Professional Documents

Culture Documents

Reciprocating Compressor Spec

Uploaded by

santoshblonkar0 ratings0% found this document useful (0 votes)

29 views2 pagese

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documente

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

29 views2 pagesReciprocating Compressor Spec

Uploaded by

santoshblonkare

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You are on page 1of 2

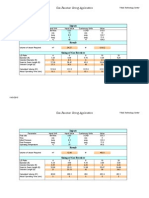

Copressor Type Reciprocating

Inlet Capacity 7906 NM3/Hr

Suction Temp, oC 1.52

Suction Pressure, Bar A 4.5

Service Ammonia

Mol Weight 17.03

1 GENERAL

1.1 Design Code API 618

1.2 Frame Rating @ RPM *

1.3 Lubricated / non lubricated Non Lubricated

1.4 Single / Double Acting Double Acting

1.5 Model Designation *

1.6 No. of Stages One

2 COMPRESSOR PERFORMANCE

2.1 Rated Capacity (Nm3/Hr) / KG/Hr 7906 / 6000

2.2

Final Stage Descharge Pressure @

pulsation suppressor o/l

8.5 Bar A

2.3

Discharge Temp

o

C (Adiabatic)

*

2.4

Discharge Temp

o

C (Predicted)

*

2.5

Shaft absorbed power at motor coupling

KW

*

2.6 Compressor Speed rpm *

2.7 Recommended Motor KW *

2.8 Motor Rating as per API 618 Yes

2.9

Capacity Control range % (Normal

Operation)

0-25-50-75-100

2.10 Capacity Control

Both (With Steps

+ Bypass)

2.11 Average Piston Speed <4.064

2.12 Elcetrical Classification

Zone II, Group

IIA, Temp CL-T1

3 UTILITY REQUIREMENTS

3.1 CW Temp in/out oC 33.5 / 43.5

3.2 Total CW Required M3/Hr *

3.3 Nitrogen Requirement, NM3/Hr *

3.4 Auxilary Electrical Load, KW *

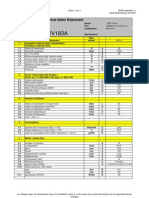

4 MECHANICAL FEATURE

4.1 No of Crank Throws * Two

4.2 Distance piece type as per API 618 Type D

4.3 No of Cylinder / stage Two

4.4 Cylinder Dia, Stage 1, mm 330.2

4.5 Rod dia stage 1/2, mm 50.8

4.6 Stroke, mm 228.6

4.7 Liner Thk, mm 19

4.8 Vol Efficeincy % (I) Average 79

4.10 Max Allowable Rod Load C/T KN 123

4.11 Combined Rod Load C/T KN (Stage 1) 46

4.12 Min Rod reversal degrees >15 140

4.13 MAWP 1 / Bar g 24

4.14 Safety valve set pressure 1/2 bar g As per API 618 8.78

4.15 Design Temp oC 220

4.16 Type of Valve (Stage I / II) MAGNUM

4.17

No of Valves (Suction / Discharge) per

cylinder

4-Apr

4.18 Valve Velocity, m/sec 46

4.19 Pulsation dampeners provided or not Yes

4.20 Pulsation Analysis

As per Approach

'1'

No

5 MATERIAL OF CONSTRUCTION

5.1 Cylinder Stage 1 Steel

Moly CI / CI FG 260

/ IS 210

5.2 Cylinder Liner 1 CI CI

5.3 Piston Steel AL

5.4 Piston Rod SS SS

5.5 Valve Seat / Seat Plate

SS / High temp

thermoplastic

SS

5.6 Valve Spring SS SS

5.7 Rod Pressure packing rings PTFE

5.8 Wear Bands Required PTFE

5.9 Type of drive-direct / v- belt / gear Direct Direct

6.0 INSPECTION & TESTING

7.0 SCOPE OF SUPPLY

8.0 SPARE PARTS

8.1 Mandatory Spare Parts

8.2 Commissioning Spare Parts

9.0 GUARANTEES

9.1 FLOW RATE Nm3/Hr (NNT)

9.2 DEL PRESSURE (-0%) KG/CM2A

9.3 POWER REQUIRED AT RATED POINT (+0%)

9.4 NOISE LEVEL

Less than 90 dBA

@ 1m

You might also like

- IMO S6A3-MPTK engine specification sheetDocument3 pagesIMO S6A3-MPTK engine specification sheetvikas_ojha54706100% (6)

- Volkswagen Audi Transmision Caja Automatica 01M Manual Despiece InglesDocument5 pagesVolkswagen Audi Transmision Caja Automatica 01M Manual Despiece InglesIngrid Garcia de Jauregui67% (6)

- Mitsubishi S4K EngineDocument25 pagesMitsubishi S4K EngineDushan Alwis100% (2)

- Application Manual, Kurbota EngineDocument364 pagesApplication Manual, Kurbota EngineEl Haji Roku88% (8)

- Liebherr T282C SpecificationsDocument22 pagesLiebherr T282C Specificationsbas100% (1)

- ST-135 Steel Pistons, Cylinder Liners, Scraper Rings, Cylinder Head Gaskets PDFDocument5 pagesST-135 Steel Pistons, Cylinder Liners, Scraper Rings, Cylinder Head Gaskets PDFPopa MihaiNo ratings yet

- Ingersoll-Rand P185Wjd: Bid SpecificationsDocument7 pagesIngersoll-Rand P185Wjd: Bid SpecificationsFelipe HernándezNo ratings yet

- Data Sheet: LPG Filling Pump P-001/002/003/004/005/006Document5 pagesData Sheet: LPG Filling Pump P-001/002/003/004/005/006Denstar Ricardo Silalahi100% (1)

- Yanmar 4jH4E BrochureDocument2 pagesYanmar 4jH4E Brochuretowndock67% (3)

- Ingersoll-Rand Compressors 15T2Document2 pagesIngersoll-Rand Compressors 15T2Dedi Mulyana100% (1)

- Workshop PDFDocument326 pagesWorkshop PDFИвайло ГайдарскиNo ratings yet

- SECTION 303-01B: Engine - 4.6L and 5.4L 2000 F-150 Workshop Manual AssemblyDocument35 pagesSECTION 303-01B: Engine - 4.6L and 5.4L 2000 F-150 Workshop Manual AssemblyHassan Vela VenegasNo ratings yet

- CVVTDocument50 pagesCVVTMoaed Kanbar94% (18)

- 8 MW TG Set Technical Details/ SpecificationsDocument2 pages8 MW TG Set Technical Details/ SpecificationsPavan KumarNo ratings yet

- BoqDocument18 pagesBoqPradeep Yallanki100% (1)

- S4S-Z3DT65SP (SPC-S4S-407 Rev 0) MEE StandardDocument17 pagesS4S-Z3DT65SP (SPC-S4S-407 Rev 0) MEE StandardPutra kurnia WijayaNo ratings yet

- Special Purpose Gear Units Api 613 Fifth Edition Data Sheet Si UnitsDocument4 pagesSpecial Purpose Gear Units Api 613 Fifth Edition Data Sheet Si UnitstutuionutNo ratings yet

- S4L2-Y2T62ST S4L2-Y2T63ST (SPC-S4L-292 Rev 9) SDFG Tractor Model 50Document28 pagesS4L2-Y2T62ST S4L2-Y2T63ST (SPC-S4L-292 Rev 9) SDFG Tractor Model 50vishal.nithamNo ratings yet

- Yanmar 21 HPDocument2 pagesYanmar 21 HPAhmet ErdemilNo ratings yet

- Fire Water Make Up PumpDocument7 pagesFire Water Make Up PumpAlvin SmithNo ratings yet

- Fan Data SheetDocument1 pageFan Data SheetSamir Ahmed100% (1)

- Turbine and AccessoriesDocument21 pagesTurbine and Accessoriespavankumar001No ratings yet

- MIV Technical Data SheetDocument3 pagesMIV Technical Data Sheetpavankumar001No ratings yet

- Bombas de Engranajes RexrothDocument14 pagesBombas de Engranajes Rexrothfabio0122100% (1)

- FGS80HAS 100 V 50-60 HZ 1Document3 pagesFGS80HAS 100 V 50-60 HZ 1Tomas GuaiquireNo ratings yet

- Case Construction Backhoe Loader Tier3Document27 pagesCase Construction Backhoe Loader Tier3Nick E100% (1)

- 4 Main Inlet ValveDocument6 pages4 Main Inlet Valvepavankumar001No ratings yet

- Technical Diary - FinalDocument99 pagesTechnical Diary - FinalSaurav KumarNo ratings yet

- 8 M 25 C Generator Set Technical DataDocument2 pages8 M 25 C Generator Set Technical Dataabuzer1981No ratings yet

- Gas Receiver Sizing Application: InputsDocument2 pagesGas Receiver Sizing Application: InputsShahzaibUsmanNo ratings yet

- LN Electrical DataDocument7 pagesLN Electrical DataBen MusimaneNo ratings yet

- 60 TPH Technical SheduleDocument32 pages60 TPH Technical SheduleSeenu HassanNo ratings yet

- Sanden Compressor ListDocument28 pagesSanden Compressor ListSIVARAMANJAGANATHANNo ratings yet

- S4L2-Z363SP (H) (SPC-S4L-279 Rev 2) MEEDocument14 pagesS4L2-Z363SP (H) (SPC-S4L-279 Rev 2) MEERusmiyanto YantoNo ratings yet

- Technical Dairy: 1-Boiler and Auxillaries Main BoilerDocument59 pagesTechnical Dairy: 1-Boiler and Auxillaries Main Boilersuleman247No ratings yet

- Bomba Vacio RotativaDocument6 pagesBomba Vacio RotativaIrene CollNo ratings yet

- Doosan Engine de 12 Maintenance ManualDocument10 pagesDoosan Engine de 12 Maintenance ManualJoseph100% (51)

- Calibration Data AdjustmentDocument4 pagesCalibration Data AdjustmentMas Inyeccion ElectronicaNo ratings yet

- Hyundai Exel 89 1.5l.full SistemDocument74 pagesHyundai Exel 89 1.5l.full SistemAlexander cesar neyra sotoNo ratings yet

- S3Q2-Y3T61DP (SPC-S3Q-016 Rev 2) MEE StandardDocument15 pagesS3Q2-Y3T61DP (SPC-S3Q-016 Rev 2) MEE StandardGeorge TekinovNo ratings yet

- Sab87 Sab81 2stage Nh3Document2 pagesSab87 Sab81 2stage Nh3Yutt WattNo ratings yet

- Motor Kipor CigueñalesDocument18 pagesMotor Kipor CigueñalesLuis Miguel MartinezNo ratings yet

- Deutz 1012 1013 Pump Applications Spec SheetDocument6 pagesDeutz 1012 1013 Pump Applications Spec Sheetahmed khodja karimNo ratings yet

- DEF STAN 91-90/1 Fuel SpecsDocument1 pageDEF STAN 91-90/1 Fuel SpecsTrong Tuan NguyenNo ratings yet

- Air-Cooled Engine Specifications and FeaturesDocument78 pagesAir-Cooled Engine Specifications and FeaturesJose SanchezNo ratings yet

- Data Sheet 1013ec PumpDocument6 pagesData Sheet 1013ec PumpJulio Alvarado MoralesNo ratings yet

- FT006579 1Document3 pagesFT006579 1Humberto RamirezNo ratings yet

- 1.0 Engine Data Sheet S4S DT61SD SPC S4S 269 Rev 4 SDMODocument19 pages1.0 Engine Data Sheet S4S DT61SD SPC S4S 269 Rev 4 SDMOrasak9995No ratings yet

- Side Pocket Mandral PDFDocument27 pagesSide Pocket Mandral PDFwajihhasnainNo ratings yet

- Ee Eipc3 5.englDocument10 pagesEe Eipc3 5.englZoran JankovNo ratings yet

- Technical Specifi Cations: 3.4 Pressure & Temperature SpecificationsDocument1 pageTechnical Specifi Cations: 3.4 Pressure & Temperature SpecificationsWilbort Encomenderos RuizNo ratings yet

- 1.0 Engine Data Sheet S4Q2-Z361SD (SPC-S4Q-373 Rev 4) - 2Document23 pages1.0 Engine Data Sheet S4Q2-Z361SD (SPC-S4Q-373 Rev 4) - 2zenNo ratings yet

- Seatrial Port SideDocument2 pagesSeatrial Port Sideshanish jobNo ratings yet

- Cvts - Tag No. Mpt-tv-4161Document2 pagesCvts - Tag No. Mpt-tv-4161biswasdipankar05No ratings yet

- Specification of Safety Relief ValvesDocument14 pagesSpecification of Safety Relief ValvesVenkateswarlu BoduguNo ratings yet

- LP Gas Amine Contactor Process DataDocument6 pagesLP Gas Amine Contactor Process DataEddy RainNo ratings yet

- Yanmar 9 HPDocument2 pagesYanmar 9 HPAhmet ErdemilNo ratings yet

- ASCO SolenoidDocument10 pagesASCO Solenoidsharib26No ratings yet

- Min1244a12 - Tag 130-Pu-029Document7 pagesMin1244a12 - Tag 130-Pu-029Monty MathewsNo ratings yet

- EASA TCDS E.007 (IM) General Electric CF6 80E1 Series Engines 02 25102011Document9 pagesEASA TCDS E.007 (IM) General Electric CF6 80E1 Series Engines 02 25102011Graham WaterfieldNo ratings yet

- Technical specs for 1996-2001 Alfa Romeo 145 1.4 Twin SparkDocument2 pagesTechnical specs for 1996-2001 Alfa Romeo 145 1.4 Twin SparkJuan Carlos Cayunao GonzalezNo ratings yet

- ServiceManuals LG Aircon LK1580BH LK1580BH Service ManualDocument66 pagesServiceManuals LG Aircon LK1580BH LK1580BH Service ManualArman Atienza Magcawas100% (1)

- Technische Daten G12V183ADocument8 pagesTechnische Daten G12V183Abora123usNo ratings yet

- Operator's Guide to General Purpose Steam Turbines: An Overview of Operating Principles, Construction, Best Practices, and TroubleshootingFrom EverandOperator's Guide to General Purpose Steam Turbines: An Overview of Operating Principles, Construction, Best Practices, and TroubleshootingRating: 5 out of 5 stars5/5 (1)

- Case Studies in Mechanical Engineering: Decision Making, Thermodynamics, Fluid Mechanics and Heat TransferFrom EverandCase Studies in Mechanical Engineering: Decision Making, Thermodynamics, Fluid Mechanics and Heat TransferRating: 5 out of 5 stars5/5 (2)

- 1 Develop Project CharterDocument1 page1 Develop Project ChartersantoshblonkarNo ratings yet

- Develop Project Team Manage Project TeamDocument1 pageDevelop Project Team Manage Project TeamsantoshblonkarNo ratings yet

- 1 Torque SpedDocument1 page1 Torque SpedsantoshblonkarNo ratings yet

- 1 AmeterDocument1 page1 AmetersantoshblonkarNo ratings yet

- Project planning and scheduling guideDocument1 pageProject planning and scheduling guidesantoshblonkarNo ratings yet

- Scope Planning Scope Definition Create WBS Scope Verification Scope ControlDocument1 pageScope Planning Scope Definition Create WBS Scope Verification Scope ControlsantoshblonkarNo ratings yet

- 1 System Used For Bonding TheDocument1 page1 System Used For Bonding ThesantoshblonkarNo ratings yet

- 1 Overlap Scarf JointDocument1 page1 Overlap Scarf JointsantoshblonkarNo ratings yet

- Cost Estimating Cost Budgeting Cost ControlDocument1 pageCost Estimating Cost Budgeting Cost ControlsantoshblonkarNo ratings yet

- 1 Peak Gust Velocity Averaged Over A ShortDocument1 page1 Peak Gust Velocity Averaged Over A ShortsantoshblonkarNo ratings yet

- 3 All Holes Left After Removal of Ties To Secure andDocument1 page3 All Holes Left After Removal of Ties To Secure andsantoshblonkarNo ratings yet

- 2 Force CoefficientsDocument1 page2 Force CoefficientssantoshblonkarNo ratings yet

- 5 of A Hydrostatic TestDocument1 page5 of A Hydrostatic TestsantoshblonkarNo ratings yet

- 4 It Shall Be The Responsibility of The ApplicatorDocument1 page4 It Shall Be The Responsibility of The ApplicatorsantoshblonkarNo ratings yet

- 1 Weld Surfaces Shall Be SmoothDocument1 page1 Weld Surfaces Shall Be SmoothsantoshblonkarNo ratings yet

- 1.6,1 Asme Code Requirements: Completed Asmeboiler and PressureDocument1 page1.6,1 Asme Code Requirements: Completed Asmeboiler and PressuresantoshblonkarNo ratings yet

- 9 Membrane Theory of Pressure Vessel DesignDocument1 page9 Membrane Theory of Pressure Vessel DesignsantoshblonkarNo ratings yet

- 2 Proper Curing of The Concrete Shall Be EnsuredDocument1 page2 Proper Curing of The Concrete Shall Be EnsuredsantoshblonkarNo ratings yet

- Example 1.5 Problem SolutionDocument1 pageExample 1.5 Problem SolutionsantoshblonkarNo ratings yet

- 2 The Rubberlining ManufacturerDocument1 page2 The Rubberlining ManufacturersantoshblonkarNo ratings yet

- 1.6.2 What Does A Hydrostatic or Pneumatic Pressure Test Do?Document1 page1.6.2 What Does A Hydrostatic or Pneumatic Pressure Test Do?santoshblonkarNo ratings yet

- 7 Physics of SolidsDocument1 page7 Physics of SolidssantoshblonkarNo ratings yet

- 1 It Is Listed As The Official or CoDocument1 page1 It Is Listed As The Official or CosantoshblonkarNo ratings yet

- 8 Relationship Between Load and Induced StressDocument1 page8 Relationship Between Load and Induced StresssantoshblonkarNo ratings yet

- 4 The Final Acceptance Shall Be Effective Only After The Submission of TheDocument1 page4 The Final Acceptance Shall Be Effective Only After The Submission of ThesantoshblonkarNo ratings yet

- 10 English Is A Germanic Language of The IndoDocument1 page10 English Is A Germanic Language of The IndosantoshblonkarNo ratings yet

- 1 Rubberlining Contractor Shall Inspect EquipmentDocument1 page1 Rubberlining Contractor Shall Inspect EquipmentsantoshblonkarNo ratings yet

- 6 Design of Tall Pressure Vessels Subject To Wind andDocument1 page6 Design of Tall Pressure Vessels Subject To Wind andsantoshblonkarNo ratings yet

- 5 Design Tolerances and Safety FactorsDocument1 page5 Design Tolerances and Safety FactorssantoshblonkarNo ratings yet

- 3 Weather DataDocument1 page3 Weather DatasantoshblonkarNo ratings yet

- SP Training Manual 1Document302 pagesSP Training Manual 1alex morris100% (2)

- ITA Side Shift Spec SheetDocument8 pagesITA Side Shift Spec SheetSean CarvalhoNo ratings yet

- 2008 Ford Escape BrochureDocument14 pages2008 Ford Escape BrochureRobert ParkerNo ratings yet

- New Holland W270B Wheel Loader Service Repair ManualDocument21 pagesNew Holland W270B Wheel Loader Service Repair ManualggjjjjotonesNo ratings yet

- SKANDIX Pricelist Volvo 850Document1,104 pagesSKANDIX Pricelist Volvo 850Woong-Sub LeeNo ratings yet

- Technical Specifications: Ford F-Series Super DutyDocument10 pagesTechnical Specifications: Ford F-Series Super DutySorcerer NANo ratings yet

- LS-20S - SullairDocument102 pagesLS-20S - SullairWalter CarmonaNo ratings yet

- Fls3 Pump Churn FinalDocument12 pagesFls3 Pump Churn FinalRaden Adlin Kristian SitanggangNo ratings yet

- Catalog V02Document4 pagesCatalog V02PUBG LIFE GAMERNo ratings yet

- The Mass in Motion: Momentum and Impulse Momentum Can Simply Be Defined AsDocument3 pagesThe Mass in Motion: Momentum and Impulse Momentum Can Simply Be Defined AsMira VeranoNo ratings yet

- Vespa scooter collectionDocument13 pagesVespa scooter collectionega alvianNo ratings yet

- Ds211l M Specification Sheet EnglishDocument4 pagesDs211l M Specification Sheet EnglishAntonio BocanegraNo ratings yet

- Engine 1104d Euro 3 - 120cvDocument304 pagesEngine 1104d Euro 3 - 120cvKaloyanNo ratings yet

- Parking Problems and SolutionsDocument14 pagesParking Problems and Solutionsapi-353654920No ratings yet

- Engine Electrical: Group 16Document35 pagesEngine Electrical: Group 16heroki wdyaNo ratings yet

- Lecture 6Document39 pagesLecture 6Kashka IraniNo ratings yet

- Cylinder Leak-Down Testing: The TestDocument2 pagesCylinder Leak-Down Testing: The TestZamriNo ratings yet

- Ahu SpecificationDocument8 pagesAhu SpecificationUzair QuraishiNo ratings yet

- Airbus ChecklistDocument2 pagesAirbus Checklistantonio cardona garciaNo ratings yet

- E15 (A), E16 (B) : Rear Wiper and WasherDocument3 pagesE15 (A), E16 (B) : Rear Wiper and Washermarran almarranyNo ratings yet

- Installation Manual - MC1101S-R56Document12 pagesInstallation Manual - MC1101S-R56Jhun AquinoNo ratings yet

- EMERSON Motor TerminologyDocument2 pagesEMERSON Motor TerminologyNikolaNo ratings yet

- Cooling SystemDocument26 pagesCooling Systemdoreen ann montanoNo ratings yet

- Capital GoodsDocument5 pagesCapital GoodsByamugisha ImerioNo ratings yet