Professional Documents

Culture Documents

A 320 Fault Verification Guide

A 320 Fault Verification Guide

Uploaded by

Vahid AlimoradiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A 320 Fault Verification Guide

A 320 Fault Verification Guide

Uploaded by

Vahid AlimoradiCopyright:

Available Formats

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 1 -

A-320

FAULT

VERIFICATION

AND

LINE

MAINTENANCE

HANDBOOK

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 2 -

For Reference Only

Air Deccan Eff List:

001=DKZ---002=DKY---003=ADT---004=ADS---005=DKR-

--006=DKS---007=DKT

008=ADR---051=ADX---052=ADY---053-ADZ---

101=DKW---102=DKX---115=DNZ

151=ADV---152=ADW---201=DKV--202=DKU--203=ADU

Note: (***) Indicates Specific Setup notes:

Note: (AOG) Indicates CB can be reset on

Ground Only

All others can be reset In-flight or on

Ground

Ref: M/M 31-51 31-60 for Details on

Messages

Ref: TSM 24-00-00-810-818 for Current

Computer Resets

(00-00) Beside C/B #s indicate AC

Effectivity (Specific)

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 3 -

This Guide is Provided For Reference Only

Always Refer to the Current TSM

If you have a Confirmed Fault

Document It

AT

A

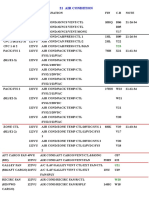

Systemor Fault Reset CB / Switch Time

21 Cabin PressureController CPC 1-----D-9

CPC 2-----Y-22

(1)

Min

21 Avionics Equip Vent

Comp

AC/Avion Vent Ctl --- D-5 D-6

Mon---Y-17

30 Sec

21 Cargo Ventilation Fwd Cargo Vent Ctl ---C-8

Fan T-22

Aft Cargo Vent & Heat Fan ---S-22

Aft Cargo Cont (Mont) ---------C-7

10 Sec

21 Pack Controller

Pack #1 Temp Ctl X-21X-22Y-18Y-19

Pack #2 Temp Ctl W-21W-22Y-20--Y-21

***Packs Off , Pack FCV-(Closed)

30 Sec

21

ZoneController

AC ZoneTemp Cont System

V-17 -----V-18------V-19-----V-20

***Resetting with Eng Running will generate

FADEC Warnings

30 Sec

21 Hot Air Valve Reset Hot Air (P/B) 10 Sec

21 Air Pack Regulator Fault Y-18 ---Y-20 ----(051-149)

X-22---Y-18---X-21---D-8 (All Others)

Test: ZoneController

30 Sec

21 Vent Avionics Faults

& Extract Faults

Avionics Vent Mont -----Y-17

If no Help ------D-5 & D-6

If no Help ------Reset (Extract Fan)

30 Sec

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 4 -

21 TrimAir Valve(Msg)

ZoneTemp Ctl (Sys 1 AC)-----V-17

(Sys 2 AC)-----V-18

(Sys 1 DC)-----V-19

(Sys 2 DC)-----V-20

30

Sec

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 5 -

ADDITIONAL FAULTS

21

Air Pack Overheat Compressor Outlet temp (which is controlled by the Pack

FCV

-----------------------------------------------------------------------------------------------------

Air Pack Fault Pack Valve disagree with the p/b switch position or the

compressor outlet temperature.

-----------------------------------------------------------------------------------------------------

Air Pack Off Pack is selected Off

-----------------------------------------------------------------------------------------------------

Air Pack Regulation Fault Pack Controller (channel failure)

-----------------------------------------------------------------------------------------------------

Air Pack 1 & 2 Fail Both Packs Failed

-----------------------------------------------------------------------------------------------------

Condition Duct Overheat Duct Temp higher than 190 deg F (Pressure Reg

Valve and Trim Air Valves close)

-----------------------------------------------------------------------------------------------------

Condition Hot Air Fault Hot air Pressure Regulating Valve disagrees with the

p/b switch position

-----------------------------------------------------------------------------------------------------

Condition Trim Air System Trim Air Fault

-----------------------------------------------------------------------------------------------------

Condition Zone Regulator Fault Primary or Secondary Zone Controller

Failure

-----------------------------------------------------------------------------------------------------

Alternate Mode Indication (on ECAM) Primary Zone Controller Fault

Hot Air P/B (Fault Light) Indicates that the duct temp O/H

(temp above 88 deg C) HAV & TAV close automatically

(Fault Light goes off when temp drops below 70 deg C &

The (HAV) is selected off.

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 6 -

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 7 -

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 8 -

ATA System or Fault Reset CB / Switch Time

22 FMGC

***ADIRUs ----------Aligned

***FDs ----------------Off

FMGC 1 --------------B-2

FMGC 2 --------------M-17

***C/B Out for 5 sec / In (B-4) 10

***(Only 1 Sys @ a time in Flt)

5

Sec

to

10

Sec

22 FMGC ----- (AOG)

***Engines ----------Off

***FDs ---------------Off

FMGC 1 -------------B-2

FMGC 2 -------------M-17

***Pull Both C/Bs

10

Sec

22 Auto Pilot (Faults) Reset FMGC as Above 10

Sec

22 FAC --------(AOG)

***Engines ----------Off

FAC 1 -------------B-3----B-4

FAC 2 -------------M-18--M-19

***With Hyd (ON) Yaw Damp

is also tested.

***Cycle FAC P/B 1st

30

Sec

22 Rudder Trim (Fault) (AOG) Reset FAC System as Above 30

Sec

22 Rudder Travel Limit (AOG) Reset FAC System as Above 30

Sec

22 Dual Cat III (Msg) (AOG) Reset FAC System as Above 30

Sec

22 MCDU (Faults) MCDU 1 -------------B-1

MCDU 2 -------------N-20

10

Sec

22 Flight Control Unit (FCU)

(Faults) ------(AOG)

***Both FDs -------------Off

FCU 1 --------------- B-5

FCU 2 ----------------M-21

*** If 1

st

reset unsuccessful , retry for 7

Min

*** If reset Successful (check) target &

Baro

References are shown

10

Sec

Or

(7)

Min

22 Wind Shear (Det) Fault Reset FAC as above XX

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 9 -

22 Auto Flight

YAW DAMPER (Fault)

***Green & Yellow Hyd-----ON

FAC 1 --------B-4

FAC 2 --------M-19

10

Sec

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 10 -

ATA System or Fault Reset CB / Switch Time

23 HF System HF 1 ------------HA-14 10

Sec

23 VHF System

VHF 1 ----------G-9

VHF 2 ----------L-4

VHF 3 ----------L-5

10

Sec

23

ACP

***If Freq wont change

Try Resetting FMGCs

ACP 1 ----------G-6

ACP 2 ----------G-7

ACP 3 ----------M-2

10

Sec

23 RMP

Or Frozen RMP

*** Reset ea RMP Separately (off 5 Sec On)

*** If no Help

RMP 1 ---------G-10

RMP 2 ---------L-2

RMP 3 ---------L-3

(2)

Min

23 CIDS (Faults)

***(AOG) Pull All:

***(Inflight) Reset

(1) at a Time:

***C/B Loc Vary by A/C

*** Pull C/Bs in order: (All Others)

G-2M-5G-5G-4G-3M-13M-12,

M-11M-10--M-9M-8M-7M-6Q-14

*** Reset C/Bs in order: (All Others)

M-13M-12M-11M-10M-9M-8M-7,

M-6Q-14G-5G-4G-3M-5G-2

*** Pull C/Bs in order: (001049) (151-300)

G-1M-5G-2M-6

*** Reset C/Bs in order: (001049) (151-300)

M-6G-2M-5G-1

*** Pull C/Bs in order: (051149)

G-2---M-5

*** Reset C/Bs in order: (051149)

M-5----G-2

***Try Resetting FAP (1

st

)

***Pull for (1) Min in Flight

***Note: Decoder / Encoder (Units) (DEU)

DEU A = Cabin Lights

DEU B = Handsets & Loud Speaker

(1)

Or

(2)

Min

23 EVAC (Faults) Try Resetting the (Horn) P/B 1st

Reset CIDS as Above

(2)

Min

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 11 -

23

FAP (Frozen)

CIDS Fwd Attd PNl -------M-14 (051-149)

*** Pull C/Bs in order: (All Others)

H-1---Q-14

*** Reset C/Bs in order: (All Others)

Q-14---H-1

*** If no Help (All)

E-1 (2000VU)

10

Sec

23 PAX ENT (Faults)

(Video & Audio)

Cabin Com Sys (PES) ------F-6 (2000VU)

***If no Help (Reset) all DEUs

M-7 through M-13

***Screens Reset by Ind (button) (hole)

15

Sec

23 TCAS (Faults) TCAS ------------------- K-10 10

Sec

23

FAP (Frozen)

CIDS Fwd Attd PNl -------M-14 (051-149)

*** Pull C/Bs in order: (All Others)

H-1---Q-14

*** Reset C/Bs in order: (All Others)

Q-14---H-1

*** If no Help (All)

E-1 (2000VU)

10

Sec

23 PAX ENT (Faults)

(Video & Audio)

Cabin Com Sys (PES) ------F-6 (2000VU)

***If no Help (Reset) all DEUs

M-7 through M-13

***Screens Reset by Ind (button) (hole)

15

Sec

23 TCAS (Faults) TCAS ------------------- K-10 10

Sec

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 12 -

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 13 -

ATA System or Fault Reset CB / Switch Time

24

Battery Charge Limiter

***Reset (1) at a Time with APU Operating

Cycle (Affected) Battery Switch

XX

24 Generator Control Unit

(GCU) (AOG)

Cycle Generator (Cont) P/B (Affected Gen) XX

24 Ground Power Control Unit

(GPCU) (AOG)

*** Engines & APU & Batteries Off

Ground Power -------------------Disconnected XX

24 Eng Gen (on-line)

No Ind on ECAM (AOG)

***Engine ---------------------------- Off

GCU 1 -----------------------------T-26

GCU 2 -----------------------------T-27

10

Sec

24 Ext Power P/B (AOG)

(No Green Avail) Light

***Engines & APU & Batteries --Off

Ground Power ------------------- Disconnected

30

Sec

24 Transformer Rectifier Unit ***Reset (Via) -------------------------CFDS

Reset P/B ---------On TRU ------103VU

***103VU Located Above Battery

XX

24 AC ESS BUS (Fault)

Reset ------AC ESS BUSS FEED---P/B

***norm pwrd by AC Buss 1 / Buss 2 takes over

XX

24 AC BUSS 1 (Fail) Reset ------AC ESS BUSS FEED---P/B XX

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 14 -

25

Flight Deck Seats

(Elect Control)

Captains Seat --------------U-11

FOs Seat -------------------U-14

Individual Seat C/B ------ Under Seat

10

Sec

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 15 -

26 SmokeDetector Cont Unit

(SDCU)

SDCU Channel 1 -----------------C-6

SDCU Channel 2 -----------------T-18

***Reset C/Bs Together

(2)

Min

26 FireDetection Unit

(FDU) (AOG)

Eng FireLoop A & B -------A-6 Q-38

Eng FireLoop A & B -------A-7 Q-39

APU FireLoop A & B ------ L-43 L-44

30

Sec

26 Cargo (Detection) (Faults)

Reset (SDCU) as above ***If no Help

Aft Cargo Vent & Heat Fan ---S-22

Aft Cargo Cont (Mont) ---------C-7

(2)

Min

26 SmokeLAV (Msg) Reset (SDCU) as Above XX

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 16 -

ATA System or Fault Reset CB / Switch Time

27

F/CTL ALT LAW

F/CLT ELAC (Fault)

F/CTL ELAC PITCH Fault

***Reset ELAC P/B Switch 1

st

ELAC 1 (Norm Supply) --------------------B-11

ELAC 2 (Norm Supply)---------------------R-20

10

Sec

27 SEC (Faults)

*** Reset SEC P/B Switch 1

st

SEC 1 (Norm Supply) -----------------------B-8

SEC 2 (Norm Supply) -----------------------Q-18

SEC 3 (Norm Supply) -----------------------Q-19

10

Sec

27 Flt Cont Data Concentrator

(FCDC)

FCDC 1 ------------------------B-10

FCDC 2 ------------------------Q-20

10

Sec

27

Slat / Flap Cont Computer

(SFCC) (AOG- Pull All)

&

Flight Cont (Msgs)

***Engines Running (Pull IAW Chart)

Slats (Fault) --------------------B-6 ---R-21

Flaps (Fault) -------------------B-7 ---Q-21

Slats (Sys 1 Fault) ------------ B-6

Slats (Sys 2 Fault) ------------ R-21

Flaps (Sys 1 Fault) ----------- B-7

Flaps (Sys 2 Fault) ----------- Q-21

*** Engines Off (Reset All C/Bs)

(2)

Min

27 Side Stick (Priority Msg) Reset FAC & SEC & ELAC P/B Switches

(As Above)

XX

27 Flaps Locked Out (Msg) ***Hydraulics ------------------------Off

Wing Tip Brake Reset (via)--------CFDS

XX

27 Flight Cont (Maint Msg) FCDC 1 --------------------------------B-10

FCDC 2 --------------------------------Q-20

10

Sec

27 Slow Slats Slat Cont & Mont Sys 1 -------------B-6

Slat Cont & Mont Sys 2 -------------R-21

10

Sec

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 17 -

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 18 -

28 Fuel Quantity Ind Comp

(FQIC)

Fuel FQI Channel 1 ----------------A-13

Fuel FQI Channel 2 ----------------M-27

FQI Channel 1 & 2 -----------------L-26

10

Sec

28 APU LP Valve(Fault) CycleAPU Master Switch XX

28 Auto Feed (Fault)

Caused by:

Ctr Tnk---above550lbs with wings B/L 1100lbs

Ctr Tnk Pp-did not S/O when slats ext (on grd)

Ctr Tnk Pp-did not S/O when low level reached

XX

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 19 -

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 20 -

ATA System or Fault Reset CB / Switch Time

29 Hyd Res Low Press (Msg) Run Engs or Pressurize Hyd Systen XX

29

PTU Faults

Green / Yellow Sol Valve ------------ N-34

***If no Help

*** With Engines Running

Master Caution --------------(Reset P/B)

Yellow (Elect) Pump --------(On then Off)

Set Parking Brake -----------(Brakes Set)

Both Eng Pumps -------------(Off)

Yellow (Elect) Pump --------(On)

PTU ----------------------------(Off then Auto)

Yellow (Elect) Pump --------(Off)

Both Eng Pumps -------------(On)

Wait

30

Sec

For

Each

Sw

29

Hyd Indication (Faults)

&

Pump Faults

Brake Pressure (Ind) ------------------C-10

Pressure Transmitter ------------------C-11

Hyd Power Warn & Cont-------------C-12

Eng 1 (Gr) Fire Valve------------------C-13

Eng 2 (Yel) Fire Valve-----------------C-14

RAT Cont--------------------------------D-14

Yellow Hyd Power -------------------- N-30

Low Level Ind ------------------ -------N-32

Solenoid Valves (G/Y (PTU) --------N-34

Solenoid Valves (Leak Test) -------- N-35

Quantity Ind ---------(49VU) -------- P-35

Yellow (Eng 2) Pump Mont ---------Q-37

Yellow (Eng 2) Pump Ctl ------------Q-36

Green (Eng 1) Pump Mont ----------R-34

Green (Eng 1) Pump Ctl -------------R-35

Yellow Elect Pump (Norm)-----------AB-03

10

Sec

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 21 -

Yellow Elect Pump---------------------AB-06

Blue Elect Pump (123VU) ------------AB-09

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 22 -

ATA Systemor Fault Reset CB / Switch Time

30

Window Heat Control Unit

WHC 1 -----------------X-13

WHC 2 -----------------W-13

***With (Fault on Ground)

***Turn Packs (On) and Pull C/B for 5 Minutes

***Window Heat (Faults)

Window (Left) Heat -------X-14

Window (Right) Heat -----W-14

(5)

Min

30 Drain Mast Control Unit Fwd Drain Mast-------B-6 or D-1 (2000VU)

Aft Drain Mast --------E-1 or D-5 (2001VU)

***Can beReset through FAP (Also)

10

Sec

30 Anti Ice(Msg) Anti IceProbes (PHC 1) -----------D-3

Anti IceProbes (PHC 2) -----------Y-12

Anti IceProbes (PHC 3) -----------Y-16

10

Sec

30

Anti Ice(Probes) (Msg)

(System1)

PITOT 1 ------------------D-2

STATIC 1 ----------------Z-13

AOA 1 -------------------- D-4

TAT 1 ---------------------Z-12

***If no Help (Reset)

ADIRU 1 (26vac)--------F-7 & AOA 1 ----D-4

ADIRU 1 (115vac)------T-6

10

Sec

30

Anti Ice(Probes) (Msg)

(System2)

PITOT 2 ------------------Y-14

STATIC 2 ----------------Y-11

AOA 2 -------------------- Y-13

TAT 2 ---------------------Y-15

***If no Help (Reset)

ADIRU 2 (26vac) ------N-9 & AOA 2 -----Y-13

ADIRU 2 (115vac) ----N-7

ADIRU 2 (28vdc) -----N-5

ADIRU (Pwr Shed) ---N-11

10

Sec

30

Anti Ice(Probes) (Msg)

(System3)

PITOT 3 ------------------Z-16 (Stby)

STATIC 3 ----------------Z-14 (Stby)

AOA 3 -------------------- Z-15 (Stby)

***If no Help (Reset)

ADIRU 3 (26vac) ------N-8 & AOA 2 -----Z-15

ADIRU 3 (115vac) ----N-6

ADIRU 3 (28vdc) -----N-4

ADIRU 3 Switching Supply N-10

10

Sec

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 23 -

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 24 -

ATA Systemor Fault Reset CB / Switch Time

31

Flight Warning Computer

FWS FWC Fault

(AOG)

***Only Reset (1) at atimein Flight

FWC 1 --------------------------F-1

FWC 2 ------------------------- Q-7

***Reset (both) at thesametimeon theground

30

Sec

31 Cent Fault DataInter Unit

(CFDIU) (AOG)

CFDS / DFSIU / Supply --------J -18

CFDS / CFDIU / Back Up -----J -17

10

Sec

31 Flight DataInter Unit

(FDIU) (AOG)

***Engines --------------------Off

Recorder FDIU & QAR -----K-17

10

Sec

31 Display Mgmt Computer

(DMC) (AOG)

EIS DMC 1 --------------------E-9 ----E-11

EIS DMC 2 --------------------Q-8 ----R-8

EIS DMC 3 --------------------E-7 ----E-10 ---Q-9

30

Sec

31 Display Mgmt Unit

(DMU) (AOG)

Capt PFD ----------------------E-3 ----E-4

Capt ND ----------------------- E-1 -----E-2

FOs PFD ----------------------R-3 ----R-5

FOs ND ----------------------- R-4 -----R-6

Upper ECAM ---------------- E-5 ------D-6

Lower ECAM ---------------- R-10 ----R-11

(2)

Min

31 SystemDataAciq Unit

(SDAC) (AOG)

***Reset all (7) C/Bs Together

SDAC 1 ------------------------------ F-2 ---F-4

SDAC 1 & 2 ------------------------ F-5

EIS SDAC 1 -------------------------Q-3 -Q-4

EIS SDAC 1 & 2 --------------------P-3 ---P-4

SDAC 2 -------------------------------F-3

SDAC 1 & 2 ------------------------- F-5

EIS SDAC 2 -----------------Q-2 ---Q-5 ---Q-6

EIS SDAC 1 & 2 --------------------P-3 ---P-4

***Additional C/Bs for Door Ind

SDAC 1& 2 Door Avionics / PAX P-2---P-5

(2)

Min

31 ECAM (Pages) Locked Reset FWCs as Above XX

31

AIDS Indication (MCDU)

&

Printer Not Allowed

Recorder FDIU / QAR -------------K-17

Printer Supply -----------------------J -21

10

Sec

31 DAR / QAR (Msg)

***Check if Mediais Full

Recorder FDIU / QAR ----------- K-17

ACCLRM ---------------------------K-18

10

Sec

31 Digital Flt DataRecorder

(DFDR)

Recorder / DFDR ------------------K-16 10

Sec

31 Invalid Dataon the(DCDU)

Or MCDU (ATC) Page

ATSU 1 -----------------------------L-16

ATSU 1 SWTG -------------------L-15

10

Sec

ATA Systemor Fault Reset CB / Switch Time

31 Clock (Off fromECAM) Clock NormSupply----------------------F-11 10

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 25 -

Clock Stand By Supply------------------N-2

***SomeAC (Stby Supply-------------N-3

Sec

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 26 -

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 27 -

ATA Systemor Fault Reset CB / Switch Time

32

Landing Gear Cont Unit

L/G LFCIU Fault

***Only Reset (1) at atimein Flight

***Open in Order:

LGCIU 1------Q-34----C-9

***Closein Order:

LGCIU---------C-9----Q-34

LGCIU 2 (OpenQ-35) -----(Close----Q-35)

30

Sec

32 BrakeSteering Cont Unit

(BSCU)

***In-Flight (Do not Reset any C/Bs

***Try Cycling AS/NWS Switch 1

st

(10 Sec)

(Note: Switch (swaps) Channels)

***On-Ground

AS/NWS (Switch) ---------------------Off

Hyd Brake& Steering Sys -----M-33 thru M-36

AS/NWS (Switch) ---------------------On

(1)

Min

32 BrakeTemp (Indication) BrakeTemp Det Unit ----------------M-37 10

Sec

32 BrakeFan (Faults) BrakeFan Cont -----------------------M-32

Fan (Wheels) 1 & 2 -------------------L-32

Fan (Wheels) 3 & 4 -------------------L-35

10

Sec

32 TirePressure(Indication) TirePressureIndication ------------M-31 10

Sec

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 28 -

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 29 -

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 30 -

ATA Systemor Fault Reset CB / Switch Time

33 Wheel Well (Lights)

And

APU (Service) Lights

Lights Sec 19 --------------------F-5 (2001VU)

APU SVC Light ----------------F-6 (2001VU)

10

Sec

33 Cabin Light (Faults)

And

Flt Attn Light

(Faults)

*** Reset CIDS (via) FAP or MCDU

***If no Help Reset ----------Q-14

***If no Help Reset CIDS (Ref Ch 23)

***Note: Decoder / Encoder (Units) (DEU)

DEU A =Cabin Lights

DEU B =Attend Lights / Signs

10

Sec

ATA Systemor Fault Reset CB / Switch Time

34 ADIRU (Faults)

(AOG)

(Stand-By Instruments)

***Quick Align (ADIRU to Off then toNAV)

(Wait 15 Seconds) (Try 1

st

)

***Only Reset C/Bs on Ground

***If no Help Reset System

ADIRU 1 --------------------C-2---F-6---F-7

ADIRU 2 ----------------N-4 ---N-6---N-8---N-10

ADIRU 3 -------------F-9---N-3---N-5---N-7---N-

9

Stand-By (Inst) -----F-12---F-13---J -1

15

Sec

34 GPWS GPWS ---------------------P-6-------P-7 15

Sec

34 Baro Reference(Fault) ***Reset FCUs (Ref Ch 22) XX

34 Wind Shear (Faults) Reset FACs Ref Ch 22 XX

34

Navigation (Sys) (Faults)

ADF -------#1-H-14----------#2-K-2

ATC -------#1-G-11----------#2-K-7

DME ------#1-G-14-----------#2-K-6

ILS ---------#1-G-12----------#2-K-9

RADAR ---#1-K-13----------#2-K-14

10

Sec

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 31 -

RA ----------#1-K-11---------#2-K-12

VOR --------#1-G-13---------#2-K-8

34 TCAS (Faults) TCAS ------------------- K-10 10

Sec

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 32 -

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 33 -

ATA Systemor Fault Reset CB / Switch Time

36 Bleed Mgmt Comp

(BMC)

Air Bleed Eng 1 ---------------- D-11----D-12

Air Bleed Eng 2 ---------------- Z-22----Z-23

(1)

Min

36 Bleed (Leak) Msgs ***Reset (affected) Bleed Switch 1

st

***If no Help ----------Reset BMC as Above

XX

36 Cross Bleed (Faults)

***Reset BMC as Above

***If no Help Reset Listed SDAC C/Bs

SDAC 1 Supply -----F-4

SDAC 2 Supply -----Q-6

10

Sec

36 Cross Bleed Valve(Msg) Air Bleed Cross Feed Valve(Bat) -----D-13

Air Bleed Cross Feed Valve(Norm)Z-20

10

Sec

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 34 -

Position) and (p/b Switch) Position

------------------------------------------------------------------------------------------------------------

AIR APU BLEED LEAK

EngineRunning------APU Bleed ValveControlled to (Open)

------------------------------------------------------------------------------------------------------------

AIR BLEED ABNORMAL PR:

(With Msg) Press RegV 4001HA or Sol 10HA or Sense

Eng Bleed Opening (Disagree)

Eng RegPress is Below theOperating Press of thePRV (Low Press Det)

Regulated Pressureis lower than (23 PSI)

HP Valve(indication) is Amber

Changethe: PRV / Check theSenseLine/ R&R theBleed Pr Reg Ctl Sol 10HA

AIR ENG BLEED FAULT (With Msg(FAV 9HA or Thrm7170HM or SenseLine

O/T (Condition)

Changethe(FAV -T-Stat) / Check theSenseLine(FAV) / ChangetheFAV /

R&R theExchanger Outlet Temp (Sensor) 6HA / Wiring

AIR ENG BLEED (LO TEMP): (With F/M Fan Air V 9HA or THRM 7170HM)

Low Temp (Reg) (Detection)

Eng Bleed Air TemperatureDrops Below 150 deg C

In Flight (Anti Ice) (ON) -- ChangetheFAV (T-Stat) / FAV

AIR ENG BLEED FAULT (With FailureMessagePress Reg V 4001HA)

Over Pressure(Condition)-----PRV and HP (Valves) CloseAutomatically

ChangethePRV - or - Bleed Regulated PressureTransducer (8HA)

AIR ENGINE BLEED LEAK

Pylon Leak-------PRV and HP (Valves) closeAutomatically

AIR ENG BLEED NOT CLOSED (With F/M Press Reg V 4001HA or Sol 10HA

Eng PRV Valve(Did Not) Auto Closewhen the(APU Bleed) Valvewas (Open)

EngineBleed Closure(Disagree)

R&R thePRV Check theSenseLine(PRV/HP) / Bleed Press Reg Sol 10HA

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 35 -

------------------------------------------------------------------------------------------------------------

AIR WING LEAK

Both or (one)--- (Detection) Loops Failed

------------------------------------------------------------------------------------------------------------

BLEED MONT FAULT-------Both BMCsFailed

------------------------------------------------------------------------------------------------------------

CROSS BLEED FAULT:

Eng and APU areRunning (Together)------APU Bleed Air is selected (ON)

------------------------------------------------------------------------------------------------------------

ENG HP VALVE FAULT (With F/M HP Bleed 4000HA or SenseLine)

HP Valve(Closed with Eng @ Idle) (Opening Disagree)

ChangetheHPV / Check theSenseLine/ Wiring

ATA Systemor Fault Reset CB / Switch Time

38 Water Quantity Ind Water System---------------D-3---(2000VU) 10

Sec

38 CoffeeMaker (Noise) (Leak) PlaceFinger over Drain Tube 10

Sec

38 ToiletteWont Flush

ToiletteSystem------------35MG (2001VU)

***If no Help (via) (2001VU)

VAC Tol Sys Lav Pwr ----B-1---B-3---B-4

15

Sec

ATA Systemor Fault Reset CB / Switch Time

49 APU Bleed (Faults) ***APU -----------------Off

ECB Supply------------L-41

APU Cont --------------L-42

10

Sec

49 APU (Will Not Shut Down) Pull C/Bs --------------L-42-----L-41 XX

49 APU (No Volts or Freqs) ***APU ---Off----On

***If no Help

APU GCU ---------Y-25

10

Sec

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 36 -

ATA Systemor Fault Reset CB / Switch Time

73

Engine(FADEC) Fault

(AOG)

Engine(IGN) Fault

***Try Resetting FADEC P/B 1st

***Engines --------------------Off

***Wait (5) Minutes then Pull C/Bs

ENG 1 FADEC A & EIU 1 -------A-4

ENG 1 FADEC B -------------------R-41

ENG 2 FADEC A & EIU 2 -------A-5

ENG 2 FADEC B -------------------Q-40

10

Sec

73 EPR Mode(Fault) CycleEngine(N1) ModeSwitch XX

73

EngineIntegration Unit

(EIU)

Try Oil PressureC/B 1

st

-------N-40 ---N-42

***If no Help

PerformCFDS (Test) FADEC 1 & 2

***If no Help

Eng Start (Switch) ---(Normto Crank) (15

Sec)

Return to (Norm) (Wait 5 Minutes)-

(Repeat)

15

Sec

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 37 -

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 38 -

Bleed Press Ind: Amb when theBld Press is below 21 PSI and The(srt vlv) not open

------------------------------------------------------------------------------------------------------------

EGT OVER LIMIT : is shown when

a. EGT is morethan 610 Deg C (Flashes Amber)

b. EGT is morethan 635 Deg C (Flashes RED)

c. N1 greater than 100% Flashes (RED)

d. N2 greater than 100% - (Steady RED)

------------------------------------------------------------------------------------------------------------

EPR MODE FAULT (A) Enginein N1 Mode(EPR) Lost

------------------------------------------------------------------------------------------------------------

FADEC FAULT (A) Both EEC channels are(faulty)

------------------------------------------------------------------------------------------------------------

FUEL FILTER CLOG (A) Fuel Filter (clogged)

------------------------------------------------------------------------------------------------------------

FUEL VALVE FLT (A) (PRSOV) fails opn or closed Or Fuel Vlv (not open)

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 39 -

------------------------------------------------------------------------------------------------------------

OIL FILTER CLOG (A) Scavengeoil filter (clogged)

OIL HI TEMP (A) Oil Temp between (156 & 165 Degrees C)

------------------------------------------------------------------------------------------------------------

OIL LO PRESSURE (R) Pressurelower than 60 PSI

------------------------------------------------------------------------------------------------------------

OIL LO TEMP (A) Oil Temp below (-10 Deg C) or (-50 DegC @ TO)

------------------------------------------------------------------------------------------------------------

TLA LEVER DISAGREE (A) Disagreement between revolvers and thrust levers

------------------------------------------------------------------------------------------------------------

THR LEVER FAULT (A) Both Revolvers or Thrust Lever (failed)

Note: Thereare(2) revolvers per throttlelever

------------------------------------------------------------------------------------------------------------

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 40 -

21) Air Conditioning

AIV---Prevents iceb/u D/S of theACM turbine, Conts pack dischargetemp

In caseof failure(via) thepack outlet PnueSensor

------------------------------------------------------------------------------------------------------------

By Pass Valve---Conts ACM by pass for pack outlet modulation

------------------------------------------------------------------------------------------------------------

Bleed Temp Sensor---Provides supplementary info to pack & zonecont

------------------------------------------------------------------------------------------------------------

Comp Temp Snsr---Provides Comp O/L temp to (PC) pri chan for O/H det

------------------------------------------------------------------------------------------------------------

Comp O/H Snsr---Prov comp O/L Temp to (PC) Sec chan for O/H det & ECAM

------------------------------------------------------------------------------------------------------------

Condenser---cools airflow in wtr extraction loop below its dew point

------------------------------------------------------------------------------------------------------------

Comp Pneu O/H Snsr---protects against pack O/H by grad closing FCV

When comp dischargetemp ^230 C

------------------------------------------------------------------------------------------------------------

Flow Amp---provides elect signal to (PC) relating to flow thru theFCV

------------------------------------------------------------------------------------------------------------

FCVconts theflow of bleed air entering thepack and trimair system

------------------------------------------------------------------------------------------------------------

Main Heat Exch---uses ramair to cool air leaving theACM comp

------------------------------------------------------------------------------------------------------------

Pack O/L Temp Snsr---prov pack O/L temp info to (PC) for ECAM & O/Hdet

------------------------------------------------------------------------------------------------------------

Pri Heat Exc---uses ramair to cool theair ent the(ACM) compressor

------------------------------------------------------------------------------------------------------------

Pack I/L Press Snsrind increased ACM bypass under low bleed press cond inflt

------------------------------------------------------------------------------------------------------------

PlenumChamber---ensures ACM fan airflow thru ramair circuit on ground

------------------------------------------------------------------------------------------------------------

Pack O/L PnueSnsr---modulates AIV to cont pack O/L temp in caseof failure

------------------------------------------------------------------------------------------------------------

Water Ext Temp Snsr---Provides info for pack temp modulation

------------------------------------------------------------------------------------------------------------

RamAir I/L & O/L Act---reg ramair flow for minimal drag

------------------------------------------------------------------------------------------------------------

Reheater---optimACM turb effic , stops press of water at turb I/L

------------------------------------------------------------------------------------------------------------

Water Ext---removes moist fromtheair leaving thecondenser by (Cent Force)

------------------------------------------------------------------------------------------------------------

Water Inj---increases thecooling effic of theheat exchanger

------------------------------------------------------------------------------------------------------------

ZoneCont---ensures cabin temp cont and mont , estab pack O/L temp demand

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 41 -

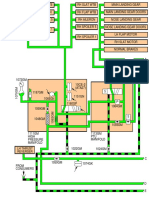

Engine BLEED AIR is sent to the OZONE FILTERS (then) to PK

FLOW CONTROL VALVE (then) PART of the AIR is sent

through the HOT AIR PRESSURE REGULATING VALVE

(which regulates the pressure to the TRIM AIR VALVE and (then)

the REST of the AIR is sent to the PRIMARY HEAT EXCANGER

(to cool the air) and (then) it is sent to the Compressor Section of

the ACM (where the air is compressed to a higher pressure , which

also raises the temperature) and (then) the air is sent to the MAIN

HEAT EXCANGER (where the air is cooled again) and (then) the

air is sent to the WATER SEPERATOR (where the moisture from

the air is removed) and (then) the air is sent to the Turbine Section

of the ACM (where the air expands to generate the power to drive

the (ACM) this removal of energy from the air lowers the

temperature of the air) and (then) the air is sent to the MIXER

UNIT (where it is mixed with the re-circulated fan air) and (then)

the mixed air is sent to the TRIM AIR VALVES and (then) to the

SUPPLY DUCTS.

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 42 -

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 43 -

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 44 -

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 45 -

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 46 -

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 47 -

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 48 -

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 49 -

29) Hydraulics

Reservoir Low PressureSwitch located on thereservoir by the(head press) gauge.

Normal Head Pressure=50 PSI and it sends aECAM messageReservoir Low Pres

At 30 PSI. (only during phases 8,9 and 10)

Note: ThePress Switch (Closes) at 30 PSI (ECAM indication) and (Opens) at 33 PSI

Note: TheBlueSystemreservoir has (2) pressureswitches (1) as listed aboveand

(1) for ECAM indication at 22 PSI (only during phases 5,6 and 7) it also provides a

CLASS II Maint Status messageviatheSDAC

Note: TheSwitch (Closes) at 22 PSI and (Opens) at 25 PSI

Note: This Warning will not automatically cancel

-----------------------------------------------------------------------------------------------------------

Hyd Press Switch (Hyd Pump) 3ea- monitors O/P press of thepump.

Sends signals to theECAM when thepress is at 1740 PSI (yell & Grn)

And 1450 for theBlueElect Pump)

Normal Pressureof thepump =1750 to 2250 PSI

Located L/H sideof engine(just abovethecasedrain filter) (for Engines)

And Down Streamof the(BlueElectric Pump)

Fin #: 1074GK (green) 2074GJ (blue) 3074GD (yellow)

-----------------------------------------------------------------------------------------------------------

Hyd Press Sw located on theHP manifold sends the(low) and(hi) pres

Signals to theSDAC for display on theECAM

a. Switch: # 1151GN (green) 2151GN (blue) 3151GN (yellow)

Sends info to theFWC, (ELACS and SECS) (FAC)

Sw (Closes) and sends a(Lo Press) warn at 1450 psi and(Opens) at 1750 PSI

Note: At 1750 PSI thewarning is automatically canceled

Note: Switch #1151GN also sends info to thebrakesystem

Switch: # 10CE1 (gr)-----10CE2 (bl)----10CE3 (yell)

------------------------------------------------------------------------------------------------------------

Hyd Press Transducer (trans) sendsinfo to theSDAC EcamInd (HP manifold)

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 50 -

Note: at 1450 PSI the(indication) changes to amber

Note: Theseonly send the(digital) indication to theECAM

FIN #: 1065GN (gr) 2065GN (bl) 3065GN (yell) 3068GN (brk press yell)

------------------------------------------------------------------------------------------------------------

PressureRelief Val protects sys fromO/P. opens at 3426 PSI and Closes at 3190

33) Lights

Integral Light Controllers:

6LF aboveFlight Deck Door Controls O/H Panel (Integral Lights)

16LF Fwd. Elect Bay (Upper) Controls Main Inst Panel (Integral Lights)

30LF Fwd Elect Bay (Upper) Controls GlareShield Integral Lights)

---------------------------------------------------------------------------------------------------

Annunciator Light Transformers - located aboveFlight Deck Door

31LP Powered fromAC ESS (Network)

35LP Powered fromAC ESS (Network)

36LP Powered fromAC NORMAL (Network)

37LP Powered fromAC NORMAL (Network)

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 51 -

36) Pneumatics

EngineBleed Air System: (Normal Operation)

EngineBleed Air is taken fromthe7

th

Stageand 10

th

StageCompressor

It is sent to the(IP) Check Valve: (To prevent backflow) (back into)--(Then-If)

(IP) 7

th

StageComp (Closes when (HP) air is being used)

The(Air Press) is 37 PSI or More(7

th

Stg (IP) Air is Used and--(Air Sent to PRV)

The(Air Press) is 36 PSI or Less (10

th

Stg (HP) Air Is Used and---(And) (The)

The(HP) Valve(Opens) to allow (10

th

StageHP) Air to beUsed ---- (Then)

Note: ValveSpring Loaded (Closed) (Pneumatically Operated)

And is (Connected) to the(PRV) viaa(SenseLine) and (Elect)

To a(Control Solenoid)

Either the(IP) or (HP) Air is used (Depending On PSI) (Then)

The(Air) is sent to thePressureRegulating Valve(PRV) (Then)

Note: Regulates Pressureto 44 PSI (Downstream)

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 52 -

Note: Pneumatically (Operated) and Electrically (Controlled)

By the(PRV) (Control ValveSolenoid) (Which)

Is installed in the(Duct) (Downstream) of the(Pre-Cooler)

When the(Solenoid) Energizes it (Opens) the(HP/PRV)

SenseLine(Which Vents) the(SenseLine) Air into the(Fan Air)

The(PRV) and (HP) Valve(Close) (viaspring loaded)

Allowing (IP) Air to beused

The(Air) is sent to theOverpressureValve(OPV) (Then)

Note: Protects Systemfromoverpressure(D/S)-(Spr Lod open)

The(Air) is sent to the(EngineStart Valve) (Then)

(If Needed thePRV & HP Valves Close) (If Not Air is sent to thePC)

The(Air) is sent to thePre-Cooler (Then)

Note: The(Air) is (Cooled) to 200 deg C / 392 deg F (Via)

By-Pass (Fan Air) blowing across thePreCooler (and is controlled by)

TheFan Air Valve(FAV) and FAV (Control T-Stat) (Which)

Controls the(ops) of theFAV by telling it to (Open)

When the(temp) (D/S) of thePreCooler is Above(200 deg C / 392 degF)

Note: TheFAV is Spring Loaded (Closed)

The(Cooled Air) is sent to theCross Bleed Valve(To BeUsed for A/C Sys)

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 53 -

Cont Temp Snsr Sends Temp Info (fromthePreCooler) outlet duct to (BMCs) (for mont)

and then theBMCssend theTemp info to the(SDACs) for ECAM Ind.

-----------------------------------------------------------------------------------------------------------

Fan Air Cont ( Temp Ctl T-Stat) (TCT) Connected to theFAV. It commands the

FAV to (OPEN) if the(Temp) D/S of thePre-Cooler exceeds 200 deg C.

(Located in pylon- aft of theprecool) (Next to theBleed Press Cont Sol)

-----------------------------------------------------------------------------------------------------------

Transferred PressureTransducer HP VALVE FAULT (Warn)

7 HA1 - 7HA2 AIR ENG ABNPRESSURE (Warn)

Note: Will not affect (Bleed PressureIndication)

Measures Transfer Pressure(between the(PRV) and (HP) Valves

SenseLine(connects) to theDuct downstreamof the(HP Valve)

Info is sent to theBMCs and then is sent to theCFDIU and SDACs (Ecam)

Messageis Gen (IF) thetransferred press is less than (23 PSI) for more

Than 15 Seconds and the(HP) Valveis closed

------------------------------------------------------------------------------------------------------------

Regulated PressureTransducer AIR ENGBLEED (Fault)

8HA1 8HA2 AIR ENG ABNORMAL PRESSURE (Warn)

WING ANTI- ICE INOP (Status Message)

Used for PressureIndication to the(ECAM)

SenseLine(connects) to theDuct downstreamof the(PRV)

Air Eng Bleed is activated (When) TheRegPress is higher than 57 PSI

For morethan 15 seconds. And the(PRV) is (Not) Closed.

Air Eng Abnormal Press is activated (When) The(Reg Press) is Lower

Than 23 PSI (AND) the(Transferred Press) is (Between) (12 to 38 PSI)

Wing Anti IceInop - is activated when (Act by the(ZoneCont) viaInfo

(Rec) fromtheBMCs.

When the(Reg Pres) is out of (Norm) Rangewhich is (12 to 60 PSI)

----------------------------------------------------------------------------------------------------------

Bleed Press Ctl Sol: Limits (Press & Temp) D/S thePreCooler. It Conts the(PRV)

Monitored by theBMC and Controlled by theEEC

When Tp Reaches (d/s of thePRV) 235 deg C (PRV) closes slightly (Lowers Press)

When Tp Reaches (d/s of thePRV) 245 deg C Bleed Pres is Limto 17.5 PSI

------------------------------------------------------------------------------------------------------------

When any of thefollowing occur: the(PRV) Automatically Closes

O/T (D/S of thePre-Cooler) @ 257 +- 3 deg C (60 sec delay)

O/P (Downstreamof thePRV 57 +_ 3 PSI (15 sec delay)

O/H in theBleed Ducting of thePylon, Wing, Fuselage

APU Bleed Valve(Not Closed) or Start Valve(Not Closed)

EngineBleed (p/b Switch) & EngineFire(p/b switch) (selected out)

Thermal Fuse(In ValveBody) Closes Valve@ 450 +- 25 deg C

------------------------------------------------------------------------------------------------------------

Bleed Press Ind: Norm=35 PSI / Amb =Lwr than 4 & Over 57 PSI

------------------------------------------------------------------------------------------------------------

Bleed Temp Ind: (O/H) 290 deg C morethan (5 seconds) or

270 deg C morethan (15 seconds) or 257 deg C morethan (55 seconds)

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 54 -

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 55 -

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 56 -

38) Water Waste

Liquid Level (SENSOR) Mounted on top of theWasteTank Sends signal to the

VacuumSystemController (When theWasteTank is (FULL)

Liquid Level (TRANSMITTER) Mounted on theBottomof theWasteTank

Sends Signal to theVSC (WEIGHT of theWASTE) In theWasteTank.

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 57 -

Note: Sys Inop (Indication) ontheFAP Check theVac Gen relay , Vac Gen

Or (Lav Door Switch)

49) APU

(Garrett GTCP 36300)

1. Normal Start Sequenceof Events

A. Master P/B Switch (ON)

B. Main Relay (Energized) ------- (107VU Panel) (relay panel abovebattery)

C. ECB starts Power Up (Test)

D. APU Fuel Pump (Energized)

E. APU (Inlet Door) (Opens)

2. Start P/B Switch (ON)

A. (ON) Light in theP/B Switch comes (ON)

B. The(ECB) (Energizes) the(Back Up Start Contactor 10KA) -- (Behind 120VU)

C. After (1.5 seconds) the(Start Contactor) is (Energized) 5KA -- (Behind 120VU)

!!!!!!!!

(If theseconditions aremet) (LineC only)

1. TheAir Intakeis: (OPEN) --------------------- (Flap Open Indication)

2. The(ECB) Power Up Test is: (Complete)

3. The(N) Speed is (Less than 7%)

4. (AN) Automatic Shutdown is: (Not Detected) (ViatheECB)

5. (A) Commanded S/D is: (Not Detected) (ViatheMaster Switch to Off)

6. The(Data) Exc bwn theDDM and ECB is: (Comp) (Approx 15 Seconds)

3. Both (Cntrs) EnergizetheStarter (Turns) & (Clutch Engages) & (APU Spools)

4. Both (Contactors) Energizethe(Igniter)

5. The(De-Oil Valve)-(Opens)-(IF) A. Oil Temp (Below 20 deg F / 6.6 Deg C)

B. Fuel Temp (Below 10 deg F / (-12 deg C)

C. Altitude(Above) 20,000 Feet

6. TheAPU (Operational) Data(Shown on theECAM)

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 58 -

7. At 7% (N) Speed the(ECB)

A. Opens the(Fuel Solenoid Valve) (In theFCU)

B. Controls the(Fuel Flow) to theAPU with (start acceleration control logic)

C. TheIGVs - (Close) to (0 Degrees)

8. At 50% (N) Speed the(ECB) (if above20,000 feet altitude58%)

A. (De-Energizes) the(Start Contactor) 5KA

B. Starter (Dis-Engages)

C. APU (Accelerates) ------------- (N) Speed and EGT Rise

D. TheIGVs (Open) to the(Fully Closed position of 15 degrees) (50% to 95%)

D. (De-Energies) the(Back-Up Start Contactor) 10KA ---- (after 5 seconds)

9. At 60% (N) Speed the(ECB)

A. (De-Energizes) the(Ignition Unit)

B. (De-Energizes) the(De-Oil Solenoid) ------- (If Open)

C. IGVs still @ 15 Degrees (Fully Closed Position)

10. At 95% (N) Speed the(ECB)

A. Controls and Monitors theAPU (Automatically)

B. TheIGVs (Open) to 22 Degrees

C. The(Green) AvailableLight in the(Start P/B) (Comes ON)

D. The(Blue) (ON) light in the(Start P/B) (Goes OFF)

11. APU (Bleed & Generator) areready for operation

A. APU Bleed and Generator (ON)

12. When you shutdown theAPU, theECB reacts as if it werean Auto Shutdown

13. Operating Notes:

A. Max EGT =635 C / 1175 deg F

B. Fuel Inlet Pressure=Min 5 PSI - Max 55 PSI

C. Fuel Inlet Temperature=(- 40 deg C to 57 deg C) or (-40 deg F to 135 deg F)

D. Oil Tank =1.65 Gallons

E. IGV Actuator =(nonoperating) Closed

F. SurgeControl Valve=(non operating) Open

G. Bleed Load Valve=(Normal) - Closed

Note: (N) =Nominal Speed

Note: (DDM) =DataMemory Module

Note: Whilethe(RAT) is being extended APU Starting is (Inhibited) by the

Battery Charging Limiters (BCLs)

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 59 -

Which prevents the(Start Contactor) frombeing energized (for 45 seconds)

P2 Sensor R/H sideinlet duct Provides Input signal to theECB , to Modify theschedules

of theSurgeValveand FCU

------------------------------------------------------------------------------------------------------------

Load Comp I/L Temp Snsr Located Below theIGV Actuator Input Signal to the

ECB , which isused in thereverseflow protection logic.

------------------------------------------------------------------------------------------------------------

Inlet GuideVanes: Cont by theECB Which Drives theAct--Cont Bleed Air Flow

a. Uses Fuel Pressureto (Drivethemopen and closed)

b. Remain (Closed) when APU is (Below 50%) - (Ign on between 7% and 50%)

c. 10 Degrees (Open) (Between 50% and 75%) (N) - (starter disengages @ 50%)

d. Minimum(Open Position) for theAPU to Start =22 Degrees

e. Maximum(Open Position) WhiletheAPU is Running =88 Degrees open

f. After APU is Started =88 Degrees (Open)

g. WhiletheAPU is Running (They Open & Close) (Depending on Load)

h. Generator Load =Close - (To Givepriority to Electric Power)

i. DriveLoad =Open - (To Givepriority to Pneumatic Air)

------------------------------------------------------------------------------------------------------------

Load Bleed Valve Allows Bleed Air to theA/C Systems Cont by theAPU Bleed

p/b Switch. (Note: When theCross Bleed Valveis in Auto) it will also moveto thepositionof

theLoad Bleed Valve.

------------------------------------------------------------------------------------------------------------

SurgeControl Valve Dumps excess bleed air (that is not needed fromtheAPU)

Into theExh Air Located in the(T-Duct) R/H sideof theAPU (Ctld by theECB)

------------------------------------------------------------------------------------------------------------

Engines

EngineSensors and Switches

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 60 -

a. N1 Provides N1 rotation speed ind to ECAM--- (2 Oclock) (R/H Fan)

b. N2 Provides N2 rotation speed ind to ECAM--- (dedicated alternator)

c. NacelleTemperatureSensor NacelleTemp (6Oclock) (Core)

d. Eng Bleed Pressure (Ref: Engines)

e. Fuel Temp Sensor - fuel temp in theFCOC---(FCOC outlet)

f. Fuel Press Diff Sw fuel press at FCOC O/L---( scav filt 8 clock)

g. Fuel Flow Trans provides fuel flow ind---(under theFMU) 7 -clock

h. p2/t2 Sensor - measures I/L press / temp---(Nosecowl) (12 Oclock)

i. p5 sensor measures ex press---(Exhaust Struts)

j. p3/t3 measures press / temp at HP (sends datato EEC)-(HP Comp (outlet)

k. p5 (4.9) measures exh press (located on exh struts)

l. p2.5 sensor & t2.5 provides air pressurefromtheL/P comp exit to AIDS

m. p12.5 sensor provides air pressurefromfan exit to AIDS

Note: p2 & p5 Used to CalculateEPR

EEC Provides Automatic Enginestarting

Powered by a(ded alt) when N2 is 10% or Higher / A/C Power if (not)

Has (2) Channels (1) activeand (1) stand-by (swaps @ eng shutdown)

Receives (info) datafromtheEIU for enginemanagement

Sends Primary engine(data) to theECAM (Via) theEEC

1. EPR

2. N1 (viatheN1 sensor) (2 Oclock R Fan)

3. N2 (viathededicated alt) -

4. EGT

5. Fuel Flow (viathefuel flow meter)

Sends Secondary engine(data) to theECAM (via) theEIU

1. Fuel Used

2. Oil Temperature

3. Oil Qty (viatheOil Level Trans) (oil tank) (7 Oclock L Fan)

4. Oil Pressure(viatheoil pressuretransmitter (9 Oclock L Fan)

Note: Oil Press Sw provides warn on ECAM press below 60 PSI

5. NacelleTemp (viatheNacelleTemp sensor) - (6 Oclock Core)

6. Vibration Monitoring

Channel (A) is Fwd and Channel (B) is Aft.

Connections are:

1. Pamb Ambient Air pressure(fromfan casesensor)

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 61 -

2. Pb Burner pressure

3. P2 Fan Inlet pressure(fromtheP2 / T2 Sensor) (10 Oclock Inlet)

4. P 2.5 Booster Stageoutlet pressure

5. P 12.5 Fan Outlet pressure

6. P 25 / 4.9 LP Turbineexhaust (fromthepressurerakes)

Electrical Connections (J -1to J -11)

------------------------------------------------------------------------------------------------------------

VariableStator VaneActuator (VSVA) located 4 Oclock position L/H Fan

a. Directs theAirflow into theH/P comp to prevent bladestall and enginesurge.

b. Drives thevariablestator vanes(via) fuel pressure

c. Controlled (via) theEEC fromthefeedback signals fromtheVSV act position

----------------------------------------------------------------------------------------------------------

Booster Stg Bleed Valve(BSBV) (2.5) (mstr L/H / SlaveR/H) (3 and 9 Oclock)

a. Permits booster compressor (airflow) dischargeinto the(Fan) air stream

b. Ensures that the(Booster Compressor) outlet matches the(HP Compressor)

Requirements @ (Low EngineSpeeds and Deceleration)

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 62 -

Flight Deck (switches)

A. FADEC Grd Power Provides power to theEEC for (on-ground) tests

B. Thrust Bump (on fwd end of thrust levers)

1. used to obtain (additional) thrust @ take-off (10% Thrust Boost)

2. used for TOGA (engages on grd when eng running & p/b is pressed.

Disengages when thep/b is pressed or eng is shut down.

C. N1 Mode(p/b switch) man selects N1 modein caseof (loss of EPR ind)

D. Modeselect switch Moving themodeselect switch to Ing/start whiletheEng

Is running , Puts theIgniters into (Continuous Ignition)

------------------------------------------------------------------------------------------------------------

Solenoid Valves: located 3 Oclock R/H Fan (6 ea) control respectiveBleed Valve)

a. pneumatic system/ HP ValveClosureSolenoid

b. Stage7 Bleed Solenoid Valve(A)

c. Stage7 Bleed Solenoid Valve(B)

d. Stage7 Bleed Solenoid Valve(C)

e. Stage10 Bleed Solenoid Valve

f. 10

th

Stage Make-Up Air Solenoid Valve

------------------------------------------------------------------------------------------------------------

Bleed Valves:

a. Stage7 Bleed Valve (1 Oclock) (R/H core)

b. Stage10 Bleed Valve (2 Oclock) (R/H core)

c. Stage7b Bleed Valve (3 Oclock) (R/H core)

d. Stage7a& 7c Bleed Valve (7 Oclock) (L/H core)

e. 10

th

StageMake-Up Air Valve (12 Oclock)

Note: 7

th

stagebleed valve bleeds off 5% of compressor airflow

10

th

stagebleed valve bleeds off 9.7% of compressor airflow

------------------------------------------------------------------------------------------------------------

LPT and HPT ActiveClearanceControl Actuator (4 Oclock) (R/H core)

a. Ensures BladeTip clearanceof the(TurbineBlades)

------------------------------------------------------------------------------------------------------------

ACOC Uses12

th

stagebleed air to cool theoil (Bleed Air is vented overboard)

------------------------------------------------------------------------------------------------------------

PressureRaising & Shut Off Valve Part of theFMU

a. Isolates theFuel Supply to theFuel Nozzles (during enginestart)

b. Opens when theFuel Pressureis (High Enough) for FMU Control

-----------------------------------------------------------------------------------------------------------

EngineVib Monitoring Unit (EVMU) Monitors Eng Vibration Levels (N1 & N2)

Note: 1 Unit =(.3 inch per second) ---Normal =1.0 to 3.0

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 63 -

LP/HP Fuel Pmp - The(LP /Inlet) sideof thepump rec theFuel fromtheA/C

TheFuel Enters LP sidethen (thefuel) is routed to theFCOC

And (some) fuel is tapped to the(IDG FCOC)

The(main) fuel is routed to theFCOC

----------------------------------------------------------------------------------------------------------IDG -

FCOC Fuel is (tapped) and sent to the(IDG FCOC) (to cool IDG oil)

This tapped fuel is (sent) through theEEC and then Routed to

The(Fuel Diverter / Return Valve) and then returned to theAircraft Fuel Tank.

----------------------------------------------------------------------------------------------------------Fuel

Diverter / Return Valve Installed on theFCOC--Controls theReturn (Fuel) Flow back to the

A/C tanks. (Thus cooling thefuel)

Controlled (via) theEEC (depending on EngDemands) For Oil / Fuel temperature

------------------------------------------------------------------------------------------------------------

Fuel Cooled Oil Cooler (FCOC) Located 9 Oclock position L/H

Usesfuel to (cool engineoil)

Has a(Drain Plug) to allow for (draining theFuel)

Fuel Filter & Fuel Filter (by-pass) valve(inside) theFCOC

------------------------------------------------------------------------------------------------------------

Fuel Filter Located in theFCOC

------------------------------------------------------------------------------------------------------------

Fuel Filter (by-pass) Valve Allows for fuel to (by-pass) thefilter if it is clogged

------------------------------------------------------------------------------------------------------------

LP/HP Fuel Pump Fuel is (routed) to theHP (inlet) sideof thepump and then routed To the

FMU.

Fuel Met Unit (FMU) 1. Controls theFuel Flow (via) inputs fromtheEEC

2. Protects against Over Speed

3. Controls theShut Off Valve

4. (Fuel is tapped) to: Supply (HP) (MuscleFuel) to Actuator

a. Stator VaneAct -- b. ActiveClearanceControl Valve(ACC) (HP turbine)

c. ActiveClearanceControl Valve(ACC) (LP turbine)

d. ACOC (air modulating valve)

e. Booster StageBleed ValveActuator (Master)

f. Booster stageBleed ValveActuator (Slave)

Note: All of theActuators arecontrolled (via) theEEC (except)

TheBVA (slave) (theslaveis controlled (via) themaster

Note: This tapped fuel is sent throughtheEEC and routed

To theFuel Diverter / Return Valveand returned To theA/C Fuel Tank

------------------------------------------------------------------------------------------------------------

The(main) Fuel is then routed to theFuel Flow Meter

Note: Excess (fuel pressure) is released (via) the(By-Pass) LinefromtheFMU

And routed through theEEC and then to theFuel Diverter / Return Valve

------------------------------------------------------------------------------------------------------------

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 64 -

Fuel Flow Meter Located L/H Fan (7 Oclock) Position (under theFMU)

Installed in the(fuel line) (between theFMU and Dist Valve)

Provides Fuel Flow (Indication) to theECAM

(Fuel pressdrives an imp (which spins and gives theindication)

Thefuel is then routed to theDistribution Valve

------------------------------------------------------------------------------------------------------------

Distrib Vlv- Lct R/H Fan 4 Oclock Position (Btn theFuel FM and Fuel manifolds)

Distributes an equal amount of fuel to (10) Fuel manifolds / 2 nozzles ea

Allows for (2) Fuel manifolds to (store) somefuel @ engineshutdown

To help supply thefuel @ next enginestart.

Thefuel is then routed to theFuel manifolds

------------------------------------------------------------------------------------------------------------

Fuel Manifolds A total of 10 manifolds (each manifold supplies 2 fuel nozzles)

------------------------------------------------------------------------------------------------------------

Fuel Nozzles A total of 20 fuel nozzles areinstalled Thefuel (mixes) with theair and then

it is Sent to theCombustion Chamber

------------------------------------------------------------------------------------------------------------

Note: For EngineStarting Problems: UseAids Report #10 in (Manual Reports)

Run Problems: UseAids Report #11 in Manual Reports

Engine Overview

VSV Actuator: Varies the

angleof theI/L GuideVanes and Stator Vanes to match theLP

Comp stageto theHP Comp stage. This changes theangleof theairflow

Across thecomp blades. TheVSV angledetermines thecompression needed

For all stages of enginepower. Controlled by the(EEC) and (via) fuel

Pressurefromthe(FMU)

------------------------------------------------------------------------------------------------------------

Booster StageBleed Valve: at low

(LP) compressor speeds thebooster provides moreair than theHP Comp can utilize. The

(BSBV) opens and bleeds off excess air to maketheenginemorestable. Theair is bleed off

into thefan dischargeair stream. At higher (compressor) speeds the(BSBV) closes to allow all

booster discharge(primary) air enters theHP Compressor.

Thereare(2) valves (master and slave) connected together (fuel press) and are

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 65 -

Synchronized to movetogether. The(master) valveis (controlled) viatheEEC. Thevalves

closeduringT/O and cruise. The(slave) valvemoves in relation to the(master) valve, to assist

in themovement of theRing

------------------------------------------------------------------------------------------------------------

TheHP Comp Bleed Valves: redirects a

portion of theBleed Air to theFan Air Stream. For Enginestability. Mounted on theoutsideof

thecase.When the(piston) valveopens it vents theair fromthecompressor. The7

th

stagehas

(3) Bleed valves and the10

th

stagehas (1).

They areused during enginestarting and transient conditions.

TheBleed Valves areconnected (via) atubeto theBleed ValveSolenoid

----Controlled by theBleed ValveSolenoid Valve(Via) theEEC

----Spring Loaded Open and held open by compressor (p3) bleed air

----When the(p3) air is (vented) by the(Solenoid Valve) theValveCloses

And stops the(Bleed Air) frombeing released into theFan Air Stream

------------------------------------------------------------------------------------------------------------

Bleed Valve(Solenoid Valve): each bleed

valvehas its own (sol Valve). It is connected to thebleed valveby atube, which transmits (p3)

pressureto or fromthebleed valve. Controlled by the(EEC)

---When the(Solenoid) is energized the(serviceport) is connected to the(Vent)

This (venting) keeps thevalveclosed.

---When the(Solenoid) is (de-energized) the(serviceport) is connected to

Theenginesupplied air (via) thetube(thus holding thevalve) open

Oil Temp Indication:---Sensor located at thescavengefilter.

---Hi-Oil-warn ind @ 155 deg C for 15 minutes

---Lo-Oil warn ind @ -10 deg C (when eng is running aboveidlespeed)

---Ind flashes Green @ 156 deg C and turns amber @ 165 degC

Oil PressureIndication:----Sensor located L/H fan case

---Low Oil pressurewarn @ 60 PSI

---Ind flashes RED

---Automatically (resets) when pressureis above60 PSI

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 66 -

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 67 -

Auto Start:

1. ModeSelector (to Ign/start) (EEC powers up)

2. Master Switch (to ON) (Imed Pressureand Start Valve) (opens)

3. N2 Increases:

a. At 16% - (Ign turned ON) (either A or B)

b. At 18% - (Fuel Flow)

c. At 43% - (Start ValveCloses) & (Ign is turned OFF)

d. Engines are(now @ Idle)

4. ModeSelector (To Normal) after both engines arerunning.

Note: Auto Start is Aborted @ 50 % N2 in caseof failure.

2. Manual Start:

1. ModeSelector (to Ign/Start) (EEC powers up)

2. Eng Manual p/b Switch (ON) (start valveopens)

3. N2 Increases:

a. At 18% - (Master Switch to ON) (Both A & B Ignition & Fuel Flow)

b. At 43% (Start Valvecloses and Ign is turned off)

4. Engines arenow @ Idle

5. Manual P/B Switch (To Off)

3. Dry Crank: (Ignition Not Available)

a. ModeSelect (to Crank) (availableon ground, only) (EEC Powered)

b. Manual Start p/b switch (ON) - (start valveopens)

c. Master Switch (ON)

4. Wet Crank:

a. ModeSelect (to Crank) (EEC Powered)

b. Manual Start p/b switch (ON) (start valveopens)

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 68 -

c. At 20% N2 (Master Switch) (ON)

d. When Finished (Cranking) Master switch (OFF)

e. Continuecranking for (30 seconds)

f. Manual Start p/b switch (Off)

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 69 -

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 70 -

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 71 -

FOR TRAI NI NG PURPOSE ONLY

w w w .amevoi c e.c om

- 72 -

You might also like

- A320 Handling of Different Class Fault MessagesDocument3 pagesA320 Handling of Different Class Fault MessagesKamran Khan Tareen100% (1)

- Airbus 319, A320, A321 FcomDocument2,451 pagesAirbus 319, A320, A321 Fcomberten69100% (3)

- Airbus A320 Fault Verification GuideDocument76 pagesAirbus A320 Fault Verification Guideprsnjt11100% (1)

- Airbus A320 Family CB List and ResetsDocument30 pagesAirbus A320 Family CB List and Resetsaeozbay94% (17)

- A320 Sharklets PDFDocument19 pagesA320 Sharklets PDFjunebug172100% (1)

- Day 1 - Complete Tech Quiz Questions - Finalised and PrintedDocument16 pagesDay 1 - Complete Tech Quiz Questions - Finalised and PrintedShabbir Bhojani89% (18)

- United A319-A320 Circuit Breaker Panels GuideDocument52 pagesUnited A319-A320 Circuit Breaker Panels GuideBELISARIO83% (6)

- A320 B1 B2 Refresher Course Notes PDFDocument2,248 pagesA320 B1 B2 Refresher Course Notes PDFcheemeng7980% (10)

- ATA 27 EFCS Troubleshooting TipspdfDocument57 pagesATA 27 EFCS Troubleshooting TipspdfMiguelSabino100% (5)

- 5 Aids ReportsDocument4 pages5 Aids ReportsRiccardo Mazzaia100% (1)

- Portuguese Fighter Colours 1919-1956Document234 pagesPortuguese Fighter Colours 1919-1956Peter Bochnička100% (2)

- How To Use TSMDocument26 pagesHow To Use TSMAhmed ElFekyNo ratings yet

- Ata 21 Airbus A320/321 TrainingDocument16 pagesAta 21 Airbus A320/321 Trainingvnhuy200350% (4)

- Airbus A320 No GoDocument5 pagesAirbus A320 No Govinay60% (5)

- Fault Verification GuideDocument45 pagesFault Verification GuideTURBOJATONo ratings yet

- A320 Fault Reset PDFDocument156 pagesA320 Fault Reset PDFariefNo ratings yet

- Classes of FaultDocument3 pagesClasses of FaultSara RazaNo ratings yet

- A340 A330 ElectricalDocument2 pagesA340 A330 Electricalpontoo75% (4)

- A320 QuestionsDocument66 pagesA320 QuestionspravinNo ratings yet

- A320 Family Centralised Fault Display SystemTroubleshooting GuidelinesDocument46 pagesA320 Family Centralised Fault Display SystemTroubleshooting GuidelinesKamran Khan Tareen67% (3)

- DGCA AIRBUS A320 QUESTION BANK - Doc Dosyasının KopyasıDocument107 pagesDGCA AIRBUS A320 QUESTION BANK - Doc Dosyasının Kopyasıskytech6650% (2)

- Ecam WarningDocument28 pagesEcam WarningBluto A Cuong100% (1)

- Airbus 320 General FamiliarizationDocument20 pagesAirbus 320 General FamiliarizationYeu Yang Leong50% (2)

- POH (Pilot Hand Books) Warrior IIIDocument354 pagesPOH (Pilot Hand Books) Warrior IIIdinna wikantariNo ratings yet

- 81 Government & Affiliate Documents That Admit Flat EarthDocument15 pages81 Government & Affiliate Documents That Admit Flat EarthCorey Aldridge75% (4)

- TM 55-1520-228-10 Oper ManualDocument292 pagesTM 55-1520-228-10 Oper Manualr etsenc0% (1)

- Usntps FTM 108Document845 pagesUsntps FTM 108MClarkNo ratings yet

- Bunrindo - Famous Airplanes of The World 33 - Nakajima Aichi D3A 'Val' Navy Type 99 Carrier Dive-BomberDocument94 pagesBunrindo - Famous Airplanes of The World 33 - Nakajima Aichi D3A 'Val' Navy Type 99 Carrier Dive-BomberJohannes73% (11)

- A330 Computer ResetDocument40 pagesA330 Computer Resetlinchienchung78% (9)

- Reset TipsDocument66 pagesReset TipsJoe Ho100% (3)

- CB RESET A320 and ProcedureDocument74 pagesCB RESET A320 and ProcedureHasry RitongaNo ratings yet

- Tips A320 ResetDocument82 pagesTips A320 Resetgarry pangkey100% (1)

- Alpha Call ListDocument8 pagesAlpha Call ListRaby AbidiNo ratings yet

- Reset BreakersDocument44 pagesReset BreakersX67% (6)

- A320 ResetsDocument253 pagesA320 ResetsEmin GulhanNo ratings yet

- Elac Sec Efcs Trouble Shooting Tips Booklet PDFDocument57 pagesElac Sec Efcs Trouble Shooting Tips Booklet PDFGenaro Rodriguez100% (1)

- CFDS Trouble ShootingDocument131 pagesCFDS Trouble Shootingmohnishvarma100% (1)

- Hydraulic A330/A340Document8 pagesHydraulic A330/A340Bawian100% (1)

- A320 FMGS Codes BragaDocument25 pagesA320 FMGS Codes BragaMarcos Braga92% (13)

- Vragen VACBI A330-200 ATA 21Document7 pagesVragen VACBI A330-200 ATA 21Arkadiy Chernov100% (1)

- AIRBUS A320 - Fault Verification Guide PDFDocument78 pagesAIRBUS A320 - Fault Verification Guide PDFHarish PatelNo ratings yet

- A320 ResetDocument82 pagesA320 ResetRenante Marcelo100% (20)

- A320 Computer ResetDocument19 pagesA320 Computer ResetIndika WidyaratneNo ratings yet

- A333 Elec PDFDocument1 pageA333 Elec PDFStephanie JohnsonNo ratings yet

- A320 Aircraft General McqsDocument3 pagesA320 Aircraft General McqsZain HasanNo ratings yet

- A320 Computer Reset NOV11Document18 pagesA320 Computer Reset NOV11igorlazniuk100% (9)

- Figure 29-00-00-13400-00-U / SHEET 1/5 - Hydraulic Power - Schematic ON A/C 101-199, 201-300, 902-999Document1 pageFigure 29-00-00-13400-00-U / SHEET 1/5 - Hydraulic Power - Schematic ON A/C 101-199, 201-300, 902-999Pankaj SrivastavaNo ratings yet

- Study Questionnaire Ata 70-80 B1Document9 pagesStudy Questionnaire Ata 70-80 B1suriya100% (2)

- Brake and Steering TS GuideDocument2 pagesBrake and Steering TS Guideyazan999100% (2)

- Circuit BreakersDocument3 pagesCircuit BreakersSuratman Bin SuparmanNo ratings yet

- All Atas A320 Ecam Warnings ResetsDocument243 pagesAll Atas A320 Ecam Warnings ResetsLuis Gallegos100% (4)

- A320 L3 Rev 0 ATA 00 Introduction PDFDocument16 pagesA320 L3 Rev 0 ATA 00 Introduction PDFcamilo148100% (1)

- 320CBTDocument360 pages320CBTlovrennNo ratings yet

- Review B777 B1 Phase 9Document6 pagesReview B777 B1 Phase 9rizwan15No ratings yet

- A330 FuelDocument54 pagesA330 FuelTienek Lee100% (3)

- A320 CB PanelsDocument67 pagesA320 CB PanelsMiklós Meixner100% (4)

- 000 Index AbjadDocument4 pages000 Index AbjadYudi RaharjaNo ratings yet

- FADEC Ground TestDocument17 pagesFADEC Ground Testphuong leNo ratings yet

- Ecam ResetDocument36 pagesEcam ResetLeonard Komon100% (1)

- See You, JimmyDocument3 pagesSee You, Jimmyrondon9899No ratings yet

- Reset A320 ComputerDocument12 pagesReset A320 ComputerYong-Un KimNo ratings yet

- Untitled 15Document24 pagesUntitled 15HENIGUEDRINo ratings yet

- OFP FormatDocument1 pageOFP FormatReljaNo ratings yet

- 1615 PDFDocument1 page1615 PDFReljaNo ratings yet

- Lemdkmia PDF 1665604396Document2 pagesLemdkmia PDF 1665604396Daniel De AviaciónNo ratings yet

- Y8 988/27 JUL/SVO-DME: - Not For Real World NavigationDocument15 pagesY8 988/27 JUL/SVO-DME: - Not For Real World NavigationVjeslav BrzęczyszczykiewiczNo ratings yet

- TV TCL32X5Document69 pagesTV TCL32X5serrano.flia.coNo ratings yet

- Electrical Connections: Section F - TransmissionDocument1 pageElectrical Connections: Section F - TransmissionvasconyNo ratings yet

- Airbus A320 Family CB List and ResetsDocument30 pagesAirbus A320 Family CB List and ResetsZbor ZborNo ratings yet

- Fitness Tracker Fty18: User'S ManualDocument2 pagesFitness Tracker Fty18: User'S ManualMiklós MeixnerNo ratings yet

- FuelDocument94 pagesFuelHend GhanemNo ratings yet

- 737NG Genfam PresentationDocument48 pages737NG Genfam PresentationMiklós Meixner100% (1)

- A320 CB PanelsDocument67 pagesA320 CB PanelsMiklós Meixner100% (4)

- Harrier Schemes - SAMDocument4 pagesHarrier Schemes - SAMpennichangeNo ratings yet

- LFMD VPT BriefDocument3 pagesLFMD VPT BriefJoni RoweNo ratings yet

- King Air 350 Manual Chapter03Document6 pagesKing Air 350 Manual Chapter03Наме СурнамеNo ratings yet

- The Tail Consists of The Horizontal StabilizerDocument8 pagesThe Tail Consists of The Horizontal StabilizerDavid GaytonNo ratings yet

- AC Honeywell LightingDocument2 pagesAC Honeywell Lightinghanie.zomorodiNo ratings yet

- RC Model Aircraft WingsDocument24 pagesRC Model Aircraft WingsTarek El HalabiNo ratings yet

- ATR 72 - Wikipedia PDFDocument17 pagesATR 72 - Wikipedia PDFRanjan Kumar SahooNo ratings yet

- 2 Edition Playbook: (June 2017)Document21 pages2 Edition Playbook: (June 2017)Riccardo PittauNo ratings yet

- Part 4Document17 pagesPart 4sadjuharNo ratings yet

- Ebbr (Brussels National) - R (25dec15) PDFDocument103 pagesEbbr (Brussels National) - R (25dec15) PDFnabatmanNo ratings yet

- Sbbu - Rnav Gnss Z Rwy 32 - Iac - 20180524Document1 pageSbbu - Rnav Gnss Z Rwy 32 - Iac - 20180524Marinho ValdenioNo ratings yet

- (HorribleSubs) Tate No Yuusha No Nariagari - 24 (720p) .MKV - TorrentDocument149 pages(HorribleSubs) Tate No Yuusha No Nariagari - 24 (720p) .MKV - TorrentFrizkyNo ratings yet

- Estimation of Wing Loading and Thrust Loading - 4 TopicsDocument12 pagesEstimation of Wing Loading and Thrust Loading - 4 TopicsPRADYUMNA BHANDIWADNo ratings yet

- Embraer E175 BrochureDocument2 pagesEmbraer E175 BrochureGrowlerJoeNo ratings yet

- EASA Part-66 Exam Questions of Module 07 Standart Practices - Part VIIDocument29 pagesEASA Part-66 Exam Questions of Module 07 Standart Practices - Part VIISteven J. SelcukNo ratings yet

- Mod 10 MCQDocument51 pagesMod 10 MCQDanielNo ratings yet

- Helicopter Module 4 Midterm ReviewerDocument13 pagesHelicopter Module 4 Midterm ReviewerjohnclientebooklibraryNo ratings yet

- QRRG-6439 - Quick-Reference Reset GuideDocument44 pagesQRRG-6439 - Quick-Reference Reset GuideJuliano JulianoNo ratings yet

- Lufthansa Technical Training Open Courses Schedule As at February 2016Document8 pagesLufthansa Technical Training Open Courses Schedule As at February 2016Anonymous tSYkkHToBP100% (2)

- A380 - Lower Pavement Loading: Body Gear Nose Gear Wing GearDocument3 pagesA380 - Lower Pavement Loading: Body Gear Nose Gear Wing GearВячеслав ЧедрикNo ratings yet

- r44 1 Poh 9Document84 pagesr44 1 Poh 9Lew AshbyNo ratings yet

- M114700 Rev F1329945174Document40 pagesM114700 Rev F1329945174arkaaaaa100% (1)