Professional Documents

Culture Documents

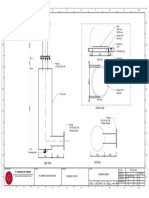

Ingersoll-Rand Compressors 15T2

Uploaded by

Dedi MulyanaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ingersoll-Rand Compressors 15T2

Uploaded by

Dedi MulyanaCopyright:

Available Formats

1.

Air Compressor

Ingersoll-Rand Type 30 single-acting, 3-stage, aircooled, heavy duty high pressure reciprocating air

compressor, vee-belt driven by a TEFC electric motor mounted on a sub-base c/w following:

10 micron industrial intake air filter/silencer with durable carbon steel canister

100% cast iron frame is designed to support the overhung crankshaft. Frame is completely sealed yet

allows for maximum accessibility

Crankshaft has a unique overhung design. Entire shaft is balanced with integral counterweight to

insure smooth operation

Solid one-piece design connecting rods.

100% cast iron cylinders separately cast and individually bolted to the frame in a V-type configuration.

Cylinders are precision-honed for low oil carryover. Radial fins on cylinders help remove heat and

ensure 360o cooling

1st and 2nd stage utilize standard automotive type piston, 3rd stage utilizes a steeple type piston

1st and 2nd stage use 1 compression ring, 1 oil scrapper ring, 2 oil control rings. 3rd stage uses 5

compression rings and 1 oil scrapper ring.

Cast iron fan type flywheel forces a cyclone air blast to provide cooling for the deep finned cylinders

and finned copper tube intercooler and finned tube aftercooler. Flywheel is balanced to keep

vibration to a minimum

Intercooler between stages is of finned copper tube construction to provide maximum cooling area.

Located directly in the flywheel air blast to remove heat of compression keeping running

temperatures and power needs to a minimum, ensuring high air delivery for horsepower expended.

Intercooler is provided with a safety valve to prevent over-pressurization

Intercooler pressure gauge indicates when valve maintenance is required in the case of high inter-

stage pressure.

Splash lubrication of running parts is simple and reliable.

Reliable time-proven finger valves are quick acting and made from premium grade stainless steel.

Valve components are easily removable for

maintenance

Centrifugal unloader automatically bleeds air from intercooler and cylinders preventing compressor

from starting against full load. This protects the motor from premature wear.

Aircooled aftercooler lowers discharge air temperature to within 40oF of ambient

Low Oil Level Switch to prevent unit from operating when oil is low.

high pressure switch for auto stop/start control (supplied loose)

Compressor Model 15T2XB15/35

Cylinder Bore 5.5” & 3” & 1.63”

Cylinder Stroke 4”

Inlet size 1.5”

NPT Discharge size 0.5”

NPT Speed 900 rpm

No. of stages 3

No. of cylinders 3

Max. discharge pressure 500 psig (35barg)

Free Air Delivery @ 500 psig 1.07 m3/min (37.3 cfm)

Motor 15 HP

Voltage 380-415V/3ph/50 hz

Control Auto stop/start

Dimension (L x W x H) 1400 x 1030 x 860

You might also like

- Air Compressor ManualDocument108 pagesAir Compressor ManualJhander BaluyotNo ratings yet

- Compresoras de Tornillo KAISHAN Serie LGDocument8 pagesCompresoras de Tornillo KAISHAN Serie LGcecoelsacNo ratings yet

- IR Pegasus 15-37Document8 pagesIR Pegasus 15-37Didi IswantoNo ratings yet

- Spare Parts Catalog for L55-L80 CompressorsDocument72 pagesSpare Parts Catalog for L55-L80 Compressorsjose molina75% (4)

- Cross Reference Compressed Air Filter: Replaced NEWDocument4 pagesCross Reference Compressed Air Filter: Replaced NEWSebastian GanciNo ratings yet

- GA5-11 Maintaining ManualDocument3 pagesGA5-11 Maintaining Manualjackyt09100% (1)

- Manual Secador KAESER TE91Document9 pagesManual Secador KAESER TE91Monica SholesNo ratings yet

- Hibon Blower Manual Installation GuideDocument55 pagesHibon Blower Manual Installation GuideRicardo RGNo ratings yet

- 88290022-798 (r03) EC 2000 User ManualDocument22 pages88290022-798 (r03) EC 2000 User ManualBilal Ijaz Sheikh100% (3)

- Parts List Quincy QGS 10-15 - (C55) - 2200773152 04Document72 pagesParts List Quincy QGS 10-15 - (C55) - 2200773152 04RUN GO0% (1)

- MAM6070Document45 pagesMAM6070Vitor FreitasNo ratings yet

- Ingersoll Rand TS1A 13ADocument43 pagesIngersoll Rand TS1A 13ARafael Eduardo García Rodríguez0% (1)

- Csa 10 To 20Document6 pagesCsa 10 To 20peterpunk75No ratings yet

- CS5000 English ManualDocument35 pagesCS5000 English ManualTaufan Justvands75% (4)

- DL067AA - Delcos 1000Document2 pagesDL067AA - Delcos 1000Jelimar Del Carmen Acevedo Padilla100% (2)

- MANY1202A.EN - Airmaster™ Q1 Software ManualDocument78 pagesMANY1202A.EN - Airmaster™ Q1 Software ManualAurangzaib Jahangir100% (2)

- Atlas Copco XC 3003/4003 Controllers GuideDocument53 pagesAtlas Copco XC 3003/4003 Controllers Guideengine2parts0% (1)

- Silenced Screw Rotary Compressor Instruction ManualDocument49 pagesSilenced Screw Rotary Compressor Instruction ManualLucyan Ionescu100% (1)

- Spare Parts UP22-30-37 EnglezaDocument70 pagesSpare Parts UP22-30-37 EnglezaTeofil Catalin Tiron86% (7)

- Atlas Copco FX 13-15Document12 pagesAtlas Copco FX 13-15Krzysztof Ciesek100% (1)

- Screw Compressor L132 - L250 Speed-Controlled Screw Compressor L160 - L250 RSDocument56 pagesScrew Compressor L132 - L250 Speed-Controlled Screw Compressor L160 - L250 RSfauzy syaeful100% (2)

- Ed 01 (EN) Creemers KompressorDocument31 pagesEd 01 (EN) Creemers KompressorsebastianNo ratings yet

- Boost air up to 45 barDocument5 pagesBoost air up to 45 barcasv9100% (1)

- Manual Comp Ingersollrand SSR-15Document74 pagesManual Comp Ingersollrand SSR-15darkomega21100% (1)

- Manual Ingersoll Rand 7 - 5 HPDocument188 pagesManual Ingersoll Rand 7 - 5 HPedgarescalante78100% (4)

- Manual de PartesDocument56 pagesManual de PartesFernando Fernandez100% (1)

- Compressor Airman PDFDocument14 pagesCompressor Airman PDFarieprachman100% (2)

- GA 75 VSD, GA 90 VSD Kompressoren Atlas CopcoDocument34 pagesGA 75 VSD, GA 90 VSD Kompressoren Atlas CopcoJimFricks67% (3)

- Service Manual: Tecom Compressor AS SeriesDocument24 pagesService Manual: Tecom Compressor AS Serieskaanerman100% (1)

- Manual Partes Sullair 1809 y 2200Document70 pagesManual Partes Sullair 1809 y 2200ramiro alvarez100% (1)

- Manuale M 260 LX - Ti017g0003 - enDocument52 pagesManuale M 260 LX - Ti017g0003 - enJose Angel Basanta HernandezNo ratings yet

- Compresor Ceccato CSC 50 ES3000 PDFDocument8 pagesCompresor Ceccato CSC 50 ES3000 PDFRenato García Espinosa67% (9)

- GA 315 VSDpart List (AIF 108332 Den)Document74 pagesGA 315 VSDpart List (AIF 108332 Den)Sales AydinkayaNo ratings yet

- D3200ib Dryer ManualDocument31 pagesD3200ib Dryer ManualCenal Permit OfisNo ratings yet

- GA 11 22 PackDocument44 pagesGA 11 22 PackTaufan JustvandsNo ratings yet

- Ceccato CompressorDocument29 pagesCeccato Compressorpeterpunk7586% (7)

- Manual de Operação PDFDocument50 pagesManual de Operação PDFRogerio Nunes Marinho100% (2)

- Comnpresor Compair L30Document8 pagesComnpresor Compair L30Roxana NegoitaNo ratings yet

- Kaeser Screw Compressor BSD Service ManualDocument137 pagesKaeser Screw Compressor BSD Service Manualhead88er85% (13)

- QGS 10-20S Instruction Manual - CE - 05-2019 PDFDocument94 pagesQGS 10-20S Instruction Manual - CE - 05-2019 PDFherrerafaridcr100% (1)

- Brochure Secador NVCDocument7 pagesBrochure Secador NVCByron PanchiNo ratings yet

- Manual Compresor RENNERDocument12 pagesManual Compresor RENNERRigoberto Villafuerte100% (1)

- GA 7-15 VSD+ Parts ListDocument52 pagesGA 7-15 VSD+ Parts ListNatan Hernandez100% (4)

- Csa Rotordryer PDFDocument8 pagesCsa Rotordryer PDFpeterpunk75No ratings yet

- Fiac Airblok 10-30Document60 pagesFiac Airblok 10-30Keli Key67% (3)

- 0000 0000 54-05 - Frequency Converters Failure ListDocument10 pages0000 0000 54-05 - Frequency Converters Failure ListFEDOR100% (1)

- Ce24a Ce24bDocument73 pagesCe24a Ce24bTina Manousi0% (1)

- Manual GA 11, GA 15, GA 18, GA 22, GA 30C PDFDocument82 pagesManual GA 11, GA 15, GA 18, GA 22, GA 30C PDFGoncalo Martins100% (2)

- Catalogo Ricambi Catalogue Pieces Detachees CAT: Spares Parts List Ersatzteilkatalog Álogo de Piezas de RecambioDocument14 pagesCatalogo Ricambi Catalogue Pieces Detachees CAT: Spares Parts List Ersatzteilkatalog Álogo de Piezas de RecambioEdmarBemvindoNo ratings yet

- Atlas Copco Technical Data GA30Document1 pageAtlas Copco Technical Data GA30castkarthickNo ratings yet

- LG ManualDocument27 pagesLG ManualAbdul_Samad0% (1)

- Atlas Copco Fault Codes PDFDocument1 pageAtlas Copco Fault Codes PDFsaad ahmed khan50% (4)

- Altas Copco FD 230 PDFDocument16 pagesAltas Copco FD 230 PDFGer DclNo ratings yet

- ELGI Pet - CompressorDocument4 pagesELGI Pet - Compressormatars59No ratings yet

- Perkins 1004.40T Engine SpecsDocument6 pagesPerkins 1004.40T Engine Specsyeferson mora guerreroNo ratings yet

- Rolls Royce Trent 1000 PDFDocument48 pagesRolls Royce Trent 1000 PDFJuan Lozano100% (1)

- Husqvarna 450 E-Series SPECSDocument2 pagesHusqvarna 450 E-Series SPECSspaceskipperNo ratings yet

- PT Cemindo Gemilang Rev 1Document11 pagesPT Cemindo Gemilang Rev 1ShahNo ratings yet

- Bebicon Air Compressors BrochureDocument2 pagesBebicon Air Compressors BrochureRktBatam100% (1)

- Compresores Serie-A ChampionDocument4 pagesCompresores Serie-A ChampionFrancisco100% (1)

- Crane Sany - 25 TonDocument9 pagesCrane Sany - 25 TonDedi MulyanaNo ratings yet

- Silencer Diesel 1200 Kw-ModelDocument1 pageSilencer Diesel 1200 Kw-ModelDedi MulyanaNo ratings yet

- 15T2 Engineering Data - 2Document2 pages15T2 Engineering Data - 2Dedi MulyanaNo ratings yet

- Ingersoll-Rand Compressors 15T2Document2 pagesIngersoll-Rand Compressors 15T2Dedi Mulyana100% (1)

- Industrial Silencer Parts ListDocument1 pageIndustrial Silencer Parts ListDedi MulyanaNo ratings yet

- Ahdp Deutz CatDocument84 pagesAhdp Deutz CatWillmer rojas rodriguezNo ratings yet

- 1NZ-FE Engine Control System PDFDocument12 pages1NZ-FE Engine Control System PDFjuan100% (1)

- Japanese OEM Bolts & Seals for Bulldozers & ExcavatorsDocument12 pagesJapanese OEM Bolts & Seals for Bulldozers & ExcavatorsAshraf MostafaNo ratings yet

- Marine Propulsion System Dimensions and SpecsDocument1 pageMarine Propulsion System Dimensions and SpecsAris RismansyahNo ratings yet

- 2018 Dmax 4JJ1Document6 pages2018 Dmax 4JJ1Matias MartinezNo ratings yet

- Stroke or Not, Mitsubishi 4G63Document60 pagesStroke or Not, Mitsubishi 4G63DustyRoadz100% (3)

- Engineering Knowledge (Motor) For Marine EngineersDocument381 pagesEngineering Knowledge (Motor) For Marine EngineersЛисица Дмитрий100% (1)

- O 540 F1B5 Parts Catalog PC 515 2Document50 pagesO 540 F1B5 Parts Catalog PC 515 2Damiian TuarezNo ratings yet

- CATALOGO DE PARTES SPLENDOR CYLINDER HEAD COVERDocument84 pagesCATALOGO DE PARTES SPLENDOR CYLINDER HEAD COVERBenjamin RomeroNo ratings yet

- TM9 2815 225 34PDocument736 pagesTM9 2815 225 34Pjamey_parker1No ratings yet

- KB InstructionsDocument2 pagesKB Instructionssd731No ratings yet

- Pi N Connection Pin Connection: 1995-1999 Mitsubishi Eclipse and Eagle Talon Turbo DSM ECU PinoutsDocument2 pagesPi N Connection Pin Connection: 1995-1999 Mitsubishi Eclipse and Eagle Talon Turbo DSM ECU Pinoutslospeed01100% (1)

- LEHM20671-00 - C4.4 Electronic Data SheetDocument3 pagesLEHM20671-00 - C4.4 Electronic Data Sheetkman548No ratings yet

- Volvo EngineDocument9 pagesVolvo EngineAditi Das0% (1)

- Clear The Fault Codes On Subaru Legacy's and Impreza'sDocument3 pagesClear The Fault Codes On Subaru Legacy's and Impreza'skhayoNo ratings yet

- 3500 PDFDocument54 pages3500 PDFmuftah76No ratings yet

- Exhaust Muffler Design Principles PDFDocument2 pagesExhaust Muffler Design Principles PDFWesley0% (1)

- Euro Iv - Himalayan Ls410 Service ManualDocument130 pagesEuro Iv - Himalayan Ls410 Service ManualANOOPVA100% (1)

- Hydromechanical Fuel Control UnitDocument2 pagesHydromechanical Fuel Control Unitm21m29No ratings yet

- Sensors in Engine Management SystemsDocument19 pagesSensors in Engine Management SystemsRohit RajNo ratings yet

- How Does The Carburetor Works: A) TemperatureDocument5 pagesHow Does The Carburetor Works: A) TemperatureKhurram SherazNo ratings yet

- R9M.413 Bottom EngineDocument3 pagesR9M.413 Bottom Enginezmatij24No ratings yet

- OM - WinGD RT Flex58t D PDFDocument514 pagesOM - WinGD RT Flex58t D PDFDexter PalmaNo ratings yet

- Inlet Manifold Pressure - Test: Testing and AdjustingDocument2 pagesInlet Manifold Pressure - Test: Testing and AdjustingAbdoulaye Boua BERTHENo ratings yet

- Workshop Manual Audi Q7 2007 Common RailDocument228 pagesWorkshop Manual Audi Q7 2007 Common RailDanilo81100% (3)

- Engine Valve Lash - Inspect Adjust (SENR9939-32)Document3 pagesEngine Valve Lash - Inspect Adjust (SENR9939-32)Guido Emanuel SteinbachNo ratings yet

- Honda Beat Fi 2015Document66 pagesHonda Beat Fi 2015Adrian ZarateNo ratings yet

- Mfpi & CrdiDocument18 pagesMfpi & CrdiAmitKumarNo ratings yet

- BMW - DME-Course-Material 4, 6, 8, and 12 Cylinder Engine ManagementDocument88 pagesBMW - DME-Course-Material 4, 6, 8, and 12 Cylinder Engine ManagementgoogleheadNo ratings yet

- Engine component diagram and data tableDocument1 pageEngine component diagram and data tableThong ChanNo ratings yet