Professional Documents

Culture Documents

Cleanroom Standards PDF

Uploaded by

Dike d'Zanmaster0 ratings0% found this document useful (0 votes)

27 views10 pagesOriginal Title

cleanroom_standards.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

27 views10 pagesCleanroom Standards PDF

Uploaded by

Dike d'ZanmasterCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 10

1

Cleanroom Standards Cleanroom Standards

CLEANROOM TUTORIAL PROGRAMME

CLASS 1 & 10 These cleanrooms are virtually the exclusive domain of

(ISO Class 3 & 4) the microelectronics industry

CLASS 100 ntil the microelectronics industry demanded finer

(ISO Class 5) line widths, this was the highest cleanliness level

and is now widely used in many fields of technology

CLASS 1,000 Used less frequently, but has been a cleanliness

(ISO Class 6) classification in the US; it is a mixed class where

UAF workstations are in close proximity

CLASS 10,000 Probably the most used cleanliness level. Is very

(ISO Class 7) frequently used as a base cleanroom cleanliness

level together with localised clean areas of Class

100 within the cleanroom itself for Pharmacare & Micro

CLASS 100,000 Normally entry level cleanroom classification for use in

(ISO Class 8) Micro and Pharmacare industries

CLEANROOM CLASSES

WD-14644-9 Particle Surface Contamination CD

ISODocument Title

ISO-14644-1 Classification of Air Cleanliness

ISO-14644-2 Specification of Testing for Continued Compliance

ISO-14644-3 Metrology & Test Methods

ISO-14644-4 Design, Construction & Start Up

ISO-14644-5 Cleanroom Operations

ISO-14644-6 Terminology

ISO-14644-7 Seprative Enclosures

ISO-14644-8 Molecular Contamination

ISO-14698-1 Biocontamination: Control General Principles & Methods

ISO-14698-2 Biocontamination: Evaluation & Interpretation of Data

Status

1999

2000

FDIS

2001

2004

CD

2004

FDIS

2003

2004

ISO CLEANROOM STANDARDS (SEP 05)

2

BASIC GUIDE TO CLEANROOM DESIGN

EU GMP "A/B" at rest "C" at rest "D" at rest

Classes ( Fed 209 D) 1 10 100 1000 10 000 100 000

ISO Standard ISO 3 ISO 4 ISO5 ISO 6 ISO 7 ISO8

Particles per m3 > 0.5 micron 35.3 353 3 530 35 300 353 000 3 530 000

Air Changes Per Hour 600 500 500 40 - 120 20 - 40 0 - 20

RoomPressure 15 Pa 15 Pa 15 Pa 10 - 15 Pa 10 15 Pa 5 - 10 Pa

Clean air inlets Cover as %of ceiling area 100% 100% 90% 20 - 50 % 10 - 20 % 5 - 10 %

Clean air inlets Locations Ceiling Ceiling Ceiling Ceiling Ceiling Ceiling / High wall

Filter Location Ceiling Ceiling Ceiling Ceiling Ceiling Ceiling / AHU

Return Locations Floor Floor LowLevel or Floor LowLevel or Floor LowSidewall Sidewall

Velocity at clean air inlets (m/s) 0.45 0.45 0.45 0.15 - 0.45 0.15 - 0.45 0.15 - 0.45

Velocity at return air (m/s) n/a n/a n/a 0.5- 1 1 - 2.5 2.5

Airlock ( required ) Yes Yes Yes Yes Yes None

Area per occupant ( m2) 40 40 30 20 10 5

Equipment in room Minimum Minimum Minimun Minimum 30%Floor 50%Floor

RoomHeight n/a n/a n/a Minimum3 Minimum2.75 Minimum2.25

Comparison of Major CleanroomStandards

US 209 E 1992 M1.5 M2.5 M3.5 M4.5 M5.5 M6.5

ISOClass 14644-1 1999 3 4 5 6 7 8

EECGGMP 1989 N/A N/A A & B N/A C D

France AFNOR 1981 N/A N/A 4000 N/A 400 000 4 000 000

Germany VDI 2083 1990 1 2 3 4 5 6

Britain BS 5295 1989 N/A N/A E or F G or H J K

Japan JACA1989 3 4 5 6 7 N/A

The above is only a guide for cleanroomdesign

17/11/2004

ardmac

adding value to CleanroomConstruction

ISO 14644-1: 1999

Classification of Air Cleanliness

ISO 14644 ISO 14644- -1 1

Very Similar to the old Fed Std 209E

ISO 14644-1 Direct Outgrowth of 209E

Changes

In Cubic Metres, not Cubic Feet

Number of Cleanliness Classes

Number of Sample Points

Treatment of Outliers

INTRO INTRO

3

3,520,000 832,000 29,300

ISO 9 35,200,000 8,320,000 293,000

ISO 8

35,200 8,320 293

ISO 7 (Class 10,000) 352,000 83,200 2,930

ISO 6 (Class 1,000) 1,000,000 237,000 102,000

352 83

ISO 5 (Class 100) 100,000 23,700 10,200 3,520 832 29

ISO 4 10,000 2,370 1,020

4

ISO 3 1,000 237 102 35 8

ISO 2 100 24 10

0.5 um 1 um 5 um

ISO 1 10 2

0.1 um 0.2 um 0.3 um

CLASS Number of Particles per Cubic Meter by Micrometer Size

ISO 14644 ISO 14644- -1 1

N/A 9

100,000 8

10,000 7

1,000 6

100 5

10 4

1 3

N/A 2

N/A 1

FS 209E ISO 144644-1

14644 14644- -1 and 209E Equivalents 1 and 209E Equivalents

cleanroom definition

define level of suspended particles in cleanroom

air

define clean space airborne particulate

cleanliness classes

provide statistically based methodology for

testing and certification of cleanrooms

COMMENTS COMMENTS

4

cleanliness class expressed in terms of an

ISO Class N which represents...

the max. allowable concentrations (in

particles per m

3

) for considered sizes of

particles

using the formula given in Sect. 3.2

ISO 14644-1

1. ISO Number

2. Particle Size

3. Occupancy

ISO 14644-1

Require 3 items to specify a Cleanroom

Classification to ISO STD 14644-1:

OCCUPANCY STATES

As Built

...installation is complete with all services connected and

functioning but with no production equipment, materials of

personnel present

At Rest

installation is complete with equipment installed and

operating in a manner agreed upon by the customer and

supplier, but with no personnel present

Operational

installation is functioning in the specified manner, with

the specified number of personnel present and working in

the manner agreed upon

5

ISO 14644 2: 2000

Specifications for testing and

monitoring to prove

continued compliance with

ISO 14644-1

14644 14644- -2 2

14644-2 Definitions

Monitoring Frequency

Continuous

Updating Constantly

Frequent

Updating at Specified Intervals Not Exceeding 60 Minutes

During Operation

Intervals:

6 months: Avg. < 183 Max < 190 Days

12 months: Avg. < 366 Max < 400 Days

24 months: Avg. < 731 Max < 800 Days

Testing Particle Conc Limits

ISO Class Max. Time Interval

5 and Cleaner 6 months

6 and Less Clean 12 months

Normally performed in operational state

May be performed in At Rest state

Table 1

6

14644-2 - Testing Schedules

Test Parameter Max. Time Interval

Airflow Volume or Velocity*1 12 months

Air Pressure Difference*2 12 months

*1 Determined by either velocity or volume measurement

*2 Test will not apply to clean zones which are not totally

enclosed.

Note: Tests may be performed in operational or

at- rest condition

Table 2

14644-2 Annex A - Optional Tests

Test Parameter Class Max. Time Interval

Installed Filter Leakage All 24 Months

Airflow Visualization All 24 Months

Recovery All 24 Months

Containment Leakage All 24 Months

Note: NOT Recommended for Microelectronics

ISO ISO 14644 14644- -4:2001 4:2001

Design, Construction, and Design, Construction, and

Start Start- -up up of Cleanroom of Cleanroom

Facilities Facilities

ISO 14644 ISO 14644- -4 4

7

1. 1. Scope Scope

2. 2. Normative References Normative References

3. Terms & 3. Terms & D Definitions efinitions

4. 4. Specification of Requirements Specification of Requirements

5. 5. Planning & Design Planning & Design

6. 6. Construction & Start Construction & Start- -up up

7. 7. Testing & Approval Testing & Approval

8. 8. Documentation Documentation

ISO 14644 ISO 14644- -4 4

Design, Construction & Start-Up

A1 A1 INFORMATIVE INFORMATIVE

Outdoor Environment

Ancillary Areas

Cleanrooms

Clean Zones

Process Core

Raw Mat er i al s

Pr oduc t

Per sonnel

Wast e

Concept of Segregation

Defines things that must be considered:-

Reference no. of standard

Use of the space or device

Choice of Design Concept

Class of space

Other environment parameters

- Material flow

- Occupancy state

- Layout and critical dimensions

- Equipment

- Maintenance

- Responsibilities

- External influences

Specification of Specification of Reqts Reqts

Section 4

8

States that design shall be complete, be approved and

integrate all relevant regulations.

Planning Procedure

Project Plan

Equipment lists

Options & Costs

Design

Complete & documented

Must satisfy all Codes & Regulations

Formally accepted = sign off

Planning & Design Planning & Design

Section 5

States that construction shall comply with the approved

design, shall be accurate, shall be undertaken in an

appropriate way.

In accordance with drgs & Specs

Clean construction protocol

Cleaning methods shall be defined

Carry out full functional tests before use for

operational activity

Training the operational personnel part of the start-up

responsibility

Construction & Start Up Construction & Start Up

Section 6

States that organised tests shall be carried out.

Carry out an agreed series of inspections and tests

Construction approval

Demonstrate that the installation complies with the

design

Functional approval

Demonstrate compliance during AS BUILT or AT

REST states

Operational approval

Demonstrate Full operational performance

Testing & Approval Testing & Approval

Section 7

9

Sets out the main things that shall be well

documented.

Record of the Installation

URS, Drgs, test records, spares list

Operational Instructions

Performance Monitoring Instructions

Maintenance Instructions

Maintenance Record

Training record

Documentation Documentation

Section 8

Annex A Control and segregation concepts

Annex B Classification examples

Annex C Development & Approval

Annex D Layout of installation

Annex E Construction and materials

Annex F Environmental control of cleanrooms

Annex G Control of air cleanliness

Annex H Additional specification TBA

Bibliography

Appendices Appendices

#Total UDAF Zone area 8.64m

2

Live filter area ~ 83%of total.

If the Average velocity in zone is 0.45 m/s

#Then, the required velocity

through filter media is 0.55 m/s.

#This is critical for choosing the correct filters

because filter efficiency is velocity dependent. See

also EN1822 for HEPAand ULPAfilters.

#EN/ISO14644-3 will define this important

difference in the section on velocity and volume

measurement.

UDAF UDAF - - Fi l t er Gr i d Fi l t er Gr i d

Gross area = 8.64 m

2

Net area = 7.17 m

2

A5.1 Unidirectional Airflow Velocity A5.1 Unidirectional Airflow Velocity

10

A5.1 Unidirectional Airflow Velocity A5.1 Unidirectional Airflow Velocity

Filter

Face

velocity

System

velocity at

working

plane

UDAF UDAF - - Filter Grid Filter Grid

#EN/ISO14644-3 will define this

important difference in the section

on velocity and volume

measurement.

You might also like

- Clean Rooms L Essentiel 3Document4 pagesClean Rooms L Essentiel 3Sweekar BorkarNo ratings yet

- Cleanroom Standards An OverviewDocument39 pagesCleanroom Standards An OverviewFatma Samir100% (1)

- Clean Room Requirements As Per Iso 14644 PDFDocument8 pagesClean Room Requirements As Per Iso 14644 PDFAnkur100% (1)

- Validation Presentation SRPDocument76 pagesValidation Presentation SRPRamakrishna Agumbe100% (1)

- Technical - Bulletin - Explanation of Part 1 and 2Document6 pagesTechnical - Bulletin - Explanation of Part 1 and 2riotstarbaby100% (1)

- 5 Eli Lilly Env MonitoringDocument47 pages5 Eli Lilly Env Monitoringparam540No ratings yet

- FS-209E and SIO-14644 Cleanroom Classification StandardsDocument8 pagesFS-209E and SIO-14644 Cleanroom Classification Standardsmaqsoodch1100% (1)

- Bulletin Iso Clean Room ClassificationsDocument1 pageBulletin Iso Clean Room Classificationsailing79No ratings yet

- Conducting The ISO 146443 Cleanroom Recovery Test With The 3400101420Document3 pagesConducting The ISO 146443 Cleanroom Recovery Test With The 3400101420Oscar Zambrano Martinez100% (1)

- Clean Room SpecsDocument7 pagesClean Room SpecsLaxminarayan Jha100% (1)

- Integrity Testing of HEPA FiltersDocument3 pagesIntegrity Testing of HEPA FilterspradeepNo ratings yet

- Particle Count - STANDARDSDocument15 pagesParticle Count - STANDARDSpraveen kumar vengadasamy100% (1)

- Mark PDFDocument42 pagesMark PDFdavincicode888No ratings yet

- Iso 14644 2015 Pharmig XPDFDocument35 pagesIso 14644 2015 Pharmig XPDFmetrologueha1100% (1)

- HEPA Leak TestDocument24 pagesHEPA Leak TestkhlowNo ratings yet

- Aseptic Area ClassificationDocument9 pagesAseptic Area ClassificationNaresh BabuNo ratings yet

- Cleanroom Guide Iso 14644Document8 pagesCleanroom Guide Iso 14644hitham shehataNo ratings yet

- 7.1 Airflow Velocity Measurement & Calculation of Air Changes: ObjectiveDocument8 pages7.1 Airflow Velocity Measurement & Calculation of Air Changes: ObjectiveHaswika Reddy GangavaramNo ratings yet

- Article2-Clean Operation Manufacturing294002107513883542Document4 pagesArticle2-Clean Operation Manufacturing294002107513883542авдей александрNo ratings yet

- Sop For Recovery TestDocument2 pagesSop For Recovery TestFrendz Forevr Ati100% (1)

- Dop Integrity TestDocument17 pagesDop Integrity TestLokesh GandhiNo ratings yet

- Standards For Classification of Clean RoomsDocument8 pagesStandards For Classification of Clean Roomszvieizikovics50% (2)

- Himedic Pharmaceutical (PVT) Ltd. Lahore: Qualification & ValidationDocument33 pagesHimedic Pharmaceutical (PVT) Ltd. Lahore: Qualification & Validationumair khan100% (1)

- Air Techniques TDA-2E Aerosol Photometer ManualDocument19 pagesAir Techniques TDA-2E Aerosol Photometer ManualDavid Silver100% (1)

- HEPA Testing MethodsDocument5 pagesHEPA Testing MethodsLongKimNo ratings yet

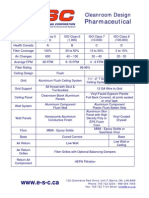

- Cleanroom Design Criteria PharmaceuticalDocument1 pageCleanroom Design Criteria PharmaceuticalNabil RamNo ratings yet

- Surface Finish MeasurementDocument14 pagesSurface Finish MeasurementRaghu Krishnan100% (1)

- Cleanrooms and GMP Design - 1.Document69 pagesCleanrooms and GMP Design - 1.Laraib BhattiNo ratings yet

- Changes To GMP Force Cleanroom Re-ClassificationsDocument5 pagesChanges To GMP Force Cleanroom Re-ClassificationsJose EvoraNo ratings yet

- Validation Part2Document48 pagesValidation Part2gvasNo ratings yet

- Clean RoomDocument30 pagesClean RoomMalathi SathivelNo ratings yet

- Supplementary Training Modules On GMP: Air Handling SystemsDocument20 pagesSupplementary Training Modules On GMP: Air Handling SystemsRambabu komati - QANo ratings yet

- OPERATION QUALIFICATION PROTOCOL FOR AIR HANDLING UNIT - Pharmaceutical GuidanceDocument15 pagesOPERATION QUALIFICATION PROTOCOL FOR AIR HANDLING UNIT - Pharmaceutical GuidanceMohamad IsmailNo ratings yet

- Hvac System & Test For Hvac QualificationDocument9 pagesHvac System & Test For Hvac Qualificationlaap85100% (1)

- Environment Validation SopDocument8 pagesEnvironment Validation SopNguyen ChienNo ratings yet

- Clean Room DesignDocument22 pagesClean Room Designerdo mandanaNo ratings yet

- Iso14644 3Document31 pagesIso14644 3Justin Southerland100% (1)

- EU GMP Annex 1 - Sterile Medicinal Product - 2008Document16 pagesEU GMP Annex 1 - Sterile Medicinal Product - 2008tungquacert100% (1)

- Classification of Cleanrooms and Cleanroom Standards: The Scottish Society For Contamination ControlDocument4 pagesClassification of Cleanrooms and Cleanroom Standards: The Scottish Society For Contamination ControlMohsinShaikhNo ratings yet

- Clean Room Validation ServicesDocument2 pagesClean Room Validation ServicesVikram BillalNo ratings yet

- GMP Cleanroom RequirementsDocument4 pagesGMP Cleanroom Requirementswaludde conradNo ratings yet

- HEPA and ULPA Filters: The Aseptic CoreDocument7 pagesHEPA and ULPA Filters: The Aseptic CoreVaidhyanadhan DeepakNo ratings yet

- Cleanroom Validation Results Sampling and Common DispensingDocument18 pagesCleanroom Validation Results Sampling and Common DispensingJanple Alzar100% (2)

- Clean Room 1Document15 pagesClean Room 1monoj5859No ratings yet

- Integrity Testing of HEPA Filters - A Practical ApproachDocument11 pagesIntegrity Testing of HEPA Filters - A Practical ApproachFajar NurrohmanNo ratings yet

- EM50Document94 pagesEM50Prasenjit Das100% (1)

- Temperature Monitor Alert System UAE Qatar OmanDocument2 pagesTemperature Monitor Alert System UAE Qatar OmanmrikovsteyneNo ratings yet

- URS ColdRoomDocument10 pagesURS ColdRoomyehudasimanjuntakNo ratings yet

- Tsi Caspture HoodDocument80 pagesTsi Caspture Hoodsenthilarasu5No ratings yet

- HEPA Cleanroom Filter TestingDocument4 pagesHEPA Cleanroom Filter TestingThanh Van LeNo ratings yet

- Validation of Dynamic Pass BoxDocument5 pagesValidation of Dynamic Pass BoxMichele Volpe100% (1)

- Classification Vs MonitoringDocument4 pagesClassification Vs MonitoringrohitdeolNo ratings yet

- 7 Iso14644Document84 pages7 Iso14644mgvtertv100% (2)

- ISO Class - Clean RoomDocument11 pagesISO Class - Clean RoomBanukumar RajendranNo ratings yet

- Cleanroom Requirements, Certification and Monitoring Per Common Accepted Standards by Sean Birch, Lighthouse Worldwide SolutionsDocument3 pagesCleanroom Requirements, Certification and Monitoring Per Common Accepted Standards by Sean Birch, Lighthouse Worldwide SolutionsApoloTrevino100% (1)

- Clean Room ValidationDocument16 pagesClean Room ValidationRehmatNo ratings yet

- ISO14644 Guide Introduction and Changes of The Cleanrooms StandardDocument7 pagesISO14644 Guide Introduction and Changes of The Cleanrooms StandardRick WylieNo ratings yet

- 7.1 - Regulatory - FS209E and ISO Cleanroom StandardsDocument6 pages7.1 - Regulatory - FS209E and ISO Cleanroom StandardsAnonymous i8hifn7No ratings yet

- Clean Room Requirements 20130927Document5 pagesClean Room Requirements 20130927HNmaichoi100% (1)