Professional Documents

Culture Documents

Technical Data

Technical Data

Uploaded by

Rajkumar RE0 ratings0% found this document useful (0 votes)

21 views13 pagesUnit weight of Materials

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentUnit weight of Materials

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

21 views13 pagesTechnical Data

Technical Data

Uploaded by

Rajkumar REUnit weight of Materials

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 13

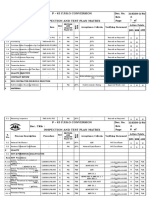

T E C H NIC A L DA T A S U S E F U L F O R

C IVIL E NG INE E RING WO RK S :

U NIT WE IG H T O F MA T E RIA L S :

Material U nit weight in kg/ m

C ement 1440

S teel 7850

Dry sand clean 1550-1600

Moist sand 1600-1750

Dry E arth(vegetable) 1750-2000

Moist E arth(vegetable) 1600

Wet E arth(vegetable) 1600-1750

Dry consolidated earth 1750-1920

G ravel (clean) 1600-2000

B ricks 1600-1920

Rubble stone 2100

T imber 720-750

Dry clay 1440

Damp plastic clay 1760

E arth loose and dry 1280

E arth packed 1550

S olid blocks A pprox 1400-1500

C oal ashes 640

A .C .sheets 17kg/ m

C oncrete 2306

B itumen 1040

L ime freshly burnt 960

L imestone crushed 1280-1440

L ime slaked 640

C ement mortar 2080

L ime mortar 1760

Plaster of Paris 800

Plastics 1100-1600

A PPRO X MA T E RIA L NE E DE D F O R 1C U M O F S IZE S T O NE

MA S O NRY WO RK WIT H DIF F E RE NT C E ME NT MO RT A R:

Proportion by

volume

Grade of

concrete

C ement in

cubic meter

S and in cubic

meter

C oarse

aggregate in

cubic meter

1:4:8 M 7.5 0.12 0.48 0.96

1:3:6 M 10 0.15 0. 45 0.90

1:2:4 M 15 0.22 0.44 0.88

1:1.5:3 M 20 0.28 0.42 0.84

1:1:2 M 25 0.38 0.38 0.76

Note: the volume of one cement bag is 0.0345 mor 1.25 cft.

A PPRO XIMA T E MA T E RIA L S RE Q U IRE D F O R 1 C U M O F

S IZE S T O NE MA S O NRY

C ement

mortar

S ize stone in

cum

C ement in cum S and in cum B oulders in

cum

1:4 1.25 0.08 0.32 0.17

1:6 1.25 0.06 0.36 0.17

1:8 1.25 0.04 0.32 0.17

Note: 40%of dry mortar is used for size stone masonry.

A PPRO XIMA T E MA T E RIA L S RE Q U IRE D F O R 1C U M O F 8

S O L ID WA L L B L O C K WO RK

C ement mortar C ement in cft S and in cft

1:6 0.25 1.50

1:5 0.29 1.45

1:4 0.35 1.40

1:3 0.40 1.20

1:2 0.55 1.10

A PPRO XIMA T E MA T E RIA L S RE Q U IRE D F O R 1 C U M O F 4

S O L ID WA L L B L O C K WO RK

C ement mortar C ement in cft S and in cft

1:6 0.33 2.00

1:5 0.36 1.80

1:4 0.45 1.8

1:3 0.55 1.65

1:2 0.75 1.50

A PPRO XIMA T E MA T E RIA L RE Q U IRE D FO R 1C U M O F

B RIC K WO RK WIT H C E ME NT MO RT A R O F DIF F E RE NT

PRO PO RT IO NS :

C ement mortar B ricks C ement in cum S and in cum

1:2 500 0.1 0.2

1:3 500 0.08 0.24

1:4 500 0.06 0.24

1:6 500 0.04 0.24

S ize of standard brick is taken as 200mm*100mm*100mmwith mortar joint less than

10mmthick and dry mortar is used.

A PPRO XIMA T E MA T E RIA L NE E DE F O R PL A S T E RING O F

100 S Q U A RE ME T RE A RE A U S ING DIF F E RE NT

PRO PO RT IO N O F C E ME NT MO RT A R:

C ement mortar C ement in cum S and in cum

1:2 0.6 1.2

1:3 0.45 1.135

1:4 0.4 1.6

1:5 0.35 1.75

1::6 0.3 1.8

T hickness of plastering is taken as 12mm.

A PPRO XIMA T E MA T E RIA L NE E DE D F O R PL A S T E RING O F

100S Q M A RE A U S ING DIF F E RE NT PRO PO RT IO N O F

C E ME NT MO RT A R T HIC K NE S S O F PL A S T E RING IS 20MM:

C ement mortar C ement in cum S and in cum

1:2 1 2

1:3 0.78 2.34

1:4 0.65 2.6

1.5 0.54 2.7

1:6

0.46 2.76

xWE IG H T O F S T E E L RO DS :

Diameter of rod Weight in kg/ m L ap length in mm

6mm 0.2218 300

8mm 0.3943 400

10mm 0.6162 500

12mm 0.8874 600

16mm 1.5771 800

20mm 2.4649 1000

25mm 3.8514 1250

32mm 6.3101 1800

T he length of one rod which is available is site is 36 feet or 11 meter.

C O NVE RS IO NS :

1cent=435.6 square feet

1acre=100 cent

1meter=3.281 feet

1square meter=10.76 square feet.

1cubic meter=35.31 cubic feet

1kg=9.81N

1kg/ cm=1Nmm

1kg=1litre

1cubic meter=1000 litres

1cubic feet=28.3 litres.

1acre=43560 square feet

1inch=2.54 cm

12 inch=1feet

1feet=30 cm.

1 gunter chain=66 feet.

1 gunta=1089 square feet.

L A B O U R O U T PU T :

Work L abours used O utput per day

E arthwork 100cft 2 M/ c

B ack filling 28.3 cubic meter 5 M/ c+0.5F / c

S huttering 7square meter 1carpenter and 2 helper.

S teel 170 kg 1fitter and 1 helper

C oncrete 120 cubic meter pumping 6 mason and 6 helper

B lock work 7 square meter 1mason and 2 helper

Plastering 10 square meter 1mason and 1.5 helper

Dadooing(wall tiling) 6 square meter 1mason and 1.5 helper

F loor tiling 8 square meter 1mason and 2 helper

G ranite dadooing 4 square meter 1mason , 1 helper,0.5

cutter and 0.5 polisher

G ranite flooring 8 square meter 1mason, 1 helper,0.5

cutter and 0.5 polisher.

Water proofing 7 square meter 1mason and 1 helper

Painting 10 square meter 1 painter and 1 helper

Window finish 1 no 1mason +1 helper

L aying reinforced

concrete

100 cubic feet 0.5 mason+6helpers+1.33

F / c

S ize stone masonry 2.83 cubic meter 3 masons ,5 helpers and

0.25 F / c

B rickwork 2.83 cubic meter 2.25 masons and 5 helpers

A PPRO XIMA T E MA T E RIA L RE Q U IRE D FO R WH IT E

WA S H ING , DIS T E MPE RING , A ND PA INT ING O F 100

S Q U A RE ME T E R A RE A :

a. L ime for white washing ( 1

coat)

10 kgs

b. Dry distemper 1

st

coat 6.5 kgs

c. Dry distemper 2

nd

coat 5.0 kgs

d. S now cemfor 1

st

coat 30.0 kgs

e. S now cemfor 2

nd

coat 20.0 kgs

f. Paint ready mixed for one

coat

10 litres

g. Paint stiff for one coat 10 kgs

B INDING WIRE C O NS U MPT IO N:

B inding wire used for tieing one tonnage

reinforcement

6 to 7 kgs

G E NE RA L PO INT S F O R C A L C U L A T IO NS O F

RE INFO RC E ME NT :

1. F or beamhook=(beamdepth-both side covers)/ 2

for example if it is a 450mmdepth beamthen hook is (450-50)/ 2=200

where cover for beamis taken as 25 mm

2. F or stirrups the hook=4d as per is codes but according to site conditions it is

50 mmper hook while doing bar bending schedule.

3. F or slab the rod the crank length is l/ 5.

4. F or beamthe bottomextra is at l/ 6.

5. F or slab the top extra extends till upto l/ 3.

6. F or beamthe top extra bar extends till l/ 3.

7. T he column capitals extends tilll/ 4.

8. Where l is effective length of the beam. It is taken as center to center of the

beam.

9. T he crank length is 1.41d, where d is (depth of slab or beam- two side covers)

C omponent C over in mm

S lab 15

B eam 25

C olumn 40

F ooting 50

Note: cover is given for the aggregates of concrete to pass through the reinforcement

and to prevent the reinforcement fromexposing to surface.

H O W T O FIND T HE WE IG HT O F T HE S T E E L :

d/ 162

d- diameter of the steel in mm

where as this formula gives the weight of steel in kg per running meter of that dia steel

how is it achieved:

(pi*d*d/ 4)*7850 will give the weight of steel of that dia in kg/ m

as pi=3.14

and d is in mm

but unit weight of steel is in kg/ m

the area of steel should be converted into m

for that the area of steel is divided by 1000000

now keeping d in the top and bringing 3.14*7850 to the bottomwe will get d/ 162 as

the formula.

WA T E R C E ME NT RA T IO :

Normally the water cement ratio is the ratio between water and cement, it is the water

content at which the concrete will give a good workability.

B U L K A GE O F S A ND :

It is the moisture content in the sand due to which the volume of the sand increases

than its original volume, so when it dries its volume will be reduced, so when sand is

mixed for mortar or concrete 16 to 20%extra is taken to get the original volume of the

sand.

T he permissible bulkage is 16 to 20%.

S E T IING T IME O F C E ME NT :

1. Initial setting time of cement is 30 minutes so any concrete or mortar should be

used before 30 minutes of stime.

2. F inal setting time of cement is 10 hours.

S T RU C T U RE S :

L oad bearing structures:

It is the structure in which the load is transferred directly fromslab to the wall and

fromwall to the foundation.

F ramed structure:

It is the structure in which the load is transferred fromslab to beams and from

beams to columns and fromcolumns to footings and fromfootings to the soil.

Difference between 43 grade cement and 53 grade cement:

43 grade attains a strength of 43n/ mm2 in 28 days

53 grade cement attains a strength of 53n/ mm2 in 28 days.

T he setting time of 43 grade cement is less.

T he setting time of 53 grade cement is high

43 grade cement is used for plastering and 53 grade cement is used for concreting

and marking.

A NG L E O F RE PO S E :

It is the slope above which that concerned material tends to fall.

Material A ngle of repose in degree

B ituminous coal

A nthracite coal 27

S laked coal 37.5 to 45

A shes 35

S oft iron ore 35

E arth(loam) 30 to 45

S and(dry) 30 to 35

S and (wet) 0 to 30

C lay 25 to 45

G ravel 30 to 45

C inders 25 to 40

C oke 30 to 45

Wheat 25

Maize 27 to 30

B arley 25

O ats 28

C ement 10

F O U NDA T IO N:

S hallow foundation and deep foundation:

S hallow foundation is the foundation in which the length of the footing is equal to the

depth of the foundation whereas in deep foundation depth is not equal to length.

L E VE L L ING :

L eveling is very important in the civil engineering practical field to know about a site.

H eight of the instrument=R.L +B ack sight

Where R.L - reduced level is taken as the road level( as 100)

If we want the level of a point first the dumpy level is set at some point and the R.L is

taken as the back sight and the staff measurement at the concerned point is taken it is

known as foresight or intermediate sight

L E VE L O F T H A T PO INT =R.L +B A C K S IG H T -F O RE S IGH T

B M- benchmark(a known r.l)

R.L -reduced level (normally 100)

B .S -backsight

F .S -foresight

PE RMIS S IB LE S T RE S S E S IN C O NC RE T E :

G rade of concrete Permissible Permissible

stresses in

concrete bending

stresses in

compression direct

M10 3.0 2.5

M 15 5.0 4.0

M 20 7.0 5.0

M 25 8.5 6.0

M 30 10.0 8.0

M 35 11.5 9.0

M 40 13.0 10.0

T A B L E O F PA INT ING C O E F F IC IE NT :

S l no Description of work Multiplying coefficient

1. Paneled or framed and

braced door, windows etc.

1.30(for each side)

2. L edged and battened or

ledged, battened and

braced, doors, windows etc

1.30(for each side )

3. F lush doors 1.2 (for each side)

4, Party paneled and party

glazed or gauged doors,

windows etc.

1.00(for each side)

5. F ully glazed or gauged

doors ,windows etc

0.80 (for each side)

6. F ully venetianed or

louvered doors windows

etc.

1.80 for each side.

7. T reills work one way or

two way

2 for painting allover

8. C arved or enriched work 2 for each side

9. Weather boarding 1.2 for each side

10. Wood single roofing 1.10 for each side

11. B oarding with cover fillets

and match boarding

1.05 for each side

12. Plain sheeted steel doors

and windows

1.10 for each side

13. F ully glazed or gauged

steel doors and windows

0.50 ( for each side)

14. Partly paneled and partly

glazed or steel gauged

doors and windows

0.80 for each side

15. C orrugated sheeted steel

doors or windows

1.50 for each side

16. C ollapsible gates 1.50 for painting allover

17. rolling shutters interlocked

lathes

1.10 for each side

WE IG HT O F MS PL A T E S :

T hickness in mm Weight in kg per

square meter

5 39.25

6 47.10

8 62.80

10 78.5

12 94.2

14 109.90

16 125.60

18 141.30

20 157.00

22 172.70

55 196.25

S Q U A RE B A RS :

0.7843 kg/ square meter

Diameter or width in mm S ectional area in square

cm.

Perimeter in cm

5 25 2.0

5.5 0.3 2.2

6.0 0.36 2.4

7.0 0.49 2.8

8.0 0.64 3.2

9.0 0.81 3.6

10 1.00 4.0

11 1.21 4.4

12 1.44 4.8

14 1.96 5.6

16 2.56 6.4

18 3.24 7.2

20 4.00 8.0

22 4.84 8.8

25 6.25 10.0

28 7.84 11.2

32 10.24 12.8

36 12.96 14.4

40 16.00 16.0

45 20.25 18.0

50 25.00 20.0

56 31.36 22.4

63 39.69 25.2

71 50.41 28.4

80 64.00 32.0

WE IG HT O F MIL D S T E E L F L A T S :

Width 3mm 4mm 5mm 6mm 8mm 10mm 12mm 16mm 18mm 20mm 25

in mm thick thick thick thick thick thick thick thick thick thick mm

thick

10 0.2 0.3 0.5

20 0.5 0.6 0.8 0.9 1.3 1.6

25 0.6 0.8 1.0 1.2 1.6 2.0 2.4

30 0.7 0.91 1.20 1.4 1.9 2.2 2.8 3.8

35 0.8 1.1 1.4 1.6 2.4 2.8 3.3 4.4 5.0 5.5

40 0.9 1.3 1.6 1.9 2.5 3.1 3.8 5.0 5.6 6.3

45 1.1 1.4 1.8 2.1 2.8 3.5 4.2 5.6 6.4 7.1

50 1.2 1.6 2.0 2.4 3.1 3.9 4.7 6.3 7.1 7.8 9.8

75 3.5 3.7 5.9 7.1 9.4 10..6 11.8 14.7

100 4.7 6.3 7.8 9.4 12.6 14.1 15.7 19.6

You might also like

- Mapei PDFDocument263 pagesMapei PDFsmkrishnan89No ratings yet

- Cost of DPWH 2022Document5 pagesCost of DPWH 2022Philip Dyaguit BaguhinNo ratings yet

- 50 Construction Thumb Rules Used by Civil EngineersDocument38 pages50 Construction Thumb Rules Used by Civil EngineersCHETAK SHINDENo ratings yet

- Print Rate AnalysisDocument124 pagesPrint Rate Analysisfelix sowah-laryeaNo ratings yet

- Mix DesignDocument6 pagesMix DesignschaktenNo ratings yet

- Ch-21 Sand CastingDocument156 pagesCh-21 Sand CastingDivya SoniNo ratings yet

- Material RequiredDocument2 pagesMaterial RequiredNikhil88% (8)

- Analysis of Rates: Unit 3Document46 pagesAnalysis of Rates: Unit 3abhishek bhure100% (1)

- Water ProofingDocument1 pageWater ProofingPratik SanasNo ratings yet

- Civil Coefficient Factor 1992Document3 pagesCivil Coefficient Factor 1992GirirajanNo ratings yet

- Thumb Rules in Civil EngineeringDocument6 pagesThumb Rules in Civil EngineeringAdil ImtiazNo ratings yet

- Civil TipsDocument5 pagesCivil Tipssanojev86% (7)

- Labour Output For Construction WorkDocument4 pagesLabour Output For Construction Workmailmaverick8167100% (2)

- Rate AnalysisDocument21 pagesRate AnalysisMugahed Abdo Al-gahdari100% (1)

- ITP For Piping WorksDocument44 pagesITP For Piping WorksSyafril Akbar100% (3)

- Rates For Diff ItemsDocument29 pagesRates For Diff ItemsMohanaNo ratings yet

- Joglekar Estimating and ValuationDocument133 pagesJoglekar Estimating and Valuationrafay100% (1)

- Standard Building Construction ProductivityDocument1 pageStandard Building Construction ProductivitySunil B S Rao100% (1)

- The Capacity of Doing Work by An Artisan or Skilled Labour in The Form of Quantity of Work Per Day Is Known As The Task Work or Out Turn of The LabourDocument6 pagesThe Capacity of Doing Work by An Artisan or Skilled Labour in The Form of Quantity of Work Per Day Is Known As The Task Work or Out Turn of The LabourAyaaz KhanNo ratings yet

- S.W. Gully TrapDocument16 pagesS.W. Gully TrapAnonymous 9b8vCz1W100% (1)

- Particulars of Items: Sno. Quantity PerdayDocument7 pagesParticulars of Items: Sno. Quantity Perdayakg20041100% (1)

- Cost Civil Works of Building Per Sq. FT Area / Build Up AreaDocument2 pagesCost Civil Works of Building Per Sq. FT Area / Build Up AreaHossen Ali MollahNo ratings yet

- Thumb Rules in Civil ConstructionDocument9 pagesThumb Rules in Civil ConstructionAnish Chandran100% (1)

- Thumb Rules For Civil EngineersDocument12 pagesThumb Rules For Civil EngineersAvdhesh ChandraNo ratings yet

- Thumb Rule To Calculate The Concrete Volume With Respect To AreaDocument4 pagesThumb Rule To Calculate The Concrete Volume With Respect To AreaGaurav ReddyNo ratings yet

- Cost Estimation DraftDocument3 pagesCost Estimation DraftYeontanNo ratings yet

- Useful Notes For Civil EngineerDocument8 pagesUseful Notes For Civil EngineerSathish KumarNo ratings yet

- Civil Thumb RulesDocument8 pagesCivil Thumb RulesNasreen khushi muhammad Nasree100% (1)

- Structural Rules of Thumb Line CardDocument2 pagesStructural Rules of Thumb Line Cardscegts100% (2)

- Cement Constant Latest - 2011Document7 pagesCement Constant Latest - 2011keshav1980100% (1)

- Civil Engineers GuideDocument46 pagesCivil Engineers GuideSrinivasan Reddy88% (17)

- Civil Mgineershould Inow The Following Details1Document25 pagesCivil Mgineershould Inow The Following Details1Srinivasan RanganathanNo ratings yet

- Date-070209 SR - No. Description Unit Rate A Rcc. WorkDocument6 pagesDate-070209 SR - No. Description Unit Rate A Rcc. WorkNiroshan Naguleswaran0% (1)

- Productivity Rate Interior Painting PDFDocument5 pagesProductivity Rate Interior Painting PDFRaphael ArchNo ratings yet

- Thumb RuleDocument6 pagesThumb RuleVivek ShuklaNo ratings yet

- Waterproofing RADocument4 pagesWaterproofing RAAnis MushrifNo ratings yet

- B S R - Buildings Dept - BatticaloaDocument263 pagesB S R - Buildings Dept - Batticaloaudithairesha100% (1)

- Rate AnalysisDocument8 pagesRate AnalysisGopal SudhirNo ratings yet

- Powder Coating Resins: Product Overview EuropeDocument7 pagesPowder Coating Resins: Product Overview EuropeAli Kesikoglu100% (1)

- Civil Engineering Project ReportDocument81 pagesCivil Engineering Project ReportAbi Nesh71% (31)

- Thump RuleDocument9 pagesThump RulefarhanyazdaniNo ratings yet

- Material ListDocument36 pagesMaterial ListSachin PawarNo ratings yet

- RATES For 2073-74: A. Approved Labour RateDocument40 pagesRATES For 2073-74: A. Approved Labour Rateक्षितिज चौलागाईंNo ratings yet

- Productivity CoefficientsDocument2 pagesProductivity CoefficientsApoorvaNo ratings yet

- Cement CoefficientsDocument2 pagesCement CoefficientsAmit Agarwal95% (57)

- Material ConsumptionDocument5 pagesMaterial ConsumptionMANIKANDAN Selvam100% (1)

- Rate Analysis - Finshing ItemsDocument52 pagesRate Analysis - Finshing ItemsRaghav Bhardwaj100% (1)

- Important Thumb Rules Used in Construction by Civil EngineersDocument5 pagesImportant Thumb Rules Used in Construction by Civil Engineersramesh_hinukaleNo ratings yet

- 1 Earth Works: Description Unit RateDocument4 pages1 Earth Works: Description Unit RateVenkatesha HebbarNo ratings yet

- Notes For Consumption For Varoius Civil Works: SL - NO. Unit Cement Consumption KG CUM BagsDocument3 pagesNotes For Consumption For Varoius Civil Works: SL - NO. Unit Cement Consumption KG CUM BagsSachidananda SahuNo ratings yet

- Labour Estimate For Various Items of WorksDocument3 pagesLabour Estimate For Various Items of WorksJalil TahirNo ratings yet

- Civil: Emerald Plaza-Detailed EstimateDocument5 pagesCivil: Emerald Plaza-Detailed EstimateVarun MattooNo ratings yet

- ConsumptionDocument3 pagesConsumptionmilindk35100% (1)

- Building Material Estimates and Rates Build Up: Second EditionFrom EverandBuilding Material Estimates and Rates Build Up: Second EditionNo ratings yet

- Animal Feed EFFORTDocument16 pagesAnimal Feed EFFORTHaftamu Tekle100% (1)

- Labour EstimateDocument1 pageLabour EstimateManasNo ratings yet

- Rate AnalyisDocument24 pagesRate Analyiskrishnashankar9_3743No ratings yet

- Mil H 8775 PDFDocument15 pagesMil H 8775 PDFNANTHA KUMARNo ratings yet

- 12 Important Points For Civil Site Engineers - Civil StudentsDocument40 pages12 Important Points For Civil Site Engineers - Civil Studentsvignesh kumar100% (1)

- Vimmr Se Fixing of Precast Concrete Columns To FoundationsDocument4 pagesVimmr Se Fixing of Precast Concrete Columns To FoundationsmagdyamdbNo ratings yet

- BbsDocument72 pagesBbsAkd DeshmukhNo ratings yet

- Rate Analysis BMDocument6 pagesRate Analysis BMparth088No ratings yet

- Permeability of Concrete - Tests On Concrete by RCPT, Salt PondingDocument11 pagesPermeability of Concrete - Tests On Concrete by RCPT, Salt Pondingsagar gillNo ratings yet

- Complete RatesDocument6 pagesComplete RatesManish Shashikant100% (1)

- Admixtures For ShotcreteDocument4 pagesAdmixtures For ShotcreteJesús Luis Arce GuillermoNo ratings yet

- Quantitynotes 180816020109 PDFDocument73 pagesQuantitynotes 180816020109 PDFOm Krish RamNo ratings yet

- 500 Bedded Child Health Care Institute, BRDMC GorakhpurDocument4 pages500 Bedded Child Health Care Institute, BRDMC GorakhpurAnkit SrivastavaNo ratings yet

- Cement Coefficiemts As Per DSR 2007 - PrintDocument41 pagesCement Coefficiemts As Per DSR 2007 - PrintVenkat Ch100% (7)

- F) 50 M3 Masonry RCC Sandwich Clean Water Reservoir: Earth WorkDocument4 pagesF) 50 M3 Masonry RCC Sandwich Clean Water Reservoir: Earth WorkEng GaaxeelNo ratings yet

- Chapter 11Document8 pagesChapter 11Krishna Rajesh KudapaNo ratings yet

- Cement SlabDocument11 pagesCement SlabAtoy Liby OjeñarNo ratings yet

- 50mc Ugt BoqDocument7 pages50mc Ugt BoqhaftamuTekle100% (1)

- Tamilnadu Based Private Sector BanksDocument15 pagesTamilnadu Based Private Sector BanksAbi NeshNo ratings yet

- Raja RajanDocument18 pagesRaja RajanAbi Nesh100% (1)

- GeopolymerconcreteDocument19 pagesGeopolymerconcreteAbi Nesh100% (1)

- Irrigation and Water Power Engineering by Dr. B. C. Punmia - Dr. Pande Brij Basi Lal - Ashok Kumar Jain - Arun Kumar JainDocument187 pagesIrrigation and Water Power Engineering by Dr. B. C. Punmia - Dr. Pande Brij Basi Lal - Ashok Kumar Jain - Arun Kumar JainSaritha Reddy85% (85)

- Primary BenefitsDocument1 pagePrimary BenefitsAbi NeshNo ratings yet

- (WWW - Entrance-Exam - Net) - PTU B. Tech Civil Engineering-5th Semester - Design of Steel Structures Sample Paper 1Document2 pages(WWW - Entrance-Exam - Net) - PTU B. Tech Civil Engineering-5th Semester - Design of Steel Structures Sample Paper 1Abi Nesh100% (1)

- Anna Univ Cbe Time TableDocument44 pagesAnna Univ Cbe Time TableKrishna KumarNo ratings yet

- Strength of MaterialsDocument4 pagesStrength of MaterialsAbi Nesh100% (1)

- Probes (On NFe Base) Compatible With FMP SeriesDocument1 pageProbes (On NFe Base) Compatible With FMP SeriesSambasiva ReddyNo ratings yet

- Specification - GL Wires - MESPL May 2021Document2 pagesSpecification - GL Wires - MESPL May 2021M. I. BhadiNo ratings yet

- Foundation Isolation ExDocument2 pagesFoundation Isolation ExKrishna KumarNo ratings yet

- Annex 1slab DesingDocument3 pagesAnnex 1slab DesingSurendra MaharjanNo ratings yet

- Assignment 1 - Design of Reinforced Concrete BeamsDocument1 pageAssignment 1 - Design of Reinforced Concrete BeamsThomas JeffersonNo ratings yet

- 05 Detailing Zinc and Sheet Metal CladdingDocument15 pages05 Detailing Zinc and Sheet Metal CladdingvaleriialukianNo ratings yet

- Ceramic Products REVISED PDFDocument16 pagesCeramic Products REVISED PDFcrimsonbunnieNo ratings yet

- ECF Series CatalogueDocument20 pagesECF Series CatalogueProcess Controls & ServicesNo ratings yet

- 8294 Statesman Door BrochureDocument6 pages8294 Statesman Door BrochureSitche ZisoNo ratings yet

- Proposed Residential at PazuriDocument7 pagesProposed Residential at PazuriMuhajir MashuaNo ratings yet

- Kayu KompositDocument41 pagesKayu KompositGalihNo ratings yet

- MMBC - Sem 7 B.archDocument8 pagesMMBC - Sem 7 B.archARTFOLIO .49No ratings yet

- Basf - Ape SystemDocument86 pagesBasf - Ape SystemdixmitNo ratings yet

- G.I TUBE Technical GuidesDocument3 pagesG.I TUBE Technical GuidesmariaNo ratings yet

- Aluminium Spice Rack - OutlineDocument13 pagesAluminium Spice Rack - OutlinedeepscubNo ratings yet

- Control MG Resid DuctileDocument4 pagesControl MG Resid Ductilejose.figueroa@foseco.comNo ratings yet

- Plastics Comparison Chart: Material Clarity MVTR O C0 Impact Strength Recycle CodeDocument2 pagesPlastics Comparison Chart: Material Clarity MVTR O C0 Impact Strength Recycle CodeCosmina RaduNo ratings yet

- Quality Control Measures in Asphalt Pavement Constructio BetongDocument125 pagesQuality Control Measures in Asphalt Pavement Constructio BetongMark James MateoNo ratings yet

- BrochureDocument8 pagesBrochureDOUDOU-38No ratings yet