Professional Documents

Culture Documents

4 - 20ma Transmitters

4 - 20ma Transmitters

Uploaded by

Imran Siddiqui0 ratings0% found this document useful (0 votes)

3 views3 pagesinstrumentation engrs

Original Title

4 -20mA Transmitters

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentinstrumentation engrs

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views3 pages4 - 20ma Transmitters

4 - 20ma Transmitters

Uploaded by

Imran Siddiquiinstrumentation engrs

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

AN104 Dataforth Corporation Page 1 of 3

DID YOU KNOW ?

In 1827 Georg Simon Ohm, a German physicist, published his work, The Galvanic Chain, Mathematically Treated, which

was the basis of "Ohm's Law". Ohm's work was initially denounced by critics of the time as a "web of naked fancies";

nonetheless, during his lifetime, he did receive the credit and fame his efforts deserved. In his honor, the unit of electrical

resistance bears his name, Ohm.

4-20 mA Transmitters

Preamble Long before the electronic age, process control was

dominated by pneumatics. Ratio controllers, PID

controllers, actuators, and recorders were all pneumatic.

The standard was a 3 to 15 psi pneumatic signal, where 3

psi was the live zero. As computer process control

began to evolve in the early 1950s, the signal

transmission technique shifted from 3-15 psi to 4-20 mA

signals., where 4 mA was the live zero. A real dead

zero has always been an alarm condition.

Over the years the 4-20 mA transmitter has become an

accepted standard technique for transmitting information

between field I/O and the control area. New network type

transmission schemes are trying to become the

standard. Meanwhile there are thousands of I/O points

and associated control components that will continue to

use the analog current loop method for transmitting data.

The 4-20 mA Transmitter Figure 1 illustrates four basic steps inherent in a process

control system. First, data is extracted from the process,

followed next by analytical examination and

interpretation. Once data is properly interpreted, the next

step is a decision on the appropriate action. Lastly, the

necessary action must be implemented. The distribution

of these steps depend on process layout and the control

philosophy adopted.

A simplified current loop is schematically shown in

Figure 2. An ideal Norton current source composed of

Isignal, and Rsignal models the 4-20 mA transmitter. The

line resistance is shown as Rline, and Vnoise represents

random induced loop noise. In this example, a 500-ohm

controller and a 250-ohm digital display are connected in

series with the signal current. The loop is powered by a 24

volt dc supply.

Figure 1

Decision

Control

Elements

Examine

Interpret

Sensors

Isignal

Rcontroller 500

Rline 10

Rsignal 10E6

Vnoise Rdisplay 250

VSupply 24

Basic Process Control System

Figure 2

Current Loop Schematic Most all process control systems are distributed

throughout a plant site and information flow may be over

long distances. Transmitting data over considerable

distances often causes major problems in distributed

process control systems.

Several advantages of this type current loop are as

follows;

! Signal voltage at any load is (Isignal * Rload), which

is independent of supply voltage variations and line

resistance (Rline).

Transmitting data reliably has prompted many different

communication schemes and associated products, some of

which employ smart electronics in the I/O sensors and

control elements.

! Random induced loop noise voltage at any load is;

Vnoise * (Rload)/( Sum all Rloads + Rline +Rsignal)

AN104 Dataforth Corporation Page 2 of 3

Note that loop noise at a load is reduced by the

factor; (Rload)/( Sum all Rloads + Rline +Rsignal).

In this example, a 10 volt induced loop noise voltage

appears at the controller input as a 0.5 mV error. The

controller is a 10 volt FS device (20mA * 500! =10)

and 0.5 mV represents an error of 0.005 %.

! Supply voltage variations are reduced at any load by

the same factor as shown above.

! Multiple loads can be series connected in a

transmitter loop, providing considerable control and

display opportunities. Loads today typically have full

scale input requirements of 1 volt, 5 volts, and 10

volts. Typical 4-20mA transmitters require a voltage

across their output terminals to maintain the device

within its operational specifications. This voltage is

often referred to as compliance voltage and has a

rather wide range. For example, in Figure 2 the loop

voltage (compliance) available for the transmitter is;

(Vsupply all load FS voltages - line IR drops);

specifically, (24 volts 15 volts - 2 mV). Depending

on transmitter specifications, a larger supply voltage

may be required or perhaps a 5 volt (250 !)

controller.

It is noteworthy to observe that selecting a supply

needs to be consistent with the number and type of

series loads and the required 4-20 mA transmitter

compliance voltage.

Multiple series loads, wide variation in supply voltage,

and some inherent noise immunity are advantages of

current loop transmitters.

Figure 3 shows the basic internal circuit blocks of a 4-20

mA transmitter. These circuits provide the following

functionality;

Figure 3

Basic 4-20 mA Circuit Functions

! Input Signal conditioning circuits provide appropriate

interfacing for all types of inputs, such as;

thermocouples, RTDs, AC-DC voltages and currents,

strain gauges. Many 4-20 mA modules have smart

signal conditioning functionality that provide

linearization, and mathematical manipulations.

! Power circuits generate all the necessary internal

voltages required and are energized from either a

local power source or the actual current loop.

! Current conversion circuits establish the 4-20 mA

current loop signal.

! The dashed line in Figure 3 illustrates isolation

between the field side and the output loop side.

Isolation is an extremely important aspect of signal

transmission. Signal loops, power supplies, and

grounds should always be completely isolated from

each other.

Standards and Definitions for 4-20 mA Transmitters

The American National Standards Institute (ANSI) and

The Instrumentation Systems, and Automation Society,

(ISA) have numerous documents on signal transmission

including 4-20 mA transmitters. See References at the end

of this article for more details.

The following was taken from; ANSI/ISA-S50.1-1982

(R1992) Compatibility of Analog Signals for Electronic

Industrial Process Instruments.

Type numbers with suffix letters are used as transmitter

identifiers. Type number is the number of wires necessary

to provide transmitter power. Shields and IO wires are

excluded. Suffix letters identify the load resistance

capability.

Figure 4 illustrates three basic transmitter types.

! Type 2 is a 2-wire transmitter energized by the loop

current where the loop source voltage (compliance) is

included in the receiver. The transmitter floats and

signal ground is in the receiver.

Field Side

Power

Current

Source

Conversion

Circuits

Input Signal

Conditioning

Circuits

Loop Side

Power

! Type 3 is a 3-wire transmitter energized by a supply

voltage at the transmitter. The transmitter sources the

loop current. Transmitter common is connected to

receiver common

! Type 4 is a 4-wire transmitter energized by a supply

voltage at the transmitter. The transmitter sources the

loop current to a floating receiver load.

If a transmitter has field inputs, which provide signals

referenced to field grounds potential ground loops exist.

This potentially will cause signal gradation.

AN104 Dataforth Corporation Page 3 of 3

Dataforths transmitters provide;

+

Transmitter

Transmitter Transmitter

Power

Supply

Power

Supply

Transmitter Transmitter

Power

Supply

+

+

ILoop

ILoop

ILoop

Type 2

Type 3

Type 4

! Transformer isolation of signals and power

! 2-wire loop powered current transmission (receiver

supplies only compliance voltage)

! Field surge suppression, protection, and excitation

! Input and Output Low Pass Filtering

! Output surge suppression, protection

! Data linearization and manipulation

Isolation

Amplifier

LPF

Power

Oscillator

Field

Side

Power

Loop

Side

Power

+V

L

-V

L

+V

F

-V

F

Field Input

Surge Suppression

Protection

Sensor Excitation

Output Loop

Surge Suppression

Protection

Linearization

+Loop

-Loop

LPF

Figure 4

Figure 5

Transmitter Types

Dataforth Basic Isolated Current Transmitter

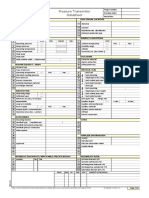

Table 1 shows transmitter class designations. It is

necessary to understand that all 4-20 mA transmitters may

not necessarily be identical in their ability to provide

current into different loads. For example, a typical

The reader is encouraged to visit Dataforth's website

www.Dataforth.com for complete detail information on

all Dataforth's product and additional application

information.

4-20mA transmitter module could not drive a 100k-ohm

load. This would require a compliance source of 2000

volts (20mAx100k!). The class standard ensures that

modules of identical classes are interchangeable with

respect to their drive capabilities. It is noteworthy to

mention here that one should always completely examine

all module specifications before replacing units.

For specific Dataforth 4-20mA-loop products, visit the

following links:

http://www.dataforth.com/catalog/doc_generator.asp?doc

_id=390

http://www.dataforth.com/catalog/doc_generator.asp?doc

_id=364

http://www.dataforth.com/catalog/doc_generator.asp?doc

_id=472

Table 1

Class Designations

Listed below are some additional references.

Class L Class H Class U

Load Resistance

Minimum

300 800

300 to

800

Supply Voltage

Minimum

23 32.7

23 to

32.7

References:

1. ANSI/ISA-50.1-1982 (R1992) formerly ANSI/ISA-

S50.1-1982 (R1992) Compatibility of Analog Signals

for Electronic Industrial Process Instruments

2. http://www.ISA.org/

Practical 4-20 mA Circuit

3. http://www.ANSI.org/

4. http://www.nssn.org/

Field inputs are usually referenced to field grounds or in

some cases actually connected to a field ground (for

example, the grounded thermocouple). Receiver grounds

are rarely identical to field grounds; therefore, isolation is

required to eliminate potential ground loop problems.

Figure 5 illustrates Dataforths basic block diagram

concept of isolated 2-wire current loop transmitters.

5. Control Engineering

http://www.controleng.com/archives/1998/ctl1001.98

/10a929.htm#List

You might also like

- The Second ConditionalDocument2 pagesThe Second ConditionalJuanManuelLaimeMNo ratings yet

- Introduction Tank Gauging - Endress+HauserDocument23 pagesIntroduction Tank Gauging - Endress+HauserLuc SchramNo ratings yet

- Citroen SaxoDocument2 pagesCitroen Saxoserzo75100% (1)

- Departure The LeftoversDocument3 pagesDeparture The Leftoversangela0% (3)

- R. G. Meadows (Auth.) - Electrical Communications - Theory, Worked Examples and Problems-Macmillan Education UK (1976)Document186 pagesR. G. Meadows (Auth.) - Electrical Communications - Theory, Worked Examples and Problems-Macmillan Education UK (1976)Laz GsodfjxNo ratings yet

- 4 To 20 Ma Transmitter WorkingDocument7 pages4 To 20 Ma Transmitter WorkingVenkata Suresh MandavaNo ratings yet

- Analog Electronics Instrumentation - Current LoopsDocument23 pagesAnalog Electronics Instrumentation - Current LoopsAnonymous WokAmg4jNo ratings yet

- E4 - Experiment 4 - Level Transmitter CalibrationDocument17 pagesE4 - Experiment 4 - Level Transmitter CalibrationAfif Samsun BaharunNo ratings yet

- LevelDocument78 pagesLevelvjgeorge100% (1)

- GWR in Chemical Processing Oct 2016 PDFDocument4 pagesGWR in Chemical Processing Oct 2016 PDFArun100% (1)

- TransmittersDocument12 pagesTransmittersUmar Adamu100% (1)

- Q & A of InstrumentsDocument86 pagesQ & A of InstrumentsAbdelrahman Mohamed Elshafei100% (1)

- Displacer Type Level Transmitter Fisher FIELDVUE™ DLC3010 Digital Level Calibration - Kishore KaruppaswamyDocument7 pagesDisplacer Type Level Transmitter Fisher FIELDVUE™ DLC3010 Digital Level Calibration - Kishore KaruppaswamymanikandanNo ratings yet

- Radar and Ultrasonic Level MeasurementDocument24 pagesRadar and Ultrasonic Level MeasurementvenkatsubbuNo ratings yet

- Flow Element Sizing & Design (DNARAYAN)Document45 pagesFlow Element Sizing & Design (DNARAYAN)AttyubNo ratings yet

- Block Diagram of A Smart Transmitter: "Prepare Notes For SENSOR, ADC, MICROPROCESSOR, and DAC"Document2 pagesBlock Diagram of A Smart Transmitter: "Prepare Notes For SENSOR, ADC, MICROPROCESSOR, and DAC"hareesh babuNo ratings yet

- Pressure Transmitter Template SmallDocument2 pagesPressure Transmitter Template Smalldiksha surekaNo ratings yet

- Hart Communication ReportDocument25 pagesHart Communication ReportMuhammed NizarNo ratings yet

- Tas PDFDocument96 pagesTas PDFchandrakrishna8No ratings yet

- DP Transmitter Interface Level Measurement Principle, Limitations, Selection, Installation, Design & Calibration Instrumentation ToolsDocument10 pagesDP Transmitter Interface Level Measurement Principle, Limitations, Selection, Installation, Design & Calibration Instrumentation Toolskali bangonNo ratings yet

- TransmittersDocument20 pagesTransmittersTimothy LeonardNo ratings yet

- Transducers - SummaryDocument27 pagesTransducers - Summaryaelle00No ratings yet

- Interview Questions For Instrument EngineersDocument4 pagesInterview Questions For Instrument EngineerszhangyiliNo ratings yet

- Special Section - Level Measurement - IsADocument8 pagesSpecial Section - Level Measurement - IsAkumar_chemicalNo ratings yet

- Technical Methods and Requirements For Gas Meter CalibrationDocument8 pagesTechnical Methods and Requirements For Gas Meter CalibrationIrfan RazaNo ratings yet

- Design of TAS Using PLC and Batch Controller: Sreeraj SDocument7 pagesDesign of TAS Using PLC and Batch Controller: Sreeraj SSreerajNo ratings yet

- Hart EndressDocument8 pagesHart EndresssuudonNo ratings yet

- Bently 3300 - 55 ManualDocument6 pagesBently 3300 - 55 Manualwagner machado de moraesNo ratings yet

- T10 Turbine Meters PDFDocument59 pagesT10 Turbine Meters PDFVictor Enrique Rosales Parada100% (1)

- Field InstrumentsDocument27 pagesField InstrumentsAfzal AsifNo ratings yet

- Electrical and InstrumentationDocument50 pagesElectrical and InstrumentationBZ SifdineNo ratings yet

- Paper ID-44201631Document13 pagesPaper ID-44201631lataNo ratings yet

- Coriolis Flow MeterDocument4 pagesCoriolis Flow MeterIsares PodkohNo ratings yet

- FLUOR - New Delhi: Flow Instruments (Part-1)Document20 pagesFLUOR - New Delhi: Flow Instruments (Part-1)Tirado Melchor Angel Miguel100% (2)

- Emergency Shut Down Valve:: Actuated Valve Partial or Total Process ShutdownDocument3 pagesEmergency Shut Down Valve:: Actuated Valve Partial or Total Process ShutdownPrasanna kumar subudhiNo ratings yet

- PCC03 P002Document11 pagesPCC03 P002Handong ZhaoNo ratings yet

- 2063 72040 Tipicos InstrumentacionDocument42 pages2063 72040 Tipicos InstrumentacionZillur RahmanNo ratings yet

- Fenwalnet 8000-Ml: Protection SystemsDocument12 pagesFenwalnet 8000-Ml: Protection SystemsricardopelezinhoNo ratings yet

- R83pqty5 Magnetic Flowmeter FDLDGAM 3 PDFDocument38 pagesR83pqty5 Magnetic Flowmeter FDLDGAM 3 PDFFelix DanielNo ratings yet

- Control and Instrumentation WorksDocument166 pagesControl and Instrumentation Worksmeledath100% (1)

- Omni Flow Computer ManualDocument57 pagesOmni Flow Computer ManualRifki AsfariNo ratings yet

- Introduction To AutomationDocument140 pagesIntroduction To AutomationAbrhamNo ratings yet

- Contact Type Guided Wave Radar Level Transmitter Working Principle Instrumentation ToolsDocument3 pagesContact Type Guided Wave Radar Level Transmitter Working Principle Instrumentation ToolsAbarajithan Rajendran100% (1)

- Principle of Mass Flow Meter: Presented byDocument22 pagesPrinciple of Mass Flow Meter: Presented byParth PatelNo ratings yet

- Vibration PNPDocument2 pagesVibration PNPkravikota1938No ratings yet

- Level Measurement PDFDocument97 pagesLevel Measurement PDFGaming UserNo ratings yet

- 3.2transmitters Guided Wave Radar 706xxxDocument58 pages3.2transmitters Guided Wave Radar 706xxxQuy le manh100% (1)

- DP LT CalibrationDocument6 pagesDP LT CalibrationkvsangeethNo ratings yet

- Temp - Controller SDC35-36 Specification ManualDocument12 pagesTemp - Controller SDC35-36 Specification ManualsunhuynhNo ratings yet

- Ip Pressure Transmitter Data SheetDocument4 pagesIp Pressure Transmitter Data SheetMohammad BabazadehNo ratings yet

- Level Measuring InstrumentsDocument12 pagesLevel Measuring Instrumentsamer_arauf100% (1)

- Module I-6 Temperature InstrumentsDocument48 pagesModule I-6 Temperature Instrumentsnabil160874No ratings yet

- Instrumentation Design Engineering Oil Gas BrochureDocument8 pagesInstrumentation Design Engineering Oil Gas Brochuresakthivel palaniNo ratings yet

- Instrument & ControlDocument100 pagesInstrument & ControlAlfian AdityaNo ratings yet

- Tutorial 4Document40 pagesTutorial 4LEDNo ratings yet

- FMP51, FMP52, FMP54 Manual Eng PDFDocument176 pagesFMP51, FMP52, FMP54 Manual Eng PDFOscar Mauricio Osorio Diaz100% (1)

- DP Level Transmitter CalibrationDocument4 pagesDP Level Transmitter CalibrationSijo Joy100% (3)

- Instrumentation ManualDocument114 pagesInstrumentation Manualqasim awaisNo ratings yet

- Analog and Digital Signals - Electrical Instrumentation SignalsDocument3 pagesAnalog and Digital Signals - Electrical Instrumentation SignalsRoona Thankam VargheseNo ratings yet

- Metering SystemDocument21 pagesMetering Systemaadianvi0% (1)

- Science of 4 20 MA Current LoopDocument3 pagesScience of 4 20 MA Current LoopJoshua HollandNo ratings yet

- 4 - 20 MA TransmitterDocument15 pages4 - 20 MA TransmitterHajasoa RakotoNo ratings yet

- Basics of The 4 - 20ma Current LoopDocument3 pagesBasics of The 4 - 20ma Current LoopNTNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- CVS-118Mk2 OME 0812Document30 pagesCVS-118Mk2 OME 0812Vincenzo barbatoNo ratings yet

- Cyco TheatreDocument2 pagesCyco TheatremaitiNo ratings yet

- Magic Lantern User GuideDocument56 pagesMagic Lantern User Guidetommy900No ratings yet

- UntitledDocument2 pagesUntitledapi-129536202No ratings yet

- IES - Electrical Engineering - Control SystemDocument101 pagesIES - Electrical Engineering - Control SystemJeetu Raj50% (2)

- Digital Death (Missing Bits)Document48 pagesDigital Death (Missing Bits)Stacey Pitsillides100% (1)

- Televisión Pública Argentina - WikipediaDocument5 pagesTelevisión Pública Argentina - WikipediaEkaterina JazminNo ratings yet

- Stay With Me SoloDocument2 pagesStay With Me SoloAurélio Abreu100% (1)

- Character Demo Furina All The World's A Stage - Genshin ImpactDocument5 pagesCharacter Demo Furina All The World's A Stage - Genshin Impactlightningplayz27No ratings yet

- Activity 1 For Module 4 AE9Document2 pagesActivity 1 For Module 4 AE9Rose Ann GarciaNo ratings yet

- Never Ending StoryDocument1 pageNever Ending StoryamicimusicasiracusaNo ratings yet

- Teori GnssDocument73 pagesTeori GnssBayu Rezky AnugrahNo ratings yet

- SAMPLE - OneClick-enDocument53 pagesSAMPLE - OneClick-enFelipeNo ratings yet

- Tetra Over IpDocument5 pagesTetra Over IpAlexDonetskNo ratings yet

- 801b English Paper 2 QPDocument7 pages801b English Paper 2 QPRudra SahaNo ratings yet

- Mystery of Love - Call Me by Your NameDocument3 pagesMystery of Love - Call Me by Your NameChandler Bess100% (2)

- English Film ReviewDocument9 pagesEnglish Film ReviewliaNo ratings yet

- Sim Aero BrochureDocument8 pagesSim Aero BrochureIludiran KolaNo ratings yet

- Your Love Bass Tabs - The Outfield @Document3 pagesYour Love Bass Tabs - The Outfield @Álvaro Diogo S. TeixeiraNo ratings yet

- DT300-Series-manual Timer 04Document2 pagesDT300-Series-manual Timer 04eeindustrialNo ratings yet

- 166 Case Studies Proved Social Media ROI PDFDocument66 pages166 Case Studies Proved Social Media ROI PDFJu Weiss100% (1)

- Garay Garay DanielaDocument5 pagesGaray Garay DanielaValeria MeloNo ratings yet

- Principal TimpaniDocument2 pagesPrincipal TimpaniFernandoNo ratings yet

- Understanding IEEE 519 1992Document2 pagesUnderstanding IEEE 519 1992Mahmoud EldabahNo ratings yet

- Mycom Nims ProptimaDocument4 pagesMycom Nims ProptimasamnemriNo ratings yet

- Indigenous Australian Worksheet Part 1Document2 pagesIndigenous Australian Worksheet Part 1Kenith GamageNo ratings yet