Professional Documents

Culture Documents

Drill Nomenclature

Drill Nomenclature

Uploaded by

Agnivesh SharmaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Drill Nomenclature

Drill Nomenclature

Uploaded by

Agnivesh SharmaCopyright:

Available Formats

Drill Nomenclature

and Geometry

Drill Nomenclature

Drill Nomenclature

and Geometry

and Geometry

Drill Nomenclature

Drill Nomenclature

Drill Nomenclature

Drill Construction:

Drill Construction:

A twist drill is made up of three components:

A twist drill is made up of three components:

Shank

Body

Drill point

Drill Body

Drill Body

Rake

or

Helix Angle

Width of land

Body

Clearance

Width of

Land

Back Taper

Land

Heel

Leading Edge

of the Land

Flutes

Drill Nomenclature

Drill Nomenclature

Drill Nomenclature

Cutting Diameter:

Cutting Diameter:

Largest diameter measured across the

top of the lands behind the point

Back Taper

Back Taper

The diameter reduces slightly toward the shank

end of the drill, this is known as back taper

Back taper provides clearance between the drill

and workpiece preventing friction and heat

Drill Flutes

Drill Flutes

Drill Nomenclature

Drill Nomenclature

Drill Nomenclature

Flute Length:

Flute Length:

The length of flute measured from the drill

point to the end of the flute runout

Flute length determines the maximum depth of

drilling

Drill Nomenclature- Flute Construction

Drill Nomenclature

Drill Nomenclature

-

-

Flute Construction

Flute Construction

Parabolic Conventional Chipbreaker

Drill Nomenclature- Flute Construction

Drill Nomenclature

Drill Nomenclature

-

-

Flute Construction

Flute Construction

Conventional:

Conventional:

Has J shaped flute geometry

Used in a wide variety of soft and

hard drilling applications

Drill up to 3 to 4 diameters before

pecking

Most drills in the industry have

this type of construction

Drill Nomenclature -Flute Construction

Drill Nomenclature

Drill Nomenclature

-

-

Flute Construction

Flute Construction

Chipbreaker

Chipbreaker

Has special tight radius

J shaped flute

Tight radius helps to Tight radius helps to

break up chips break up chips

Heel is rolled for

increased chip space

Used in equipment with

fixed feeds where long

stingy chips are

produced

Drill Nomenclature- Flute Construction

Drill Nomenclature

Drill Nomenclature

-

-

Flute Construction

Flute Construction

Parabolic:

Parabolic:

Compound radius,

Compound radius,

cleared heel flute shape

cleared heel flute shape

Parabolic flutes

substantially increase

available flute space

for chips!

Drill Nomenclature

Drill Nomenclature

Land:

Land:

The part of the drill body

The part of the drill body

between the flutes

between the flutes

The lands provide the drill with

much of its torsional strength

Reducing the land width increases

chip space, but reduces strength

Drill Webs

Drill Webs

Drill Nomenclature -Webs

Drill Nomenclature

Drill Nomenclature

-

-

Webs

Webs

The thickness

The thickness

measured

measured

across the

across the

base of the

base of the

flutes

flutes

Contributes

to the

torsional

strength of

the drill

Drill Nomenclature

Drill Nomenclature

Web Thickness

Web Thickness

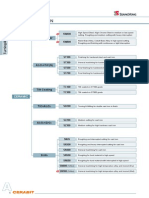

Webs normally fall into three categories:

Webs normally fall into three categories:

Light

Medium

Heavy

Web Construction

Web Construction

Web Construction

Light General

Purpose

Heavy

Duty

Drill Nomenclature- Web Thickness

Drill Nomenclature

Drill Nomenclature

-

-

Web Thickness

Web Thickness

Light:

Light:

Generally 14 to 16 % of

the cutting diameter

Found on fast helix

general purpose drills

Weakest of the drill

webs

Drill Nomenclature- Web Thickness

Drill Nomenclature

Drill Nomenclature

-

-

Web Thickness

Web Thickness

Medium

Medium

Typically 17 % to 22% of the

cutting diameter

Found on all GP drills

Found on all GP drills

Drill Nomenclature- Web Thickness

Drill Nomenclature

Drill Nomenclature

-

-

Web Thickness

Web Thickness

Heavy

Heavy

Generally 25 % to 40% of the cutting

diameter

Used on cobalt, coolant hole, parabolic,

and other

heavy duty

heavy duty drills

Drill Nomenclature- Web Construction

Drill Nomenclature

Drill Nomenclature

-

-

Web Construction

Web Construction

There are three common web

There are three common web

contructions:

contructions:

Tapered

Parallel (Pre-thinned )

Parallel-Tapered

Web Constructions

Web Constructions

Web Constructions

Parallel Web - Thin

Parallel Web - Heavy

Thinned Web then

Parallel

Constant Increase

Effects of Drill Re

Effects of Drill Re

-

-

Sharpening

Sharpening

A A

B

B

Web thickness

Section

A-A

Section

B-B

Drill

Diameter

Drill

Diameter

Web thickness

Chisel

edge length

Chisel edge

length

Web Thinning

Web Thinning

Drill webs are non-cutting

Dont contribute to the

cutting process

They consume power

and torque to move

through the work piece

Must reduce the chisel

edge length to be as

short as possible in

length!

Ground notch to

thin web and

reduce chisel

edge length

Web/Point Thinning

Web/Point Thinning

No Thinning

Conventional

Stock is removed

in such a way

as to follow

the flute contour.

No thinning as

received from the

manufacture.

Web/Point Thinning

Web/Point Thinning

Split Point

High Tensile

Notched

Two secondary back-off

grinds, adjacent to

the chisel and almost

to center

Notched point results

in centering ability

and reduction of forces

Web/Point Thinning

Web/Point Thinning

Gash Type

Flatted Lip

Type

Flatting the face

of the flute,

Eliminates

hogging-in

Grinding two half-round

gashes near the center

of the drill

Web Thinning

Web Thinning

K Notch

K Notch

Half radius notch

Half radius notch

Web is typically thinned to 8% to 12 % of

the drill diameter

Shortens chisel edge length reducing

thrust

Improves chip evacuation

Used in tougher materials and some large

diameter drills

Web Thinning

Web Thinning

R Notch

R Notch

Full radius notch

Full radius notch

Web is typically thinned to 8% to 12 % of

the drill diameter

Shortens chisel edge length reducing

thrust

Improves chip evacuation

Used primarily on coolant hole drills

Drill Helix Angles

Drill Helix Angles

Drill Nomenclature

Drill Nomenclature

Drill Nomenclature

Helix Angle:

Helix Angle:

Angle formed between a line

Angle formed between a line

drawn parallel to the axis of the

drawn parallel to the axis of the

drill and the edge of the land

drill and the edge of the land

Various Helix Angles

Various Helix Angles

Various Helix Angles

High Helix Angle

Slow Helix Angle

Regular Helix Angle

Drill Nomenclature- Helix Angle

Drill Nomenclature

Drill Nomenclature

-

- Helix Angle

Helix angles generally fall into three categories:

Helix angles generally fall into three categories:

Slow Spiral

Regular Spiral

Fast Spiral

Drill Nomenclature- Helix Angle

Drill Nomenclature

Drill Nomenclature

-

-

Helix Angle

Helix Angle

Slow Spiral

Slow Spiral

12 to 22 helix angle

Used in materials producing broken chips such Used in materials producing broken chips such

as brass or bronze, or cast iron as brass or bronze, or cast iron

Also used in horizontal applications where the

drill is not rotating

Drill Nomenclature- Helix Angle

Drill Nomenclature

Drill Nomenclature

-

-

Helix Angle

Helix Angle

Regular

Regular

28 to 32 helix angle

Found on most general purpose and cobalt drills

Used in a wide variety of drilling applications Used in a wide variety of drilling applications

Drill Nomenclature- Helix Angle

Drill Nomenclature

Drill Nomenclature

-

-

Helix Angle

Helix Angle

Fast Spiral

Fast Spiral

34 to 38 helix angle

Used on high helix general purpose and deep Used on high helix general purpose and deep

hole parabolic drills hole parabolic drills

For softer ferrous and non-ferrous materials

producing stringy chips

Drill Nomenclature- Helix Angle

Drill Nomenclature

Drill Nomenclature

-

-

Helix Angle

Helix Angle

How does changing the helix angle

How does changing the helix angle

effect performance?

effect performance?

Fast Spiral Drills

Fast Spiral Drills

Provides greater lifting power for chips, but are

weaker

Generally used in deep holes

Slow Spiral Drills

Slow Spiral Drills

Are stronger, but have less lifting power for chips

Generally limited to shallow holes

Various Helix Angles

Various Helix Angles

Regular Helix

Drill

High Helix Drill

Drill Margins

Drill Margins

Drill Nomenclature

Drill Nomenclature

Drill Nomenclature

Margins:

Margins:

The cylindrical portion of

The cylindrical portion of

the land that is

the land that is

not cut

not cut

away

away

to provide clearance

to provide clearance

The balance of the land is

reduced in diameter, known

as cleared diameter or

body clearance

Body clearance prevents Body clearance prevents

excessive rubbing and excessive rubbing and

friction friction

Margins

Margins

Margins

No

Margin

Single

Margin

Double

Margin

Triple

Margin

Drill Nomenclature- Margins

Drill Nomenclature

Drill Nomenclature

-

-

Margins

Margins

Single Margin:

Single Margin:

Has one margin adjacent to

the cutting edge

Single margins create the

least amount of rubbing and

friction with minimal support

in the hole

Most standard tools are

Most standard tools are

single margin

single margin

Drill Nomenclature

Drill Nomenclature

Drill Nomenclature

Double Margin:

Double Margin:

Has a margin at both the cutting edge and

heel

Used in specialized applications where Used in specialized applications where

precision hole size, and finish are required precision hole size, and finish are required

The additional margin adds stability and

reduced the possibility of chatter, but creates

more friction

Often used when drilling through a bushing

for support

Drill Nomenclature

Drill Nomenclature

Drill Nomenclature

Triple Margin:

Triple Margin:

Has three margins per land, one at the cutting and

heel and one in the middle of the land

Used where very high precision and hole size is Used where very high precision and hole size is

required required

Provides the greatest amount of stability and the

greatest amount of friction and rubbing

Drill Points

Drill Points

Drill Nomenclature- Points

Drill Nomenclature

Drill Nomenclature

-

-

Points

Points

The drill points has four main

The drill points has four main

features:

features:

Point Angle

Cutting Lips

Chisel Edge

Lip Relief

140

Drill Point Angles

Drill Point Angles

90

Soft and ductile

material

118

Split

(reduce thrust &

self centering -NC)

High alloyed

steels

118

Chamfer

(to reduce burr)

45

General purpose

118

Helical Point

(self centering)

118

Point Angle

High Point Angle High Point Angle (Flatter Point) (Flatter Point)

Recommend for harder and tougher Recommend for harder and tougher

materials materials

Stronger cutting edges

Shorter cutting lip produces a narrower chip

Point angle greater than 130 are generally

used in materials that have been hardened or

are extremely tough

Drill

Drill

Nomenclature

Nomenclature

Shorter, flatter cutting lips

produce narrow chips

Point Angle

Lower Point Angle

Lower Point Angle

(Sharper Point)

(Sharper Point)

For softer materials For softer materials

Points sharper than 118 are generally

used for soft non-ferrous materials and

non-metallic

Drill

Drill

Nomenclature

Nomenclature

Longer cutting lips

produce wider chips

Drill Nomenclature

Drill Nomenclature

Cutting Lips

Cutting Lips

Cutting edges that extend from

Cutting edges that extend from

the center of the drill to the

the center of the drill to the

outer diameter

outer diameter

On most standard drills, the

cutting edge should form a

straight line

Some specialty and high

performance drills have curved

cutting lips

Drill Nomenclature

Drill Nomenclature

-

-

Points

Points

Elements of Drill Points

Elements of Drill Points

Lip Relief Angle Lip Relief Angle

Varies with the diameter of the drill and hardness

of the material

On larger diameters and drills for harder materials,

lip relief is decreased to as low as 8

Drills for soft materials and small diameters have

high relief angles up to 24

Lip relief angles are measured across the margin Lip relief angles are measured across the margin

width width

Incorrect Lip Clearance Incorrect Lip Clearance

Incorrect Lip Clearance

No lip

clearance

Extreme pressure

required to make drill

cut; top of drill shows

signs of rubbing and

heat caused by little or

no lip clearance

Corners of drill

broken due to

excessive lip

clearance

Excessive

=

Suggested Lip Relief Angles Suggested Lip Relief Angles

Suggested Lip Relief Angles

Drill Diameter Range Lip Relief Angle

#80 to #61 24

#60 to #41 21

#40 to #31 18

1/8 to 1/4 16

F to 11/32 14

S to 1/2 12

33/64 to 3/4 10

49/64 and larger 8

Drill Nomenclature

Drill Nomenclature

Chisel Edge

Chisel Edge

The edge at the end of the web, that

The edge at the end of the web, that

connects the cutting lips

connects the cutting lips

The chisel edge

does not cut

does not cut - it

penetrates displacing the workpiece

material

The chisel edge consumes 60% to 70%

of the thrust required!

Drill Nomenclature

Drill Nomenclature

Chisel Edge Angle

Chisel Edge Angle

The angle formed between the

The angle formed between the

chisel edge and the cutting lips

chisel edge and the cutting lips

The chisel edge angle is generally

125 to 135

Chisel edge angle is an indication

of lip relief

4:00

Drill Nomenclature

Drill Nomenclature

-

-

Points

Points

118 Degree

118 Degree

General purpose point

Used in a wide variety of

non-hardened Materials

Most common drill point

used in the industry

Cutting

lips

Single primary clearance

ground in one

operation

Drill Nomenclature

Drill Nomenclature

-

-

Points

Points

118 Four Facet

118 Four Facet

General

purpose point

Used primarily

on solid

carbide drills

Facets provide

primary and

secondary

relief grinds to

maintain edge

strength

Cutting

face

Primary

clearance

Secondary

clearance

Drill Nomenclature

Drill Nomenclature

-

-

Points

Points

Double Angle:

Double Angle:

118 or 135 point with a 90 outer

chamfer

Similar to a Racon, but is easier to

regrind

Minimizes outer corner wear

Helps to eliminate burrs on breakthrough

90 degrees

135 or 118 degree

Drill Nomenclature- Points

Drill Nomenclature

Drill Nomenclature

-

-

Points

Points

90 Degree

90 Degree

Generally used for soft non-ferrous

materials and non-metallic

Occasionally used in soft cast iron

90 degrees included

Drill Nomenclature

Drill Nomenclature

-

-

Points

Points

Helical

Helical

Superior self centering point

Chisel has S shape and crown to

produce the self centering feature

Produce accurate hole size with good

finish

Excellent for producing straight holes

in deep hole applications

Minimizes burrs on breakthrough

Drill Nomenclature

Drill Nomenclature

-

-

Points

Points

Racon

Racon

118 point with corner radius

Prevents grabbing when exiting angled

or curved surfaces

Reduces outer corner wear

Minimizes burrs on breakthrough

Allows for increased feed rates

Long radius Cutting lips

Drill Nomenclature

Drill Nomenclature

-

-

Points

Points

Bickford point:

Bickford point:

Combination Helical and Racon point

Has helical S chisel with corner

radius

Self centering point

Prevents grabbing when exiting

angled or curved surfaces

Reduces outer corner wear

Reduces burrs on breakthrough

Drill Nomenclature

Drill Nomenclature

-

-

Points

Points

Split Point: (Crankshaft)

Split Point: (Crankshaft)

Self centering point

Minimizes chisel length,

reduces thrust

Split produces positive rake

angle improving the chip

cutting ability at the center of

the drill point

118 and 135 are the two

most common split points

Extremely good for off hand

operations

Cutting lip

Primary

clearance

Secondary

clearance

Drill Nomenclature

Drill Nomenclature

-

-

Points

Points

135 Four Facet Split

135 Four Facet Split

Point

Point

Heavy duty point for

hard and tough

materials

Used primarily on solid

carbide drills

Facets provide primary

and secondary relief

grinds to maintain

edge strength

Split self centers and

reduces thrust

Drill Nomenclature

Drill Nomenclature

-

-

Points

Points

Flat Bottom:

Flat Bottom:

Has 150-180 end to create flat bottom holes

Bushings

Press fit parts

Generally used with drill bushings to

prevent wandering and chatter

Drill styles

Drill styles

-

-

Drill Lengths: Common standard lengths

Screw Machine: Screw Machine: ( Short flute, short OAL )

Jobber Length: Jobber Length: ( Longer flute, longer OAL )

Taper Length: Taper Length: ( Longer flute, longer OAL )

Extension Length: Extension Length: ( Standard shank, long length flutes )

Aircraft Extension Length: Aircraft Extension Length: ( 6 or 12 inch OAL, jobber length

flutes )

Always use the shortest drill possible!

Always use the shortest drill possible!

You might also like

- GTD Setup Guide (A4)Document41 pagesGTD Setup Guide (A4)Eden Abdula100% (7)

- Sheet Metal (C) FabricationDocument67 pagesSheet Metal (C) FabricationAl VlaerNo ratings yet

- Dental BursDocument38 pagesDental BursMithra Rajendran100% (1)

- Drills TheoryDocument56 pagesDrills TheoryrohanNo ratings yet

- Gearmanufacturing MethodsDocument9 pagesGearmanufacturing Methodskumar pNo ratings yet

- Milling CutterDocument11 pagesMilling CutterRing MasterNo ratings yet

- Multi Point Cutting Tool Design PDFDocument73 pagesMulti Point Cutting Tool Design PDFsrutiiNo ratings yet

- Radiant Energy CollectionDocument66 pagesRadiant Energy CollectionKatamba Rogers100% (1)

- BroachingDocument35 pagesBroachingAbdulaziz FarhanNo ratings yet

- Tool AnglesDocument13 pagesTool AnglesAkshay KakaniNo ratings yet

- Drill BitsDocument23 pagesDrill BitsIndah CharismasariNo ratings yet

- 2833-How To Use DrillsDocument1 page2833-How To Use DrillsSandra Barnett CrossanNo ratings yet

- Cutting Tool FundamentalsDocument25 pagesCutting Tool FundamentalssatenawuNo ratings yet

- PPTs On Milling Cutters and Twist DrillDocument30 pagesPPTs On Milling Cutters and Twist DrillTulsi ChouhanNo ratings yet

- What Is DRILLING?Document21 pagesWhat Is DRILLING?Tharindu ChathurangaNo ratings yet

- F - BoringDocument44 pagesF - BoringedsaregNo ratings yet

- TB Grinding EnglishDocument20 pagesTB Grinding EnglishVk PrabakranNo ratings yet

- Machine ToolDocument23 pagesMachine ToolMohammad Anaitullah HassanNo ratings yet

- PDC Bits CourseDocument76 pagesPDC Bits CourseRobert Koch100% (1)

- Production Technology (IV Sem)Document24 pagesProduction Technology (IV Sem)Shubham AgrawalNo ratings yet

- Ch-6 Reaming, Boring, BroachingDocument47 pagesCh-6 Reaming, Boring, BroachingAnkush AhirraoNo ratings yet

- PDC BitsDocument75 pagesPDC Bitsamin peyvand100% (1)

- JJ104 Workshop Technology Chapter4 Twist DrillDocument52 pagesJJ104 Workshop Technology Chapter4 Twist DrillAh TiangNo ratings yet

- H - Additional MachiningDocument51 pagesH - Additional MachiningedsaregNo ratings yet

- Titanium DRILLINGDocument50 pagesTitanium DRILLINGDome StoiNo ratings yet

- The Shape of The Cone of The Twist Drills Unit-2Document5 pagesThe Shape of The Cone of The Twist Drills Unit-2Akesh KakarlaNo ratings yet

- Vol69 Num620 Super Abrasive Grinding Process Improvements Via Power MonitoringDocument5 pagesVol69 Num620 Super Abrasive Grinding Process Improvements Via Power MonitoringSaravana kumarNo ratings yet

- Grinding MachineDocument9 pagesGrinding Machinejineesha p jNo ratings yet

- BroachingDocument20 pagesBroachingKareem AbdelazizNo ratings yet

- Grinding Machine PDFDocument23 pagesGrinding Machine PDFNagi NayakNo ratings yet

- FB15Document1 pageFB15Eden Abdula0% (1)

- Micro Precision Grinding OperationDocument29 pagesMicro Precision Grinding OperationAzmi MustafaNo ratings yet

- Tool & Cutter GrinderDocument64 pagesTool & Cutter GrinderAFIFAHZABIDI ZABIDINo ratings yet

- Cutting Force Modelling For Drilling of Fiber-Reinforced PDFDocument141 pagesCutting Force Modelling For Drilling of Fiber-Reinforced PDFLuis FelipeNo ratings yet

- 2 Grade InformationDocument17 pages2 Grade InformationAndres Alejandro RoblesNo ratings yet

- 13 Tool Cutter GrinderDocument26 pages13 Tool Cutter GrinderAnonymous ITnkbIEFNo ratings yet

- Korucut, Metal Cutting Tools, Korloy Products Traders, Dinox Tools TraderDocument94 pagesKorucut, Metal Cutting Tools, Korloy Products Traders, Dinox Tools Tradernitiin guptaNo ratings yet

- Diamond and CBN English 07Document26 pagesDiamond and CBN English 07Vk PrabakranNo ratings yet

- C9 - GrindingDocument7 pagesC9 - GrindingHans PinonNo ratings yet

- Milling: General Mill InformationDocument11 pagesMilling: General Mill Informationsravan_inboxNo ratings yet

- Drill Press Text BookDocument138 pagesDrill Press Text BookKartik Sheth100% (1)

- Gun Drill Sharpening Fixture - LIT-079Document2 pagesGun Drill Sharpening Fixture - LIT-079Ron Biggs100% (1)

- Hand Reaming and BroachingDocument25 pagesHand Reaming and Broachingpradeep_i19No ratings yet

- Tapping ChucksDocument14 pagesTapping ChucksDHAMODHARANNo ratings yet

- AFIADORA DE BROCAS - Manual de InstruçãoDocument8 pagesAFIADORA DE BROCAS - Manual de InstruçãolccortesNo ratings yet

- Benchworking StudyDocument100 pagesBenchworking StudyBrianRuaroNo ratings yet

- DIN 69871 enDocument69 pagesDIN 69871 enalphatoolsNo ratings yet

- Drill CompleteDocument35 pagesDrill Completesiva kumarNo ratings yet

- 5.1 Chordal Tooth Thickness MeasurementDocument20 pages5.1 Chordal Tooth Thickness Measurementsharma RISHINo ratings yet

- Machine Tools and Machining1Document62 pagesMachine Tools and Machining1Faisal MaqsoodNo ratings yet

- EdmDocument31 pagesEdmAbhishek PandeyNo ratings yet

- Broaching BasicsDocument5 pagesBroaching Basicssaritha0003No ratings yet

- 2016 Endmills and Drills Metric InchDocument396 pages2016 Endmills and Drills Metric InchyoungkyNo ratings yet

- Gear Shaving PresentationDocument45 pagesGear Shaving PresentationHimanshu MishraNo ratings yet

- Unit One Material and Geometry of Cutting Tools 2015Document46 pagesUnit One Material and Geometry of Cutting Tools 2015elnat feyisa100% (1)

- Broaching MachineDocument26 pagesBroaching Machinesanaashraf100% (1)

- Chisel NewDocument4 pagesChisel NewCornelius BillyNo ratings yet

- Engraving Tools Catalog: Quality Cutting Tools and Resharpening Service For The Engraving and Sign Making IndustriesDocument8 pagesEngraving Tools Catalog: Quality Cutting Tools and Resharpening Service For The Engraving and Sign Making IndustriesCristian FuentesNo ratings yet

- Gear Cutting AttachmentDocument40 pagesGear Cutting AttachmentGoutham Reddy100% (1)

- Grinding WheelsDocument26 pagesGrinding Wheelsznovak77No ratings yet

- Rotary Cutting Instruments1Document30 pagesRotary Cutting Instruments1Rishabh Madhu SharanNo ratings yet

- DRILLBITSDocument56 pagesDRILLBITSKathrine Kate CadiangNo ratings yet

- Metal SpinningDocument22 pagesMetal SpinningthirumalaikumaranNo ratings yet

- Screen ReaderDocument3 pagesScreen ReaderEden AbdulaNo ratings yet

- Basic Industrial Training Report: Content 1.0 Types of Circuit Board 1.1 BreadboardDocument1 pageBasic Industrial Training Report: Content 1.0 Types of Circuit Board 1.1 BreadboardEden AbdulaNo ratings yet

- Know More About Your MobitelDocument4 pagesKnow More About Your MobitelEden AbdulaNo ratings yet

- A Step Toward HackingDocument63 pagesA Step Toward HackingSatendra KumarNo ratings yet

- SRS FormatDocument2 pagesSRS FormatEden AbdulaNo ratings yet

- Where Dkfodsn Dsonvkdsb Dsofj SfsDocument1 pageWhere Dkfodsn Dsonvkdsb Dsofj SfsEden AbdulaNo ratings yet

- RCZ ManualDocument276 pagesRCZ ManualEden Abdula100% (1)