Professional Documents

Culture Documents

Estimate Gadawara Power Plant, NTPC

Uploaded by

Gopal Sudhir0 ratings0% found this document useful (0 votes)

925 views420 pagesThe document appears to be a tender summary or cost estimate for a construction project. It includes line items for various types of earthwork, excavation, backfilling, concrete work and other structural elements. The document provides estimated quantities, rates and totals for each line item, with the totals broken down by project location (offshore/onshore). It also includes subtotals for indirect costs, direct costs, contingencies, overhead and margins to arrive at a final projected total project cost.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document appears to be a tender summary or cost estimate for a construction project. It includes line items for various types of earthwork, excavation, backfilling, concrete work and other structural elements. The document provides estimated quantities, rates and totals for each line item, with the totals broken down by project location (offshore/onshore). It also includes subtotals for indirect costs, direct costs, contingencies, overhead and margins to arrive at a final projected total project cost.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

925 views420 pagesEstimate Gadawara Power Plant, NTPC

Uploaded by

Gopal SudhirThe document appears to be a tender summary or cost estimate for a construction project. It includes line items for various types of earthwork, excavation, backfilling, concrete work and other structural elements. The document provides estimated quantities, rates and totals for each line item, with the totals broken down by project location (offshore/onshore). It also includes subtotals for indirect costs, direct costs, contingencies, overhead and margins to arrive at a final projected total project cost.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You are on page 1of 420

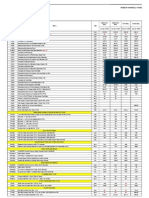

FTS-Rev

ITD CEMENTATION INDIA LIMITED

PROJECT TITLE :

Tender no. Div 2/044/13 Revision- R2 Date: 16-Sep-13

COMBINED SECTION % of

ITEM FINAL TENDER SUMMARY OFFSHORE ONSHORE TOTALS GRAND

Rs. Lakhs Rs. Lakhs Rs. Lakhs Rs. Lakhs TOTAL

A INDIRECT COSTS

01. STAFF - i) CONSTRUCTION * INDIAN 576.15 576.15 1.78%

ii) OTHERS * INDIAN 642.73 642.73 1.99%

02. STAFF - i) CONSTRUCTION * EXPAT 0.00 0.00%

ii) OTHERS * EXPAT 0.00 0.00 0.00%

03. INDIRECT LABOUR - i) CONSTRUCTION * (added in B 05.) 0.00 0.00 0.00%

ii) OTHERS * 208.86 208.86 0.65%

04. SITE ESTABLISHMENT 697.78 697.78 2.16%

05. INSURANCE 355.71 355.71 1.10%

06. BONDS 183.18 183.18 0.57%

07. INTEREST ON ADVANCE - Interest bearing 0.00 0.00 0.00%

08. BANK CHARGES - Interest on External borrowing 0.00 0.00 0.00%

09. TAXES 2496.00 2,496.00 7.72%

10. DESIGN & PROFESSIONAL SERVICES 0.00 0.00%

SUB TOTAL 5,160.42 5,160.42 15.96%

B DIRECT COSTS

01. LOCAL MATERIALS ( DM )

i) CEMENT 417.43 417.43 5.80%

ii) REBAR & HT STRAND 480.68 480.68 12.78%

iii) STRUCTURAL STEEL 36.64 36.64 1.37%

iv) BITUMEN 0.00 0.00 0.00%

v) OTHERS 1- AGREGATES 197.07 197.07 3.87%

vi) OTHERS 2 Sand 73.39 73.39 0.76%

vii) OTHERS 3 0.00 0.00%

viii) REMAINING OTHERS 1175.54 1,175.54 8.50%

02. IMPORTED MATERIALS 0.00 0.00 0.00%

03. ENABLING WORKS 58.13 58.13 0.18%

04. SHUTTERING & STAGING MATERIAL 335.18 335.18 1.97%

05. LABOUR & LABOUR CONTRACT (PRW) 589.72 589.72 4.95%

06. a. SUB-CONTRACT 3363.13 3,363.13 22.11%

b. Div-III -PILING 0.00 0.00 0.00%

07. PLANT HIRE 1009.29 1,009.29 3.12%

08. POL 421.77 421.77 1.37%

09. PLANT WEAR PARTS 65.37 65.37 0.20%

10. PLANT MOB & DE-MOB 50.15 50.15 0.16%

11. PLANT LABOUR/OPERATOR 64.08 64.08 0.20%

SUB TOTAL 8,337.56 26,926.95 83.30%

C OTHER COSTS

01. i) GTE on (CV-Sub Con Value) 323.25 323.25 1.00%

ii) MISC.ISSUE / CONSUMABLE IDM 0.00 0.00%

02. LABOUR CESS 1% 323.25 323.25 1.00%

03. PRICE INFLATION 2% 646.51 646.51 2.00%

04. RISK & BENEFIT COSTS 0.00 0.00%

05. DLP PROVISION 0.20% 64.65 64.65 0.20%

06. PROVISIONAL SUMS 0.00 0.00%

07. OTHERS (SPECIFY) 0.00 0.00%

SUB TOTAL 1,357.66 28,284.61 87.50%

D CONTINGENCIES

01. PROJECT CONTINGENCY 0.50% ON T.O. 161.63 161.63 0.50%

02. ADDITIONAL CONTINGENCY 2.00% ON T.O. 646.51 646.51 2.00%

SUB TOTAL 808.13 29,092.74 90.00%

E TENDER ADJUSTMENTS 0.00 0.00%

SUB TOTAL 0.00 29,092.74 90.00%

F OVERHEAD & MARGIN

01. OVERHEAD -ITD CEM 4.00% ON T.O. 0.00 0.00 4.00%

02. ITD FEE ON T.O. 0.00 0.00 0.00%

03. FINANCING CHARGES 3.00% ON T.O. 0.00 969.76 3.00%

04. MARGIN excl Sub Con 3.00% ON T.O. 0.00 755.35 2.34%

04.a. MARGIN on Sub Con 3.00% ON Sub Con 100.89 100.89 0.66%

05. MARGIN ON FREE ISSUE MATERIALS 0.00% Mat= 7,142.0 0.00 0.00 0.00%

SUB TOTAL 0.00 0.00 100.00%

G OTHER DIVISION'S WORK (SPECIFY) 0.00 0.00%

H GRAND TOTAL Rs. Lakhs 0.00 0.00 100.00%

I NEGOTIATION MARGIN 3.00% ON G.Total 969.76 969.76 3.00%

J QUOTE AMOUNT Rs. Lakhs 969.76 103.00%

K CURRENCY SPLIT

L CAPITAL PURCHASE 149.05

M RESIDUAL VALUE 85.85

CURRENCY SPLIT

Civil works for 3 x 800 MW Gadarawara Power plant, M.P.

Page 1 of 430

FTS-Rev

For Internal Assessment:

` Lacs %

1. Direct Cost 23,215.47 100%

[Incl.Sttaff-Construction, Indir.Lab-Construction, Client Estimate

Design Fee, Inflation, Risk, DLP & Proj.Conting.] % above #DIV/0!

2. Indirect cost

2(i) Type I

Insurrance & Bond 538.89

Interest & Bank Charges 0.00

Taxes 2,496.00

GTE & Cess 646.51

Addnl.Contingency 646.51

4,327.90 18.64%

2(ii) Type II 1,549.37 6.67%

3. Site Margin 3,232.53 13.92%

Total Price 32,325.27 1.39

Page 2 of 430

1

2

345678

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

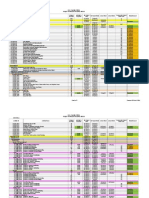

A B C D G H I J K L M N

Markup==> 4.0636

SASAN

Rate Amount Rate Amount Rate Amount

PP1 EARTHWORK

PP2 Earthwork in excavation in the all types of soil including bailing / pumping out anywater accumulating inside the excavation if required strutting, shoring / sheet piling, dressing and transporting the excavated soil up to 1.0 KM lead and filling / stacking selectively as directed by the Engineer, all complete as per drawing & specification.

- 1.53

PP3 Up to 2.0 mdepth fromGround level Cu.M 24828.74 68 1,685,072 1.53 99 1,970,578 108

PP4 Between 2.0mto 4.0mdepth fromground level Cu.M 12664.31 78 986,142 1.53 114 2,277,326 164

PP5 Between 4.0mto 6.0mdepth fromground level Cu.M 2151 65 140,281 1.53 180 72,078 180

PP6 Between 6.0mto 8.0mdepth fromground level Cu.M 0.001 85 0 1.53 211 - 196

PP7 Between 8.0mto 10.0mdepth fromground level Cu.M 0.001 225 0 1.53 426 - 348

PP8 Earthwork in excavation belowground level in hard rock byanymechanical means without blasting & wedging, without damaging the existing structures, including setting out, clearing & grubbing, removal of debris, dewatering if required, strutting & shoring if required, dressing the sides, leveling to grade and stacking / disposal of surplus excavated material within a lead of 1.0 KM etc as directed by the Engineer, all complete as per drawing & specification.

- 1.53 -

PP9 Up to 2.0 mdepth fromGround level Cu.M 0.001 15793170883 15,793,171 1.53 33,786,600 390

PP10 Between 2.0mto 4.0mdepth fromground level Cu.M 0.001 15793170913 15,793,171 1.53 609 30,456,108 624

PP11 Between 4.0mto 6.0mdepth fromground level Cu.M 0.001 301339012 301,339 1.53 677 1,693,746 781

PP12 Between 6.0mto 8.0mdepth fromground level Cu.M 0.001 301339042 301,339 1.53 724 217,053 937

PP13 Between 8.0mto 10.0mdepth fromground level Cu.M 0.001 301339082 301,339 1.53 785 78,486 1447

PP14 Earthwork in excavation belowground level in hard rock by means of controlled blasting including provision of sensor to assess the impact of blast on the adjacent structures, without damaging the existing structures, including setting out, clearing & grubbing, removal of debris, dewatering if required, strutting & shoring if required, dressing the sides, leveling to grade and stacking / disposal of surplus excavated material within a lead of 1.0 KM etc as directed by the Engineer, all complete as per drawing & specification.

- 1.53 - NA

PP15 Up to 2.0 mdepth fromGround level Cu.M 0.001 361607308 361,607 1.53 1063 4,145,526 NA

PP16 Between 2.0mto 4.0mdepth fromground level Cu.M 0.001 361607338 361,607 1.53 1109 14,305,680 NA

PP17 Between 4.0mto 6.0mdepth fromground level Cu.M 0.001 241071826 241,072 1.53 1228 7,365,232 NA

PP18 Between 6.0mto 8.0mdepth fromground level Cu.M 0.001 241071856 241,072 1.53 1274 2,547,102 NA

PP19 Between 8.0mto 10.0mdepth fromground level Cu.M 0.001 241071906 241,072 1.53 1350 1,350,238 NA

PP20 Disposal of surplus excavated earth beyond a lead of 4.0 KM but anywhere within plant boundaryas directed bythe Engineer dumping and leveling the area from where the dumped earth is to be transported complete with all lifts as specified and directed byEngineer.

Cu.M 13705.682 415 5,682,896 1.53 - 81

PP21 Earthworkin Backfilling around foundations in plinths etc to proper grade and level with selected material within a lead of 1.0 KM from available excavated soil includingre- excavating loose thickness watering and ramming in layers with proper compaction as per specification and direction of Engineer.

Cu.M 30746.17 305 9,382,448 1.53 142 17,001,135 152

PP22 Supplyand Laying sand under floor, foundations & Plinths including cost of sand, transporting for all leads, loading, unloading & spreading in layers of 250 mmthickness at all depths, watering, compaction complete as per specification and direction of Engineer.

Cu.M 0.001 645 1 1.53 663,740 496

PP23 Providing and Laying rubble soiling with specified sizes of approved qualityhard rockrubble or hard broken hard metal of sizes ranging from100 mmto 230 mmbelowfinished ground floor level, belowfoundation hand packing, filling in interstices with sand including watering thoroughlycompacting the layer all complete as per drawings and direction of Engineer.

Cu.M 661.206 1620 1,071,153 1.53 2485 19,877,255 1365

PP24 Providing & laying of approved qualityhard crushed stone metal size 40 mmaverage thickness in transformer yard, stacker area and in other places where required as per drawing including loading,unloading & transportation spreading, compacting, all labour, materials complete.

Cu.M 0.001 1510 2 1.53 2316 2,315,946 1365

PP25 Providing & laying of approved qualityhard crushed stone metal size 10 mmaverage thickness in transformer yard, stacker area and in other places where required as per drawing including loading, unloading & transportation complete.

Cu.M 0.001 1668 2 1.53 2558 6,393,774 NA

PP26 PLAIN AND REINFORCED CEMENT CONCRETE - 1.53 -

PP27 The following items shall be read along with General Notes. - 1.53 -

PP28 Supplying and laying in position plain cement concrete of following nominal mix (by volume) using graded crushed stone (20 mmdown) as coarse aggregate including mixing, conveying, laying, compacting and curing etc. complete as per drawings specification and directions of Engineer.

- 1.53 -

PP29 M-10 Cu.M 1287.332 6013 7,741,249 1.53 5774 42,147,569 5245

PP30 Supplying, laying, finishing and curing of following screed concrete with 10 mmdowngraded crushed stone over RCC roof and trenches etc. including cleaning and backing of surface before laying as per drawings and specification.

- 1.53 -

PP31 M-15 Cu.M 3762 6304 23,717,105 1.53 6220 621,993 5554

PP32 Supplying and laying in position design mix cement concrete of following grades for reinforced concrete work in foundation and substructure in all kinds of workusing graded crushed stone (20 mmdown) as coarse aggregate including mixing, conveying, laying, compacting and curing etc. complete as per drawings, specifications and directions of the Engineer.

- 1.53 -

PP33 M - 20 Cu.M 0.001 65616 66 1.53 7389 3,694,597 5408

PP34 M - 25 Cu.M 472.49635 65759 31,070,713 1.53 7608 383,433,947 5275

PP35 Extra over above item(12-a-ii) above for supplying and using special admixtures / plasticizers for producing Self Compacting Concrete (SCC) with a Slump value of 660 mmto 750 mmand Passing abilityof 60 mmto 80 mm. Admixtures shall be of M/s. BASF / Sunandha Chemicals or equivalent make, for small column and thin walled section concreting including additional precaution to ensure leakproof shuttering with smooth surface.

Cu.M 0.001 1088 1 1.53 1669 834,354 NA

PP36 Supplying and laying in position design mix cement concrete of following grades for reinforced concrete work in superstructure in all kinds of workusing graded crushed stone (20 mmdown) as coarse aggregate including mixing, conveying, laying, compacting and curing etc. complete as per drawings, specifications and directions of the Engineer.

- 1.53 -

PP37 M - 25 Cu.M 0.001 6514000870 6,514,001 1.53 7927 143,477,982 5469

PP38 Extra over above item (12-b-i) above for supplying andusing special admixtures / plasticizers for producing Self Compacting Concrete (SCC) with a Slump value of 660 mmto 750 mmand Passing abilityof 60 mmto 80 mm. Admixtures shall be of M/s. BASF / Sunandha Chemicals or equivalent make, for small column and thin walled section concreting including additional precaution to ensure leak proof shuttering with smooth surface.

Cu.M 0.001 1088 1 1.53 1669 1,168,095 NA

PP39 Supplying and laying in position design mix cement concrete of following grades for reinforced concrete works in T.G. Foundation using graded crushed stone (20 mm down) as coarse aggregate including mixing, conveying, laying, compacting and curing of concrete bythe application of a membrane curing compound to all concrete surfaces. The compound shall conformto ASTM C 309, Type I with white pigmentation and shall be applied bya sprayer. etc. complete as per drawings, specifications and directions of the Engineer.

- 1.53 -

PP40 M - 30 Cu.M 9192.296 8063 74,117,032 1.53 10216 20,432,425 6401

PP41 M - 35 Cu.M 0.001 8464 8 1.53 10831 21,661,817 6499 M40 rate

PP42 Extra over above item(12-c-i & ii) above for supplying and using special admixtures / plasticizers for producing Self Compacting Concrete (SCC) with a Slump value of 660 mmto 750 mmand Passing abilityof 60 mmto 80 mm. Admixtures shall be of M/s. BASF / Sunandha Chemicals or equivalent make including additional precaution to ensure leakproof shuttering with smooth surface.

Cu.M 0.001 680 1 1.53 1043 4,171,770

PP43 Carrying our Ultrasonic Pulse Velocity(UPV) testing for top deck of TGcomplete as per specification, drawing and direction of Engineer including labour, machineryand submission of test results complete

LS for each TG

0.001 1300000 1,300 1.53 1993860 1,993,860 1920625

PP44 Supplying and laying in position design mixcement concrete of following grades for reinforced concrete work in Equipment foundations / Block foundations using graded crushed stone (20 mm down) as coarse aggregate including mixing, conveying, laying, compacting and curing of concrete by the application of a membrane curing compound to all concrete surfaces. The compound shall conformto ASTM C 309, Type I with white pigmentation and shall be applied bya sprayer. etc. complete as per drawings, specifications and directions of the Engineer.

- 1.53 -

PP45 M - 35 Cu.M 0.001 66529 67 1.53 8789 30,761,685 6499 M40 rate

PP46 Extra over above item (12-d-i) above for supplying and using special admixtures / plasticizers for producing Self Compacting Concrete (SCC) with a Slump value of 660 mmto 750 mmand Passing abilityof 60 mmto 80 mm. Admixtures shall be of M/s. BASF / Sunandha Chemicals or equivalent make including additional precaution to ensure leakproof shuttering with smooth surface.

Cu.M 0.001 544 1 1.53 834 2,920,239 NA

PP47 Supplying and laying pre cast reinforced cement concrete elements cast at Project site with following grade of concrete at various elevations in all kinds of workincluding supplyof materials, formwork, mixing, laying, compacting and curing, storing, handling, transporting, erection without damage, setting in position with cement sand mortar (1:2 byvolume) grouting/welding etc. complete as per drawings, specification and direction of Engineer.

- 1.53 -

PP48 M - 25 Cu.M 0.001 6514005785 6,514,006 1.53 15466 2,706,585 2102

PP49 Providing and mixing as cement concrete admixtures - super plasticizers (including super plasticizers cum retarder, super plasticizers cum water proofing and super plasticizers cum. pumping aid for concrete), at all levels, for all kinds of works, including all labour, material,equipment, handling, transportation, testing, etc., all complete, as per specifications, drawings and instructions of the Engineer / manufacturers.

MT 0.001 187000 187 1.53 286809 172,085,497 NA

PP50 Dismantling concrete work (both PCC and RCC of all grades), for all types of structures, at all levels, including all labour,equipment, scaffolding,staging,stacking of serviceable material upto a lead of 500 mand disposal of unserviceable material upto a lead of 2 kmbeyond the plant boundaryor as directed bythe Engineer, cutting of reinforcement, propping, shoring, enclosures, including all labour, material, equipment, handling, transportation, etc., all complete, as per specifications, drawings and instructions of the Engineer.

Cu.m 0.001 1500 2 1.53 2301 230,061 8807

PP51 Chipping of Cement Concrete work (both PCC and RCC), for all type of structures, at all levels, for making grooves, removing surface concrete etc., according to shapes, sizes and profiles as shown on the construction drawings, stacking of serviceable material upto a lead of 500 m, disposal of unserviceable material upto a lead of 2.00 km. beyond the plant boundaryor as directed bythe Engineer, cutting of reinforcement, including all labour, equipment, scaffolding, staging, handling, transportation, propping and shoring, enclosures, etc., all complete, as per specifications, drawings and instructions of the Engineer.

Cu.m 0.001 2200 2 337,423 NA

PP52 Making of Circular opening of diameter varying from25 mmto 150 mmand depth upto 450 mmin cement concrete work(both PCC and RCC) of all grades, for all type of structures, at all levels and for all positions, bycoring using diamond bits for pockets / thorough opening according to size as shown on the construction drawings, stacking of serviceable material upto a lead of 500 m, disposal of unserviceable material upto a lead of 2.00 km. beyond the plant boundary or as directed by the Engineer, finishing neatlythe surface area of cement concrete exposed after creation of circular opening including all labour, equipment, scaffolding, staging, handling, transportation, propping and shoring, enclosures, etc., all complete, as per specifications, drawings and instructions of the Engineer.

Sq.m 0.001 7200 7 11043 1,104,292 NA

PP53 Making of slit type opening of rectangular, square and or similar shape of varying size (in plan) and depth upto 450 mmin cement concrete work(both PCC and RCC) of all grades, for all type of structures, at all levels and for all positions, bysawing using wall sawmachine with on the construction drawings, locating the reinforcement before making the opening byuse of rebar detector and obtaining specific clearance fromthe Engineer, if the cutting of the reinforcement bar are involved in the making of the opening, cutting of reinforcement, stacking of serviceable material upto a lead of 500 m, disposal of unserviceable material upto a lead of 2.00 Kms. beyond the plant boundaryor as directed bythe Engineer, finishing neatlythe surface area of cement concrete exposed after creation of opening including all labour,equipment,scaffolding,staging,handling, transportation, propping and shoring, enclosures, etc., all complete, as per specifications, drawings and instructions of the Engineer.

Sq.m 0.001 6000 6 1.53 920,243 NA

PP54 Supplying, fabricating and installing following embedded items in cement concrete, as per drawings and specification including necessarytemplates : (Base rate of structural steel will be applied for this item)

- 1.53 - NA

PP55 Anchor bolt assembly complete with sleeves, nuts, washers, anchor plates, etc. MT 0.001 141105 141 21,089,725 NA

PP56 Insert plates, edge protection angles, pipe sleeves, hangers, conducts and other miscellaneous embedded fixtures of MS, GI, WI, CI, cast steel or other metal items.

MT 1 80811 80,811 14,802,770 NA

PP57 Taking, deliveryand installing following embedded Items in cement concrete, as per drawings and specifications including necessarytemplates :

- -

PP58 Anchor bolt assembly complete with sleeves, nuts, washers, anchor plates, etc. MT 0.001 21705 22 1.53 3,471,104 27300 Free issue material

PP59 Insert plates, edge protection angles, pipe sleeves, hangers, conducts and other miscellaneous embedded fixtures of MS, GI, WI, CI, cast steel or other metal items.

MT 0.001 36105 36 1.53 4,985,467 27300 Free issue material

PP60 Supply, fabrication and fixing of necessary templates against itemno 20-a above, if templates are not supplied byJPL.

MT 0.001 75411 75 1.53 1,652,099 27300 Free issue material

PP61 Forming expansion / isolation j oints in concrete as per drawings and specifications using Bitumen boards / expanded polystyrene boards complete with bitumen sealing compound including supplyof all materials

- 1.53 -

PP62 12 mmThick Sq.M. 8997.168 681 6,127,071 208,895 NA

PP63 25 mmThick Sq.M. 0.001 906 1 1390 277,913 855

PP64 50 mmThick Sq.M. 0.001 1231 1 1888 377,607 NA

PP65 Supplying and filling the expansion j oints of following dimension with bitumen / other j oint sealing compound confirming to IS : 1834 including through cleaning of the joints, as per manufacturer' s specification and as directed bythe Engineer.

- -

PP66 25 mm x25 mm RM 0.001 50 0 1.53 76 19,076 186

PP67 Same as above item(22-a) but with Silica Sealant RM 0.001 775 1 1.53 1189 297,162 71

PP68 Providing vertical expansion j oint with polyurethane foam road of required diameter and sealed with silicon sealant over road including fixing of rod with all materials complete at various elevations as per drawings and specifications similar to C/S Group & McCoyor approved equivalent.

- 1.53 - NA

PP69 25 wide with 25 x12 poly-sulphide including fixing of 25 mm dia rod. R.M. 0.001 1261 1 4.06 1934 290,026 NA

PP70 50 wide with 50 x12 poly-sulphide including fixing of 50 mm dia rod. R.M. 0.001 2607 3 4.06 3999 399,884 NA

PP71 Providing horizontal expansion j oint on roof with polyurethane foamrod and sealed with silicon sealant including fixing of rod complete with all materials joint filler, sealing compound, etc. as per drawing and specifications similar to C/S Group & McCoyor approved equivalent.

- 1.53 - NA

PP72 25 wide with 25 x12 poly-sulphide including fixing of 25 mmdia rod. R.M. 0.001 1042 1 1.53 1597 119,804 NA

PP73 50 wide with 50 x12 poly-sulphide including fixing of 50 mm dia rod. R.M. 0.001 2248 2 1.53 3447 172,354 NA

PP74 Providing & Fixing desired thickness of SIL FIL of Dawn Color, manufactured byThe Supreme Industries Limited or equivalent, thickness built up using minimum10 mmspecifically extruded high performance sheet, minimumdensity30 kg/ cum& compression strength of 0.21 kg/sqm, when tested as per ASTM D-3575, including using double sided adhesive SIL SEAM TAPE(manufactured byThe Supreme Industries Limited) or equivalent of 2 mmx25 mmx 25 mmat four places per sq.mtr to the casted surface to formthe expansion joint. SIL FIL will become one side of the shuttering while the expansion j oint is being created.

Sq.M. 0.001 636 1 1.53 976 195,168 NA

PP75 Supplying and installing ribbed water stops with central bulbs as per relevant Indian Standards, drawings and specification

- 1.53 -

PP76 230 mmx6 mm RM 4834.1 300 1,450,230 1.53 460 46,012 380 230x10mm- 936.98

PP77 230 mmx8 mm RM 0.001 370 0 1.53 567 56,748 NA

PP78 150 mmx6 mm RM 0.001 280 0 1.53 429 42,945 NA

PP79 150 mmx8 mm RM 0.001 300 0 1.53 460 46,012 NA

PP80 Providing and placing in position at ground floor level, building paper (kraft paper) of 250 micron as per IS : 1397 between the concrete surfaces including the cost of all labours, materials etc. complete as per drawings, specifications as directed bythe Engineer in charge.

Sq.M. 0.001 50 0 1.53 77 38,343 39

PP81 Providing, applying and painting 85/25 industrial grade hot bitumen at the rate of 1.2 kg/sqm or 0.4 kg/sqm over concrete surface after cleaning with brushes and finallywith cloth soaked kerosene oil.

- 1.53 -

PP82 1.2 kg/sqm Sq.M. 0.001 116 0 1.53 179 1,071,163 175 1.7kg/sqm

PP83 0.4 kg/sq.m Sq.M. 0.001 59 0 1.53 90 270,552 NA

PP84 Providing, mixing and laying in position and curing ordinary plumconcrete of mix 1:4:8 mixusing size less than 80 mm boulder as coarse aggregate as per drawing and specification and direction of Engineer at all locations for ground filling.

Cu.M 0.001 3898 4 1.53 5979 1,195,779 5573 1:5:10 using 150mm boulder,ceme nt free issue

PP85 Supplying & laying of transformer rail 52 kg/mincluding fixing with guard angle & U-bolts and whatever necessary complete as per approved drawing & direction of Engineer.

MT 0.001 77330 77 1.53 118604 5,930,201 28284 Rail free issue

PP86 Supplying necessarymaterials and grouting under column base using following flowable grout including preparation of concrete surfaces complete as per specification and instruction of Engineer (No formwork to be paid separately)

- 1.53 -

PP87 Ordinarygrout with 1:2 cement : sand mix Cu.M 0.001 6683 7 1.53 10251 51,254 2397 cement free issue

PP88 Non- shrink grout of approved make (Combextra GP1 or equivalent) Cu.M 0.001 86000 86 1.53 131902 21,104,246 45711

PP89 Concrete mix 1:1:2 (1 part Cement : 1 part Sand : 2 parts of 6 mm downgraded stone chips) with non-shrink hand grout using approved admixture.

Cu.M 0.001 6016 6 1.53 9228 230,688 NA

PP90 Taking, delivery of grouting material from store and grouting for equipment foundations including preparation of concrete surfaces for TGlevel and other equipment foundations complete as per specifications and directions of Engineer (No formwork to be paid separately)

Cu.M 0.001 28000 28 1.53 42945 1,717,787 9750

PP91 Same as item no. (32) above except when non-shrink grout of approved make (Combextra GP2 or equivalent) are supplied bycontractor.

Cu.M 0.001 30000 30 1.53 46012 1,840,487 56280

Civil works for 3 x 800 MWGadarawara Power plant, M.P.

Item

No.

Description Unit Qty Quote ITD CEM Quote

Factor

Page 3 of 429

9

10

A B C D G H I J K L M N

SASAN

Rate Amount Rate Amount Rate Amount

Item

No.

Description Unit Qty Quote ITD CEM Quote

Factor

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

127

128

129

130

131

132

133

134

135

136

137

138

139

140

141

142

143

144

145

146

147

148

149

150

151

152

153

154

155

156

157

158

159

160

161

162

163

164

165

166

167

168

169

170

171

172

173

174

175

176

177

178

179

180

PP92 Supplying and providing inj ection of cement mortar with approved waterproofinggroutingcompoundat construction j oints in concrete under pressure through nozzles along the joint including installation of 12 / 18 mm dia threaded nozzles in concrete, grouting, sealing the nozzles etc. all complete as per drawings, specification and direction of Engineer.

Each 0.001 900 1 1.53 1380 69,018 NA

PP93 Providing, applying and fixing in position in line and level MS black medium qualitypipe sleeves with lugs including bends as per drawings of following sizes as embedment in masonryand concrete.

0.001 - 1.53 -

PP94 80 NB RM 0.001 577 1 1.53 885 22,123 693

PP95 100 NB RM 0.001 800 1 1.53 1228 30,693 977

PP96 150 NB RM 0.001 1145 1 1.53 1755 43,886 1457

PP97 200 NB RM 0.001 1766 2 1.53 2708 67,712 2094

PP98 Supplying and laying in position Netlone 300 or equivalent Geo-textile of 3 mm thk. (min.) having tensile stress of 6T/m2 in M/D as shown in design drawing belowcoal stock drainage pipe complete as per drawing.

Sq.M. 0.001 2100 2 1.53 3221 64,417 NA

PP99 Providing and laying as per Manufacturer' s Instruction acrylic based polymer modified cementitious composite coating system"Tapecrete of CICO" or Equivalent waterproofing to underground structure complete as per drawing and direction of Engineer.

Sq.M. 0.001 800 1 1.53 1227 613,496 NA

PP100 FORMWORK - 1.53 -

PP101 Supplying, installing, dismantling and removing following classes / class of formworks for foundation & sub- structure in all kinds of workincluding necessaryrendering of concrete surface after exposure as per drawings, specification and direction of Engineer.

- 1.53 -

PP102 Ordinary Sq.M. 6346.248 935 5,935,138 1.53 718 43,804,471 467

PP103 Plywood Sq.M. 4230.832 1021 4,320,628 1.53 850 51,850,855 439

PP104 Curved / Ornamental Sq.M. 4160.4 1582 6,579,825 1.53 1709 170,939 601

PP105 Supplying, installing, dismantling and removing following classes / class of formwork for superstructures in all kinds of workincluding necessaryrendering of concrete surface after exposure as per drawings, specification and direction of Engineer.

- 1.53 -

PP106 Ordinary Sq.M. 9519.372 833 7,925,466 1.53 1115 7,133,502 536

PP107 Plywood Sq.M. 6346.248 1304 8,276,457 1.53 1838 47,785,458 536

PP108 Curved / Ornamental Sq.M. 6240.6 1869 11,664,468 1.53 2704 1,352,214 601

PP109 Extra over formworkitem38.b for TGdeckslab, columns and beams using leak proof type laminated plywood shuttering, including designing the formworkfor the lateral thrust due to SCC.

Sq.M. 0.001 12870000593 12,870,001 1.53 2722 27,216,420 NA

PP110 Modular shuttering consisting of prefabricated Steel / / Timber beams & formwork modules including necessary fixtures, clips, pins, screws, fittings etc as directed by Engineer-in-Charge.

Sq.M. 0.001 391372457 391,372 1.53 6582 6,581,839 NA

PP111 Fixing in position and removing forms for pockets and openings less than 0.1 sq.mincluding necessaryrendering of concrete surface after exposure.

Each 0.001 400 0 1.53 613 368,097 952

PP112 REINFORCEMENT STEEL - 1.53 -

PP113 Supplying, cutting, bending and binding with 1.6 mmgalvanized annealed soft iron wire and placing in position following types of Jindal Panther TMT / High Yield steel deformed bars, of all diameters in RCC members as per drawings, including preparation of bar bending schedule as per specification and direction of Engineer. (Base rate of reinforcement steel will be applied for this item)

- 1.53 -

PP114 Using straight bar MT 0.001 49892 50 1.53 77395 356,015,238 5937 steel free issue

PP115 Using cut and bent bar MT 1044.02 49264 51,432,225 1.53 76431 321,009,811 4937 steel free issue

PP116 Using welded reinforcement mesh MT 0.001 50618 51 1.53 78508 23,552,341 NA

PP117 Extra over itemno -40-i, for bending of bars at site as per BBS and as directed bythe engineer. MT 0.001 2200 2 1.53 3374 337,423 NA

PP118 STRUCTURAL STEEL WORKS - 1.53 -

PP119 Preparation of fabrication drawing, receiving fabricated material at site, transporting, stacking at store, erecting structural steel works as per specification, drawings, including necessaryloading, stacking, including addition of gussets, base-plate, cap-plates, stiffeners, shimplates, spacers, washers etc. as specified / required and erecting in position byall sorts of mechanical means including suitable type of crane and erection bolts, nuts [shot blasting of steel surfaces to near white metal surface (Sa 2) and applying Inorganic Zinc Silicate primer of minimum75 micron (DFT)] etc. complete.

MT 0.001 19905 20 1.53 25008 410,132,931

PP120 Supplying,fabricatinganderectionincluding transportation, storing etc for Miscellaneous steel work in handrails, sag rods, ladders, platforms and other structures not included above.

MT 75.55 81534 6,159,867 1.53 119530 62,753,358 20899 Str.steel free issue

PP121 Providing and application of synthetic enamel paint of Shalimar make or equivalent and colour in two coats of minimum 50 micron each including surface preparation using wire brush, necessary cleaning and applying two coats of primer with Zinc chromate primer of DFT 25 microns per coat over steel sections alreadyhaving primer coats at all elevations

MT 0.001 7000 7 1.53 10736 2,684,043 3205

PP122 Providing and applying high performance epoxy based Polyamide cured painting systemof approved colour and shade consisting of Zinc silicate primer, intermediate (under) coat, finish coat and final finish coat including shot blast cleaning of steel surfaces to near white metal surface (Sa 2), to steel surfaces of all types, shapes and sizes, at all levels, to achieve an even shade, including all labour,material,consumablesequipment,handling, transportation, protection and cleaning, scaffolding and staging, testing, etc., all complete, as per specifications, drawings and instructions of the Engineer.

- 1.53 - NA

PP123 Blast cleaning byshot blasting of steel surfaces to near white metal surface (Sa 2) and applying Inorganic Zinc Silicate primer of minimum75 micron (DFT), including touch up painting for the damaged surfaces of primer.

MT 0.001 10300 10 1.53 15798 8,293,693 NA

PP124 Applying intermediate (under) coat over inorganic Zinc Silicate primer, (excluding cost of primer), consisting of minimum75 micron DFT epoxybased Titaniumdioxide/ Miscellaneous iron oxide (pigmented) including touch up painting for the damaged surfaces of intermediate paint.

MT 0.001 2500 3 1.53 3834 64,896,324 NA

PP125 Applying finish coat over Intermediate (under) coat, (excluding cost of Intermediate coat), consisting of minimum75 micron DFT Epoxybased colour pigmented finish Polyamide cured paint and Final Finish coat with minimum25 micron DFT Polyurethane colour pigmented finish paint, including final touch up painting for the damaged surfaces of Finish and Final Finish Paint.

MT 16925 4050 68,546,250 1.53 6212 105,132,045 NA

PP126 Dismantling of erected structural steel member at any elevation, lowering of material and carriage of dismantled material up to field fabrication shop or return to owners store, includingtemporarydismantling,cutting,re-welding, supporting and restoring to correct position of all temporarily dismantled members, realignment of adjacent connected members to their correct position (Weight of such temporarily dismantled and adjacent members not to be paid), including all labour, material, equipment, handling, transportation, all complete as per specifications, drawings and Instructions of Engineer.

MT 100 18000 1,800,000 1.53 27607 2,760,730 29355

PP127 Additions to, alterations in and / or modification of "Erection Marks" (of structural steel) either in erected position or in shop, including all labour, material, equipment, handling, transportation, cutting of parts, gouging of welds, cutting, grinding, fabrication, welding, drilling holes, straightening, removal of bends, raising to required levels, primer painting, with Zinc silicate primer, touch up painting, transportation, return of unutilized steel pieces to the Owner' s store, temporarilydismantling, cutting, re-welding, supporting and restoring to correct position of all temporarilydismantled members, realignment of adjacent connected members to their correct position (Weight of such temporarilydismantled and adjacent members not to be paid),.etc, including all labour, material, equipment, handling, transportation, all complete as per specifications, drawings and Instructions of Engineer.

- 1.53 - NA

PP128 In erected Position MT 50 30000 1,500,000 1.53 46012 2,300,608 NA

PP129 In fabrication yard MT 50 25000 1,250,000 1.53 38343 1,917,174 NA

PP130 Re-erection of dismantled fabricated structural steel members requiring addition to, alterations in and / or modification, (dismantling and additions to, alterations in and / or modification to be paid separatelyunder relevant items), includingalllabour,material,equipment,handling, transportation, carriage of modified "Erection Marks" fromthe field fabrication shop to erection site, raising to required levels, aligning in position, tackwelding, final welding, touch up painting, including temporarilydismantling, cutting, re- welding, supporting and restoring to the correct position of all temporarily dismantled members, realignment of adjacent connected members to their correct position (Weight of such temporarily dismantled and adjacent members not to be paid), etc., all complete as per specifications, drawings and Instructions of Engineer.

MT 80 30000 2,400,000 1.53 46012 3,680,973 NA

PP131 Providing,supplying,fabrication,transportation, erection and alignment including installation in position bybolting / welding / screwing of factorymade electro- forged gratings fabricated using mild steel conforming to IS : 2062, at all levels, in floorings, platforms, drain covers trench covers, walk-ways, passages, staircase treads with edge binding strips and anti-skid nosing etc. with all fittings and fixtures, (clips, bolts, self drilling and taping screws, nuts and lockwashers) etc., self drilling and tapping screws, welding, edge preparation, painting byblast cleaning of steel surfaces to near white metal surface (Sa 2 ) and applying high performance painting systemconsisting of zinc silicate primer (minimum 75 micron DFT) followed byintermediate coat (minimum 75 micron DFT) consisting of epoxy based Titaniumdioxide / Micaceous iron oxide and finished with finish coat (minimum 75 micron DFT) consisting of epoxybased coloured pigmented finish including all labour, material, equipment, handling, transportation, preparation of fabrication drawings, etc., all complete, as per specifications, drawings and instructions of Engineer.

MT 130 143705 18,681,663 1.53 214885 27,935,047 104495

PP132 Extra over item47.a above for finishing the fabricated grating unit with hot dipped galvanization @610 g. / Sq. M. over blast / chemicallycleaned steel surfaces, instead of painting with high performance painting system

MT 130 27000 3,510,000 1.53 41411 5,383,423 NA

PP133 Providing and fixing in position at all levels, high strength structural steel bolts (Propertyclass 8.8 ,class 10.9 and product grade C as per IS:1367) conforming to IS : 3757 and high strength structural hardened and tempered nuts (Propertyclass 8 as per IS:1367) conforming to IS : 6623 with hardened and tempered washers as per IS:6649 etc., up to and inclusive of 39 mmdiameter and 300 mm long, installing the same as per IS:4000 for structural steel works including all labour, material, equipment, handling, transportation, testing, all complete, as per specifications, drawings and instruction of Engineer.

MT 250 359705 89,926,276 1.53 546173 136,543,140 NA

PP134 Providing and fixing in position at all level, permanent mild steel bolts (Propertyclass 4.6 as per IS:1367 and MT 50 153705 7,685,255 1.53 230222 11,511,118 NA

PP135 Product grade C as per IS:1363), nuts, washers, etc. up to and inclusive of 39 mm diameter and 300 mm long for structural steel works, including all labour, material, equipment, handling, transportation, testing, all complete, as per specifications, Drawings and Instruction of Engineer.

- 1.53 - NA

PP136 Supplying, Fabricating, transporting, erecting in position at all levels the chequered plates for platformwalkways, stair treads, trenches, etc. Complete as per specification and approved fabrication drawings.

- 1.53 -

PP137 6 o/p chequered plate MT 6 80000 480,000 1.53 122699 3,067,478 21080

PP138 ARCHITECTURAL WORKS - 1.53 -

PP139 Damp Proofing / Protective Layer - 1.53 -

PP140 Supplying and laying 40 mmthick damp proof course with cement concrete (1:1:3 nominal mixbyvolume) with a minimum of 2%admixture of waterproofing compound etc. with all materials complete.

Sq.M. 700 220 153,860 1.53 337 235,981 436 Concerete free issue

PP141 Making plinth protection (minimum 75mm thick and minimum750mmwide) of cement concrete M20 over 75mmbed of drybrick ballast consolidated and grouted with fine sand including finishing the top smooth including shuttering.

Sq.M. 954 698 666,250 1.53 1071 535,562 138 Concerete free issue

PP142 Providing and injecting chemical emulsion for PRE- CONSTRUCTIONAL anti-termite treatment as per IS: 6313 Part (II) - 1981 and creating a chemical barrier under and around the column pits, wall trenches, basement, excavation, top surface of plate filling, junction of wall and floor along the external perimeter of building floor together with plinth protection, expansion joints, surroundings of pipes and conduits etc. complete (plinth area of building at ground floor under action area onlyshall be measured).

- 1.53 -

PP143 Chlorpyriphos emulsifiable concentrate conforming to IS:8944 - 1978 with 1%concentration (The workshall be get executed by an approved specialist agency and the contractor shall furnish 10 years guarantee on non-judicial stamp paper)

Sq.m. 100 220 22,000 1.53 337 33,742 94

PP144 Masonry - 1.53 -

PP145 Supplying and laying in position full brick work (FlyAsh bricks) of class designation minimum75 in foundation and plinth in cement-sand mortar (1:6) including mixing mortar, laying bricks, raking joints, curing etc. with all materials complete as per drawings and specifications.

Cu.M 1000 5865 5,864,659 1.53 8995 8,994,855 777 brick& cement free issue

PP146 Supplying and laying in position full brick work (FlyAsh bricks)ofclassdesignationminimum75in superstructure at various elevations in cement-sand mortar (1:6)

Cu.M 661.165 6164 4,075,125 1.53 9453 18,906,558 894 brick& cement free issue

PP147 Supplying and laying in positionbrickwork of class designation minimum75 in half brick (FlyAsh bricks) thick walls at various elevations in cement-sand mortar (1:4) with HB netting at everyfourth layer including mixing mortar, laying bricks, raking joints curing scaffolding, equipment as required etc. with all materials complete as per drawings and specifications.

Sq.M. 1500 6586 9,878,654 1.53 10101 15,151,275 NA

PP148 Optional for item(54 & 55) above for Laying in position Pre Engineered Non Load bearing light gauge steel (LGS) Structure (byJindal Fab Infra Private Limited or equivalent) constructed using hot dip galvanized (275 gsm) cold rolled C profile sections having tensile strength of 350 Mpa with all necessaryfasteners, fixtures and fittings etc complete.

- 1.53 - NA

PP149 External wall: The external / outer wall shall be Cladded with PPGI Sheet / PPGL Sheets (0.5 thk ) including screwing, and all complete etc.

Sq.M. 4500 1500 6,750,000 1.53 2301 10,352,737 NA

PP150 Internal wall: Internal Surface of the wall shall be cladded with 6mmCP board and 12.5 mmthick GypsumBoard and without paint.

Sq.M. 4500 1400 6,300,000 1.53 2147 9,662,555 NA

PP151 Supplying and fixing 17.5 cm. X 17.5 cmglass bricks in pattern with epoxy mortar match to the bricks as per manufacturer' s manual, drawings and directions of the Engineer in charge.

Sq.M. 200 158 31,500 1.53 242 48,313 NA

PP152 Dismantling of brick work and removal of debris fromthe site as directed byEngineer for all heads and lifts etc. Cu.M 150 800 120,000 1.53 1227 184,049 2202

PP153 Plastering - 1.53 -

PP154 Providing 18 mm thick cement plaster on exterior surfaces in two layers vertical, horizontal or curved up to any elevation and heights under layer 12 mm thick Cement plaster 1:6 (1 cement: 6 coarse sand) finishing with a top layer 6 mmthick cement plaster 1:4 (1 cement: 4 fine sand) including the cost of all materials, equipment, labour, scaffolding, curing, as per specification and the direction of Engineer-in-charge.

Sq.M. 3220.5 295 950,150 1.53 453 10,860,047 86

PP155 12 mm thick (minimum) cement-sand (1:6) plaster to interior faces of walls, beams columns etc. at various elevations including mixing etc., with all materials complete

Sq.M. 54300 194 10,514,255 1.53 297 16,126,122 76

PP156 Extra over plaster for supplying and fixing galvanized chicken wire mesh (gauge-22) at junctions of brickwork and concrete workwith an minimumoverlapping of 150 mmon either side of the junction and as per drawing & instruction of engineer, complete in all respect.

Sq.M. 0.001 250 0 1.53 383 1,533,739 172

PP157 Providing 6 mmthick cement plaster on ceiling wherever directed bythe Engineer in 1:4 (1 cement: 4 sand) mortar including the cost of all materials, equipment, scaffolding, etc. complete.

Sq.M. 1815 156 283,792 1.53 240 1,846,571 86

PP158 Supplying & laying Vineratex or equivalent granular decorative textured coat finish over plaster surfaces at various elevations including mixing, laying, finishing etc. with materials & labour complete as per manufacturers specification and drawing.

Sq.M. 1000 500 500,000 1.53 767 766,869 437

PP159 25 mm x 12 mm Drip course at various elevations to parapet, chajja, windowheads, door heads etc. with all materials at all elevations complete as per drawings and specification.

R.M. 2000 200 400,000 1.53 307 613,496 138

PP160 Flooring, Skirting and Dado - 1.53 -

PP161 40 mm. thick cement concrete floor 1:1.5:3 with top of concrete floor painted with two coats of Epoxypaint as per manufacturer' s specification.

Sq.M. 200 724 144,720 1.53 1110 221,963

PP162 Providing and laying overall 40 mmthick cement concrete flooring with metallic concrete hardener topping (ironite), at various elevations, consisting of under layer 28 mm average thick cement concrete of grade M 20 and top layer 12 mmthick metallic cement hardener consisting of mix 1:2 (1 cement hardener mix : 2 stone aggregate 6 mm nominal size) byvolume (Ironite shall be added in mix @ 1.5 kg / m2) including finishing of joints at maximumtwo (2) metres interval, or anysurface, and including 40 mmwide and 4 mmthick, glass strip placed between the panels including labour, materials and equipment and curing including scouring of surface providing necessaryshape etc. complete in all respects and in accordance with specifications and direction of the Engineer.

Sq.M. 355 404 143,349 1.53 619 22,914,978 256

PP163 Providing and laying overall 40 mmthick cement concrete (grade M25) flooring including cement slurry, finishing of joints at maximumtwo (2) metres interval, or anysurface, and including 40 mmwide and 4 mmthick, glass strip placed between the panels including labour, materials and equipment and curing including scouring of surface providing necessaryshape etc. complete in all respects and in accordance with specifications and direction of Engineer.

Sq.M. 1962.5 368 722,985 1.53 565 5,650 357

PP164 Providing 25 mmthick and 150 mmhigh cement mortar (1:3) skirting finished with a floating coat of neat cement at all elevations including labour, materials and equipment and curing complete in all respects and in accordance with specifications and direction of the Engineer

Sq.M. 2000 326 651,525 1.53 500 999,270 515

PP165 Providing and laying non-skid fullyvitrified 10 mmthick tiles similar to "MARBONITE","FERRASTONE",of "BOSS Profile Ltd." or similar approved laid on 20 mm thick cement mortar (1:4) including grouting the joints with white cement and matching pigments etc., in floors, skirting and dado complete as per manufacturer' s specification . (Base rate of cement will be applied for this item)

- 1.53 -

PP166 600 mmx600 mm(Base rate = Rs. 1500/-) Sq.M. 2500 1963 4,908,125 1.53 3011 7,527,782 1799

PP167 400 mmx400 mm(Base rate = Rs. 1270/-) Sq.M. 1500 1717 2,575,725 1.53 2634 3,950,489 1721

PP168 Supplying & laying 50 mm thick floor with matt finish unglazed ceramic tiles of approved colour and shade and of minimumthickness 7.2-7.5 mmover necessaryunder bed and 15 mmthick cement sand mortar 1:3 including cement slurry and joining with white cement slurry mixed with pigment to match the shade of tile complete with all materials as per specification and drawing. (Base rate = Rs. 1000/-) (Base rate of cement will be applied for this item)

Sq.M. 300 1433 429,825 1.53 2197 659,239 NA

PP169 Same as above item no 70 but with tiles of designer series of Kajaria, Nitco or of approved equivalent manufacturers (Base rate = Rs. 1200/-) (Base rate of cement will be applied for this item)

Sq.M. 100 1717 171,715 1.53 2634 263,366 NA

PP170 Supplying and placing 5 mmthick glazed ceramic tiles of approved make, size in skirting, dado etc on 12 mmthick 1:3 cement mortar in base and jointed with white cement slurry and matching pigments etc, including labour, materials and equipment, cleaning of surfacelaid as per manufacturer' s instruction and direction of Engineer in charge. (Base rate = Rs. 750/-) (Base rate of cement will be applied for this item)

Sq.M. 2600 1433 3,725,150 1.53 2197 5,713,407 NA

Page 4 of 429

9

10

A B C D G H I J K L M N

SASAN

Rate Amount Rate Amount Rate Amount

Item

No.

Description Unit Qty Quote ITD CEM Quote

Factor

181

182

183

184

185

186

187

188

189

190

191

192

193

194

195

196

197

198

199

200

201

202

203

204

205

206

207

208

209

210

211

212

213

214

215

216

217

218

219

220

221

222

223

224

225

226

227

228

229

230

231

232

233

234

235

236

237

238

239

240

241

242

243

244

245

246

247

248

249

250

251

PP171 Supplying & laying 40 mm thick acid/alkali resistant floor with 20 mmthick unglazed ceramic vitreous acid / alkali resistant tiles laid on potassiumsilicate based under bed mortar as per IS: 4832 (part I) over a primer coat and alkali resistant bituminoustic readymade paint conforming to IS: 158 with 6 mmwide joints in between tiles filled with resin type (epoxy/Furane) mortar conforming to IS- 4832(Part-II) including preparation of surface, acid curing sealing the edges bybituminastic filler etc complete as per specification, drawing and direction of Engineer. (Base rate = Rs. 4450/-)

- 1.53 -

PP172 The tile samples shall be approved by Engineer before execution. Sq.M. 900 1156 1,040,625 1.53 1773 1,596,047 2811

PP173 All as per item(73-a) above but with Acid/Alkali resistant paint over 20 mmthick unglazed ceramic normal tile all as per specification complete.

Sq.M. 400 6331 2,532,500 1.53 9710 3,884,194 NA

PP174 Supplying and laying polished kota stone slab of approved size and 20 mmthick (the tile sample shall be got approved fromthe Engineer) in flooring and skirting laid on 20 mm thick cement mortar 1:4 bedding, cement floated mixed with pigment, all joints well filled on completion, including polishing at site all as per specifications and directions of Engineer. (Base rate = Rs. 350/-) (Base rate of cement will be applied for this item)

Sq.M. 500 964 482,125 1.53 1479 739,454 940

PP175 Providing, supplying and laying 2 mmthick homogeneous flexible heavy duty antistatic PVC tiles of approved manufacture, size and colour on floor, dodo etc using rubber based adhesive of approved manufacture including rolling with light wooden roller weighing about 5 kg, material, labour, equipment etc. complete as per drawing and direction. (Base rate = Rs. 750/-)

Sq.M. 200 1488 297,500 1.53 2281 456,287 1873

PP176 Providing and laying 18 mmthick Polished granite stone (slab) over 20 mmthick base in cement mortar 1:4 (1 cement : 4 coarse sand) including labour materials and equipment and also including scouring of surface providing necessaryshape etc. complete in all respect with standard accordance with specification & direction of engineer. The joints shall be grouted with white cement by mixing & matching colour pigment. (Base rate = Rs. 2750/-) (Base rate of cement will be applied for this item)

Sq.M. 3000 3484 10,452,750 1.53 5344 16,031,789 7217

PP177 Supplying, fitting and fixing Polished granite slabs 12 mm thick in columns, walls, facias, skirting, dado etc. with cement mortar (1:3) including making suitable arrangement to hold the stone properlybybrass/copper hooks including filling the j oints with necessarycement mortar (1 white cement : 2 stone dust) with admixture of pigment matching the shades, all complete including edge molding. (Base rate = Rs. 2000/-) (Base rate of cement will be applied for this item)

Sq.M. 500 2697 1,348,375 1.53 4136 2,068,055 8265

PP178 Providing and laying 18 mmthick Adanga White Marble slab (1.5 mx 0.6 m) flooring over 22 mmthick base in cement mortar 1:4 (1 cement : 4 coarse sand) having 5 mmthick white cement topping, including labour materials and equipment and also including scouring of surface providing necessaryshape etc. Complete in all respect with standard accordance with specification & direction of engineer. The j oints shall be grouted with greycement by mixing & matching colour pigment. (Base rate = Rs. 1600/-) (Base rate of cement will be applied for this item)

Sq.M. 500 2427 1,213,375 1.53 3722 1,861,000 4593

PP179 Providing and laying over-all 40 mm thick granite work with 18 mmthick greygranite in flooring above as per floor pattern indicated in drawing and/or instructed bythe Engineer / Architect. (Base rate = Rs. 2750/-) (Base rate of cement will be applied for this item)

Sq.M. 100 3734 373,425 1.53 5727 572,736 7217

PP180 18 mmthick marble slab skirting or dado matching with floor marble slab as per instruction of engineer. (Base rate = Rs. 1600/-) (Base rate of cement will be applied for this item)

Sq.M. 100 2527 252,675 1.53 3875 387,537 9263

PP181 Supplying and fixing glass mosaic tiles 20 x 20 x 4.5 mm thick in pattern as per drawings and directions of the Engineer in charge.

Sq.M. 25 3077 76,919 - NA

PP182 Supplying & Laying precast cement concrete tiles (minimumsize 600 mmX 600 mm) 20 mm. thick on roof surface including preparation of bed with 15 mmthick sand cement mortar (4:1) to proper slope as per direction of the Engineer - in -charge complete including cost of all labour and materials etc.

Sq.M. 800 2527 2,021,400 1.53 - NA

PP183 Doors, Windows, Ventilators and Rolling Shutters (Rate shall be inclusive of cost of all required hardware) - 1.53 -

PP184 Supplying, fitting & fixing full glazed aluminumdoor with minimum 15 micron colour anodized aluminum frame and shutter of approved colour and make, complete with all fitting and fixtures (e.g. push plate, double actingfloor spring, locks etc.) sealing, grouting frames, rawbolt fixing, etc., as required with all materials complete including 8 mmthick toughened float glass (Vendor' s drawing to be approved by Architect before fabrication).

- 1.53 -

PP185 Single leaf Sq.M. 20 10500 210,000 1.53 16104 563,649 7808

PP186 Double leaf Sq.M. 50 8500 425,000 1.53 13037 651,839 7808

PP187 Supplying and fixing of best quality anodized aluminum windows and ventilators conforming to IS: 1949 & IS: 1948 including supplying and fixing approved glazing including all fixtures and fittings, fixing material such as puttyetc. and all labour complete as per specification, drawing and direction of Engineer. (thickness of aluminumsections is 3 mm)

- 1.53 -

PP188 With 4 mmthickclear float glass Sq.M. 500 4000 2,000,000 1.53 6135 3,067,478 4840

PP189 With 4 mmthickground glass Sq.M. 50 4300 215,000 1.53 6595 329,754 4840

PP190 With 6 mmthickclear toughened glass Sq.M. 29 5000 145,000 1.53 7669 383,435 5660

PP191 With 6 mmthick wired glass Sq.M. 400 4500 1,800,000 1.53 6902 2,760,730 5465

PP192 Fire proof glass (2hr fire rating) Sq.M. 100 7000 700,000 1.53 10736 1,073,617 NA

PP193 Extra for colour anodizing over and above itemno 84 natural colour anodizing Sq.M. 1200 450 540,000 1.53 690 828,219 NA

PP194 Supplying, erecting and fixing heavydutysteel louvers from approved manufacturer at various elevations including frame, louvers fitting including bird screen as per specification and fixture, mastic caulking, grouting the frame, rawl bolt including one coat of primer and two coat of approved synthetic paint with all material, labour, equipment etc. complete .

Sq.M. 200 3800 760,000 1.53 5828 1,165,642 6402

PP195 Supplyingandinstalling partition fromapproved manufacturer at all elevations in 100 mm x 45 mm and bottomframe 200 mmx 45 mmof 3 mmthick Anodized aluminum section of best approved quality frame work including full glazing with 8 mm thick toughened float glass superior qualityfirst grade of Modi float or equivalent approved byEngineer including frame, glazing beds, fittings and fixture, mastic caulking, putty, grouting the frame, rawl bolt, sealing after finishing etc. (glazing to be fixed to the framework with anodized aluminumchannels or angles and rubber beading all around. The itemrate shall include for all works including fixing of partitions to floor and roof and fixing of glass etc. complete as per specification and directions)

Sq.M. 400 5600 2,240,000 1.53 8589 3,435,575 6089

PP196 Providing, erecting and fixing 45 mm thick flush type hollowmetal doors with two outer sheets of 18 G rigidly connected with continuous vertical 20 Gstiffener at the rate of 150 mmcentre to centre and reinforced by18 G pressed steel channel fixed in pressed steel frame as per IS: 4351. Mineral wool insulation is to be provided inside the channel with fixtures, fittings, hold fast and locking arrangements etc. including finishing with two coats of zinc chromate primer and two coats of Synthetic enamel paint.

- 1.53 -

PP197 Single leaf shutters Sq.M. 200 8402 1,680,365 1.53 12886 2,577,241 8744

PP198 Double leaf shutters Sq.M. 250 11024 2,756,124 1.53 16909 4,227,175 8822

PP199 Supplying fitting and fixing fullyglazed frame less door (10 mmthick toughened) fitted with Stainless steel end caps with locating lug and screw. Single extrusion profile for universal frameless glass door rails. Trackshall be extruded hardened aluminumwith a maximumchannel wall thickness of 4.20 mmin 6060-T5 alloy. The weight of the extrusion shall be no less than 5.76 kg per lineal meter length. The rate should include the twin wheel carriage with a stabilizer wheel to prevent free side swing of the slydstakdoor panel, all complete as per manufacturer' s detail, drawing and direction of the Engineer in charge including the cost of glass.

Sq.M. 25 15000 375,000 1.53 23006 575,152 14834

PP200 Supplying and erecting including assembling, fitting and fixing best quality fully glazed openable, fixed or partly openable type steel windows,ventilators with frames fromapproved manufacturer including fabrication, one coat of shop paint, all fittings and fixtures as per Schedule of fixtures, at various elevations, includingglazing beads, frames, shutters, transom, coupling mullions, weather bars, inclusive of supplyof caulking, mastic, puttyetc. including supplying, fitting and fixing 4 mm thick clear float glass as per drawings, specification & windowschedule.

Sq.M. 0.001 3190 3 1.53 4893 978,525 3615

PP201 Extra over item(90) above for providing 5 mmthick clear float glass. Sq.M. 30 3410 102,300 1.53 5230 156,901 NA

PP202 Extra over item(90) above for providing 6 mmthick wired glass. Sq.M. 10 3960 39,600 1.53 6074 60,736 NA

PP203 Providing fitting and fixing fire proof metal doors with mineral wool insulation, conforming to IS: 3614 (Parts I &II) meeting TAC requirements and having a fire rating of two hours (min) at all levels and for all type of work, including all labour, materials workmanship including preparation of working drawings, equipments, handlings, transportation, steel frames ,shutter insulation, fitting, hinges, panic lock, latch, horizontal full width lever, openable on pressing door stoppersholdfasts/expandinganchorboltsbolting arrangements , grouting frames , blast cleaning of steel surfaces to near white metal surfaces applying inorganic zinc silicate primer of minimum 75 micron (DFT) and finish with suitable fire retardant painting systemtesting etc. all complete as per drawings, specification

- 1.53 -

PP204 Single leaf Sq.M. 130 23000 2,990,000 1.53 35276 4,585,879 28106

PP205 Double leaf Sq.M. 100 24000 2,400,000 1.53 36810 3,680,973 28106

PP206 Providing and fixing doors fabricated from roll formed section made of Galvanized steel colour coated with total thickness of 0.6 mm. Coated sections should be painted with 12-16 microns thick polyester paint over a primer coat of Epoxyprimer of 5-7 microns thick. The frame and shutter should be cut and mitre jointed with corner bracket made of CRCA electroplated made of CRCA electroplated EPDM gasket should be used all around glass in shutter,

Sq.M. 10 9000 90,000 1.53 13804 138,036 NA

PP207 between frame and glazed shutter and both sides of fixed glass. The frame along with the shutter should be fixed to brick/concrete masonrybyusing Nylon self expanding caps and driving MS electroplated 80 mmlong screws into the caps through frames similar to NCL ALTECK and Seccolor ltd.

- 1.53 - NA

PP208 Providing and fixing factorymade 38 mmthick solid core flush door fromapproved manufacturer with frame of teak wood and well matched commercial plyveneering wood with vertical grains or cross bands and face veneer on both faces of shutters including providing and fixing lipping with first class wood batten 10 mm thick on all edges of shutters including anodized aluminumtower bolt and mortised lock, with one coat of approved primer and two coats of synthetic enamel paint of approved make and shade, complete in all respect.

Sq.M. 700 13500 9,450,000 1.53 20705 14,493,832 8510

PP209 Same as above item no 93 but low in height as per drawing and direction of the engineer in charge. Sq.M . 50 12500 625,000 1.53 19172 958,587 NA

PP210 Supplying and fixing glazed vision panel (of minimumsize 200 mmX 200 mm) to doors with 6 mmthick glazing of tempered safetyglass or wired glass including fitting and fixture with all material, labour, equipment etc. complete as per the instructions of Engineer. (Actual size of vision panel will be measured and paid)

Sq.M. 5 10000 50,000 1.53 15337 76,687 13273

PP211 Supplying, fitting and fixing in position PVC door upto 1.0 M. wide including PVC frame and shutter of approved colour and make of approved SystemDS-06 or approved equal, complete in all respect including all accessories, complete hardware, grouting, fitting and fixing hardware with necessaryfittings etc. as per manufacturer' s specification, drawing and instruction of Engineer/Architect

Sq.M. 50 6000 300,000 1.53 9202 460,122 NA

PP212 Supplying, erecting and fixing of steel rolling shutter with 18 SWGsteel laths with the provision of manual operation arrangement / mechanical gear operation arrangement, of any size with slide guides, bottomrail brackets, door supervision shaft, housing box at top with all necessaryfittings, fixtures, locking arrangements gear, mechanical device etc. including finishing with 2 coats of Synthetic enamel paint of approved qualityover one shop coat of zinc chromate primer etc. complete as per drawings specification and direction of Engineer including, labour, material equipment etc. complete (Measurement on the basis of opening covered by rolling shutters).

- 1.53 -

PP213 Hand operated Sq.M. 100 4500 450,000 1.53 6902 690,182 4684

PP214 With mechanicallyoperated Sq.M. 18 6000 108,000 1.53 9202 1,380,365 6246

PP215 With electricallyoperated Sq.M. 200 25000 5,000,000 1.53 38343 7,668,694 12492

PP216 Providing and fixing automatic operation systemfor doors (4 nos. sliding opening of openable size 2.4 mx 2.4 m) suitable for door openings consisting of sliding door shutters, opening on opposite sides, complete with solid state controller unit heavydutyreversible associate cabling and circuit etc. so as to provide flawless automatic operation, with all labour, material, equipment, handling, transportation, workmanship, preparation of working drawings, testing etc all complete as per specification, drawings, testing etc all complete as per specification, drawings and instructions of the Engineer. The Electric operating mechanismshall be mounted and concealed within Aluminumheader and the controller unit shall be Micro processor based. The bottom rail of the door shall have security lock. Weather

Sq.M. 25 30000 750,000 1.53 46012 1,150,304 NA

PP217 stripping shall be provided along the edges of sliding door panels. Basic sensor system shall be of active infrared sensor type, header mounted on each side of the door and shall remain active throughout the door opening and closing cycle. Two pulsed infrared photo

- 1.53 - NA

PP218 Glazing - 1.53 -

PP219 Providing and fixing Unitised vertical Structural glazing system with IG unit(insulated double Glass unit) for vision panel and single glass for spandrel panel of approved make having main frame of verticals and horizontals made out of specially designed extruded aluminumsections to withstand wind pressure of 200 kg/sq.m. at a height to the Masonry/RC wall with necessary clamps, brackets and anchor fasteners . All clamps and brackets shall be Mild steel Hot Dip galvanized minimum 80 microns thick and shall conformto IS: 4756-1996 .The extruded aluminumsections shall be anodized as per the approved colour with anodic coating of minimum 20 microns .Extruded section shall be 6063 T5 or T6 alloy conforming to ASTM B 221 or BSH79 conforming to IS: 63400. Anyother fastening straps, clamps, nuts, bolts, rivets, washers etc. shall be stainless steel SS 304 grade or aluminum. All tapes shall be Norton make. Rate shall include providing Column closers, Fire stops at all floor levels. rate shall include to provide column closers , Fire stops (at all elevations. to be done under specific instruction glazing). Rate shall include EPDM gaskets, open cell polythene backer rods etc. The structural glazing sealant shall be DowCorning 983 and weather sealant shall be DowCorning 991H. All sealant shall be blackin colour. Rate shall include to conduct the performance test conforming to ASTM specifications, etc. complete all as directed.

Sq.M. 200 1800 360,000 1.53 2761 552,146 NA

PP220 Supplying bubble free float glass set in puttyand fitted and fixed with nails and puttycomplete in all floors. - 1.53 - NA

PP221 6 mmthickclear glass Sq.M. 15 800 12,000 1.53 1227 18,405 NA

PP222 4 mmthickclear glass Sq.M. 15 700 10,500 1.53 1074 16,104 NA

PP223 10 mmthickclear glass Sq.M. 15 1200 18,000 1.53 1840 27,607 NA

PP224 4 mmthickfigured glass Sq.M. 15 1500 22,500 1.53 2301 34,509 NA

PP225 Supplying and fixing composite double glazing consisting of clear float glass of 6 mmthick on one side and tinted glass of 6 mmthick on other side and are separated by 12 mm air gap hermetically sealed by beading of anodized aluminum.

Sq.M. 200 3500 700,000 1.53 5368 1,073,617 NA

PP226 Extra for 12 mm clear toughened float glass on both sides instead of 6 mmthick glass Sq.M. 200 3200 640,000 1.53 4908 981,593 NA

PP227 Extra for 8 mmclear toughened float glass on both sides instead of 6 mmglass Sq.M. 100 3000 300,000 1.53 4601 460,122 NA

PP228 Supplying and fixing Glaverbal heat reflecting glass of thickness 8 mmof AIS float glass or of approved equivalent Sq.M. 10 5000 50,000 1.53 7669 76,687 NA

PP229 Painting - 1.53 -

PP230 Providing and applying white cement puttyof minimum 2 mm thick (over plaster) at various elevations in interior surfaces with all materials etc. complete as per specifications

Sq.M. 1000 120 120,000 1.53 184 184,049 97

PP231 Providing and applying Oil bound crylic distemper of approved make consisting of a priming coat with approved primer over white cement putty and two (2) finishing coats of paint of approved manufacture and quality approved shades, including labour, materials, equipment and scaffolding etc. complete as per manufacturer' s instructions at all elevations.

Sq.M. 2683 160 429,280 1.53 245 9,815,929 76

PP232 Providing and applying acrylic emulsion paint of approved make consisting of a priming coat with approved primer over white cement puttyand two (2) finishing coats of paint of approved manufacture and qualityapproved shades, including labour, materials, equipment and scaffolding etc. complete as per manufacturer' s instructions at all elevations.

Sq.M. 5500 160 880,000 1.53 245 1,349,690 144

PP233 Providing and applying chemical resistant paint of approved make applied on a clean surface free of oils etc. after applying approved primer coat to seal the surface porosity followed bytwo (2) full coats of the paint, including labour, material, equipment, and scaffolding etc. at all elevations and heights as per manufacturer' s specification and direction of the Engineer.

Sq.M. 1000 320 320,000 1.53 491 490,796 427 acid & alkali resistance paint

PP234 Providing and applying three (3) coats of water proof cement paint of approved manufacturer (Snowcemor equivalent approved bythe Engineer-in-charge) and in approved shades to plastered surfaces including cleaning and preparing the wall surface, curing etc. complete as per specifications and directions of Engineer at all elevations including labour, material, scaffolding etc. complete.

Sq.M. 3755.5 180 675,990 1.53 276 5,245,387 66

PP235 Providing and applying three (3) coats of synthetic plaster composed of synthetic fiber and petroleumbased chemical similar to 'RENOVO' of approved shade to plastered surfaces including cleaning and preparing the wall surface, curing etc. complete as per specifications and directions of Engineer at all elevations including labour, material, scaffolding etc. complete.

Sq.M. 1500 350 525,000 1.53 537 805,213 437

PP236 Providing and application of ready mix two component resin and polymer bonded granular textured coating finish of approved colour and shade for all types plaster and / exposed concrete surfaces in all kinds of workat all levels including preparation of surfaces , preparation of working drawing,labour,materials,equipments,handling, transportation, mixing , laying, applying , finishing, testing, curing, making grooves, scaffolding, staging, etc. all complete as per specifications, drawing and the instruction of the Engineer for the following nominal thickness:

- 1.53 - 437

PP237 1.2 mmpigmented granular for interior application Sq.M. 2500 420 1,050,000 1.53 644 1,610,426 NA

PP238 2.5 mmnatural stone chips for external finish in readymix. Sq.M. 2500 480 1,200,000 1.53 736 1,840,487 NA

PP239 Painting with best quality synthetic enamel paint of approved make and brand including smoothening surface by sand papering etc. including using of approved puttyetc. on the surface , if necessary:

- 1.53 -

PP240 On timber or plastered surface: Sq.m. 1000 150 150,000 1.53 230 230,061 211

PP241 False Ceiling - 1.53 -

Page 5 of 429

9

10

A B C D G H I J K L M N

SASAN

Rate Amount Rate Amount Rate Amount

Item

No.

Description Unit Qty Quote ITD CEM Quote

Factor

252

253

254

255

256

257

258

259

260

261

262

263

264

265

266

267

268

269

270

271

272

273

274

275

276

277

278

279

280

281

282

283

284

285

286

287

288

289

290

291

292

293

294

295

296 297

298

PP242 Providing and fixing Glass Reinforced (GRG) false ceiling systemhaving fine texture finish, at all levels for all kind of workwhich includes providing and fixing GI perimeter Channels of size 0.55 mmthickness having one flange of 20 mmand another flange of 30 mmand a web of 27 mmalong with perimeter of ceiling, screwfixed to brickwall / partition with the help of nylon sleeves and screws at 610 mmcenters. Then suspending GI intermediate channels of size 45 mm, 0.9 mmthickwith two flanges of size 45 mm, 0.9 mmthickwith two flanges of size 15 mmeach fromthe soffit at 1200 mm centers with ceiling angle of width 25 mmx25 mmx0.55 mm thickfixed to soffit with GI cleat and steel expansion fastener. Ceiling section of 0.55 mmthickness having knurled web of 51.5 mmand two flanges of 26 mmeach with lips of 10.5 mmare then fixed to the intermediate channel with the help of connecting clips and in direction perpendicular to the intermediate channel at 457 mmcenters. 12 mmthickGRG Board is then fixed to the ceiling sections with 25 mmdrywall screws at 230 mmcenters .The itemto include all labour, material supporting equipments fromRCC, preparation of working drawing, providing openings for AC ducts, return air grill light fixtures, etc all complete as per specifications, drawings and direction of the Engineer in charge.

- 1.53 -

PP243 12 mmthick GRGplaster board, finished seamless. Sq M. 1000 1241 1,240,625 1.53 1903 1,902,795 300

PP244 Providing and fixing insulation of resin bonded mineral wool 25 mmnominal thickness conforming to IS: 8183, having a density of 32 kg/cum for glass wool or 48 kg/cumfor rock wool insulation over false ceiling , at all levels for all kinds of work, handling transportation etc. including all labour, material, scaffolding, equipment, wrapped in polyethylene sheet bags with or without framed strips 25 x 3 mm(minimum) at maximum300 mm. centre to centre spacing to hold the insulation between horizontal sheeting runners, keeping in position with galvanized hexagonal wire netting of 0.3 mmwire diameter and 19 mm mesh size for glass/rock wool as per specifications drawings and instruction of the Engineer .

Sq M 200 525 105,000 1.53 805 161,043 NA

PP245 Providing and fixing insulation of resin bonded mineral wool 50 mmnominal thickness conforming to IS: 8183, having a density of 32 kg/cum for glass wool or 48 kg/cumfor rock wool under deck insulation, at all levels for all kinds of work, handling transportation etc. including all labour ,material, scaffolding, equipment, wrapped in polyethylene sheet bags with or without framed strips 25 x 3 mm (minimum) at maximum300 mm. centre to centre spacing to hold the insulation between horizontal sheeting runners, keeping in position with galvanized hexagonal wire netting of 0.3 mmwire diameter and 19 mmmesh size for glass/rock wool as per specifications drawings and instruction of the Engineer .

SQM 100 709 70,875 1.53 1087 108,704 NA

PP246 Providing and fixing Polyisocyanurate or rigid fenolic foam (fire and non toxic) preformed insulation slab conforming to IS: 12436/ IS: 13204 having 30 mmnominal thickness, having a densityof 32 kg/cumbottomface of the slab laminated with 0.05 mmthick aluminumfoil, as under deck insulation at all levels fixed with adhesive followed by metal expansion fasteners at the spacing not more than 450 center to center including all labour ,material, scaffolding etc. all complete as per specifications drawings and instruction of the Engineer

Sq.m. 3000 1313 3,937,500 1.53 2013 6,039,097 NA

PP247 Preparation of grading underbed with 1:1 1/2:3 concrete of cement: coarse sand: 12 mmdown stone chips (by volume) at various elevations for roof waterproofing works etc. complete including mixing laying, curing etc. with all materials complete as per drawing and specification.

Cu.m . 500 5200 2,600,000 1.53 7975 3,987,721 NA

PP248 Preparation of minimum25 mmto maximum50 mmthick grading underbed with 1:4 cement: coarse sand mortar (by volume) at various elevations for roof waterproofing works including mixing, laying, curing etc. with all materials complete as per drawings and specifications.

Sq.M 11000 210 2,310,000 1.53 322 3,542,937 NA