grid-A) W2=Max(A1,A2,A3,A4) = 26.0 MT

Load on module lifting point (grid-B) W3=Max(B1,B2,B3,B4) = 37.0 MT

Total load of sling at spreader bar W=W1+W2+W3 = 66.7 MT

Tension on sling L1 TL1 = 45.5 MT

Tension on sling L2 TL2 = 48.9 MT

Basic sling load Fs=max(TL1,TL2) = 48.9 MT 107.8 Kips

SWL of spreader beam SWL(sb) = 100.0 MT

Hence, by applying vertical point load 0.5*SWL(sb) with min. sling angle 45 deg, Basic load for padeye, Fpb, can be determined:

Fpb= MAX(0.5*(SWL(sb)+W1)+/sin(45deg), Fs) Fpb = 73.3 MT

Where

1

� RIGGING EQUIPMENT - STRUCTURAL DESIGN NOTE

Weight contingency γwc = 1.05

COG shift γcog = 1.10

DAF γdaf = 1.12

SKL γskl = 1.10

Tilt Factor γt = 1.05

Yaw Factor γw = 1.05

Static Sling load, Fst= Fs*γwc Fst = 51.3 MT

Dynamic Sling load, Fdy=Fst*γdaf Fdy = 57.5 MT

Sling design load, Fsd=Fs*γwc*γcog*γdaf*γt*γw*γskl Fsd = 76.7 MT 169.1 Kips DNVGL-ST-N001 (2016) sec.16.3.4.1

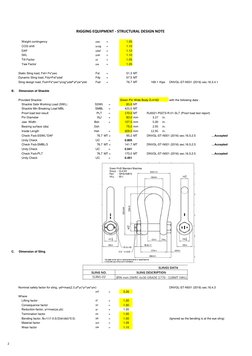

B. Dimension of Shackle

Provided Shackle: Green Pin Wide Body G-4163 with the following data :

Shackle Safe Working Load (SWL) SSWL = 85.0 MT

Shackle Min Breaking Load MBL SMBL = 425.0 MT

Proof load test result PLT = 170.0 MT RJ0021-P0273-R-01-SLT (Proof load test report)

Pin Diameter (dp) = 83.0 mm 3.27 in.

Jaw Width Bsh = 127.0 mm 5.00 in.

Bearing surface (dia) Dsh 75.0 mm 2.95 in.

Inside Length Hsh = 329.0 mm 12.95 in.

Check Fsd<SSWL*DAF 76.7 MT < 95.2 MT DNVGL-ST-N001 (2016) sec.16.5.2.5 …Accepted

Unity Check UC = 0.805

Check Fsd<SMBL/3 76.7 MT < 141.7 MT DNVGL-ST-N001 (2016) sec.16.5.2.5 …Accepted

Unity Check UC = 0.541

Check Fsd<PLT 76.7 MT < 170.0 MT DNVGL-ST-N001 (2016) sec.16.5.2.5 …Accepted

Unity Check UC = 0.451

C. Dimension of Sling

Nominal safety factor for sling, γsf=max(2.3,γf*γc*γr*γw*γm) DNVGL-ST-N001 (2016) sec.16.4.3

γsf = 3.26

Where

Lifting factor γf = 1.30

Consequence factor γc = 1.30

Reduction factor, γr=max(γs,γb) γr = 1.30

Termination factor γs = 1.30

Bending factor, fb=1/(1-0.5/(Dsh/dsl)^0.5) γb = 1.00 (Ignored as the bending is at the eye sling)

Material factor γm = 1.35

Wear factor γw = 1.10

2

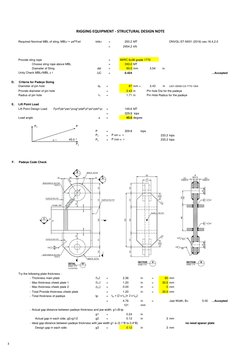

� RIGGING EQUIPMENT - STRUCTURAL DESIGN NOTE

Required Nominal MBL of sling, MBLr > γsf*Fsd MBLr = 250.2 MT DNVGL-ST-N001 (2016) sec.16.4.2.0

= 2454.2 kN

Provide sling rope = IWRC 6x36 grade 1770

Choose sling rope above MBL = 590.0 MT

Diameter of Sling dsl = 90.0 mm 3.54 in.

Unity Check MBLr/MBL ≤ 1 UC = 0.424 …Accepted

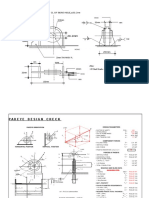

D. Criteria for Padeye Sizing

Diameter of pin hole dh = 87 mm = 3.43 in L001-00000-CS-7770-1004

Provide diameter of pin hole = 3.43 in Pin hole Dia for the padeye

Radius of pin hole rh = 1.71 in Pin Hole Radius for the padeye

E. Lift Point Load

Lift Point Design Load Fp=Fpb*γwc*γcog*γdaf*γt*γw*γskl*γc = 149.6 MT

= 329.8 kips

Load angle α = 45.0 degree

Pz P

P = 329.8 kips

Pz = P sin a = 233.2 kips

a= 45.0 o Py = P cos a = 233.2 kips

Py

F. Padeye Code Check

Try the following plate thickness :

- Thickness main plate (tm) = 2.36 in = 60 mm

- Max thickness cheek plate 1 (tc1) = 1.20 in = 30.5 mm

- Max thickness cheek plate 2 (tc1) = 0.00 in = 0 mm

- Total Provide thickness cheek plate = 1.20 in = 30.5 mm

- Total thickness of padeye tp = tm + (2 x tc1)+ 2 x tc2)

= 4.76 in < Jaw Width, B= 5.00 …Accepted

121 mm

- Actual gap distance between padeye thickness and jaw width, g1=B-tp

g1 = 0.24 in

Actual gap in each side, g2=g1/2 g2 = 0.12 in 3 mm

- Ideal gap distance between padeye thickness with jaw width g1 is (0.1*B to 0.4*B) no need spacer plate

Design gap in each side: g3 = 0.12 in 3 mm

3

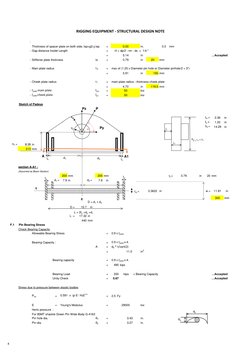

� RIGGING EQUIPMENT - STRUCTURAL DESIGN NOTE

-

Thickness of spacer plate on both side, tsp=g2-g3tsp = 0.00 in. 0.0 mm

- Gap distance Inside Length = H + dp/2 - rm - ds > 1/4 "

= 5.14 in …Accepted

- Stiffener plate thickness ts = 0.79 in 20 mm

- Main plate radius rm = max of (1.25 x Diameter pin hole or Diameter pinhole/2 + 3")

= 5.91 in 150 mm

- Cheek plate radius rc = main plate radius - thickness cheek plate

= 4.70 in 119.5 mm

- fyield main plate fym = 50 ksi

- fyield cheek plate fyc = 50 ksi

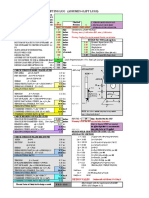

Sketch of Padeye

Pz P

rm tm = 2.36 in

tc = 1.20 in

h2 = 14.29 in

rc a Py tc

h2 = rm + h1

tm

h1 = 8.39 in

213 mm

A d1 d2

A1

ts ts

section A-A1 :

(Assumed as Beam Section)

200 mm 200 mm ts ts = 0.79 in 20 mm

ts

d1 = 7.9 in d2 = 7.9 in

Y

tm = 2.3622 in w= 11.81 in

X 300 mm

D = d1 + d2

D= 15.7 in

L = 2ts +d2 +d1

L = 17.32 in

440 mm

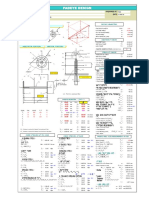

F.1 Pin Bearing Stress

Check Bearing Capacity

Allowable Bearing Stress = 0.9 x fyield

Bearing Capacity : = 0.9 x fyield x A

A = dp * t/sqrt(2)

2

= 11.0 in

Bearing capacity = 0.9 x fyield x A

= 495 kips

Bearing Load = 330 kips < Bearing Capacity …Accepted

Unity Check = 0.67 …Accepted

Stress due to pressure between elastic bodies

0.5

Phe = 0.591 x (p E / Kd) < 2.5 Fy

E = Young's Modulus = 29000 ksi

Hertz pressure :

dh

For 85MT shackle Green Pin Wide Body G-4163

Pin hole dia. dh = 3.43 in. dp

Pin dia. dp = 3.27 in.

4

� RIGGING EQUIPMENT - STRUCTURAL DESIGN NOTE

dp dh x dp

Kd =

dh - dp

= 71.1 in.

2 2

Bearing capacity = plate thickness x (2.5 Fy) x Kd / (0.591 x E)

Bearing capacity at cheek plate = 2 *tc x (2.5 Fy)^2 x Kd / (0.591^2 x E)"

= 263.3 kips

Bearing capacity at main plate = tm x (2.5 Fy)^2 x Kd / (0.591^2 x E)

= 259.0 kips

Total Bearing capacity = 522.3 kips

Bearing Load = 329.8 kips < Bearing Capacity …Accepted

Unity Check = 0.631 …Accepted

F.2 Pin Pull-Out Shear

Allowable Shear Stress = 0.4 x Fy

= 20 ksi (main plate)

= 20 ksi (cheek plate)

Shear Capacity = (2 x (rm-fhole/2) x tm x 0.4Fy) + (4 x (rc-fhole/2) x tc x 0.4Fy)

= 683.6 kips

Main plate 2.4 in thk. 6 in. rad.

1.20 in thk. Cheek plate

5 in. rad.

3 in. dia. hole

Shear force, Py = 149.6 kips

= 149.6 kips < Shear capacity …Accepted

UC = 0.22

F.3 Tension Failure

Pz Block Shear 2

P

rm Block Shear 1

a

rc

Py tm = 2.36 in.

tc = 1.2 in

h1 = 8.39

A A1 h2

ts d1 ts

d2

Refer to AISC D1 - Block Shear 1

Allowable Tensile Stress without pin hole = 0.60 x Fy

= 30 ksi

Tensile Capacity = Block Shear 1 length x tm x 0.60 Fy

= 873.3 kips

Maximum Tension = 329.8 kips < Tensile Capacity

Unity Check = 0.378 …Accepted

Refer to AISC D1 - Block Shear 2

Allowable Tensile Stress without pin hole = 0.60 x Fy

= 30 ksi

Tensile Capacity = Block Shear 2 length x tm x 0.60 Fy

= 594.3 kips

Maximum Tension = 329.8 kips < Tensile Capacity

Unity Check = 0.555 …Accepted

5

� RIGGING EQUIPMENT - STRUCTURAL DESIGN NOTE

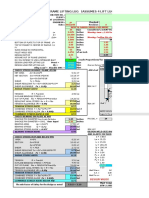

F.4 Combined Stress

P = 329.76 kips

Pz = P sin a = 233.179 kips

Py = P cos a = 233.179 kips

section A-A1:

tm = 2.36220 in.

ts = 0.78740 in. Neutral Axis

ts ts

d1 =7.87 in d2 =7.87 in

X 1 2 3 tm w= 11.81 in

4 5

Y sb b-b

sb a-a D= 15.7 in. D = d1 + d2

L= 17.3 in.

Area Ordinat thd sb a-b Centre of Gravity

No. b (in) h (in) A*X' A*Y'

(in2) x' y' Xcog Ycog

4 0.000 0.000 0.000 8.661 0.000 0.000 0.000

1 0.787401575 11.81 9.3000186 0.393700787 5.906 3.661424646 54.92136969

2 15.7480315 2.362204724 37.2000744 8.661417323 5.906 322.2053688 219.6854787

3 0.787401575 11.81 9.3000186 16.92913386 5.906 157.4412598 54.92136969

8.66

5.91

5 0.000 0.000 0 8.661 2.362 0 0

Total 55.8001116 483.3080532 329.5282181

Ordinat Relative to COG

A*X^2 A*Y^2 A*X*Y IX0 IY0 IX IY IXY

X Y

0.00 -5.91 0 0 0 0 0 0 0 0

-8.27 0.00 635.7040428 0 0 108.1129325 0.480501922 108.1129325 636.1845 0

0.00 0.00 0 0 0 17.29806919 768.8030752 17.29806919 768.8031 0

8.27 0.00 635.7040428 0 0 108.1129325 0.480501922 108.1129325 636.1845 0

8.66 -3.54 0 0 0 0 0 0 0 0

233.5239341 2041.172 0

F.5 In-plane Bending

S Ig + S (A x x' )

Iy 2

=

= 2041.2 in^4

Sy = Iy / (Xcog)

= 235.7 in^3

Inplane Moment M = Py * h1 - ( Pz * 0 )

= 1955.40 kips-in

Allowable In-plane Bending Stress = 0.66 x fyield

= 33 ksi

In-plane Bending Stress = M / Sx

= 8.297 ksi

Unity Check = 0.251 …Accepted

F.6 Out-of-Plane Bending

Sx = Ix / (Ycog)

3

= 26.96 in^3 = 0.0004 m

5% of static sling force will be applied, as per API 20th edition section 2.4.2.

5% of sling force = 16.4882 kips

6

� RIGGING EQUIPMENT - STRUCTURAL DESIGN NOTE

Out-of-plane Moment M = 138.267 kips-in.

Allowable out-of-plane Bending Stress = 0.66 x fyield

= 33 ksi

Out-of-plane bending stress = M / Sx

= 5.128 ksi

Unity Check = 0.155

…Accepted

Axial Tensile Stress

Allowable tensile stress = 0.6 x Fy

= 30 ksi

Axial Tensile Force (Pz) = 233.179 kips

Tensile Area (As) = 2*(((rm-dh/2)*tm)+2*((Rc-dh/2)*tc))

= 55.8001 in^2

Axial Tensile Stress = Pz / As

= 4.179 ksi

Unity Check = 0.139 …Accepted

Combined Axial Tension and Bending

UC = fa / Ft + fip / Fb + fop / Fb

= 0.139 + 0.3 + 0.155

= 0.545 …Accepted

Horizontal Direction (Main Plate)

Allowable shear stress = 0.4 x fyield

= 20 ksi

Shear force, Py = 233.179 kips

Shear Area (As) = 55.8001 in^2

Shear stress = Py / As

= 4.179 ksi

Unity Check = Shear Stress / Allowable Shear Stress

= 0.209 …Accepted

F.7 Von Misses Stress

2 2 2 0.5

s = (fx + fy + 3fs )

where

fx : total stress in x-dir. = 12.48 ksi (due to in-plane moment and tension)

fy : total stress in y-dir. = 5.13 ksi (due to out of plane moment)

fs : shear stress = 4.18 ksi (due to Pv)

s = 15.309 ksi

Allowable stress = 0.75x Fy = 37.5 ksi

Unity Check = 0.408 …Accepted

G. Welding Sizing

Weld of cheek plate to main plate

Weld type : E60XX electrode with Fv Fexx = 60 ksi

Allowable Shear Stress for Fillet Weld is the lesser of :

Fs = 0.6*(1/22)*Fexx

= 12.7 ksi

Allowable Shear Stress = 12.7 ksi

=

Load at Check Plate = Ps*(tc/(2*tc+tm)) Tc = 0

= 83.12 kips

half

Effective weld length =

perimete

= 375.4 mm 14.78 in

Minimum Fillet Size = 11.2 mm 0.44 in

7

� RIGGING EQUIPMENT - STRUCTURAL DESIGN NOTE

Size of fillet welds: Min 0.7 x Thk Cheek Plate

Min 0.7 x Thk Cheek Plate = 21.4 mm 0.84 in

Max Thk Cheek Plate-2mm = 28.5 mm 1.12 in

Used fillet weld size = 22 mm 0.87 in …Accepted