Professional Documents

Culture Documents

Bro Sura Nafta

Uploaded by

Daniel MikicCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bro Sura Nafta

Uploaded by

Daniel MikicCopyright:

Available Formats

1

1

Oil and Gas Production

and Exploration, Part I

Presented by:

Steven Marzuola

American Translators Association

52

nd

Annual Conference

Boston, October 26, 2011

2

Introduction

Dope, Joints, Tripping

Internal Flush

Strippers

Casing, Tubing, Liner

API - American Petroleum Institute

2

3

Why oil?

Refined products 45 megajoules

/ kg

One gallon carries one airline

passenger 45 miles

Coal: 24 megajoules per

kilogram

Club sandwich: 1.3 megajoules

Convenience of liquid fuel

Large amount of power in small volume

(Energy density)

4

Life of an Oilfield

Reservoir formation

Discovery and exploration

Drilling

Primary production

Second production, interventions

Abandonment

3

5

Early oil discoveries

Usually guided by surface seepage. Lake

Maracaibo, Caspian Sea, western

Pennsylvania

Used by ships, seeking tar for repairs.

Oil was usually a nuisance encountered when

drilling water wells

Research in mid 1800s, search to replace

whale oil used in lamps

First rotary drilled well - 1859, Titusville, PA

6

Blowouts

In movies, often

portrayed as

success.

Today, a blowout

is a huge and

expensive

mistake.

4

7

8

Historical practices

On land, in the USA: Surface owner owns

everything to the center of the earth.

Often led to inefficiencies, legal battles.

Today, mineral rights on most property

are bought and sold separately from the

surface land. Field or reservoir usually

managed as a single unit.

5

9

Congestion

Spindletop, Texas, 1902

10

Requirements of a Reservoir

1. Source or Generator rock

2. Reservoir

3. Seal or cap rock

4. Structure, hydrocarbons trap

5. Timing

6. Maturation

7. Migration

6

11

Exploration aided by geology

Surface features

Anticlines

Faults, Salt domes

Presence of iron

Subsurface surveys

Gravimeter, Magnetometer

Seismic - 2D, 3D

12

Anticlines

Salt dome

7

13

Structural trap

14

Gravimeter

8

15

Seismic surveying

16

3D Seismic images

9

17

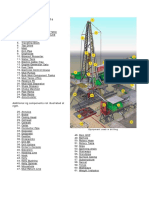

Rig = factory

18

Todays drilling

Most wells drilled using rotary drilling

Steel drill pipe comes in 30-foot sections

that are threaded on both ends.

Each section of drill pipe is called a joint.

After drilling 30 feet, the kelly must be

raised and another joint of pipe added

below the kelly. This is called making a

connection.

10

19

Drill string components

Typical rotary drilling

Bottom Hole Assembly (BHA)

Additional components: mud

motors, LWD / MWD tools,

steerable subs

20

Drill bits

Diamond bits

Tricone rock bit

Tungsten carbide inserts

11

21

Surface components

Kelly, kelly bushing, swivel, hose

22

Pipehandling tools

Drill pipe slips

Tongs

12

23

Top Drive

Advantages

Drill with triples

Reduced connection

time

Quickly restore

pressure control while

tripping out

24

Pressure control

13

25

Flow of drilling mud

26

Hydrostatic pressure

Pressure is proportional to:

Height (depth) of fluid column

Density (i.e. lbs/gallon)

Mud column must

counterbalance formation

pressure

Drilling mud 1.5 - 2.5 times

more dense than water

14

27

Mud system components

Shale shakers

Desanders and desilters (hydrocyclones)

Degassers

Centrifuges

Mud agitators

Cuttings washers

28

Water-based vs. oil-based muds

Water most widely used, but can cause

skin damage, contaminate formation

In response, oil-based muds were

developed

Adverse effects on rubber products,

(seals, pump parts), environmental

concern

15

29

Modern improvements

Major changes in past 20 years are:

Computers and software => 3D seismic

Top drive - all offshore rigs, big/deep onshore

MWD - Measure While Drilling technology

Mud motors

Directional drilling => horizontal wells

30

Horizontal drilling

Multilateral completions

Multiple exit points from

main well bore

Increased length of hole

exposed to productive

formations

16

31

Completions

Most wells lined with steel casing.

Purposes:

Protect from cave-ins

Protect surface formations, water supply

Isolate producing formations

Prevent blowouts

Innermost pipe is tubing, removable, to

isolate flow from casing

32

Casing and wellhead

17

33

Casing and tubing

connections

Non-upset

www.glossary.oilfield.slb.com

External upset

IF = internal flush

34

Wellheads/Christmas trees

18

35

Flange connection

36

Separation

equipment

19

37

Stages of production

Primary recovery - natural flow

Secondary recovery - mechanical pumping,

gas lift

Tertiary or Enhanced Oil Recovery - Gas

injection, thermal, chemical

38

Workover and well servicing

Together known as intervention

Workover rig similar to drilling. Performs

acidizing, fracturing stimulation,

cementing, deeper drilling, recompletion

to a different zone, sidetracking

Well servicing - wireline, rod pulling units,

flexible tubing

20

39

Well servicing rig

40

Flexible tubing rig

21

41

Pumping

42

Typical

Subsurface

Pump

22

43

Other methods

44

Flowlines and Pipelines

Flowlines link individual wells or groups to a

processing facility.

Gas / oil / water separation

Metering

Sand removal

Pipelines lead from field / process facility,

ultimately to refinery

23

45

Pigs

Dumb pigs: Cleaning, water displacement,

chemical treatment

Smart pigs: Measure internal diameter, inspect

for cracking, corrosion

Magnetic flux, X-ray, ultrasonic, video

46

Peak Oil, or Hubberts Peak

M. King Hubbert - Shell geophysicist

Theory: production tends to follow bell-

shaped curve. Can be predicted in

advance.

Production increases early due to

discoveries and new infrastructure. Later

declines due to depletion.

24

47

Source: http://www.theoildrum.com/node/8310

Peak Oil (cont.)

48

Peak Oil (cont.)

In 1956, Hubbert predicted peak of USA

production late 1960s - early 1970s.

Controversial, but proven right by 1976.

Actual peak was in 1970.

Is it applicable to world production?

Rapidly growing demand in China, India

New technologies, increased depletion rates

What is the effect of higher real prices?

25

49

Historical oil production

Source: http://wikipedia.org

50

Steven Marzuola

281-381-9337

www.techlanguage.com

2011 Steven Marzuola

Houston Interpreters and

Translators Association

American Translators Association

You might also like

- Installation, Testing, and Maintenance of Fire Hydrants: FieldDocument85 pagesInstallation, Testing, and Maintenance of Fire Hydrants: FieldCristiam MondragónNo ratings yet

- 100 Basic Terminologies For Petroleum IndustryDocument7 pages100 Basic Terminologies For Petroleum IndustryHumaira Mirza100% (1)

- Process TrainingDocument49 pagesProcess TrainingMuddassar Mahmood0% (2)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- Groundwater & WellsDocument31 pagesGroundwater & WellsArman Atienza Magcawas17% (6)

- Corrosion Prevention Yanbu RefineryDocument10 pagesCorrosion Prevention Yanbu RefineryOmid Hn100% (1)

- A Masters Guide To Ships Piping 2 ND EditionDocument42 pagesA Masters Guide To Ships Piping 2 ND EditionMoe LattNo ratings yet

- Oil and Gas Well CompletionsDocument93 pagesOil and Gas Well CompletionsKhalid Waheed Shaikh100% (3)

- PET305 Oil ProductionDocument49 pagesPET305 Oil ProductionShafayet A Siddique100% (1)

- UH Final Presentation 1 - Sept 9, 2013 - PrintingDocument68 pagesUH Final Presentation 1 - Sept 9, 2013 - PrintingTauqeer IqbalNo ratings yet

- Drilling Methods and Type of Rigs PDFDocument26 pagesDrilling Methods and Type of Rigs PDFnamdq-1No ratings yet

- Oil & Gas HandbookDocument170 pagesOil & Gas HandbookRagh100% (10)

- 03 ProductionDocument65 pages03 Productionkarthikv83No ratings yet

- Understanding Process Equipment for Operators and EngineersFrom EverandUnderstanding Process Equipment for Operators and EngineersRating: 4.5 out of 5 stars4.5/5 (3)

- Low Pressure SewersDocument23 pagesLow Pressure SewersUlil A JaNo ratings yet

- Cooling Water BasicsDocument163 pagesCooling Water BasicsTin Aung Kyi94% (16)

- Drilling Simulator: Lab ReportDocument22 pagesDrilling Simulator: Lab ReportFizz MartinNo ratings yet

- BOPs and Their ControlDocument59 pagesBOPs and Their Controlelflaco79No ratings yet

- BOPs and Their ControlDocument59 pagesBOPs and Their ControlYoun Seok Choi100% (1)

- Rig Components PDFDocument19 pagesRig Components PDFBalant AxNo ratings yet

- Circulating Water SystemDocument44 pagesCirculating Water SystemVinoth100% (1)

- Flow Assurance IntroductionDocument71 pagesFlow Assurance IntroductionClement ChimaNo ratings yet

- Chapter (4) Drilling Methods and Type of RigsDocument26 pagesChapter (4) Drilling Methods and Type of RigsFarhat Mirza100% (1)

- Troubleshooting Catalyst Losses in The FCC Unit Kou BASF FCCU Galveston 2016Document31 pagesTroubleshooting Catalyst Losses in The FCC Unit Kou BASF FCCU Galveston 2016GOPALJI SINGHNo ratings yet

- The Well From HellDocument56 pagesThe Well From HellberrouiNo ratings yet

- Sand Vac OGJ-APRIL-2002 PDFDocument6 pagesSand Vac OGJ-APRIL-2002 PDFAquiles CarreraNo ratings yet

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentFrom EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentNo ratings yet

- Flow Assurance Technology Options Pipe Sizing For Deep Water Long Distance Oil Gas TransportDocument40 pagesFlow Assurance Technology Options Pipe Sizing For Deep Water Long Distance Oil Gas TransportIsaac Mohanadasan100% (1)

- Plumbing Systems For BuildingsDocument62 pagesPlumbing Systems For BuildingsDileep Kumar100% (1)

- 2 - Life of WellDocument18 pages2 - Life of WellmsvaletNo ratings yet

- Oil and Gas Artificial Fluid Lifting TechniquesFrom EverandOil and Gas Artificial Fluid Lifting TechniquesRating: 5 out of 5 stars5/5 (1)

- Heat Recovery Steam Generators (HRSG) and Treatment ChemistriesDocument50 pagesHeat Recovery Steam Generators (HRSG) and Treatment ChemistriesMarioNo ratings yet

- CondenserDocument57 pagesCondenserEzhil Vendhan Palanisamy100% (1)

- PETE 2050 - Introduction To Petroleum Engineering: Oil and Gas Production OperationsDocument61 pagesPETE 2050 - Introduction To Petroleum Engineering: Oil and Gas Production OperationsJaiyeola Solomon AdeniyiNo ratings yet

- Esanda Oil Gas GlossaryDocument12 pagesEsanda Oil Gas Glossary786tip786No ratings yet

- Hole ProblemsDocument39 pagesHole Problemsgeber39100% (1)

- Hole ProblemsDocument39 pagesHole ProblemsBayu Raka Janasri100% (1)

- Production - CHEN515Document33 pagesProduction - CHEN515Levi Inuwa100% (1)

- Day 2Document8 pagesDay 2Gleden UmayamNo ratings yet

- Parte Superior Do Formulário Parte Superior Do FormulárioDocument16 pagesParte Superior Do Formulário Parte Superior Do FormulárioVinícius Roppe PortellaNo ratings yet

- Question Bank 2015Document74 pagesQuestion Bank 2015Jayakumar ViswanathanNo ratings yet

- Oil Well DrillingDocument21 pagesOil Well DrillingMoonking 03No ratings yet

- Drilling Cost and Hole ProblemsDocument39 pagesDrilling Cost and Hole ProblemsArun Sharma100% (1)

- Sand Vac Ogj April 2002Document6 pagesSand Vac Ogj April 2002Aquiles CarreraNo ratings yet

- FPEC PetroBowl Competition SampleQuestions 2013 5 PDFDocument15 pagesFPEC PetroBowl Competition SampleQuestions 2013 5 PDFSrWilson Z AriasNo ratings yet

- 02.understanding Process Equipment For Operators & Engineers-54Document5 pages02.understanding Process Equipment For Operators & Engineers-54Aatish ChandrawarNo ratings yet

- An Overview of Offshore Drilling: ResearchDocument9 pagesAn Overview of Offshore Drilling: ResearchvalynoNo ratings yet

- Rig ComponentDocument10 pagesRig ComponentAfasceoNo ratings yet

- Reservoir Normal Pressure Clay MudDocument6 pagesReservoir Normal Pressure Clay MudJohanes SiraitNo ratings yet

- 24 (Lecture - Vessels, Drums & Tanks)Document39 pages24 (Lecture - Vessels, Drums & Tanks)Daison PaulNo ratings yet

- Lecture Note 11-Production and FacilitiesDocument59 pagesLecture Note 11-Production and FacilitiesMOHAMAD IJAM SIREGAR BIN MULIA MoeNo ratings yet

- Hydraulic Fracturing PDFDocument21 pagesHydraulic Fracturing PDFSarah HayesNo ratings yet

- Final HE IndustrialSeminar DeshbandhuRawatDocument22 pagesFinal HE IndustrialSeminar DeshbandhuRawatdeshbandhu_rawat_me12100% (1)

- Dictionar de Petrol Si GazeDocument8 pagesDictionar de Petrol Si GazeLaPoupeeNo ratings yet

- FPEC PetroBowl Competition SampleQuestions 2013.5Document15 pagesFPEC PetroBowl Competition SampleQuestions 2013.5Nur Syaffiqa Mohamad Ruzlan100% (2)

- Boiler Water Treatment For Kiln DryingDocument42 pagesBoiler Water Treatment For Kiln DryingSyavash EnshaNo ratings yet

- List of Methods For Well TestingDocument6 pagesList of Methods For Well TestingRizwan FaridNo ratings yet

- Rotary Valve Fast Cycle Pressure Swing Adsorption PaperDocument14 pagesRotary Valve Fast Cycle Pressure Swing Adsorption Paperabhi_mohit2005No ratings yet

- هندسة انتاج 2 محاضرة 1Document16 pagesهندسة انتاج 2 محاضرة 1L ́ RadiCallyNo ratings yet

- Galet RailDocument1 pageGalet RailDaniel MikicNo ratings yet

- Mental Mesh Functional Overview 1-13-280109Document20 pagesMental Mesh Functional Overview 1-13-280109Daniel MikicNo ratings yet

- BVAA Valve User Issue 20Document92 pagesBVAA Valve User Issue 20Daniel MikicNo ratings yet

- Böhler C 9 Mv-Ig: DescriptionDocument1 pageBöhler C 9 Mv-Ig: DescriptionDaniel MikicNo ratings yet

- WPS Volume Licensing Overview PDFDocument3 pagesWPS Volume Licensing Overview PDFDaniel MikicNo ratings yet

- Bro Sura NaftaDocument25 pagesBro Sura NaftaDaniel MikicNo ratings yet

- Williams Material Suffix Common Designation Astm Casting Specification Service RecommendationsDocument1 pageWilliams Material Suffix Common Designation Astm Casting Specification Service RecommendationsDaniel MikicNo ratings yet

- 16 Materiales Compatibility With Hydrogen AzkarateDocument19 pages16 Materiales Compatibility With Hydrogen AzkaratebracioNo ratings yet

- DIN 17172celicneCeviZaTransportGasovaDocument0 pagesDIN 17172celicneCeviZaTransportGasovaDaniel MikicNo ratings yet

- Handwheels: Product Details Order / Inquiry CAD DataDocument1 pageHandwheels: Product Details Order / Inquiry CAD DataDaniel MikicNo ratings yet