Professional Documents

Culture Documents

Tatoray Reacrors

Tatoray Reacrors

Uploaded by

gshdavidOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tatoray Reacrors

Tatoray Reacrors

Uploaded by

gshdavidCopyright:

Available Formats

Tatoray

TM

Aromatics

A

r

o

m

a

t

i

c

s

Application

The Tatoray process is used to selectively convert

toluene, C

9

aromatics (A

9

) and C

10

aromatics (A

10

)

into more valuable benzene and xylenes. In a modern

aromatics complex, this process is integrated between

the aromatics fractionation and xylene recovery sections

of the plant. Toluene is fed to the Tatoray process unit

rather than being blended into the gasoline pool or sold

for solvent applications.

Incorporating a Tatoray unit into an aromatics complex

can more than double the yield of para-xylene from a

given naphtha feedstock. To maximize the production of

para-xylene from the complex, A

9

and A

10

by-product

can be fed with toluene to the Tatoray unit. The avail-

ability of additional methyl groups from the A

9

and A

10

shifts the chemical equilibrium from benzene production

to xylenes production. In recent years, the demand for

para-xylene has outstripped the supply of mixed xylenes

contained in reformate. The Tatoray process therefore

provides an ideal way to produce additional mixed

xylenes from low-value toluene and heavy aromatics.

Process chemistry

The two major reactions in the Tatoray process are

disproportionation and transalklyation. The conversion

of toluene into benzene and xylenes is called toluene

disproportionation. Transalklyation is the conversion of a

mixture of toluene and A

9

/A

10

into xylenes and benzene.

The Tatoray process is designed to function at a much

higher level of conversion per pass than other toluene

disproportionation processes. With a typical 50:50 feed-

stock ratio of toluene and C

9

+

aromatics, the overall

conversion is approximately 50% per pass. This high

conversion level minimizes the amount of unconverted

feed that must be recycled back through the BT frac-

tionation section of the complex which reduces the size

of the benzene and toluene columns, the size of the

Tatoray process unit, and the utility consumption of all

of these units.

The Tatoray process reactions are conducted in a

hydrogen atmosphere to minimize coke formation on the

catalyst. Since there is negligible ring destruction in the

Tatoray process, there is very little hydrogen consump-

tion due to the primary reactions. In addition, the methyl

groups are highly stable at reaction conditions and are

therefore essentially conserved in the reaction. Most of

the hydrogen consumption can therefore be attributed to

the cracking of nonaromatic impurities in the feed to the

Tatoray unit and the dealkylation of C

2

-

C

4

from the A

9

+

.

UOPs TA-20

TM

catalyst has demonstrated higher activity

and higher stability than to its predecessor TA-5

TM

. The

stability of TA-20 is nearly an order of magnitude higher,

which results in improved on-stream efficiency and a

reduction in regeneration frequency. Commercial perform-

ance of this catalyst has been outstanding.

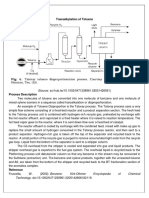

Process description

The Tatoray process uses a flow scheme consisting of a

fixed-bed reactor and a product separation section. The

fresh feed to the Tatoray unit is combined with hydrogen-

rich recycle gas, preheated by exchange with the hot

reactor effluent, and vaporized in a fired heater where it

is raised to reaction temperature. The hot feed vapor

goes to the reactor, where it is sent down-flow over a

fixed bed of catalyst.

The reactor effluent is cooled by exchange with the

combined feed, mixed with make-up gas to replace the

small amount of hydrogen consumed in the reactor, and

then sent to a product separator. Hydrogen-rich gas is

taken off the top of the separator and recycled back to

the reactor. A small portion of the recycle gas is purged

to remove accumulated light ends from the recycle gas

loop. Liquid from the bottom of the separator is sent to a

stripper column.

The C

5

overhead from the stripper is cooled and sepa-

rated into gas and liquid products. The stripper overhead

Stripper

Purge

Gas to

Isomar Unit

Recycle Gas

Toluene from

Toluene Column

Separator Reactor Heater Feed Surge

Drum

C

9

Aromatics

from A

9

Column

Toluene from

Parex Unit

Fuel Gas

Overhead Liquid

Product

Tatoray Process

Tatory 2

gas is exported to the fuel gas system. The overhead

liquid is typically recycled back to the benzene column

so that any benzene in this stream may be recovered as

a product stream, along with the benzene from the ED

Sulfolane

TM

.

Features and benefits

Ability to handle wide range of feedstocks - A

Tatoray unit is capable of processing feedstocks

ranging from 100 wt-% toluene to 100 wt-% A

9

+

.

The ability to process A

9

+

makes more feedstock

available for xylenes production and dramatically

shifts the selectivity of the unit away from benzene.

More PX from naphtha by adding a Tatoray unit -

An aromatics complex without a Tatoray unit can

produce approximately 200,000 MTA of para-xylene

from 25,000 BPSD of Light Arabian naphtha. If an

A

7

Tatoray unit (toluene feed only) is added to the

complex, the same amount of naphtha can produce

280,000 MTA of para-xylene, a 40% increase.

When an A

7

/A

9

+

Tatoray process unit is added to

the complex, the endpoint of the naphtha is

increased from 300 to 360F (149C to 182C) in

order to maximize the amount of A

9

+

precursors in

the feed. The heavier naphtha will produce approxi-

mately 420,000 MTA para-xylene an increase of

110% over the base complex.

Xylenes produced are low in EB - The Tatoray

process produces petrochemical grade benzene

and xylene products. TA-20 shows a high yield of

xylenes which contain an equilibrium distribution of

xylene isomers and is very low in ethyl benzene

(EB). This low EB concentration makes the xylenes

produced by the Tatoray process valuable as feed-

stock to either a Parex

TM

unit or a para-xylene crys-

tallization unit.

Highly stable catalyst - The excellent stability of

TA-20 has allowed operation at higher conversion

and space velocity, while maintaining long cycle

lengths. This translates to higher on-stream times

and capital utilization.

Economics

The investment cost and utility consumption for a typical

Tatoray unit is shown below. The basis for this case is a

unit processing 1680 KMTA (34,800 BPD) of a feed

consisting of 50 wt-% toluene and 50 wt-% A

9

+

. The

investment cost is limited to the Tatoray unit and stripper

column and does not include further downstream product

fractionation.

Estimated Erected Cost, US MM$ 27

(2006 US Gulf coast basis, Inside battery limits only)

Utility Consumption

Electric power, kW 1137

Cooling water, m

3

/h 609

Fuel fired, mmkcal/hr * 9

* does not include fuel credit for light ends

Commercial experience

As of 2006, UOP has licensed a total of 48 Tatoray

units. 42 of these units are in operation and the rest are

in various stages of design and construction. Feedstocks

range from 100 wt-% toluene to a mixture of 30 wt-%

toluene and 70 wt-% A

9

+

. Design feed rates range from

92 to 2700 KMTA ( 2000 to 59,000 BPD).

For more information

Tatoray technology services are available upon request.

For more information, contact your local UOP

representative or our Des Plaines sales office:

e-mail: info@uop.com

fax: +1-847-391-2253

phone: +1-847-391-2000

2006 UOP LLC. All rights reserved.

The information in this document should not be construed as a representation for

which UOP assumes legal responsibility, or an authorization or recommendation

to practice a patented invention without a license.

UOP 4680-17 1106AR0Ah

UOP LLC

25 East Algonquin Road

Des Plaines, IL 60017-5017

U.S.A.

www.uop.com

You might also like

- Ebook Understanding Social Problems PDF Full Chapter PDFDocument67 pagesEbook Understanding Social Problems PDF Full Chapter PDFjames.chandler475100% (33)

- New Olefin Production Technologies in SINOPECDocument10 pagesNew Olefin Production Technologies in SINOPECTrevor J. HutleyNo ratings yet

- A Project Report On Linear Alkyl Benzene (L.A.B.) : Pritesh S. Chauhan (CH-09)Document131 pagesA Project Report On Linear Alkyl Benzene (L.A.B.) : Pritesh S. Chauhan (CH-09)Navjyot Singh100% (1)

- Questionnaire FOR LOANS AND ADVANCESDocument4 pagesQuestionnaire FOR LOANS AND ADVANCEStulasinad12371% (7)

- Uop Sulfolane Process: Thomas J. Stoodt and Antoine NegizDocument12 pagesUop Sulfolane Process: Thomas J. Stoodt and Antoine NegizAshraf Serag100% (1)

- Uop Par-Isom Process: Nelson A. CusherDocument6 pagesUop Par-Isom Process: Nelson A. CusherBharavi K S100% (1)

- Uop Sulfolane Process: Thomas J. Stoodt and Antoine NegizDocument12 pagesUop Sulfolane Process: Thomas J. Stoodt and Antoine NegizBharavi K S100% (1)

- WheelHorse 36 Inch Tiller Manual Models 79271, 99271, 9861915Document20 pagesWheelHorse 36 Inch Tiller Manual Models 79271, 99271, 9861915Kevins Small Engine and Tractor Service100% (3)

- Tech Papers PxMax and XyMaxDocument18 pagesTech Papers PxMax and XyMaxSaurav De100% (1)

- Tatoraytechsheet PDFDocument2 pagesTatoraytechsheet PDFAnubhavAgarwalNo ratings yet

- 42 Aromatics ComplexDocument4 pages42 Aromatics Complexmostafamagdy100% (1)

- Base Aromatics Production Processes: P A R T 2Document12 pagesBase Aromatics Production Processes: P A R T 2Bharavi K SNo ratings yet

- Transalkylation of Toluene PDFDocument2 pagesTransalkylation of Toluene PDFAidonNo ratings yet

- Uop Tatoray Process: Antoine Negiz and Thomas J. StoodtDocument10 pagesUop Tatoray Process: Antoine Negiz and Thomas J. StoodtBharavi K SNo ratings yet

- Para-Xylene Production ProcessDocument3 pagesPara-Xylene Production ProcessHashan Eranda100% (2)

- UOP PX-Plus ™ XPDocument2 pagesUOP PX-Plus ™ XPana_dcz7154No ratings yet

- Axen ExxonDocument8 pagesAxen ExxonAkshata DalviNo ratings yet

- TA 20HP CatalystDocument1 pageTA 20HP Catalystdimkuh0% (1)

- Linear Alkylbenzene Detal ProcessDocument1 pageLinear Alkylbenzene Detal Processramirali100% (1)

- Process Design For The Production of Ethylene From EthanolDocument144 pagesProcess Design For The Production of Ethylene From EthanolJorge RicoNo ratings yet

- TSPenex ProcessDocument2 pagesTSPenex Processstavros7100% (1)

- Uop Parex Process: Scott E. CommissarisDocument8 pagesUop Parex Process: Scott E. CommissarisBharavi K SNo ratings yet

- UOP Aromatics Paraxylene Capture Paper1Document16 pagesUOP Aromatics Paraxylene Capture Paper1thanga1981100% (1)

- Linear Alkylbenzene ProductionDocument20 pagesLinear Alkylbenzene ProductionAhmed AtefNo ratings yet

- Production of Maleic Anhydride PresentationDocument15 pagesProduction of Maleic Anhydride PresentationNqobile LowakwaMkhize100% (1)

- Ethylene and Acetylene Plant PDFDocument405 pagesEthylene and Acetylene Plant PDFاحمد الدلالNo ratings yet

- IsomerizationDocument10 pagesIsomerizationRizwan Shehzad100% (2)

- Selective - Hydrogenation Description (UOP)Document1 pageSelective - Hydrogenation Description (UOP)Wong Yee Sun100% (1)

- Aromatics PDFDocument24 pagesAromatics PDFGerardo RiosNo ratings yet

- PolypropyleneDocument9 pagesPolypropyleneprocesspipingdesignNo ratings yet

- Hydrotreating PresentationDocument24 pagesHydrotreating PresentationAnyamanee SiripojanakulNo ratings yet

- Isomerization ProcessDocument35 pagesIsomerization ProcessAsim Memon100% (1)

- Catalytic Isomerization of Light Alkanes - T.loftenDocument133 pagesCatalytic Isomerization of Light Alkanes - T.loftenIrina Ammosova100% (2)

- Dehydration of Ethanol To EthyleneDocument10 pagesDehydration of Ethanol To EthylenewiboonwiNo ratings yet

- Steam CrackingDocument4 pagesSteam CrackingJoseph BirungNo ratings yet

- Spheripol PlantDocument17 pagesSpheripol PlantTato Flores100% (1)

- Maleic AnhydrideDocument6 pagesMaleic AnhydrideTechnologist ChemicalNo ratings yet

- 28 Olefin CrackingDocument2 pages28 Olefin CrackingRohisham Ismail100% (1)

- Linear Alkylbenzene 6035 1 HighDocument1 pageLinear Alkylbenzene 6035 1 HighSavan JaviaNo ratings yet

- Ax EnsDocument29 pagesAx EnsAhmed Khalid100% (1)

- Acetic Acid ProductionDocument6 pagesAcetic Acid Productionmmoradi55No ratings yet

- T Basak AromaticsDocument41 pagesT Basak AromaticsDP PurwadiNo ratings yet

- 0910 4 AbsDocument9 pages0910 4 AbsEngr Muhammad AqibNo ratings yet

- Iocl Section 1 - Process SpecficationDocument73 pagesIocl Section 1 - Process SpecficationYogi173No ratings yet

- Ethylene ProductionDocument14 pagesEthylene ProductionMaria Cecille Sarmiento Garcia100% (1)

- C4 Operations Optimization PDFDocument45 pagesC4 Operations Optimization PDFViệt HàNo ratings yet

- Acetic Acid ProductionDocument4 pagesAcetic Acid Productionfatin_mujahidahNo ratings yet

- Best Practices For Aromatics Extractive Distillation in Integrated ComplexesDocument8 pagesBest Practices For Aromatics Extractive Distillation in Integrated ComplexesNaiduJagarapuNo ratings yet

- Cativa BPDocument12 pagesCativa BPGhaya Bani Rushaid100% (1)

- CCR PlatformingDocument35 pagesCCR Platformingmohammed67% (3)

- Phenol PlantDocument33 pagesPhenol PlantrakeshNo ratings yet

- A Financial Analysis For The Production of HQ Propylene-MustangDocument19 pagesA Financial Analysis For The Production of HQ Propylene-Mustangandrei12320003181No ratings yet

- "New Reforming Concepts For Large Scale NH Plants": Paper AbstractDocument17 pages"New Reforming Concepts For Large Scale NH Plants": Paper AbstractAlfonso Blanco100% (1)

- UOP Olfins.Document28 pagesUOP Olfins.agarwalashwin32100% (1)

- International Thermodynamic Tables of the Fluid State: Propylene (Propene)From EverandInternational Thermodynamic Tables of the Fluid State: Propylene (Propene)No ratings yet

- Separation ChainDocument2 pagesSeparation ChainKaleem UllahNo ratings yet

- Transalkylation of TolueneDocument2 pagesTransalkylation of TolueneAidonNo ratings yet

- Us 20030130549Document11 pagesUs 20030130549Văn Đại - BKHNNo ratings yet

- UOP CCR PlatformingDocument3 pagesUOP CCR PlatformingEduardo Carrillo Diaz100% (1)

- Benzene Toluene Fractionation Unit: BackgroundDocument2 pagesBenzene Toluene Fractionation Unit: BackgroundHemanth Peddavenkatappa GariNo ratings yet

- PERP Program - Optimizing Aromatics Production New Report AlertDocument4 pagesPERP Program - Optimizing Aromatics Production New Report AlertTissa Novida Aulia ZahraNo ratings yet

- Worksafe Bulletin: Safe Procedures For Vacuum Truck OperationsDocument2 pagesWorksafe Bulletin: Safe Procedures For Vacuum Truck OperationsgshdavidNo ratings yet

- Crude Oil Properties (Laboratory)Document15 pagesCrude Oil Properties (Laboratory)gshdavidNo ratings yet

- P&ID SymbolDocument18 pagesP&ID SymbolBagus Okti100% (1)

- Basket Strainer Intro PDFDocument4 pagesBasket Strainer Intro PDFgshdavidNo ratings yet

- 007 UTube CleaningDocument2 pages007 UTube CleaninggshdavidNo ratings yet

- Inspection and Testing of Piping Systems ES-14-602-02Document44 pagesInspection and Testing of Piping Systems ES-14-602-02Edmund MoraldeNo ratings yet

- Code Pid PDFDocument6 pagesCode Pid PDFMejdi Sylas ToudjiNo ratings yet

- Hot Tapping GuideDocument3 pagesHot Tapping GuidegshdavidNo ratings yet

- Hot Tapping: Typical Hot Tap ApplicationDocument1 pageHot Tapping: Typical Hot Tap ApplicationgshdavidNo ratings yet

- Catalyst in Refining PetrochemicalsDocument5 pagesCatalyst in Refining PetrochemicalsgshdavidNo ratings yet

- Hot Tap ProcedureDocument21 pagesHot Tap ProcedureImanuel Sitepu100% (1)

- Pages: 20-25 May, 2000: By: Bill RockwellDocument7 pagesPages: 20-25 May, 2000: By: Bill RockwellgshdavidNo ratings yet

- Tatoray ReacrorsDocument2 pagesTatoray ReacrorsgshdavidNo ratings yet

- Proposed Basket StrainerDocument1 pageProposed Basket StrainergshdavidNo ratings yet

- Mesh Size EquivalentsDocument2 pagesMesh Size EquivalentsFrancisco Chavez ContrerasNo ratings yet

- Munters High Temp Psych ChartDocument2 pagesMunters High Temp Psych ChartaniruddhaskNo ratings yet

- Filtration System With BypassDocument1 pageFiltration System With BypassgshdavidNo ratings yet

- Filtration System Without BypassDocument1 pageFiltration System Without BypassgshdavidNo ratings yet

- Minimum Oil Circuit BreakerDocument4 pagesMinimum Oil Circuit BreakergshdavidNo ratings yet

- Portable 8X8X10: Command ContainerDocument9 pagesPortable 8X8X10: Command ContainergshdavidNo ratings yet

- Roboshot at + Series: High-Performance, High-Reliability and High-Productivity Electric Injection Molding MachineDocument12 pagesRoboshot at + Series: High-Performance, High-Reliability and High-Productivity Electric Injection Molding MachineLeandro SalvadorNo ratings yet

- LSpy MRD - v1.7-3 GCDocument14 pagesLSpy MRD - v1.7-3 GCStephen BakerNo ratings yet

- Gpib TutorialDocument14 pagesGpib Tutorialangelo_lopez1993No ratings yet

- HR Project - GEPGODocument44 pagesHR Project - GEPGOMuhammed Bilal Asmat Ullah100% (2)

- Renewable and Sustainable Energy Reviews 16 (2012) 2696 - 2723Document28 pagesRenewable and Sustainable Energy Reviews 16 (2012) 2696 - 2723Raquel Gámez100% (1)

- CF60 LRDocument100 pagesCF60 LRAnonymous x57K8VUwNo ratings yet

- LN SATA Series - Standalone DVR User's Manual (20080507)Document121 pagesLN SATA Series - Standalone DVR User's Manual (20080507)Kulik MonicaNo ratings yet

- IBH Link UA Manual PDFDocument302 pagesIBH Link UA Manual PDFjavixl1No ratings yet

- Resolution - December 5, 2020Document1 pageResolution - December 5, 2020Dennis AlbisoNo ratings yet

- FDN335NDocument5 pagesFDN335NFernando YanoNo ratings yet

- Types of SolidsDocument39 pagesTypes of SolidsTHARIK ANWAR100% (2)

- NPC v. Pinatubo CommercialDocument13 pagesNPC v. Pinatubo CommercialZafra ChunNo ratings yet

- SG33 - 40 - 50CX User ManualDocument95 pagesSG33 - 40 - 50CX User ManualKatherine SmithNo ratings yet

- MGP1-BOC1888PO001-H02-0001 - 003 - Overall - Code 1 - MK - 150823Document10 pagesMGP1-BOC1888PO001-H02-0001 - 003 - Overall - Code 1 - MK - 150823jobertNo ratings yet

- The Tylenol Crisis: How Effective Public Relations Saved Johnson & JohnsonDocument7 pagesThe Tylenol Crisis: How Effective Public Relations Saved Johnson & Johnsonchocobearsweets100% (1)

- MoneyGirls Inc Rock FellowshipDocument1 pageMoneyGirls Inc Rock FellowshipHaileyNo ratings yet

- Amitabh BachchanDocument26 pagesAmitabh BachchanSai KuamrNo ratings yet

- FP-70 Angus Ficha TecnicaDocument2 pagesFP-70 Angus Ficha TecnicaAnonymous UArnIExNo ratings yet

- Plastocrete Rt6 Plus Pds enDocument2 pagesPlastocrete Rt6 Plus Pds enVSMS8678No ratings yet

- CAD Slides 02Document45 pagesCAD Slides 02KyogbsyNo ratings yet

- Internship's Report On: Management and Maintenance of The Network System of Radiant Communications LimitedDocument44 pagesInternship's Report On: Management and Maintenance of The Network System of Radiant Communications LimitedMahamudul HasanNo ratings yet

- Assignment 2-CE LAWS, ETHICS AND CONTRACTSDocument3 pagesAssignment 2-CE LAWS, ETHICS AND CONTRACTSLuke MoraledaNo ratings yet

- Cheat Codes of Counter StrikeDocument102 pagesCheat Codes of Counter StrikeNeha PankiNo ratings yet

- SKF CouplingDocument16 pagesSKF CouplingmatchutNo ratings yet

- CONSOLIDATED LABOR ASSOCIATION OF THE PHILIPPINES v. MARSMAN & CO. INC.Document1 pageCONSOLIDATED LABOR ASSOCIATION OF THE PHILIPPINES v. MARSMAN & CO. INC.EnauxNo ratings yet

- Styleitaliano Rubber Dam Perforations UPDATED ViaDocument6 pagesStyleitaliano Rubber Dam Perforations UPDATED ViablokolbNo ratings yet

- Contingency Fees Agreement FormDocument4 pagesContingency Fees Agreement FormYolanda GarsulaNo ratings yet