Professional Documents

Culture Documents

Industry Indan Cotton Textile Profile

Uploaded by

Sakhamuri Ram'sCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Industry Indan Cotton Textile Profile

Uploaded by

Sakhamuri Ram'sCopyright:

Available Formats

INDUSTRY PROFILE

INTRODUCTION

The Textile Sector in India ranks next only to Agriculture. It accounts for

20 per cent of the country's industrial output and 30% of the foreign exchange

earnings. About 16 per cent of the country's work force is employed in this sector.

But presently, the Indian textile industry stands at the cross-roads. It is facing

challenges and exciting opportunities at the same time, following a focus thrust on

this sector in the planning process, economic liberalization and globalization of

trade. It can either flourish or perish.

Man-Made Fiber

Till the early seventies, the Indian man-made fiber textile industry was

minuscular. Fiber flexibility introduced by the Government's Textile Policy of

1985 has, however, helped man-made fibers to grow rapidly in the last two

decades. Falling input prices and easy of maintenance have popularized man-made

and blended fabrics among the common masses.

They are also increasingly being used in industrial applications. India's man-

made textile industry is capable of expansion in terms of raw material base and

yarn and fabric conversion facilities.

Today, it accounts for almost 32 per cent of the fiber/yarn base. Given the Indian

advantages of lower production costs, dominance of medium-sized units capable of

catering to a small lot and volume orders, large domestic consumption which could

neutralize adverse effects of overseas demand fluctuations and decline in

production in the developed countries, the Indian synthetic textile producers have

an edge.

Spinning and Weaving

Spinning is the conversion of fibers into yarn. These fibers can be

natural fibers (cotton) or manmade fibers. Spinning also entails production of

manmade filament yarn (yarn that is not made from fibers).Final product of

spinning is yarn. Cotton value chain starts from the ginning that adds value to it by

separating cotton from seed and impurities. Spinning is the foundation process and

all the subsequent value additions i.e., weaving, knitting, processing, garments and

made ups, depend upon it. Any variation in quality of spinning product directly

affects the entire value chain.

Since 1947, the mill sector loom age has declined from two lakh to 1.33 lakh,

while that of the power looms has grown from 24,000 to almost 14 lakh. Now the

mill sector accounts for only six per cent of cloth production, while the

unorganized /decentralized power loom, hosiery and handloom sectors account for

54.17 per cent and 23 per cent respectively. But the power loom sector suffers

from serious technological infirmities, leading to the production of low-value

items, including downstream garments. Though the per capita cloth production

(inclusive of exports) and per capita cloth availability are on the incline (22.92 to

34.82 sq. mtr. in 1985-86 and 1995-96 and 21 to 27.99 sq.mtr during this period

respectively), meeting the cloth requirements of India's teeming millions, its poor

quality acts as dampener on increasing our export market share. For this, a

Technology Up gradation Fund Scheme is being mounted during the Ninth Plan.

Upgrading technology level in the weaving sector by installing shuttle less or

automatic looms and related accessories would ensure productivity enhancement

and production of defect-free fabrics with value addition.

Processing

Processing and finishing are the weakest links in the Indian textile industry

today. A conscious drive has been initiated to upgrade it by incentives in

investment to the high-tech processing machinery, strengthening testing

infrastructure by upgrading or setting up new laboratories, developing natural and

vegetable dyes for commercial scale application, providing support for eco-

friendly processing and other such measures. This would help improve the garment

quality, contributing to value addition and higher unit value realization in exports

and hence a larger market share

HISTORY OF TEXTILE INDUSTRY

India has been well known for textile goods since very ancient times. The

traditional textile industry of India was virtually decayed during the colonial

regime. However, the modern textile industry took birth in India in the early

nineteenth century when the first textile mill in the country was established at fort

gloster near Calcutta in 1818. The cotton textile industry, however, made its real

beginning in Bombay, in 1850s.

The first cotton textile mill of Bombay was established in 1854 by a Parsi

cotton merchant then engaged in overseas and internal trade. Indeed, the vast

majority of the early mills were the handiwork of Parsi merchants engaged in

yarn and cloth trade at home and Chinese and African markets.

The first cotton mill in Ahmadabad, which was eventually to emerge as a rival

centre to Bombay, was established in 1861. The spread of the textile industry to

Ahmadabad was largely due to the Gujarati trading class.

The cotton textile industry made rapid progress in the second half of the

nineteenth century and by the end of the century there were 178 cotton textile

mills; but during the year 1900 the cotton textile industry was in bad state due to

the great famine and a number of mills of Bombay and Ahmadabad were to be

closed down for long periods.

The two world wars and the Swadeshi movement provided great stimulus

to the Indian cotton textile industry. However, during the period 1922 to 1937

the industry was in doldrums and during this period a number of the Bombay

mills changed hands. The Second World War, during which textile import from

Japan completely stopped, however, brought about an unprecedented growth of

this industry. The number of mills increased from 178 with 4.05 lakh looms in

1901 to 249 mills with 13.35 lakh looms in 1921 and further to 396 mills with

over 20 lakh looms in 1941. By 1945 there were 417 mills employing 5.10 lakh

workers.

The cotton textile industry is rightly described as a Swadeshi industry

because it was developed with indigenous entrepreneurship and capital and in

the pre-independence era the Swadeshi movement stimulated demand.

The partition of the country at the time of independence affected the cotton

textile industry also. The Indian union got 409 out of the 423 textiles mills of the

undivided India. 14 mills and 22 per cent of the land under cotton cultivation

went to Pakistan. Omen mills were closed down for some time.

FUTURE PROSPECTS

The future outlook for the industry looks promising, rising income

levels in both urban and rural markets will ensure a rising market for the

cotton fabrics considered a basic need of new economic reforms (NER)

proper attention has been given to the development of the textiles industry in

the Tenth plan.

Total outlay on the development of textile industry as envisaged in

the tenth plan is fixed at Rs.1980 crore. The production targets envisaged in

the terminal year of the Tenth plan are 45,500 million sq meters of cloth 4,150

million kg of spun yarn and 1,450 million kg of manmade filament yarn. The

per capita availability of cloth would be 28.00 sq meters by 2012-2013 as

compared to 23.19 sq meters in 2008-09showing a growth of 3.19 percent.

The export target of textiles and apparel is placed at $32 billion by 2012-2013

and $50 billion by 2020.

INDIAS MAJOR COMPETITORS IN THE WORLD

To understand Indias position among other textile producing the industry

contributes 9% of GDP and 35% of foreign exchange earnings, Indias share in

global exports is only 3% compared to China 13.75% percent. In addition to

China, other developing countries are emerging as serious competitive threats to

India. Looking at export shares, Korea (6%) and Taiwan (5.5%) are ahead of

India, while Turkey (2.9%) has already caught up and others like Thailand (2.3%)

and Indonesia (2%) are not much further behind. The reason for this development

is the fact that India lags behind these countries in investment levels, technology,

quality and logistics. If India were competitive in some key segments it could

serve as a basis for building a modern industry, but there is no evidence of such

signs, except to some extent in the spinning industry.

Indias Competitive Position in Stages of Textile Manufacture

Some of the competitors in India

Vinayagar spinning mills, Tirupur.

Vasantha spinners Ltd, Hyderabad.

Sri Balaji spinning mills, Guntur.

Indu spin industries Ltd, Hyderabad.

Kasim Textile Pvt Ltd, Madurai.

PROBLEM FACED BY THE TEXTILE INDUSTRY IN INDIA

The cotton textile industry is dealing with some problems.

Sickness

Sickness is widespread in the cotton textile industry. After the engineering

industry, the cotton textile industry has the highest incidence of sickness. As

many as 125 sick units have been taken over by the Central Government.

Sickness is caused by various reasons like the problems mentioned below.

Obsolescence

The plant and machinery and technology employed by a number of units

are obsolete. The need today is to make the industry technologically up-to-date

rather than expand capacity as such. This need was foreseen quite some time

back and schemes for modernization of textile industry had been introduced.

The soft loan scheme was introduced a few years back and some units were able

to take advantage of the scheme and modernize their equipment. However, the

problem has not been fully tackled and it is of utmost importance that the whole

industry is technologically updated.

Government Regulations

Government regulations like the obligation to produced controlled cloth are

against the interest of the industry. During the last two decades the excessive

regulations exercised by the government on the mill sector has promoted

inefficiency in both production and management. This has also resulted in a

colossal waste of raw materials and productive facilities. For example, the mills

are not allowed to use filament yarn in warp in order to protect the interest of art

silk and power loom sector which use this yarn to cater to the affluent section of

society.

Low Yield and Fluctuation of Cotton Output

The cotton yield per hectare of land is very low in India. This results in

high cost and price.

Further, being largely dependent on the climatic factors, the total raw

cotton production is subject to wide fluctuation causing serious problems for the

mills in respect of the supply of this vital raw material.

Competition from Man-made Fibers

One of the serious challenges facing the cotton textile industry is the

competition from the man-made fibers and synthetics. These textures are

gradually replacing cotton textiles. This substitution has in fact been supported

by a number of people on the ground that it is not possible to increase

substantially the raw cotton production without affecting other Crops

particularly food crops.

Competition from other Countries

In the international market, India has been facing severe competition from

other countries like Taiwan, South Korea, China and Japan.

Labour Problems

The cotton textile industry is frequently plagued by labour problems. The

very long strike of the textile workers of Bombay caused losses amounting to

millions of rupees not only to the workers and industry but also to the nation in

terms of excise and other taxes and exports.

INVESTMENT

Investment is the key for Indian textiles to make rapid strides. The Vision

Statement prepared by the Indian Cotton Mills federation has projected that the

industry has the potential to reach a size of $85 billion by 2020 from the current

level of $ 36 billion. Further, the vision statement has estimated that textile

exports could touch $40 billion by 2020 from $ 11 billion in 2012.

In the process, Indias share in the global textile and clothing trade is

expected to double from three percent in 2012 to six percent by 2020.

To reach these this ambitious target, it is estimated that new investment to

the tune of Rs.1, 40,000 Crores will be needed in the next five years. After

analyzing the capacity and technology levels in various segments of textile

Industry and the need for modernization, funds required for various segments

have been below.

STRUCTURE

Unlike other major textile-producing countries, Indias textile industry is

comprised mostly of small-scale, nonintegrated spinning, weaving, finishing, and

apparel-making enterprises. This unique industry structure is primarily a legacy of

government policies that have promoted labor-intensive, small-scale operations

and discriminated against larger scale firms:

Composite Mills

Relatively large-scale mills that integrate spinning, weaving and,

sometimes, fabric finishing are common in other major textile-producing

Countries. In India, however, these types of mills now account for about only 3

percent of output in the textile sector.

Spinning

Spinning is the process of converting cotton or manmade fiber into yarn to

be used for weaving and knitting. Largely due to deregulation beginning in the

mid-1980s, spinning is the most consolidated and technically efficient sector in

Indias textile industry. Average plant size remains small, however, and technology

outdated, relative to other major producers. In 2002/03, Indias spinning sector

consisted of about 1,146 small-scale independent firms and 1,599 larger scale

independent units.

Weaving and Knitting

Weaving and knitting converts cotton, manmade, or blended yarns into

woven or knitted fabrics. Indias weaving and knitting sector remains highly

fragmented, small-scale, and labor-intensive. This sector consists of about 3.9

million handlooms, 380,000 power loom enterprises that operate about 1.7

million looms, and just 137,000 looms in the various composite mills. Power

looms are small firms, with an average loom capacity of four to five owned by

independent entrepreneurs or weavers. Modern shuttleless looms account for less

than 1 percent of loom capacity.

Fabric Finishing

Fabric finishing (also referred to as processing), which includes dyeing,

printing, and other cloth preparation prior to the manufacture of clothing, is also

dominated by a large number of independent, small scale enterprises. Overall,

about 2,300 processors are operating in India, including about 2,100 independent

units and 200 units that are integrated with spinning, weaving.

Growth

India has already completed more than 50 years of its independence. The

analysis of the growth pattern of different segment of the industry during the last

five decades of post independence era reveals that the growth of the industry

during the first two decades after the independence had been gradual, though lower

and growth had been considerably slower during the third decade. The growth

thereafter picked up significantly during the fourth decade in each and every

segment of the industry. The peak level of its growth has however been reached

during the fifth decade i.e., the last ten years and more particularly in the 90s. The

Textile Policy of 1985 and Economic Policy of 1991 focusing in the direction of

liberalization of economy and trade had in fact accelerated the growth in 1990s.

The spinning spearheaded the growth during this period and man-made fiber

industry in the organized sector and decentralized weaving sector.

SAFETY AND HEALTH ISSUES IN THE TEXTILE INDUSTRY

The textile industry consists of a number of units engaged in spinning,

weaving, dyeing, Safety and health issues in the textile industry. Printing,

finishing and a number of other processes that are required to convert fiber

into a finished fabric or garment. There are several safety and health issues

associated with the textile industry. This article aims at studying each of

these issues in relation to the US and Indian textile industries in detail, along

with the possible solutions for these problems.

The major safety and health issues in the textile industry can be stated as under:

1) Exposure to cotton dust

2) Exposure to chemicals

3) Exposure to noise

4) Ergonomic issues

Exposure to cotton dust

The workers engaged in the processing and spinning of cotton are exposed

to significant amounts of cotton dust. They are also exposed to particles of

pesticides and soil. Exposure to cotton dust and other particles leads to respiratory

disorders among the textile workers. The fatal disease of byssinosis, commonly

known as brown lung, is caused among people working in the textile industry on

account of excessive exposure to cotton dust.

The symptoms of this disease include tightening of the chest, coughing,

wheezing and shortness of breath.

In the year 1938 in USA, it was estimated that about 35000 people had

already been affected by the disease, while 100000 other people were at risk of

contracting it. Hence the Occupational Safety and Health Administration i.e.

OSHA made it compulsory for employers in the textile industry to protect their

workers from over exposure to cotton dust and its evil effects. The OSHA

determined certain guidelines which are applicable to all private employers in the

US textile industry.

OSHA has laid down a Cotton Dust Standard with a view to reducing the

exposure of the workers to cotton dust and protecting them from the risk of

byssinosis. It has set up Permissible Exposure Limits (PELs) for cotton dust for

different operations in the textile industry. This standard has helped bring down the

rate of occurrence of byssinosis significantly. Different states might adopt different

standards for occupational safety and health; however, in those states where there

are no standards fixed by the State, the Federal standards are accepted.

For an eight-hour day, the OSHA Cotton standard has been determined

at 200 micrograms of cotton dust per cubic meter of air in case of yarn

manufacturing, 500 micrograms in case of textile waste houses, 750 micrograms in

case of weaving operations, and 1000 micrograms in case of for waste recycling.

Employers are required to measure the quantity of respirable cotton dust once in 6

months or whenever there is any change that might lead to a change in the level of

dust. If the level of dust in the atmosphere is higher than that as per OSHA

guidelines, the management should take measures to reduce the same. As per these

guidelines, the employer is required to inform the employees in writing of the dust

level present in the atmosphere as well as the steps that the management is

planning to take for its reduction. If the dust level cannot be reduced, it is the duty

of the management to provide respirators to the employees.

The OSHA Cotton Dust Standard was amended in the year 2000, which

exempted a method of washing cotton from the rule.

A study conducted by R. Steinberg, J. Hannak and K. Balakrishnan

regarding textile units in India revealed that pulmonary function in textile workers

decreased significantly with exposure to cotton dust over a long period of time.

Another study conducted on textile units in Mumbai, India indicated an 11-33%

incidence of chronic bronchitis in textile workers. Another study revealed an

increase in the rate of occurrence with an increase in exposure to cotton dust.

Studies have revealed that acute respiratory diseases are more common among the

children working in carpet weaving units in Jaipur as compared to other children in

the same city. The prevalence of respiratory diseases among child textile workers

was 26.4%, while it was 15.2% among other children. Experts believe that this is

on account of high exposure to cotton dust.

Exposure to chemicals

Workers in the textile industry are also exposed to a number of chemicals,

especially those engaged in the activities of dyeing, printing and finishing.

Chemicals based on benzidine, optical brighteners, solvents and fixatives, crease-

resistance agents releasing formaldehyde, flame retardants that include

organophosphorus and organobromine compounds and antimicrobial agents are

used in textile operations.

Studies have revealed links between exposure to formaldehyde and nasal and

lung cancer as well as to brain cancer and leukemia, which can be fatal. In the long

run, exposure to formaldehyde could lead to respiratory difficulty and eczema.

Contact of the chemicals with skin as well as inhalation of the chemicals can lead

to several serious health effects.

A study conducted in USA revealed a correlation between the presence of

cancer of the buccal cavity and pharynx and occupation in the textile industry.

Another study revealed that textile workers were at high risk for developing cancer

of the stomach while another study indicated a low degree of correlation between

oesophageal cancer and working in the textile industry. Moreover, a high degree of

colorectal cancer, thyroid cancer, testicular cancer and nasal cancer was among

textile workers. Also, a relationship between the presence of non-Hodgkin's

lymphoma and working in the textile industry was observed.

As per a study conducted on 1300 people working in 'tie and dye' units in

Jodhpur and neighbouring areas, 100 workers were observed to have occupation-

related dermatitis. This constituted 7.69% of the total sample. Red RC base and

naphthol were observed to be the most common culprits in this regard.

Exposure to noise

High levels of noise have been observed in most of the units engaged in

the textile industry, particularly those in developing countries. In the long run,

exposure to high noise levels has been known to damage the eardrum and cause

hearing loss. Other problems like fatigue, absenteeism, annoyance, anxiety,

reduction in efficiency, changes in pulse rate and blood pressure as well as sleep

disorders have also been noted on account of continuous exposure to noise. Lack

of efficient maintenance of machinery is one of the major reasons behind the noise

pollution in a majority of the units. Though it causes serious health effects,

exposure to noise is often ignored by textile units because its effects are not

immediately visible and there is an absence of pain.

A study of 77 employees in textile mills in Nagpur was conducted by Ruikar

MM, Motghare DD and VasudeoND. This study revealed that 76.6% of the

employees were at risk for developing noise-induced hearing loss. The study of

Indian textile units by R. Steinberg, J. Hannak and K. Balakrishnan indicated that

21.3% of the workers studied suffered from noise-induced hearing loss.

POLICY OF GOVERNMENT OF INDIA TOWARDS SPINNING

INDUSTRY

The Cotton production policies in India historically have been

oriented toward promoting and supporting the textile industry. The Government Of

India announces a minimum support price for each variety of seed cotton (kapas)

based on recommendations from the Commission for Agricultural Costs and

Prices. The Government Of India is also providing subsidies to the production

inputs of the cotton in the areas of fertilizer, power, etc

Markets for Indian Cotton

The three major groups in the cotton market are

Private traders

State-level cooperatives

The Cotton Corporation of India Limited.

SUGGESTIONS OF INDUSTRY

It is suggested that Government should provide good Infrastructure.

It is suggested that Government should provide loans.

It is suggested to maintain the inventory properly.

It is suggested to use the advanced technology to produce quality output.

It is suggested to find the labour problems and solve them.

It is suggested to utilize the optimum resources.

It is suggested Modernization and consolidation for creating a global

competitive industry.

It is suggested to increase Indias share in world trade to 9%by 202

COMPANY PROFILE

INTRODUCTION

Y.S.R. Spinning & Weaving Mills Pvt. Ltd was established in 1999, with a

spindle capacity of 4500 spindles. After expansion made in 2003 and 2006, it was

having 25514 spindle and 1030 rotors and 8 numbers of air jet weaving machines

to produce 5 tons of ring spun, 2 tons of open end, 1.5 tons of ring doubling and

2000 meters of fabric per day.

In spinning department the mill has a complete range of LMW,

Trumac machines from blow room to spinning departments and in weaving

Department PICANOL Omni plus air jet weaving machine.

The company best quality products are the key of our success and fame. The

quality of the company products has helped us in standing amongst the major

companies in this field. The company has a strong clients based at different regions

of Andhra Pradesh, Gujarat, Karnataka, Maharashtra, West Bengal, Orissa and

TamilNadu. The company known as one of the best cotton yarn manufacturers in

India due to the fine quality of cotton yarn. The company provides genuine quality

cotton blended yarn, which is used to make superior quality garments. The

company also widely renowned as one of the best cotton fabric suppliers in India.

The cotton fabric is highly admired by the clients due to its durability and supreme

quality.

The company gives the top most priority to the customers and strives to provide

them the best quality fabrics. The company knows the value of the time and thus

delivers the products within the stipulated time. You can avail the products easily

at reasonable prices, which would not affect your pocket. Due to the superior

quality of our products we deal with various reputed companies located in India

and China. The company chief motive is to maintain a long lasting relationship

with our honored clients.

Company has achieved a great height of success due to the hard work of

Mr. Y. Sridhar Reddy, the chairman and Mr. Y. SrinivasuluReddy, the managing

director of the company. The company has a highly skilled team of employees,

who carries loads of experience in this field. The company has a strong

infrastructural base, which is well equipped with the advanced machineries. The

company always endeavors to provide the best and pure fabrics to our customers

and thus always check the quality content of the fabric.

The company is engaged in the manufacturing of a wide range of fine

cotton fabrics. The fine cottons fabrics have a remarkable characteristic of

providing smoothness and softness to the body. The company reckoned as one of

the leading cotton fabrics manufacturers, based in India. The cotton fabric is used

by big companies for production of various types of garments. The company has

also become one of the foremost organic cotton yarn suppliers in India. The

organic cotton is grown without the use of any harmful pesticides & chemicals and

thus this leads to the increase in its quality

Name of CEO

Mr. Y. Sridhar Reddy

Primary Business Type

Manufacturer

Establishment Year

1999

No. of Employees

300

Market Cover

China

Annual Turnover

Rs.70.00 Crores

VISSION

The company has a vision to excel in all fields of textile industry and

agriculture produce basis.

The company will be intensively customer focused and will offer products

and services which provide the best value for the customers.

MISSION

To manufacture a high quality yarn thereby withstanding high level of

competitiveness.

Developing a long term relationship with the customers and suppliers.

To use latest technological strategies during production thereby forming an

innovative approach.

To provide a safe, fulfilling and rewarding work environment for the

employees.

The company operates in the servicing and supporting the communities.

HISTORY

Mr. Yerram Sridhar Reddy started his business as cotton commission

agent in 1977 at his native place Idupulapadu, Inkollu Mandalam, Prakasam

District, Andhra Pradesh, and planned to forward integration of Ginner in 1983. He

started a firm Sri Srinivasa Trading Company in 1989, supplied cotton bales to

various spinning mills in TamilNadu and Andhra Pradesh.

It was in the year 1999, he established a Spinning Mill at Ganapavaram

village with a capacity of 4500 spindles. His hardwork, innovative thoughts and

strategic approach has made Y.S.R. Spinning & Weaving Mills Pvt. Ltd., turn in to

one of the leading suppliers of 100% cotton yarns to many domestic and exported

oriented weaving mills in and around the country.

POLICIES OF THE COMPANY

Quality Policy

Quality is integrals to everything at Y.S.R we adopt holistic quality assurance

system and an integrated system which covers the entire production process. All

lots are tested before giving to the mixing.

The company believes quality is a continual process. With a focus clearly an

delivering quality products and services, we integrate to constantly innovate and

excel.

Value

By a clear comprehension of the market dynamics and the assimilation of the

cutting edge technology the company assures the highest quality standards are met

at all times.

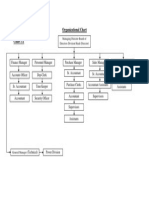

ORGANISATION STRUCTURE

Chairman : Y. Sridhar Reddy

M.D : Y. Srinivasula Reddy

Directors : D . Subba Rao,

P. Srinivas Reddy,

Y. Jaya Lakshmi

COMPETITORS

Y.S.R spinning mills is having 50 spinning mills as competetors.

Some of them are..

Dhanalakshmi cotton mills pvt Ltd., Ganapavaram.

ICM (Idupulapadu cotton mills), Ganapavaram.

Vasantha Spinning mills, Thimmapuram.

Tirumula spinning mills,Ganapavaram

Pujitha spinning mills,

Amaravathi textile mills,Martur

Prasuna vamsi Krishna spinning mills, Ganapavaram.

Siva Swathi textile pvt Ltd., Ganapavaram.

NSL textiles Pvt Ltd, Edlapadu.

PRODUCTS

The company offers an exclusive collection of white cotton fabrics of all

sizes. The white cotton fabric is made up of pure cotton. The company also deals

with the manufacturing and supplying of organic cotton yarn.

It provides organic cotton yarn in all shades. It uses environment friendly

procedure for producing our organic cotton yarn.

Below listed are the two divisions that look after our manufacturing

processes.

Cotton Fabrics

The company is happy to acquaint as one of the salient cotton fabric manufacturers

in India. The cotton fabrics include organic cotton fabrics and white cotton fabrics.

It uses pure and good quality yarn for making the fabric. The fabric provides

immense comfort to the users. It gives soothing effect to the body and will be the

right choice in the hot and sweaty summers. The cotton fabrics are light in weight

in comparison to its thickness.

The cotton Fabric is easily washable and its significant feature is its

durability. The company ensures our customers to provide good quality cotton

fabric on time and that too at moderate prices.

Cotton Yarn

The company provides the best quality cotton yarn that includes organic cotton

yarn and cotton blended yarn. Cotton yarn is produced from genuine quality fiber,

which is obtained from the seed hair of the cotton plant. The cotton yarn is used to

manufacture genuine quality cotton fabrics. The significant feature of the cotton

yarn is its high tensile strength and its superior quality. The cotton yarn is used by

various industries for manufacturing the best quality garments. The company is

widely known as one of the prominent cotton yarn suppliers from India.

PROCESS

No. of machines in the company

1. Carding-12 8.Textile ring frames-8

2. brakering-2 9.Doubling-8

3. Finishing-3 10.TDF force-3

4. Simplex-4 11.cheese winding-2

5. Ring frame LR6-13 12.Cone winding-4

6. Ring frame LR60-6

7. Auto corners-5

Preparation

S.No M/C Count Hank Limits No.of times

for shift

1. LD2 40s KBR 0.1200 0.1180-

0.1220

4 times

2. LD06 40s KBR 0.1200 0.1180-

0.1220

4 times

3. RSB new 40s KBR 0.0985 0.0980-

0.0990

7 times

4. RSB 951 40s KBR 0.0985 0.0980-

0.0990

7 times

5. BRRSb 40s KBR 0.0985 0.0980-

0.0990

7 times

STAGES

Mixing

Flexi cleaner

Carding Section

Bracer stage

Finishing stage

Grooving stage

Ring frame threading

Cheese winding

TFO

LR60,LR6

Auto corners

Doubling

Cone winding

Finishing

Packing section

PROCESS

The cotton is first brought from the various areas in Guntur district.

After bringing the cotton, the process is started.

The starting point is the MIXING: In this the waste materials such as seeds

of cotton and dust are removed. Then the plane cotton is obtained.

This cotton is sent into the 2 blow rooms to store it.

After that the cotton is sent into the MBO and Flexi cleaner machines for

final cleaning and sent that cotton from pipes to next department.

The CARDING DEPARTMENT, the sliver is formed.

The DRAWING SECTION is next department. In this section 12 cans are

present ,those are divided into6-6 on either side differ in countings.

The next stage is BRAKER STAGE; in this the quality of the sliver

improves.

Next the sliver is sent to the FINISHING STAGE, in this again 4-4 cans

division is present differ in countings and material.

The GROVING STAGE comes next in which the sliver is simplified into

thread form.

To these machines the air cleaning machine is present to clean the waste

present on the machines.

The RING FRAME THREAD MACHINE is the oldest process machine of

preparing tread.

The latest process machine of preparing thread is the LR60 and LR6.

In LR60-the man power is low

In LR6-the man power is high.

CHEESE WINDING is another stage, in this 2 singles are formed into 1

double.

The TFO, the weights are fix and sent to the market.

And in this process, the exhaust panels are present on the floor at every

machine, to exhaust the extra waste outside.

AUTO CORNERS, the weighting is fixing.

Later the TEXTILE RING FRAMES, it is same as the process of LR

process, used for doubling thread but these are not sent for market.

DOUBLING and CONE WINDING machines are used for preparing yarn

for export.

FINISHING, in this stage the yarns that prepared are stored in rooms based

on their counts weights-50, 40.

PACKING SECTION-At last the yarns are packed and sent for market

COOLERS:-The coolers are present in company at machines to maintain

the climate that is exact opposite to outside climate. To maintain these

coolers the compressors are present.

The total process is done based on air machines because the machines

work only based on air.

AWARDS OF THE COMPANY

Best exporter award from Government of A.P in 2005-2006.

Stood first in India in scientific processing of cotton Seed in 2007-

2008

First in India domestic sales in cotton seed extraction in 2010-2011

SWOT ANALYSIS

Strength

YSR Spinning mill have rich resources of raw materials.

YSR Spinning mill is rich in highly trained manpower. The company have a

huge advantage due to lower wage rates.

It produces quality output.

Weakness

Labour force giving low productivity as compared to other competing

companies.

Technology obsolescence despite measures .

Low bargaining power in a customer-ruled market.

Company seriously lacks in trade pact memberships.

Opportunity

Low per-capita domestic consumption of textile indicating significant Potential

growth.

Companies need to concentrate on new product developments.

Increased use of CAD to develop designing capabilities and for developing

greater options.

Threats

Competition in post-2005 is not just in exports, but is also likely within the

country due to cheaper imports of goods of higher quality at lower costs.

Alternative competitive advantages would continue to be a barrier.

You might also like

- Demand Forecasting Indian Textile IndustryDocument23 pagesDemand Forecasting Indian Textile IndustryAbhishek Moses RichardNo ratings yet

- Alphamed Formulations PVT LTDDocument51 pagesAlphamed Formulations PVT LTDBhargav BezawadaNo ratings yet

- Export Procedure in JCT LTD - Textile IndustryDocument52 pagesExport Procedure in JCT LTD - Textile IndustrydikshaluNo ratings yet

- Baseline Survey Technical Textiles Sector 20042022Document652 pagesBaseline Survey Technical Textiles Sector 20042022Space MuskNo ratings yet

- Final Textile IndustryDocument121 pagesFinal Textile IndustryJas KaurNo ratings yet

- Demonetisation in India: A Study of Its' Impact On Various Key SectorsDocument8 pagesDemonetisation in India: A Study of Its' Impact On Various Key SectorsHimanshuNo ratings yet

- Mirza International Pvt. Ltd.Document93 pagesMirza International Pvt. Ltd.Arjun PatelNo ratings yet

- Introduction To Packaging IndustryDocument85 pagesIntroduction To Packaging Industryshellybal50% (2)

- A Project Report On ExideDocument90 pagesA Project Report On ExidePiyush Bhardwaj100% (3)

- Indian Automobile IndustryDocument10 pagesIndian Automobile IndustryneemolnNo ratings yet

- EuroChem - Europe - Final PDFDocument36 pagesEuroChem - Europe - Final PDFYuvrajNo ratings yet

- CSR Indian OilDocument9 pagesCSR Indian OilDeepak NayakNo ratings yet

- Ralco PROJECT REPORTDocument67 pagesRalco PROJECT REPORTSahil Nayyar100% (2)

- Data Analysis and InterpretationDocument7 pagesData Analysis and InterpretationATS PROJECT DEPARTMENTNo ratings yet

- Procurement, Processing & Distribution of Basmati Rice Special Reference Jagat Agro IndustriesDocument86 pagesProcurement, Processing & Distribution of Basmati Rice Special Reference Jagat Agro IndustriesKhushboo Khanna100% (1)

- List of Operational SEZs in IndiaDocument128 pagesList of Operational SEZs in IndiaParesh LilaNo ratings yet

- Pranav Kaistha ReportDocument18 pagesPranav Kaistha ReportRahul JunejaNo ratings yet

- Customer Satisfaction Varun MotorsDocument66 pagesCustomer Satisfaction Varun Motorsbhanu prasadNo ratings yet

- Textile Industry in India Project ReportDocument16 pagesTextile Industry in India Project ReportmitNo ratings yet

- Indian Textile Industry Chapter 1Document6 pagesIndian Textile Industry Chapter 1himanshuNo ratings yet

- Survey of Steel Industries in India To Study The Potential For Waste Heat Recovery Boilers For Electric Arc FurnaceDocument42 pagesSurvey of Steel Industries in India To Study The Potential For Waste Heat Recovery Boilers For Electric Arc FurnaceChinmay JoshiNo ratings yet

- Challenges in Individual Investment During PandemicDocument22 pagesChallenges in Individual Investment During Pandemicroshini rajendranNo ratings yet

- EPGDM - Project Report GuidelinesDocument7 pagesEPGDM - Project Report GuidelinesManish GuptaNo ratings yet

- A Project Report OnDocument7 pagesA Project Report OnbanalavjuNo ratings yet

- EXIMDocument18 pagesEXIMPushpak RoyNo ratings yet

- Growth Trends in Cotton Textile Industry in India and Tamil NaduDocument6 pagesGrowth Trends in Cotton Textile Industry in India and Tamil NaduJohn HaynesNo ratings yet

- Marketing Strategies of Top FMCG Retail Stores in IndiaDocument76 pagesMarketing Strategies of Top FMCG Retail Stores in IndiaSimar ZuluNo ratings yet

- Medical Tourism: Medical Tourism and The Growth of Health Care Sector in IndiaDocument7 pagesMedical Tourism: Medical Tourism and The Growth of Health Care Sector in IndiaAbhinav RanaNo ratings yet

- Logistics & Supply Chain Management Interim Project ReportDocument29 pagesLogistics & Supply Chain Management Interim Project ReportSuduNo ratings yet

- Final ThesisDocument225 pagesFinal ThesisAnonymous VdwBhb4frFNo ratings yet

- Investment Strategy For Indian Markets Post-CovidDocument21 pagesInvestment Strategy For Indian Markets Post-CovidJcoveNo ratings yet

- Textile IndustryDocument80 pagesTextile Industryankitmehta23No ratings yet

- A Study of Organized Retail Sector S Growth and Its Future Prospects in IndiaDocument9 pagesA Study of Organized Retail Sector S Growth and Its Future Prospects in IndiaBarunNo ratings yet

- Indian Textile Industry Evaluation and Future OpportunitiesDocument45 pagesIndian Textile Industry Evaluation and Future OpportunitiesVikram RattaNo ratings yet

- Black BookDocument12 pagesBlack BookAbhijit NambiarNo ratings yet

- An Organization Study at TULSYAN NEC LTD: Objectives of The StudyDocument81 pagesAn Organization Study at TULSYAN NEC LTD: Objectives of The StudyShowmiya MahaNo ratings yet

- Salem Steel PlantDocument69 pagesSalem Steel PlantKavuthu Mathi100% (2)

- ShodhgangaDocument52 pagesShodhgangaChrz J100% (1)

- List of Licensed Commercial Banks in NepalDocument2 pagesList of Licensed Commercial Banks in Nepalnocadmin100% (1)

- DSM Textile IndustryDocument30 pagesDSM Textile IndustryeshuNo ratings yet

- Profile of Bajaj Pulsar Bike CustomersDocument70 pagesProfile of Bajaj Pulsar Bike CustomersvinothNo ratings yet

- Strategic Management Mid ProjectDocument25 pagesStrategic Management Mid ProjectDea HandayaniNo ratings yet

- Consumer's Perception Towards FOUR WHEELER INDUSTRYDocument91 pagesConsumer's Perception Towards FOUR WHEELER INDUSTRYShubhamprataps0% (1)

- Project Report On Digiworld at MumbaiDocument77 pagesProject Report On Digiworld at Mumbaisantosh888888No ratings yet

- Womens Health Challenges in Unorganized ConstructionDocument94 pagesWomens Health Challenges in Unorganized ConstructionShashank KUmar Rai Bhadur100% (1)

- Industrial Research Project: Version 1.0, 9 July, 2021 School of Business UPES, DehradunDocument5 pagesIndustrial Research Project: Version 1.0, 9 July, 2021 School of Business UPES, Dehradunraja rockyNo ratings yet

- Indian Pharma Industry OverviewDocument9 pagesIndian Pharma Industry OverviewrakeshNo ratings yet

- Project Guidelines From Mumbai UniversityDocument3 pagesProject Guidelines From Mumbai UniversityRavi VaithyNo ratings yet

- Amul Industr-BBA-MBA Project ReportDocument61 pagesAmul Industr-BBA-MBA Project ReportpRiNcE DuDhAtRaNo ratings yet

- Indian Oil (PBM)Document37 pagesIndian Oil (PBM)AsraNo ratings yet

- Final Report Based On 60 Days Market Work As A Nilons' Army Soldier in Mumbai MarketDocument54 pagesFinal Report Based On 60 Days Market Work As A Nilons' Army Soldier in Mumbai MarketKabir SinghNo ratings yet

- Summer InternshipDocument60 pagesSummer InternshipAyush AroraNo ratings yet

- Project Report ON A Comprehensive Study of Indian Banking SystemDocument55 pagesProject Report ON A Comprehensive Study of Indian Banking Systemkaushal2442No ratings yet

- Tata Vs HyundaiDocument49 pagesTata Vs HyundaiAnkit SethNo ratings yet

- Jai Beverages Company ProfileDocument4 pagesJai Beverages Company ProfileSherry SherNo ratings yet

- Aayush Leather IndustryDocument50 pagesAayush Leather IndustryRahul JaiswalNo ratings yet

- Portrait of an Industrial City: 'Clanging Belfast' 1750-1914From EverandPortrait of an Industrial City: 'Clanging Belfast' 1750-1914No ratings yet

- Indian Textile IndustryDocument17 pagesIndian Textile IndustryVin BankaNo ratings yet

- Project On Vardhman - ManishDocument46 pagesProject On Vardhman - ManishManish JhaNo ratings yet

- Cotton Textiles in IndiaDocument3 pagesCotton Textiles in IndiaNitin ShettyNo ratings yet

- Climate defined as weather averaged over 30 yearsDocument4 pagesClimate defined as weather averaged over 30 yearsSakhamuri Ram'sNo ratings yet

- Capital Budgeting VishakaDocument105 pagesCapital Budgeting VishakaSakhamuri Ram'sNo ratings yet

- "Funds Flow Statement": Eswar College of EngineeringDocument8 pages"Funds Flow Statement": Eswar College of EngineeringSakhamuri Ram'sNo ratings yet

- MBA Program VIIT: Performance Appraisal ProcessDocument86 pagesMBA Program VIIT: Performance Appraisal ProcessSakhamuri Ram'sNo ratings yet

- SpencersDocument12 pagesSpencersSakhamuri Ram'sNo ratings yet

- Funds Flow StatementDocument101 pagesFunds Flow StatementSakhamuri Ram'sNo ratings yet

- Funds Flow Statement Tirumala MilkDocument101 pagesFunds Flow Statement Tirumala MilkSakhamuri Ram's100% (3)

- Capital Budgeting CclaDocument50 pagesCapital Budgeting CclaSakhamuri Ram'sNo ratings yet

- Ratio Analysis 1012Document74 pagesRatio Analysis 1012Sakhamuri Ram'sNo ratings yet

- Financial Reports of Devi Sea LTD: Profit & Loss Account For The Year Ended 31St March, 2009Document11 pagesFinancial Reports of Devi Sea LTD: Profit & Loss Account For The Year Ended 31St March, 2009Sakhamuri Ram'sNo ratings yet

- Narasimhulu CR COLLEGE Funds Flow 021Document94 pagesNarasimhulu CR COLLEGE Funds Flow 021Sakhamuri Ram'sNo ratings yet

- Financial Reports of Devi Sea LTD: Profit & Loss Account For The Year Ended 31St March, 2009Document11 pagesFinancial Reports of Devi Sea LTD: Profit & Loss Account For The Year Ended 31St March, 2009Sakhamuri Ram'sNo ratings yet

- List of The Tables: SL NO NO Title of The Table Page NoDocument9 pagesList of The Tables: SL NO NO Title of The Table Page NoSakhamuri Ram'sNo ratings yet

- Capital Budgeting Krishna MurthyDocument54 pagesCapital Budgeting Krishna MurthySakhamuri Ram'sNo ratings yet

- Financial Statement Analysis of Tirumala MilkDocument6 pagesFinancial Statement Analysis of Tirumala MilkSakhamuri Ram'sNo ratings yet

- Financial Reports of Devi Sea LTD: Profit & Loss Account For The Year Ended 31St March, 2009Document11 pagesFinancial Reports of Devi Sea LTD: Profit & Loss Account For The Year Ended 31St March, 2009Sakhamuri Ram'sNo ratings yet

- Capital Budgeting KarimullaDocument51 pagesCapital Budgeting KarimullaSakhamuri Ram'sNo ratings yet

- Dairy IndustryDocument16 pagesDairy IndustrySakhamuri Ram'sNo ratings yet

- Industry Indan Cotton Textile ProfileDocument30 pagesIndustry Indan Cotton Textile ProfileSakhamuri Ram'sNo ratings yet

- Performance AppraisalDocument85 pagesPerformance AppraisalSakhamuri Ram'sNo ratings yet

- Master of Business Administration: A Study On Ratio Analysis With Reference To Jocil LimitedDocument97 pagesMaster of Business Administration: A Study On Ratio Analysis With Reference To Jocil LimitedSakhamuri Ram'sNo ratings yet

- Amaravathi 16 PointsdDocument16 pagesAmaravathi 16 PointsdSakhamuri Ram'sNo ratings yet

- CottonDocument17 pagesCottonSakhamuri Ram's100% (1)

- Cotton IndustryDocument18 pagesCotton IndustrySakhamuri Ram'sNo ratings yet

- Sreemsbi ResumeDocument4 pagesSreemsbi ResumeSakhamuri Ram'sNo ratings yet

- Sagar Cement PointsDocument16 pagesSagar Cement PointsSakhamuri Ram'sNo ratings yet

- VivekDocument24 pagesVivekSakhamuri Ram'sNo ratings yet

- Employee performance report by monthDocument2 pagesEmployee performance report by monthSakhamuri Ram'sNo ratings yet

- Organizational Chart 3.1 - Management StructureDocument1 pageOrganizational Chart 3.1 - Management StructureSakhamuri Ram'sNo ratings yet