Professional Documents

Culture Documents

Water Curtain Nozzle

Uploaded by

ramana_bvrCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Water Curtain Nozzle

Uploaded by

ramana_bvrCopyright:

Available Formats

International Journal on Engineering Performance-Based Fire Codes, Volume 3, Number 2, p.

87-91, 2001

87

ON THE PROPERTIES OF A WATER CURTAIN DISCHARGED

FROM A DRENCHER SYSTEM

N.K. Fong and W.T. Chan

Department of Building Services Engineering, The Hong Kong Polytechnic University, Hong Kong, China

(Received 20 June 2001; Accepted 11 July 2001)

ABSTRACT

Upon activation, a water curtain would be discharged from a drencher sprinkler system. Properties of the water

curtain under various operating conditions were studied experimentally. These included the water discharge

pattern, mass flux distribution, water droplet velocity and water droplet size.

1. INTRODUCTION

Drencher systems are required in all refuge floors

for covering external wall openings as specified in

the local codes on fire services installations [1]. A

drencher system is a sprinkler that produces a water

curtain [2]. It can be controlled either manually or

automatically to let water flow to the drencher

spray nozzles. Water discharged from the drencher

heads is blocked by the metallic part and the

direction of the water is changed by 90. Because

of the shape of the drencher nozzle outlet, a

curtain-like spray pattern is formed and discharged

to the windows concerned.

The required water discharge pressure and flow

rate of the system are based on the potential hazard

of the protected area. The number of drencher

heads can be determined from the area to be

protected. For example, if the protected area is 2.5

m (height) 3 m (width), according to the

regulations stated above, the maximum spacing

between sprinklers is 2.5 m to 3 m, and one

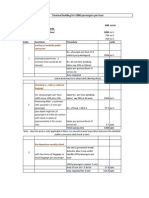

drencher head is required. Different standards [3-6]

have different requirements. Four standards were

reviewed, they are NFPA (13, 80A) [3,4], Australia

Standard (AS2118.1, AS 2118.2) [5] and Chinese

regulation [6]. A summary is given in Table 1. For

example, Australia Standard (AS 2118) [5]

required the flow rate to be 7.5 m

2

5 L/m

2

/min, or

0.625 L/s. For Chinese regulation, the flow rate

should be 0.57 L/s at 3 bar with 10 mm orifice size

drencher head. According to NFPA [3,4], the flow

rate in each sprinkler should not be less than 56.8

L/min; i.e. 0.95 L/s.

Performance of the system depends on the physical

properties of the water curtain. The physical

properties of the drencher spray pattern were

studied and reporting the results becomes the

objective of this paper.

Table 1: Summary of operating conditions of drencher system under different codes

Description Water pressure Water flow rate

Australia Standard

(AS 2118.1 & AS 2118.2 - 1995)

Not less than 70 kPa for light

hazard system, 35 kPa for

ordinary hazard system or 50 kPa

for high hazard systems

Less than 1 MPa

Not less than 5 L/m

2

/min

NFPA (13, 80A) Not less than 48 kPa Not less than 56.8 L/min for each

sprinkler OR 37 L/min/m for

water curtain

Chinese Regulation

3 bar 0.57 L/s

- 10 mm orifice diameter

drencher head

4 bar 0.66 L/s

3 bar 0.93 L/s

- 12.7 mm orifice diameter

drencher head

4 bar 1.08 L/s

3 bar 2.06 L/s

- 19 mm orifice diameter

drencher head 4 bar 2.37 L/s

International Journal on Engineering Performance-Based Fire Codes

88

2. EXPERIMENTAL SETUP

Experiments were carried out in a fire chamber at

the laboratory of Department of Building Services

Engineering, The Hong Kong Polytechnic

University. The chamber is of length 4 m, width

2.9 m and height 2.6 m as shown in Fig. 1.

Pipeworks were installed inside the chamber so that

the sprinkler nozzle was placed at the ceiling centre

of height 2.5 m (as typical protected area is of this

height) above the floor level. A fire resistant board

was mounted between the drencher and ceiling.

Three window type sprinkler heads as shown in Fig.

1 were used in this experiment. They were labeled

as A, B and C with orifice diameter of 10 mm (k-

factor = 43), 13 mm (k-factor = 84) and 19 mm (k-

factor = 111) respectively. The working pressures

of 2, 3 and 4 bars were listed in Table 2. Nine tests

labeled as A1 to C3 in Table 2 were carried out.

The water pattern, mass flux distribution, water

droplet velocity and size were measured.

Photographs of exposure time 5 s were taken to

study the water curtain. A 105 mm zoom lens

together with specially designed optical

arrangement were used. The settings were similar

to those for droplet velocity measurement, but the

sheet cutter was not used. The nozzle was installed

at 1.4 m above finished floor level at the center of

the room, and the camera was set at 1.2 m above

finished floor level and 1.5 m away from the

sprinkler head.

Fig. 1: Equipment setup for droplet velocity

measurement

3. PHYSICAL PROPERTIES

The tested nozzle was installed at 2.5 m above

finished floor level at the center of the room.

Twenty-one measuring cylinders of diameter 140

mm were placed 500 mm away from each other.

By measuring the collected water level h

m

(in mm)

and duration of water collection t

m

(in mm), the

mass flux density M

f

(in mm/min) can be

calculated.

Table 2: Summary of results

Nozzle

number

Tests

Pressure

(bar)

Flow rate

(m

3

/h)

Mean

droplet size

(mm)

Mean droplet

velocity (m/s)

Mean mass

flux density

(mm/min)

A1 2 3.15 2.5 4.8 21.0

A A2 3 3.53 1.9 5.9 22.7

A3 4 3.98 1.6 7.5 25.8

B1 2 3.60 3.6 5.9 21.5

B B2 3 4.02 3.4 6.7 29.5

B3 4 4.37 3.3 7.9 31.2

C1 2 3.76 3.9 7.4 24.5

C C2 3 4.35 3.7 8.5 29.8

C3 4 5.07 3.6 10.1 31.5

International Journal on Engineering Performance-Based Fire Codes

89

m

m

f

t

h

M = (1)

A metal water sheet cutter [7] of length 0.9 m,

width 0.5 m and height 1.5 m was used to give a

sheet of water throwing out as shown in Fig. 1. In

this way, paths of droplets can be captured. The

slot of the cutter was 10 mm wide with two layers

of blade edges. Water droplets passing through the

first blade edge but not moving along the gaps

would be blocked by the second blade. A scale

was placed at the area to be studied. The sprinkler

head was installed at 1.4 m above the finished floor

level. Images of the water droplets were captured

by a camera with a macro lens installed 1.5 m away

from the water curtain. Water droplets can be

frozen at a certain time interval by using a flash

unit. It was set manually to a very low power

mode, taking only 1/128 of the total power output.

The multi-speed flash unit was set to give five

bursts at an interval of 1/100 s, i.e. the fastest

setting of the flashlight. The very low power

flashes occurred within a very short time interval,

i.e. about 1/6000 of a second. Shutter speed was

set to 1/15 s, which was longer than the five times

flash, i.e. (5 0.01 s) or 0.05 s.

In order to reduce the vibration while taking

photographs, the camera was actuated by a cable

shutter release. The captured images were

processed with a personal computer to measure the

water droplet velocity. About 10 water droplets

were counted in three randomly selected

photographs taken from the same drencher, for the

velocity measurement for each setting. Diameters

of water droplets were measured in a similar way

but with the flashlight only flashed once in taking a

photograph. Water droplets were enlarged up to

ten times of its original size on the screen.

The graphics software PhotoShop was used to

measure the size of the droplets. An example is

shown in Fig. 2. There were about 100 water

droplets counted in five randomly selected

photographs for the droplets size measurement for

each setting. For each counted droplet a cross was

marked on the screen in order to reduce duplicated

measure.

The droplet velocity, V

d

(in m/s), is obtained by

dividing the distance between the droplets images,

D

d

(in m), measured in the photographs by the time

interval between flashes, t

d

(in s):

d

d

d

t

D

V = (2)

Fig. 2: Typical example of droplet capture

International Journal on Engineering Performance-Based Fire Codes

90

4. WATER CURTAIN

From the photographs taken in the experiment, a

curtain-like spray pattern with an example shown

in Fig. 3 (test A1) was formed after discharging

water through the nozzle. This water curtain was

formed by fast-moving water droplets. In fact,

water was not evenly distributed in the curtain as

shown in Fig. 3. Less water was found in the

darker part of the water curtain. Those regions

having more water would be brighter. Similar

spray patterns were observed for different sprinkler

heads.

As shown in Table 2, the mass flux was very high

because of the nozzle design. An example for the

mass flux density for test C3 is shown in Fig. 4.

The line with marker in the figure represents the

mass flux density along the centerline.

For tests A1 to A3, the mass flux density ranged

from 21 mm/min at 2 bar up to 25.8 mm/min at 4

bar. The mass flux density increased for sprinkler

heads of larger orifice diameter.

As the fire chamber was not large enough to

accommodate the entire pattern, some water was

deflected by the wall and dropped to the lower

levels. As a result, the mass flux density was

higher near the wall although it was placed far

away from the sprinkler head.

Fig. 3: Water curtain

Fig. 4: Mass flux distribution for test C3

International Journal on Engineering Performance-Based Fire Codes

91

5. CONCLUSION

A water curtain would be formed when discharging

water from a drencher system. There are water

droplets inside the curtain with non-uniform

distribution. From the photographs taken, areas

with less water droplets appeared darker. The mass

flux density of the water spray at the floor level

increased when the water supply flow rate and

pressure increased. The mass flux density was

higher along the centerline in a direction parallel to

the linear nozzle.

This paper on preliminary study of water curtain is

only the first of a series of reports. Further studies

must be carried out to assess the performance of the

system.

REFERENCES

1. Code of Practice for Minimum Fire Service

Installation and Equipment, Fire Services

Department, Hong Kong (1998).

2. A. Coppalle, D. Nedelka, B. Bauer, Fire

protection: Water curtains, Fire Safety Journal,

Vol. 20, No. 3, pp. 241-255 (1993).

3. NFPA 13: Installation of sprinkler system, National

Fire Protection Association, Boston, Ma, USA

(1982).

4. NFPA 80A: Recommended practice for protection

of buildings from exterior fire exposures, National

Fire Protection Association, Boston, Ma, USA

(1993).

5. Australia Standard, Automatic fire sprinkler

systems, Part I: Standard (AS2118.1) and Part 2:

Wall wetting sprinklers (Drenchers) (AS2118.2),

Australia (1995).

6. Handbook of fire prevention and inspection,

Shang-hai, Shang-hai Ke Xue Ji Shu Chu Ban She,

China (1982).

7. W.K. Chow and L.C. Shek, Physical properties of

a sprinkler water spray, Fire and Materials, Vol.

17, No. 6, pp. 279-292 (1993).

You might also like

- Check List For: Pre-Commissioning - Visual Inspection) : Video Surveillance System (CCTV) Testing and CommissioningDocument1 pageCheck List For: Pre-Commissioning - Visual Inspection) : Video Surveillance System (CCTV) Testing and Commissioningeid albouriny100% (1)

- Online Enclosure Integrity Training PDFDocument6 pagesOnline Enclosure Integrity Training PDFsujiNo ratings yet

- Challenge Brief - CAFHI 50K Prototype (Call 6)Document3 pagesChallenge Brief - CAFHI 50K Prototype (Call 6)Arun KumarNo ratings yet

- Alantek Coaxial CatalogDocument24 pagesAlantek Coaxial CatalogThuận Trần ChuNo ratings yet

- Basic Framework For Submission of Performance-Based SolutionsDocument83 pagesBasic Framework For Submission of Performance-Based Solutionsahmed abdohNo ratings yet

- Explosion Proof Axial Fan CertificateDocument7 pagesExplosion Proof Axial Fan CertificateShahlan AnuarNo ratings yet

- Nfpa EseDocument3 pagesNfpa EseAlejandro ArroyaveNo ratings yet

- MDB Testing & Commissioning Procedure - Method Statement HQDocument3 pagesMDB Testing & Commissioning Procedure - Method Statement HQHansika RajapakshaNo ratings yet

- Technical Submittal Softcopy - LCC - Dafna PalaceDocument252 pagesTechnical Submittal Softcopy - LCC - Dafna PalaceAslamNo ratings yet

- Flexible Sprinkler HoseDocument7 pagesFlexible Sprinkler HoseSopi LabuNo ratings yet

- TSKII Series: In-Line Centrifugal Duct FanDocument4 pagesTSKII Series: In-Line Centrifugal Duct FanKarin Aca Ovi100% (1)

- Cla-Val: Fire Protection Pressure Relief ValveDocument2 pagesCla-Val: Fire Protection Pressure Relief ValveShoaib AhmedNo ratings yet

- Grundfos CRE BrochureDocument2 pagesGrundfos CRE BrochureGrundfosEgyptNo ratings yet

- Ansul R-102Document4 pagesAnsul R-102heliopintoNo ratings yet

- Web Based Access ControlDocument11 pagesWeb Based Access ControlNAZMUL AHMED NOYONNo ratings yet

- Product Catalog: Quantum Climate Changer Model CLCPDocument59 pagesProduct Catalog: Quantum Climate Changer Model CLCPĐoàn Thanh TùngNo ratings yet

- Air Distribution System Case StudyDocument16 pagesAir Distribution System Case Studytmy3dataNo ratings yet

- MECH QCDD Exam Questions KIC by Amr SaadDocument4 pagesMECH QCDD Exam Questions KIC by Amr SaadSHERIF KHATTABNo ratings yet

- Air Filter ReportDocument48 pagesAir Filter ReportKrishna KumarNo ratings yet

- Spec EN Diesel Oil Leak Detection System - Generator - Application - 201810Document5 pagesSpec EN Diesel Oil Leak Detection System - Generator - Application - 201810Arunkumar SelvamNo ratings yet

- CCTV Annexure A DPSDocument17 pagesCCTV Annexure A DPSrajaNo ratings yet

- Pressure Regulators For 200/300 Bar Inert Gas SystemsDocument4 pagesPressure Regulators For 200/300 Bar Inert Gas SystemsDiego Martinez ConteiroNo ratings yet

- 9968specification For Elasomeric Cables - 1Document14 pages9968specification For Elasomeric Cables - 1aashish_rajj100% (1)

- Water Leak PDFDocument16 pagesWater Leak PDFNobita NobiNo ratings yet

- Mr. Slim System Pre-Commissioning and Installation Check ListDocument4 pagesMr. Slim System Pre-Commissioning and Installation Check Listamerico zambrano contrerasNo ratings yet

- Asd 640Document2 pagesAsd 640RICHI100% (1)

- Suwannee County Fire Rescue: Fire Service Water Main / Fire Hydrant RequirementsDocument8 pagesSuwannee County Fire Rescue: Fire Service Water Main / Fire Hydrant RequirementsMahmoud AbdallahNo ratings yet

- Xpelair CataloguesDocument39 pagesXpelair Cataloguestafadzwa simbiNo ratings yet

- Filter Pro Series Top Mount HaywardDocument2 pagesFilter Pro Series Top Mount Haywardhendrick starNo ratings yet

- Key Maintenance SwitchDocument4 pagesKey Maintenance SwitchkuraimundNo ratings yet

- Week 13 - 3.1 - UtilitiesDocument59 pagesWeek 13 - 3.1 - UtilitiesWahedaNo ratings yet

- K2000 Admin Guide v33Document170 pagesK2000 Admin Guide v33amlesh80100% (1)

- CONCRESIVE 2200 - v1Document2 pagesCONCRESIVE 2200 - v1VaishamNo ratings yet

- 1729Document52 pages1729praj24083302No ratings yet

- ELLIPS ESE Lightning ArresterDocument6 pagesELLIPS ESE Lightning ArresterRuchir Chaturvedi100% (1)

- Fire Sprinkler For Non-Storage Facilities PPT Presentation PDFDocument62 pagesFire Sprinkler For Non-Storage Facilities PPT Presentation PDFMickoAngeloRamirezAquino100% (2)

- CP Plus Red Series - 2020 - 1596589468Document9 pagesCP Plus Red Series - 2020 - 1596589468Nico Rivera CallangNo ratings yet

- 3102306-EN R003 EST4 Audio and Network Application GuideDocument74 pages3102306-EN R003 EST4 Audio and Network Application GuideShashish AshuNo ratings yet

- Sr. No. Description of Item Qty. UNIT Rate Amount A Pumps: IITM at Madras Bill of Quantities For Pumps DATE: 04.07.16Document2 pagesSr. No. Description of Item Qty. UNIT Rate Amount A Pumps: IITM at Madras Bill of Quantities For Pumps DATE: 04.07.16sanjay khatriNo ratings yet

- DAT PowerControl ENDocument4 pagesDAT PowerControl ENPedro Velozo100% (1)

- ProWatch Vista IntegrationDocument23 pagesProWatch Vista Integrationwgamber62No ratings yet

- MvwsDocument1 pageMvwsparthasutradharNo ratings yet

- DTH ComponentsDocument1 pageDTH Componentsdev007100% (2)

- NFS2-640 Installation Manual PDFDocument76 pagesNFS2-640 Installation Manual PDFshahzada Kabir100% (1)

- DuraSystems - Grease Duct Access Doors BrochureDocument2 pagesDuraSystems - Grease Duct Access Doors BrochureDuraSystemsNo ratings yet

- MX Zonecheck PDFDocument2 pagesMX Zonecheck PDFNarendra Reddy BhumaNo ratings yet

- NVR Instruction ManualDocument20 pagesNVR Instruction ManualChad HenkeNo ratings yet

- Fire Hydrant Equipment NAFFCODocument6 pagesFire Hydrant Equipment NAFFCOStanisclaus Kostka Rheyno ANo ratings yet

- Cálculo Inergen PDFDocument12 pagesCálculo Inergen PDFamardonesNo ratings yet

- Disk Electrostatic Automatic Coating System - OTSON - DM - OTS - 5000!3!0Document16 pagesDisk Electrostatic Automatic Coating System - OTSON - DM - OTS - 5000!3!0otsontek9227No ratings yet

- Fire Detection and Diversion System IntroductionDocument15 pagesFire Detection and Diversion System IntroductionmishtinilNo ratings yet

- HOSE Hydrant Booklet withoutCropMarks FinalDocument8 pagesHOSE Hydrant Booklet withoutCropMarks FinalSergio PantaNo ratings yet

- Tyco Water SprayDocument6 pagesTyco Water SprayFadlul Akbar HerfiantoNo ratings yet

- Labsystem Room Air Control in LaboratoriesDocument22 pagesLabsystem Room Air Control in LaboratoriesJulio AlceramNo ratings yet

- Information On Fire Flow Testing of Hydrants PDFDocument5 pagesInformation On Fire Flow Testing of Hydrants PDFMohamed MasryNo ratings yet

- Piping Guide b03Document8 pagesPiping Guide b03Jeferson Binay-anNo ratings yet

- VTT10000 Manual PDFDocument6 pagesVTT10000 Manual PDFalekyaNo ratings yet

- Use of A Pressure Waves Mitigation DevicDocument14 pagesUse of A Pressure Waves Mitigation Devicyassentaha20000No ratings yet

- S06-All Examples 2upDocument5 pagesS06-All Examples 2upAvinash MeenaNo ratings yet

- 2100 - Soal Latihan 2 Drainase PerkotaanDocument2 pages2100 - Soal Latihan 2 Drainase PerkotaanNur Rahman100% (1)

- Fluid Dynamics in Complex Fractured-Porous SystemsFrom EverandFluid Dynamics in Complex Fractured-Porous SystemsBoris FaybishenkoNo ratings yet

- Vehicle Skid ControlDocument30 pagesVehicle Skid ControlUday Vir Singh Rana0% (2)

- 2015 Global State of Information Security SurveyDocument8 pages2015 Global State of Information Security SurveyIDG_WorldNo ratings yet

- Goa Room BookingDocument5 pagesGoa Room BookingjagadeeshNo ratings yet

- NCSC TG 019.2Document42 pagesNCSC TG 019.2bromlantNo ratings yet

- AJS PRGM 5-10Document17 pagesAJS PRGM 5-10dillumiya132No ratings yet

- Open Directory Admin v10.5 2nd EdDocument278 pagesOpen Directory Admin v10.5 2nd EdKurgan GlNo ratings yet

- Appendix-I of G.O.Ms - No.59Document2 pagesAppendix-I of G.O.Ms - No.59maheshNo ratings yet

- Totalflow Abb Xfc6200Document168 pagesTotalflow Abb Xfc6200Jhon Erick Izquierdo SoteloNo ratings yet

- Survey Paper On CP-ABE Cloud Computing-51129037 PDFDocument3 pagesSurvey Paper On CP-ABE Cloud Computing-51129037 PDFFisehaNo ratings yet

- Scribe AffidavitDocument1 pageScribe AffidavitAlok RanjanNo ratings yet

- Write A Java Program To Implement The DES Algorithm LogicDocument6 pagesWrite A Java Program To Implement The DES Algorithm Logicpradeepthi gajulaNo ratings yet

- Formal Verification and Analysis of Primary Authentication Based On 5G-AKA ProtocolDocument6 pagesFormal Verification and Analysis of Primary Authentication Based On 5G-AKA ProtocolSharique A MNo ratings yet

- Razer Cortex Diagnostics ReportDocument15 pagesRazer Cortex Diagnostics ReportPedriHidayatNo ratings yet

- Library SecuritiesDocument4 pagesLibrary SecuritiesNithin Kumar KandimallaNo ratings yet

- ACE Integrated Sol LTD v.01Document14 pagesACE Integrated Sol LTD v.01Canine BabyNo ratings yet

- ARK Ecosystem Whitepaper Version 2.0.0 - April 1, 2019Document50 pagesARK Ecosystem Whitepaper Version 2.0.0 - April 1, 2019Arrom BaelahNo ratings yet

- Siebel Briefings Administration Guide: Siebel Innovation Pack 2017 July 2017Document58 pagesSiebel Briefings Administration Guide: Siebel Innovation Pack 2017 July 2017sbl clsNo ratings yet

- UD02500B - Baseline - User Manual of Hik Design Tool - V1.0 - 20160801Document33 pagesUD02500B - Baseline - User Manual of Hik Design Tool - V1.0 - 20160801Pedro roncancioNo ratings yet

- AuthenticatorDocument2 pagesAuthenticatorAiny ArimNo ratings yet

- Samsung PCIEDocument4 pagesSamsung PCIEUmesh TiwariNo ratings yet

- The Spellman Files by Lisa LutzDocument10 pagesThe Spellman Files by Lisa LutzSimon and SchusterNo ratings yet

- M2000 Administrator Guide-3850&3650-SUSE10-V200R012 - 06Document200 pagesM2000 Administrator Guide-3850&3650-SUSE10-V200R012 - 06Sandip J. BaldhaNo ratings yet

- DesDocument19 pagesDesAmir HelmiNo ratings yet

- Bus Terminal Building AreasDocument3 pagesBus Terminal Building AreasRohit Kashyap100% (1)

- Heather Goodwin: 12235 Conveyor Court Bristow, VA 20136 C: 703-402-8921Document4 pagesHeather Goodwin: 12235 Conveyor Court Bristow, VA 20136 C: 703-402-8921kanishk parasharNo ratings yet

- SMS BitsDocument11 pagesSMS BitsSathish Anandhan100% (1)

- Sanchez Information Assurance and SecurityDocument9 pagesSanchez Information Assurance and SecurityMarneil Allen SanchezNo ratings yet

- How To Format A Computer-Windows7Document18 pagesHow To Format A Computer-Windows7Lyndon AlfonsoNo ratings yet