Professional Documents

Culture Documents

LEAKSEAL For Mass Concrete and Other General Types of Concrete Works

LEAKSEAL For Mass Concrete and Other General Types of Concrete Works

Uploaded by

Romubit0 ratings0% found this document useful (0 votes)

5 views1 pageOriginal Title

Concrete

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

5 views1 pageLEAKSEAL For Mass Concrete and Other General Types of Concrete Works

LEAKSEAL For Mass Concrete and Other General Types of Concrete Works

Uploaded by

RomubitCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 1

LEAKSEAL for mass concrete

and other general types of concrete works

The proportions recommended for such types of work are four parts of cores aggregate two

parts of the aggregate and part of waterproofed cement. Care should be taken to select clean

and added aggregates.

LEAKSEAL (Waterproofing compound for cement)

Directions:

LEAKSEAL waterproofing compound is most modern waterproofing compound, use in the

construction of all concrete structure which need to be waterproofed. Two percent of the

compound by weight should be mixed with cement to obtain water repellent properties. This

carton contains 1 kilo of LEAKSEAL which is sufficient for one bag of cement weighting 1

cwt or 50,8 kilos. LEAKSEAL should first be added to the Portland cement, mixed thoroughly

and passed through a fine sieve to ensure even distribution of LEAKSEAL throughout the

cement.

LEAKSEAL for tiling work

It is advisable to have bedding one part of cement waterproofed with LEAKSEAL to three parts

of clean sand, about thick to avoid moisture coming through the joints of the tiles.

LEAKSEAL rendering for underground cellars, tanks, reservoirs, sewers, etc.

LEAKSEAL should first be added to be Portland cement, mixed thoroughly and passed through

a fine sieve. One part of this mixture is than added to two and half parts of clean, sharp and

LEAKSEAL renderings to prevent dampness:

For such work three costs are recommended, each coat being 3/8 thick one part of cement

waterproofing which LEAKSEAL should be mixed two to two and half parts of clean sharp and

well graded sand.

LEAKSEAL for base coats and coloured renderings:

Leak seal is of particular value in producing water repellent coating, on which to apply

coloured renderings. The coating is made up of 3 parts of clean sharp sand and to one part

cement (Leak seal added). Such backings which are non absorbent are essential to avoid

considerable variation in the colour and texture of the finishing coat.

You might also like

- Construction Techniques Used at Hunnarshala Campus.Document23 pagesConstruction Techniques Used at Hunnarshala Campus.priti kocheta100% (2)

- Flooring ReportDocument4 pagesFlooring Reportn.k.indiaNo ratings yet

- 1 00701 Planicrete enDocument6 pages1 00701 Planicrete enaungpyaeNo ratings yet

- Concrete Blocks - Sand - Cement Blocks: Previous NextDocument11 pagesConcrete Blocks - Sand - Cement Blocks: Previous NextFeteneNo ratings yet

- AAC Block Adhesive TDS NEWDocument2 pagesAAC Block Adhesive TDS NEWAakriti VermaNo ratings yet

- 701 Planicrete Latex GBDocument4 pages701 Planicrete Latex GBaygunbayramNo ratings yet

- UNIT-1 Cement Mortar & Concrete: Prepared By-Deepti Singh (Assistant Professor)Document39 pagesUNIT-1 Cement Mortar & Concrete: Prepared By-Deepti Singh (Assistant Professor)Harkamal Singh DevgunNo ratings yet

- Idrosilex: Powdered or Liquid Waterproofer For Cementitious MortarsDocument4 pagesIdrosilex: Powdered or Liquid Waterproofer For Cementitious Mortarsmulti5torpeNo ratings yet

- Sika PDS E SikaLatexDocument2 pagesSika PDS E SikaLatexlwin_oo2435No ratings yet

- Plaster and Render - Autonopedia PDFDocument12 pagesPlaster and Render - Autonopedia PDFIgnacio Luis Reig MataixNo ratings yet

- Lesson 2 CONSTRUCTION EQUIPMENTDocument56 pagesLesson 2 CONSTRUCTION EQUIPMENTSolomon OpokuNo ratings yet

- Vol of Cement CalculationsDocument4 pagesVol of Cement CalculationsDoroNo ratings yet

- Building MaintenanceDocument13 pagesBuilding MaintenanceChinmoy DasNo ratings yet

- Planicrete NoRestrictionDocument4 pagesPlanicrete NoRestrictionFloorkitNo ratings yet

- Perlite ConcreteDocument10 pagesPerlite ConcretepaolocparreraNo ratings yet

- Bahasa Inggris Teknik 2.3 Dan 2.4Document4 pagesBahasa Inggris Teknik 2.3 Dan 2.4Ca sawNo ratings yet

- Fundamentals of ConcreteDocument12 pagesFundamentals of ConcreteMuhammad Sajid100% (1)

- Libro Concreto PcaDocument326 pagesLibro Concreto Pcaemilio_castelblanc_1No ratings yet

- Materials For Concrete MixDocument8 pagesMaterials For Concrete MixTana RobinNo ratings yet

- Mod 04 - MortarDocument42 pagesMod 04 - MortarVictor creedNo ratings yet

- WORK & METHEDOLOGY g-3Document17 pagesWORK & METHEDOLOGY g-3gerearegawi721No ratings yet

- Latex Modified Concrete As Repair MaterialDocument32 pagesLatex Modified Concrete As Repair MaterialBalan-Nogi Dan0% (1)

- MortarDocument35 pagesMortarNaol AdugnaNo ratings yet

- Presentation Title: My Name My Position, Contact Information or Project DescriptionDocument10 pagesPresentation Title: My Name My Position, Contact Information or Project DescriptionSanjay Kumar100% (1)

- Concrete Mix DesignDocument15 pagesConcrete Mix DesignrizaizatNo ratings yet

- Your Guide To PlasteringDocument8 pagesYour Guide To PlasteringChristopher GeorgeNo ratings yet

- FinishesDocument75 pagesFinishesYna VictoriaNo ratings yet

- Leca ConcreteDocument11 pagesLeca ConcretediartoNo ratings yet

- Abdulrahman's Project1Document58 pagesAbdulrahman's Project1Abubakar MusaNo ratings yet

- Concrete Basics Portland Cement AssociationDocument3 pagesConcrete Basics Portland Cement AssociationDeep DebnathNo ratings yet

- Cement Additives PDFDocument2 pagesCement Additives PDFDario RomeroNo ratings yet

- Concrete As Building MaterialDocument92 pagesConcrete As Building MaterialUmed Abd-alsatarNo ratings yet

- Reteta PaveleDocument6 pagesReteta Pavelecristi_amaNo ratings yet

- Tape CreteDocument2 pagesTape CreteApril VasquezNo ratings yet

- Mud Plasters and Renders: Fundamental PropertiesDocument4 pagesMud Plasters and Renders: Fundamental PropertiesvikasdrawingNo ratings yet

- MortarDocument56 pagesMortarAlemayehu DargeNo ratings yet

- Protective CoatingDocument22 pagesProtective CoatingpravinNo ratings yet

- Porous Concrete PresentationDocument27 pagesPorous Concrete PresentationAshish pareek100% (1)

- Analisa Harga Satuan 2007 Dan 2002Document5 pagesAnalisa Harga Satuan 2007 Dan 2002Yayatto KungNo ratings yet

- Light Weight ConcreteDocument46 pagesLight Weight ConcreteJay BadiyaniNo ratings yet

- Damp Proof CourseDocument11 pagesDamp Proof CourseSenthil YoungsterNo ratings yet

- Presentation On Self Healing Bendable ConcreteDocument32 pagesPresentation On Self Healing Bendable ConcreteAJEET SINGHNo ratings yet

- Concrete WorksDocument82 pagesConcrete WorksarnoldalejadoNo ratings yet

- Up LabDocument6 pagesUp LabHafiz Ahmad RazaNo ratings yet

- Concrete Basics Portland CementDocument3 pagesConcrete Basics Portland CementDeep DebnathNo ratings yet

- 51 Properties of Concrete How To CalculaDocument10 pages51 Properties of Concrete How To CalculaOmer ElbalalNo ratings yet

- Waterproofing RoofsDocument16 pagesWaterproofing RoofsIshita Sehgal100% (1)

- Cemcoat Putty - TDS - 9Document2 pagesCemcoat Putty - TDS - 9adel.jordan999No ratings yet

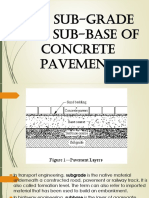

- The Sub-Grade and Sub-Base of Concrete PavementDocument16 pagesThe Sub-Grade and Sub-Base of Concrete PavementPatrick TaylorNo ratings yet

- Several: This PageDocument20 pagesSeveral: This PageSgnillum FfotsirhkNo ratings yet

- Foamed Concrete: Satyendra Kumar Meena Pushpendra Kumar Meena Rakesh Kumar Meena Rupayan Roy Pawan Kumar MeenaDocument58 pagesFoamed Concrete: Satyendra Kumar Meena Pushpendra Kumar Meena Rakesh Kumar Meena Rupayan Roy Pawan Kumar Meenadevika11No ratings yet

- Fibre Reinforced Concrete: Presented by Sumit Sharma Ankita Khanna B.arch IX SemesterDocument15 pagesFibre Reinforced Concrete: Presented by Sumit Sharma Ankita Khanna B.arch IX SemesterAnkita SharmaNo ratings yet

- Book PDFDocument60 pagesBook PDFSiva KrishnaNo ratings yet

- Concrete Basics Portland Cement AssociationDocument3 pagesConcrete Basics Portland Cement AssociationDeep DebnathNo ratings yet

- Concrete Technology: Properties of Fresh ConcreteDocument22 pagesConcrete Technology: Properties of Fresh ConcreteUsama AliNo ratings yet

- Causes and Repair of CracksofDocument16 pagesCauses and Repair of CracksofBharath PbbpNo ratings yet

- 12 1tapecreteDocument2 pages12 1tapecreteelephantynose100% (1)

- Concrete Crafts: Making Modern Accessories for the Home and GardenFrom EverandConcrete Crafts: Making Modern Accessories for the Home and GardenRating: 4 out of 5 stars4/5 (3)

- Fresco Painting - Modern Methods and Techniques for Painting in Fresco and SeccoFrom EverandFresco Painting - Modern Methods and Techniques for Painting in Fresco and SeccoNo ratings yet