Professional Documents

Culture Documents

Hall Design (Option 1)

Hall Design (Option 1)

Uploaded by

brotherkh26Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hall Design (Option 1)

Hall Design (Option 1)

Uploaded by

brotherkh26Copyright:

Available Formats

Department of Civil Engineering, N-W.F.

P UET, Peshawar Hall Design (Option 1)

Prof Dr. Qaisar Ali (http://www.eec.edu.pk)

Page 1 of 30

90'

60'

BRICK

MASONRY

WALL

Example 1(a): Design slab and beams of a 90 60 Hall. The height of Hall is 20.

Concrete compressive strength (f

c

) = 3 ksi.

Steel yield strength (f

y

) = 40 ksi.

Figure 1: 90 60 Hall.

Department of Civil Engineering, N-W.F.P UET, Peshawar Hall Design (Option 1)

Prof Dr. Qaisar Ali (http://www.eec.edu.pk)

Page 2 of 30

90'

60'

10' 10'

18" BRICK

MASONRY

WALL

BEAM

Solution: Assume structural configuration. Take time to reach to a reasonable

arrangement of beams, girders and columns. It depends on experience. Several

alternatives are possible.

First option for structural arrangement of the given Hall, figure 2:

Beams spaced at 10 c/c running along 60 side of Hall.

As height of Hall is 20, assume 18 thick brick masonry walls.

Figure 2: Structural Arrangement (90 60 Hall).

Discussion: Various structural configurations

Discussion: Beam as thickened slab portions

Department of Civil Engineering, N-W.F.P UET, Peshawar Hall Design (Option 1)

Prof Dr. Qaisar Ali (http://www.eec.edu.pk)

Page 3 of 30

10.75'

l = 10 - b /2= 9.25'

b = 18" (assumed)

n w

w

10'

l = 10 - 2*(b /2) = 8.5'

n w

Slab

Beam

(1) SLAB DESIGN:

Step No 1: Sizes.

Minimum thickness of continuous one way slab as given under ACI 9.5.2,

table 9.5 (a) is:

Table 2.1: ACI formulae for continuous one way slab thickness, ACI 9.5.2

Case Slab thickness (in)

End span (one end continuous) l/24

Interior span (both ends continuous) l/28

(i) l = Span length in inches.

(ii)For f

y

other than 60,000 psi, the values from above formulae shall be multiplied by

(0.4 + f

y

/100000).

Span length l of slab is defined in ACI 8.7

Span length (l):

According to ACI 8.7.1: Span length of members not built integrally with

support shall be considered as the clear span plus depth of the member, but

need not exceed distance between center of supports.

According to ACI 8.7.4: Span lengths for slabs built integrally with supports

can be taken equal to clear span, if clear span of slab is not more than 10.

ACI 8.7.1 applies to end span.

ACI 8.7.4 applies to other spans.

Assuming the thickness of slab equal to 6. Span length for end span of slab will

be equal to clear span plus depth of member (slab), but need not exceed center to

center distance between supports.

Figure 3: c/c & clear spans of slab.

Department of Civil Engineering, N-W.F.P UET, Peshawar Hall Design (Option 1)

Prof Dr. Qaisar Ali (http://www.eec.edu.pk)

Page 4 of 30

10'

Beam

Main

steel

reinforcement

Shrinkage reinforcement

Slab

6"

5"

Table 2.2: Span length of slab (figure 3)

Case c/c distance Clear span (l

n

)

l

n

+ depth of slab

(ACI 8.7.1)

Span

length(l)

End span (one end continuous) 10.75 9.25' 9.25 + 0.5 = 9.75' 9.75

Interior spans (both ends

continuous)

10 8.5' n/a 8.5

Table 2.3: Slab thickness calculation according to ACI 9.5.2.

Span Formula for thickness Thickness of slab (in)

End span (one end continuous) l/24 (0.4+f

y

/100000) (9.75/24)(0.4 +40000/100000) 12=3.9

Interior span (both ends continuous) l/28 (0.4+f

y

/100000) (8.5/28)(0.4 + 40000/100000)12=2.9

l = Span length in inches.

Therefore,

Slab thickness (h

f

) = 3.9 (Minimum requirement by ACI 9.5.2.1).

Though any depth of slab greater than 3.9 can be taken as per ACI minimum

requirement, we will use the same depth as assumed i.e. 6

Effective depth (d) = h

f

0.75 (3/8)/2 = 5 (for #3 main bars)

Figure 4: Effective depth of slab.

Step No 2: Loading.

Table 2.4: Dead Loads.

Material Thickness (in) (kcf)

Load = x thickness

(ksf)

Slab 6 0.15 (6/12) 0.15 = 0.075

Mud 3 0.12 (3/12) 0.12 = 0.03

Tile 2 0.12 (2/12) 0.12= 0.02

Department of Civil Engineering, N-W.F.P UET, Peshawar Hall Design (Option 1)

Prof Dr. Qaisar Ali (http://www.eec.edu.pk)

Page 5 of 30

0

1/11

1/12

1/12

1/16

1/12

19.92 in-k/ft

18.36 in-k/ft 15.48 in-k/ft

11.64 in-k/ft

15.48 in-k/ft

l = 9.25' l = 8.5'

n n

Service Dead Load (D.L) = 0.075 + 0.03 + 0.02 = 0.125 ksf

Service Live Load (L.L) = 40 psf or 0.04 ksf (for Hall)

Class Activity: Calculate live load per square foot on the class room floor

when it is fully occupied.

Service Load (w

s

) = D.L + L.L = 0.125 + 0.04 = 0.165 ksf

Factored Load (w

u

) = 1.2D.L + 1.6L.L

= 1.2 0.125 + 1.6 0.04 = 0.214 ksf

Step No 3: Analysis.

Our Slab system is:

One-way,

Clear spans less than 10, and

Exterior ends of slab are discontinuous and unrestrained.

Refer to ACI 8.3.3 or page 396, Nilson 13

th

Ed, following ACI moment

coefficients apply:

Figure 5: Bending Moment Diagram for slab.

(i) AT INTERIOR SUPPORT (left side of support):

Negative moment (-M

Lint

) = Coefficient (w

u

l

n

2

)

Department of Civil Engineering, N-W.F.P UET, Peshawar Hall Design (Option 1)

Prof Dr. Qaisar Ali (http://www.eec.edu.pk)

Page 6 of 30

10'

Beam

Main

steel

reinforcement

Shrinkage reinforcement

Slab

6"

5"

= (1/12) {0.214 (9.25)

2

}

=1.53 ft-k/ft = 18.36 in-k/ft

(ii) AT INTERIOR SUPPORT (right side of support):

Negative moment (-M

Rint

) = Coefficient (w

u

l

n

2

)

= (1/12) {0.214 (8.5)

2

}

= 1.29 ft-k/ft = 15.48 in-k/ft

(iii)AT EXTERIOR MID SPAN:

Positive moment (+M

Mext

) =Coefficient (w

u

l

n

2

)

= (1/11) {0.214 (9.25)

2

}

= 1.66 ft-k/ft = 19.92 in-k/ft

(iv) AT INTERIOR MID SPAN:

Positive moment (+M

Mint

) =Coefficient (w

u

l

n

2

)

= (1/16) {0.214 (8.5)

2

}

= 0.97 ft-k/ft = 11.64 in-k/ft

Discussion: ACI analysis vs actual conditions for beam support, concepts of hinge,

roller supports etc.

Step No 4: Design.

Figure 6: Reinforcement Placement in slab.

A

smin

= 0.002bh

f

(for f

y

40 ksi, ACI 10.5.4)

= 0.002 12 6 = 0.144 in

2

/ft

a = A

smin

f

y

/ (0.85f

c

b) = 0.144 40/ (0.85 3 12) = 0.188

Department of Civil Engineering, N-W.F.P UET, Peshawar Hall Design (Option 1)

Prof Dr. Qaisar Ali (http://www.eec.edu.pk)

Page 7 of 30

M

n

= A

smin

f

y

(d-a/2)

= 0.9 0.144 40 (5-0.188/2) = 25.4 in-k/ft

M

n

calculated from A

smin

is greater than all moments as calculated in Step No 3.

Therefore A

s

= A

smin

= 0.144 in

2

/ft

Using (#4) {#13, 13 mm}, with bar area A

b

= 0.20 in

2

Spacing =Area of one bar (A

b

)/A

s

= (0.20 in

2

/0.144 in

2

/ft) 12 = 16.67 in

Discussion: Bar numbers commonly used in slabs?

Using 3/8 (#3) {#10, 10 mm}, with bar area A

b

= 0.11 in

2

Spacing = Area of one bar (A

b

)/A

s

= (0.11 in

2

/0.144 in

2

/ft) 12 = 9.16 9

Finally use #3 @ 9 c/c (#10 @ 225 mm c/c). This will work for both Positive and

Negative steel as A

smin

governs.

Shrinkage steel or temperature steel (A

st

):

A

st

= 0.002bh

f

A

st

= 0.002 12 6 =0.144 in

2

/ft

Shrinkage reinforcement is same as main reinforcement, because:

A

st

= A

smin

= 0.144 in

2

Maximum spacing for main steel reinforcement in one way slab according to

ACI 7.6.5 is minimum of:

(i) 3h

f

= 3 6 =18

(ii) 18

Therefore 9 spacing is O.K.

Maximum spacing for temperature steel reinforcement in one way slab

according to ACI 7.12.2.2 is minimum of:

(i) 5h

f

=5 6 =30

(ii) 18

Therefore 9 spacing is O.K.

Department of Civil Engineering, N-W.F.P UET, Peshawar Hall Design (Option 1)

Prof Dr. Qaisar Ali (http://www.eec.edu.pk)

Page 8 of 30

l = 60'-0"

n

b

h

h

h

w

w

f

(2) BEAM DESIGN (single span, simply supported):

Data Given:

Exterior supports of beam = 18 brick masonry wall.

f

c

= 3 ksi; f

y

= 40 ksi

Beams c/c spacing =10

Step No 1: Sizes.

According to ACI 9.5.2.1, table 9.5 (a):

Minimum thickness of beam (simply supported) = h

min

= l/16

l = clear span (l

n

) + depth of member (beam) c/c distance between supports

[ACI 8.7]

Figure 7: Clear span of Beam.

Figure 8: Beam cross-section.

Let depth of beam = 5

l

n

+ depth of beam = 60 + 5 = 65

c/c distance between beam supports = 60 + 2 (9/12) = 61.5

Therefore l = 61.5

Depth (h) = (61.5/16) (0.4+f

y

/100000) 12

= 36.9 (Minimum requirement by ACI 9.5.2.1).

Though any depth of beam greater than 36.9 can be taken as per ACI minimum

requirement, we will use the same depth as assumed i.e. 60

Department of Civil Engineering, N-W.F.P UET, Peshawar Hall Design (Option 1)

Prof Dr. Qaisar Ali (http://www.eec.edu.pk)

Page 9 of 30

103.16 k

V =84.71 k

3.355 k/ft

61.5'

wl /8 =19034 in-k

2

u

Take h = 5 = 60

d = h 3 = 57

Step No 2: Loads.

Service Dead Load (D.L) = 0.075 + 0.03 + 0.02 = 0.125 ksf (Table 2.3)

Service Live Load (L.L) = 40 psf or 0.04 ksf (for Hall)

Beam is supporting 10 slab. Therefore load per running foot will be as follows:

Service Dead Load from slab= 0.125 10 = 1.25 k/ft

Service Dead Load from beams self weight = h

w

b

w

c

= (54 18/144) 0.15 =1.0125 k/ft

Total Service Dead Load = 1.25 + 1.0125 =2.2625 k/ft

Service Live Load = 0.04 10 = 0.4 k/ft

w

s

= D.L +L.L = 1.0125 + 0.4 = 1.4125 k/ft

w

u

=1.2D.L + 1.6L.L =1.2 2.2625 + 1.6 0.4 =3.355 k/ft

Step No 3: Analysis.

Figure 9: Shear Force & Bending Moment Diagrams.

Department of Civil Engineering, N-W.F.P UET, Peshawar Hall Design (Option 1)

Prof Dr. Qaisar Ali (http://www.eec.edu.pk)

Page 10 of 30

M

u

= w

u

l

2

/8 (l = span length of beam)

M

u

= 3.355 61.5

2

/8 = 1586.18 ft-k =1586.18 12 = 19034 in-k

d = 57 = 4.75

V

max

= 103.16 k

V

u

= 84.70 k

Step No 4: Design of beam.

(A) Flexural Design:

Step (a): According to ACI 8.10, b

eff

for T-beam is minimum of:

(i) 16h

f

+ b

w

= 16 6 + 18 =114

(ii) (c/c span of beam)/4 =(61.5/4) 12 =184.5

(iii)c/c spacing between beams =10 12 =120

So b

eff

= 114

Step (b): Check if beam is to be designed as rectangular beam or T-beam.

Trial #1:

(i) Assume a = h

f

= 6

A

s

=M

u

/ {f

y

(da/2)}

A

s

=19034/ {0.9 40 (576/2)} = 9.79 in

2

(ii) Re-calculate a:

a =A

s

f

y

/ (0.85f

c

b

eff

)

a =9.79 40/ (0.85 3 114) = 1.34 < h

f

Therefore design beam as rectangular beam.

Trial #2:

A

s

=19034/ {0.9 40 (571.34/2)} = 9.38 in

2

a = 9.38 40/ (0.85 3 114) = 1.29

This value is close enough to the previously calculated value of a,

therefore, A

s

= 9.38 in

2

, O.K.

Step (c): Check for maximum and minimum reinforcement.

A

smax

=

max

b

w

d

max

= 0.85

1

(f

c

/f

y

) {

u

/(

u +

y

)}

max

= 0.85 0.85 (3/40) {0.003/(0.003

+ 0.005)} = 0.0203

Department of Civil Engineering, N-W.F.P UET, Peshawar Hall Design (Option 1)

Prof Dr. Qaisar Ali (http://www.eec.edu.pk)

Page 11 of 30

h = 60"

b = 18"

6"

d'

d

1.5" clear cover

A

smax

= 0.0203 18 57 = 20.83 in

2

A

smin

=

min

b

w

d = (200/40000) 18 57 = 5.13 in

2

A

smin

<A

s

<A

smax

,

O.K.

Note that

min

&

max

can also be found using table A.4, Nelson 13

th

Ed.

Beam (main reinforcement):

A

s

= 9.38 in

2

Using #8, 1 {#25, 25 mm}, with bar area A

b

= 0.79 in

2

No. of bars = A

s

/A

b

= 9.38/0.79 = 11.87 12 bars

Use 12 #8 bars (12 #25 bars, 25 mm).

Check the capacity of designed beam:

Area of 12 #8 Bars = 12 0.79 = 9.48 in

2

a = A

s

f

y

/ (0.85f

c

b

eff

) = 9.48 40/ (0.85 3 114) = 1.30

d = 1.5 + (3/8) + 1 + (1/2) = 3.375

d = h d = 60 3.375 = 56.625

Figure 10: Beam section dimensions.

M

d

= A

s

f

y

(d a/2) = 0.9 9.48 40 (56.625 1.30/2) = 19103.2 in-k

M

d

> (M

u

= 19034 in-k), O.K.

Skin Reinforcement:

According to ACI 10.6.7 If the effective depth d of a beam or joist

exceeds 36 in., longitudinal skin reinforcement shall be uniformly

distributed along both side faces of the member for a distance d /2 nearest

the flexural tension reinforcement. The spacing s

sk

between longitudinal

Department of Civil Engineering, N-W.F.P UET, Peshawar Hall Design (Option 1)

Prof Dr. Qaisar Ali (http://www.eec.edu.pk)

Page 12 of 30

bars or wires of the skin reinforcement shall not exceed the least of d/6, 12

in., and 1000A

b

/(d 30). It shall be permitted to include such

reinforcement in strength computations if a strain compatibility analysis is

made to determine stress in the individual bars or wires. The total area of

longitudinal skin reinforcement in both faces need not exceed one-half of

the required flexural tensile reinforcement.

Figure 11: Skin reinforcement for beams and joists with d > 36 inches.

Maximum area of skin reinforcement allowed by ACI:

A

skin, max

= Main flexural reinforcement/2 = 9.38/2 = 4.69 in

2

Range up to which skin reinforcement is provided:

d/2 = 56.625/2 = 28.3125

For #6 bar used in skin reinforcement,

s

sk

is least of:

d/6 = 56.625/6 = 9.44

12

1000A

b

/(d 30) = 10000.44/(56.625 30) = 16.53

Therefore s

sk

= 9.44 9

With this spacing, 3 bars on each face are required. And for #6 bar, the

total area of skin reinforcement is:

A

skin

= 6 0.44 = 2.64 in

2

< A

skin, max

= 4.69 in

2

, O.K

Department of Civil Engineering, N-W.F.P UET, Peshawar Hall Design (Option 1)

Prof Dr. Qaisar Ali (http://www.eec.edu.pk)

Page 13 of 30

(B) Shear Design:

V

u

= 84.71 k

V

c

= 2 (f

c

)b

w

d = (0.75 2 (3000) 18 57)/1000 = 84.29 k

V

c

< V

u

{Shear reinforcement is required}

s

d

= A

v

f

y

d/(V

u

V

c

)

Using #3, 2 legged stirrups with A

v

= 0.11 2 =0.22 in

2

}

s

d

= 0.75 0.22 40 57/(84.71 84.29) = 895

Maximum spacing and minimum reinforcement requirement as permitted by

ACI 11.5.4 and 11.5.5.3 shall be minimum of:

(i) A

v

f

y

/(50b

w

) =0.22 40000/(50 18) 9.5

(ii) d/2 =57/2 =28.5

(iii) 24

(iv) A

v

f

y

/ 0.75(f

c

)b

w

= 0.22 40000/ {(0.75 (3000) 18} = 11.90

Other checks:

(a) Check for depth of beam:

V

s

8 (f

c

)b

w

d (ACI 11.5.6.9)

8 (f

c

)b

w

d = 0.75 8 (3000) 18 57/1000 = 337.18 k

V

s

= (A

v

f

y

d)/s

d

= (0.75 0.22 40 57)/9.5 = 39.6 k < 337.18 k, O.K.

So depth is O.K. If not, increase depth of beam.

(b) Check if V

s

4 (f

c

)b

w

d {ACI 11.5.4.3}:

If V

s

4 (f

c

)b

w

d, the maximum spacing (s

max

) is O.K.

Otherwise reduce spacing by one half.

4 (f

c

)b

w

d = 0.75 4 (3000) 18 57/1000= 168.58 k

V

s

= (A

v

f

y

d)/s

d

= (0.75 0.22 40 57)/9.5 = 39.6 k < 168.58 k, O.K.

Arrangement of stirrups in the beam: With #3, 2 legged vertical

stirrups @ 9.5 c/c (maximum spacing and minimum reinforcement

requirement as permitted by ACI), the shear capacity (V

n

) of the

beam will be equal to:

V

n

= V

c

+ V

s

Department of Civil Engineering, N-W.F.P UET, Peshawar Hall Design (Option 1)

Prof Dr. Qaisar Ali (http://www.eec.edu.pk)

Page 14 of 30

s/2 = 4.75"

42.145 k

12.56'

d = 4.75'

V = 87.22 k

V = 84.29 k

V /2 = 42.145 k

u

#3 @ 9.5" c/c

Theoretically no

stirrups needed

#3, 2 legged stirrups @ 12" c/c

c

c

V

s

= (A

v

f

y

d)/s

max

V

s

= (0.75 0.22 40 57/9.5) = 39.6 k

Therefore V

n

= 84.29 + 39.6 = 123.89 k > (V

u

= 87.22 k)

It means that theoretically, from a section at a distance equal to s/2 up

to a section where shear is equal to V

c

/2, #3, 2 legged vertical

stirrups @ 9.5 c/c shall be provided. Beyond the value of V

c

/2, no

shear reinforcement is theoretically required. However # 3, 2 legged

vertical stirrups @ 12 c/c are recommended to hold the flexural

reinforcement bars.

Figure 12: Stirrups arrangement.

Department of Civil Engineering, N-W.F.P UET, Peshawar Hall Design (Option 1)

Prof Dr. Qaisar Ali (http://www.eec.edu.pk)

Page 15 of 30

S1 S2

A

A

B

1

M1 M1

M1 M1

MT1 MT1

B

1

B

1

B

1

B

1

B

1

B

1

B

1

S2 S2 S2 S2 S2 S2 S1

MT1 MT1

90'-0"

60'-0"

L /4 = 2.5' L /3 = 3.25' L /3 = 3'

L = 9.25'

1 1 2

MT1

1

M1 (Main steel Reinforcement)

M1 (Shrinkage Reinforcement)

h =6"

f

MT1

#3 @ 18" c/c (supporting bars or chairs)

#3 @ 18" c/c (supporting bars or chairs)

L = 8.5'

2

L /3 = 3' L /3 = 3'

2 2

(3) DRAFTING:

(I) Slab (S1 and S2):

Panel Depth (in) Mark

Bottom

Reinforcement

Mark Top reinforcement

S1 6" M1 3/8" @ 9" c/c MT1 3/8" @ 9" c/c Non continuous End

S2 6" M1 3/8" @ 9" c/c MT1 3/8" @ 9" c/c Continuous End

Section A-A. Refer to figure 5.15, chapter 5, Nelson 13

th

Ed for bar cutoff.

Department of Civil Engineering, N-W.F.P UET Peshawar Hall Design (Option 1)

Prof Dr. Qaisar Ali (http://www.eec.edu.pk)

Page 15 of 30

A

A

B

B

L = 60'-0"

0.14L = 8.375'

s /2 = 4.75"

0.14L - (greatest of d or 12d )= 4.75'

#3, 2 legged vertical stirrups @ 9.5" c/c

#8 Spacer bars @ 3' c/c

d

2 #8 bars

6 #8 Bars (6 + 6) #8 Bars

#3, 2 legged vertical stirrups @ 9.5" c/c

#3, 2 legged

vertical stirrups @ 12" c/c

17'-6" 25'-0" 17'-6"

Greatest of d or 12d = 3.75'

b

b

Beam (B1) Details

(a) Use graph A2 to find location of points where bars can be bent up or cutoff for simply supported beams uniformly loaded.

(b) Approximate locations of points where bars can be bent up or cotoff for continuous beams uniformly loaded and built

integrally with their supports according to the coefficients in ACI code.

C

C

Skin reinforcement

#6 @ 9" c/c

SECTION A-A SECTION B-B

60"

18"

6 #8 Bars

#3, 2 legged

stirrups @ 9.5" c/c

#3, 2 legged

stirrups @ 9.5" c/c

60"

18"

2 #8 Bars 2 #8 Bars

6" 6"

(6+6) #8 Bars

SECTION C-C

#3, 2 legged

stirrups @ 12" c/c

60"

18"

2 #8 Bars

6"

(6+6) #9 Bars

Skin Reinforcement

#6 @ 9" c/c

Department of Civil Engineering, N-W.F.P UET Peshawar Hall Design (Option 1)

Prof Dr. Qaisar Ali (http://www.eec.edu.pk)

Page 16 of 30

Appendix A

Comparison of ACI coefficients analysis with analysis of SAP2000 (finite element

method based software): Assumptions made in SAP model are,

a. Brick masonry walls are modeled as hinged support.

b. Slab is modeled as shell element.

c. Beams are modeled as frame elements.

Figure 13: Plan view of hall showing variation in slab moment (kip-in/in). Marked

points show the locations picked for comparison purpose.

Table 2.5: Slab moments

ACI 318-02

(kip-in/in)

See figure

9

SAP Results

(k-in/in)

Percentage Difference

M

(at wall)

0 M

I

0.02 -

M

F

4.59 64

M

G

3.40 51 M

(at ext. mid span)

1.66

M

H

1.55 - 7

M

B

1.47 -4

M

C

1.48 -4 M

(at int. support)

1.53

M

E

0.617 -60

M

A

1.04 7

M

(at int. mid span)

0.97

M

D

1.2 19

Department of Civil Engineering, N-W.F.P UET Peshawar Hall Design (Option 1)

Prof Dr. Qaisar Ali (http://www.eec.edu.pk)

Page 17 of 30

Conclusions:

There is more variation between SAP and ACI in slab moments.

Less variation in beam moment.

Table 2.6: Simply supported beam moment.

ACI 318-02 SAP Results Percentage Difference

M

,mid span

(k-in) 19034 18987.253 0.25

Department of Civil Engineering, N-W.F.P UET Peshawar Hall Design (Option 1)

Prof Dr. Qaisar Ali (http://www.eec.edu.pk)

Page 18 of 30

Appendix B

Relevant Pictures

Figure 14: Supporting chairs for slab reinforcement.

Figure 15: Reinforcement in slab.

Department of Civil Engineering, N-W.F.P UET Peshawar Hall Design (Option 1)

Prof Dr. Qaisar Ali (http://www.eec.edu.pk)

Page 19 of 30

Figure 16: Flexure and shear reinforcement in a beam.

Figure 16: Local arrangement for bar bending.

Department of Civil Engineering, N-W.F.P UET Peshawar Hall Design (Option 1)

Prof Dr. Qaisar Ali (http://www.eec.edu.pk)

Page 20 of 30

Appendix C

Minimum uniformly distributed live load:

Representative values of minimum live loads to be used in a wide variety of buildings are found

in Minimum Design Loads for Buildings and Other Structures, SEI/ASCE 7-02, American Society

of Civil Engineers, a portion of which is reproduced in table C1. The table gives uniformly

distributed live loads for various types of occupancies; these include impact provisions where

necessary. These loads are expected maxima and considerably exceed average values.

Table C1: Minimum uniformly distributed live loads.

Occupancy or Use

Live

Load,

psf

Live

Load, psf

Apartments (see residential) Dining rooms and restaurants 100

Access floor systems Dwellings (see residential)

Office use 50 Fire escapes 100

Computer use 100 On single-family dwellings only 40

Armories and drill rooms 150 Garages (passenger cars only) 40

Assembly areas and theaters Trucks and buses (see foot note)

Fixed seats (fastened to floors) 60

Grandstands (see stadium and arena

bleachers)

Lobbies 100

Gymnasiums, main floors, and

balconies

100

Movable seats 100 Hospitals

Platforms (assembly) 100 Operating rooms, laboratories 60

Stage floors 150 Private rooms 40

Balconies (exterior) 100 Wards 40

On one and two family residences

only, and not exceeding 100ft2

60 Corridors above first floor 80

Bowling alleys, poolrooms, and

similar recreational areas

75 Hotels (see residential)

Catwalks for maintenance access 40 Libraries

Corridors Reading rooms 60

First floor 100 Stack rooms 150

Other floors, same as occupancy

served except as indicated

Corridors above first floor 80

Dance halls and ballrooms 100 Manufacturing

Decks (patio and roof) Light 125

Same as area served, or for the

type of occupancy accommodated

Heavy 250

Department of Civil Engineering, N-W.F.P UET Peshawar Hall Design (Option 1)

Prof Dr. Qaisar Ali (http://www.eec.edu.pk)

Page 21 of 30

Table C1: (Continued)

Occupancy or Use

Live

Load,

psf

Occupancy or Use Live

Load, psf

Marquees and Canopies 75

Sidewaks, vehicular

driveways, and yards subject

to trucking

250

Office Buildings Stadium and arenas

File and computer rooms shall be

designed for heavier loads based on

anticipated occupancy

Pleachers 100

Lobbies and first-floor corridors 100

Fixed seats (fastened to

floors)

60

Offices 50 Stairs and exitways 100

Corridors above first floor 80

One and two-family

residences only

40

Penal institutions Storage areas above ceilings 20

Cell blocks 40

Storage warehouses (shall be

designed for heavier loads if

required for anticipated

storage)

Corridors 100 Light 125

Residential Heavy 250

Dwellings (one and two-family) Stores

Uninhabitable attics without storage 10 Retail

Uninhabitable attics with storage 20 First floor 100

Habitable attics and sleeping areas 30 Upper floors 73

All other areas except stairs and

balconies

40 Wholesale, all floors 125

Hotels and multifamily houses

Walkways and elevated

platforms (other than

exitways)

60

Private rooms and corridors serving

them

40

Yards and terraces,

pedestrians

100

Public rooms and corridors serving

them

100

Reviewing stands, grandstands and

bleachers

100

Schools

Classrooms 40

Corridors above first floor 80

First-floor corridors 100

a

Garages accommodating trucks and buses shall be designed in accordance with an approved method that contains provisions for

truck and bus loadings.

Department of Civil Engineering, N-W.F.P UET Peshawar Hall Design (Option 1)

Prof Dr. Qaisar Ali (http://www.eec.edu.pk)

Page 22 of 30

90'

60'

90' x 60' Hall

90'

60'

90' x 60' Hall

Appendix D

Various Structural Configurations

Department of Civil Engineering, N-W.F.P UET Peshawar Hall Design (Option 1)

Prof Dr. Qaisar Ali (http://www.eec.edu.pk)

Page 23 of 30

90'

60'

90' x 60' Hall

90'

60'

90' x 60' Hall

Department of Civil Engineering, N-W.F.P UET Peshawar Hall Design (Option 1)

Prof Dr. Qaisar Ali (http://www.eec.edu.pk)

Page 24 of 30

90'

60'

90' x 60' Hall

90'

60'

90' x 60' Hall

Department of Civil Engineering, N-W.F.P UET Peshawar Hall Design (Option 1)

Prof Dr. Qaisar Ali (http://www.eec.edu.pk)

Page 25 of 30

90'

60'

90' x 60' Hall

90'

60'

90' x 60' Hall

Department of Civil Engineering, N-W.F.P UET Peshawar Hall Design (Option 1)

Prof Dr. Qaisar Ali (http://www.eec.edu.pk)

Page 26 of 30

90'

60'

90'

60'

90' x 60' Hall

90' x 60' Hall

Department of Civil Engineering, N-W.F.P UET Peshawar Hall Design (Option 1)

Prof Dr. Qaisar Ali (http://www.eec.edu.pk)

Page 27 of 30

90'

60'

90' x 60' Hall

90'

60'

90' x 60' Hall

Department of Civil Engineering, N-W.F.P UET Peshawar Hall Design (Option 1)

Prof Dr. Qaisar Ali (http://www.eec.edu.pk)

Page 28 of 30

Appendix E

Cutoff or bend points for bars in approximately equal spans with uniformly

distributed loads:

Department of Civil Engineering, N-W.F.P UET Peshawar Hall Design (Option 1)

Prof Dr. Qaisar Ali (http://www.eec.edu.pk)

Page 29 of 30

References

Design of Concrete Structures by Nilson, Darwin and Dolan (13

th

ed.)

ACI 318-02/05

You might also like

- CIVL 314 - Week 3 - Flat Plate and Flat SlabDocument67 pagesCIVL 314 - Week 3 - Flat Plate and Flat SlabAhmed SamyNo ratings yet

- C1 Assignment1 Due by 01feb2021Document2 pagesC1 Assignment1 Due by 01feb2021JP de AzevedoNo ratings yet

- Beam On Elastic FoundationDocument8 pagesBeam On Elastic Foundationgorakdias50% (2)

- Macbeth Key QuotesDocument3 pagesMacbeth Key Quotesifodifodf50% (2)

- Mchat DOTorgDocument2 pagesMchat DOTorgtraviscNo ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- 4.2 Continuous Load Path: 4.3 Overall FormDocument10 pages4.2 Continuous Load Path: 4.3 Overall FormSirajMalikNo ratings yet

- Structural Analysis - I, B. Tech., 4th Semester, Civil Engineering, Module-II, Lecture PPT CompressedDocument110 pagesStructural Analysis - I, B. Tech., 4th Semester, Civil Engineering, Module-II, Lecture PPT CompressedNIRBHAY KUMAR BHARTINo ratings yet

- Hoang - On The Conceptual Basis of The Crack Sliding TheoryDocument54 pagesHoang - On The Conceptual Basis of The Crack Sliding TheoryLarsNo ratings yet

- Beams On Elastic FoundationDocument20 pagesBeams On Elastic FoundationShashi Bhushan KumarNo ratings yet

- Important RCC Questions-Short and LongDocument15 pagesImportant RCC Questions-Short and LongmailjoelsamuelNo ratings yet

- Computers and Structures: Hamdolah Behnam, J.S. Kuang, Bijan SamaliDocument17 pagesComputers and Structures: Hamdolah Behnam, J.S. Kuang, Bijan SamaliSayna KellenyNo ratings yet

- SDMF Question Paper 1Document2 pagesSDMF Question Paper 1G. SASIDHARA KURUPNo ratings yet

- Deep BeamDocument30 pagesDeep BeamKrishan Dutt Yadav100% (1)

- Assignment 05 - FinalDocument8 pagesAssignment 05 - FinalAshok Kumar RajanavarNo ratings yet

- Introduction To Beams: Part ADocument49 pagesIntroduction To Beams: Part AMorad AJNo ratings yet

- Complex Engineering ProblemDocument31 pagesComplex Engineering ProblemAhmad Mukhtar 164-FET/BSCE/F17100% (1)

- Advanced Structural AnalysisDocument3 pagesAdvanced Structural AnalysisAmit ThoriyaNo ratings yet

- CE8011 Design of Prestressed Concrete Structure - by WWW - Learnengineering.inDocument185 pagesCE8011 Design of Prestressed Concrete Structure - by WWW - Learnengineering.inSourav DasNo ratings yet

- Chapter 6 Special Structure: Special Structural Elements Deep Beams and CorbelsDocument14 pagesChapter 6 Special Structure: Special Structural Elements Deep Beams and Corbelsomar100% (1)

- Design of SlabDocument4 pagesDesign of SlabCharan ReddyNo ratings yet

- PHEngg Handouts and Workbook 4Document175 pagesPHEngg Handouts and Workbook 4AMmarNo ratings yet

- CE2305 FOUNDATION ENGINEERING Anna University Question Bank Question Paper 2 Marks and 16 MarksDocument11 pagesCE2305 FOUNDATION ENGINEERING Anna University Question Bank Question Paper 2 Marks and 16 MarksPrabhumk07No ratings yet

- Finite Difference Buckling Analysis of Non Uniform ColumnsDocument8 pagesFinite Difference Buckling Analysis of Non Uniform ColumnsJules NanaNo ratings yet

- Two Hinged Parabolic ArchDocument10 pagesTwo Hinged Parabolic ArchHans Izairi100% (1)

- Conjugate Beam METHODDocument13 pagesConjugate Beam METHODAdam Ahmed100% (1)

- Design of Concrete Structures - I Question PaperDocument3 pagesDesign of Concrete Structures - I Question PaperSourav Sil50% (2)

- Chapter 4 - ColumnsDocument27 pagesChapter 4 - ColumnsFeyisa GuyeNo ratings yet

- Matrix Structure Analysis Mtech Paper 1Document2 pagesMatrix Structure Analysis Mtech Paper 1Bipul Prince BarmanNo ratings yet

- Moment of Inertia LectureDocument26 pagesMoment of Inertia LectureMohdmuslim AbdkohaNo ratings yet

- Unit Ii Design of Flat SlabDocument23 pagesUnit Ii Design of Flat SlabARUN PRATHAPNo ratings yet

- BEAMDocument114 pagesBEAMPaul Macharia Ndungu100% (1)

- Analytical Behavior of Concrete-Encased CFST Columns Under Cyclic Lateral Loading, 2016 (Wei-Wu Qian)Document15 pagesAnalytical Behavior of Concrete-Encased CFST Columns Under Cyclic Lateral Loading, 2016 (Wei-Wu Qian)Phan Đào Hoàng Hiệp100% (1)

- Temam Mohammed HS 2Document16 pagesTemam Mohammed HS 2Temam MohammedNo ratings yet

- Progressive Collapse Analysis of Steel Braced FramesDocument9 pagesProgressive Collapse Analysis of Steel Braced FrameswalaywanNo ratings yet

- Shear, Bond, Anchorage, Development Length and Torsion: Version 2 CE IIT, KharagpurDocument19 pagesShear, Bond, Anchorage, Development Length and Torsion: Version 2 CE IIT, Kharagpurapi-3696315No ratings yet

- Design Concept of SubstructureDocument19 pagesDesign Concept of SubstructureMaithri R HebbarNo ratings yet

- Concrete Mix Design ExampleDocument4 pagesConcrete Mix Design ExampleTheke MarkNo ratings yet

- Conjugate Beam MethodDocument12 pagesConjugate Beam MethodKobina BondzieNo ratings yet

- ECG353 Week 10 - 11 Chapter 4Document44 pagesECG353 Week 10 - 11 Chapter 4Muhd MuqhreyNo ratings yet

- Unbraced WallDocument7 pagesUnbraced WallakanagesNo ratings yet

- Concrete Structures: Temesgen Wondimu, PHD Chapter 2: Strain-Compatibility Analysis of RC Sections Under BendingDocument25 pagesConcrete Structures: Temesgen Wondimu, PHD Chapter 2: Strain-Compatibility Analysis of RC Sections Under BendingAbrehaAbayNo ratings yet

- (LECT-21,22) Prestressed Concrete SlabsDocument22 pages(LECT-21,22) Prestressed Concrete SlabsSushil MundelNo ratings yet

- Lateral Loads ResistanceDocument23 pagesLateral Loads ResistanceAbdelrahman Hassan El-MallaNo ratings yet

- Final Exam of Structural Behavior and Analysis IDocument3 pagesFinal Exam of Structural Behavior and Analysis INeven Ahmed HassanNo ratings yet

- The Auxiliary Law of MotionDocument11 pagesThe Auxiliary Law of MotionSabid UddinNo ratings yet

- Properties of Hardened Concrete-Creep, Shrinkage PDFDocument10 pagesProperties of Hardened Concrete-Creep, Shrinkage PDFPratik SinhaNo ratings yet

- Bamboo Ethiopia ThesisDocument147 pagesBamboo Ethiopia ThesisSumetha RNo ratings yet

- Torsion Design of Prestressed ConcreteDocument20 pagesTorsion Design of Prestressed ConcreteDr. M.V.Krishna RaoNo ratings yet

- Lecture On Limit State Design by Manish BhutaniDocument27 pagesLecture On Limit State Design by Manish BhutaniTarunNo ratings yet

- SDD NotesDocument117 pagesSDD NotesPooja0% (1)

- Memo STRUCTURAL ANALYSIS II - SAN2601 Assignments 2020Document28 pagesMemo STRUCTURAL ANALYSIS II - SAN2601 Assignments 2020Rachel Du PreezNo ratings yet

- Composite - Design ProjectDocument6 pagesComposite - Design ProjectSomen DasNo ratings yet

- 100000Document76 pages100000Dandu ManNo ratings yet

- Concrete Lectures Slab.2 Direct Design Method - PPT ExamplesDocument58 pagesConcrete Lectures Slab.2 Direct Design Method - PPT ExamplesUmer WaheedNo ratings yet

- Addis College: Department of Civil EngineeringDocument12 pagesAddis College: Department of Civil EngineeringAlemayehu DargeNo ratings yet

- Finite Element Analysis of A Prestressed Concrete Beam Using FRP TendonDocument105 pagesFinite Element Analysis of A Prestressed Concrete Beam Using FRP TendonVietnhut Phan100% (1)

- Celebrating Literacy in the Rwenzori Region: Lest We Forget: a Biographical Narrative of Uganda’S Youngest Member of Parliament, 1980-1985From EverandCelebrating Literacy in the Rwenzori Region: Lest We Forget: a Biographical Narrative of Uganda’S Youngest Member of Parliament, 1980-1985No ratings yet

- Elastic, Plastic and Yield Design of Reinforced StructuresFrom EverandElastic, Plastic and Yield Design of Reinforced StructuresNo ratings yet

- Computational Wind Engineering 1: Proceedings of the 1st International Symposium on Computational Wind Engineering (CWE 92) Tokyo, Japan, August 21-23, 1992From EverandComputational Wind Engineering 1: Proceedings of the 1st International Symposium on Computational Wind Engineering (CWE 92) Tokyo, Japan, August 21-23, 1992S. MurakamiNo ratings yet

- Self-Assessment Grammar and VocabDocument4 pagesSelf-Assessment Grammar and VocabBettyNo ratings yet

- Pressure Drop Calculation - Primary Pump & Secondary PumpDocument6 pagesPressure Drop Calculation - Primary Pump & Secondary PumpAzher ANo ratings yet

- Swot TescoDocument3 pagesSwot TescoGhada SalahNo ratings yet

- Does Loving A Group Mean Hating Its Rivals? Exploring The Relationship Between Ingroup Cohesion and Outgroup Hostility Among Soccer FansDocument20 pagesDoes Loving A Group Mean Hating Its Rivals? Exploring The Relationship Between Ingroup Cohesion and Outgroup Hostility Among Soccer FansRaihan Nurul HadiNo ratings yet

- Annotated BibliographyDocument7 pagesAnnotated BibliographykristineenguyenNo ratings yet

- 19910009728Document118 pages19910009728ramsiNo ratings yet

- Blue Collar Apologetics Session 6 Handout MaterialDocument2 pagesBlue Collar Apologetics Session 6 Handout Materialcalmncool555No ratings yet

- Imle 15.02.2016 PDFDocument70 pagesImle 15.02.2016 PDFRaZy Abo RayaNo ratings yet

- Digimon World Data SquadDocument85 pagesDigimon World Data SquadIrvandra AfrenNo ratings yet

- Presentation Ectopic HormonesDocument12 pagesPresentation Ectopic HormonesCritic CrazzyNo ratings yet

- Ppe Wah-RiggerDocument107 pagesPpe Wah-Riggerchanks498No ratings yet

- Materi Bahasa Inggris, Rabu 5-4-2023 FixDocument3 pagesMateri Bahasa Inggris, Rabu 5-4-2023 Fixbabon333No ratings yet

- Well Construction Journal - May/June 2013Document28 pagesWell Construction Journal - May/June 2013Venture PublishingNo ratings yet

- Electrostatics MCQs 2homework 2Document29 pagesElectrostatics MCQs 2homework 2hdiehjrrorNo ratings yet

- Menu Menu Menu Menu Menu Menu Menu MenuDocument89 pagesMenu Menu Menu Menu Menu Menu Menu MenuRodriguez Ernesto ErnestoNo ratings yet

- The United Kingdom's International Organisation For Educational Opportunities and Cultural Relations. We Are Registered in England As A CharityDocument4 pagesThe United Kingdom's International Organisation For Educational Opportunities and Cultural Relations. We Are Registered in England As A CharityRidwan baritoNo ratings yet

- Evaluation FormDocument2 pagesEvaluation FormTifuh Kevin TifuhNo ratings yet

- Palawan State University: Official List of Enrolled StudentsDocument3 pagesPalawan State University: Official List of Enrolled Studentsggg10No ratings yet

- Rapport An Nuel TT CernDocument88 pagesRapport An Nuel TT Cernangelo tavaniNo ratings yet

- Pensioners Request FormDocument2 pagesPensioners Request FormKaleemullah Jaffer AllahbakshNo ratings yet

- Kuesioner American Pain SocietyDocument15 pagesKuesioner American Pain SocietyNamira Firdha KNo ratings yet

- Sustainability in Higher EducationDocument50 pagesSustainability in Higher EducationAnonymous D8zliENo ratings yet

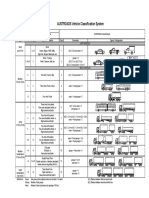

- Austroads ClassesDocument1 pageAustroads ClassesSasana SanNo ratings yet

- 0452 w04 QP 1Document12 pages0452 w04 QP 1MahmozNo ratings yet

- Grove - III. Piano Music From c1750Document15 pagesGrove - III. Piano Music From c1750Ticiano BiancolinoNo ratings yet

- Sports Exercise and Health Science Paper 3 SL MarkschemeDocument21 pagesSports Exercise and Health Science Paper 3 SL Markschemegoingnow0001No ratings yet

- Business LawsDocument3 pagesBusiness LawsVsubramanian VsmNo ratings yet

- Conformity, Deviance, and Crime: Anthony Giddens Mitchell Duneier Richard P. AppelbaumDocument38 pagesConformity, Deviance, and Crime: Anthony Giddens Mitchell Duneier Richard P. AppelbaumMishal Hasnain NaqviNo ratings yet