Professional Documents

Culture Documents

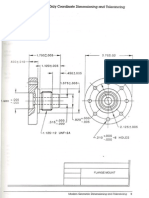

FCF Ref Chart

FCF Ref Chart

Uploaded by

Kaveri SomasundaramCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FCF Ref Chart

FCF Ref Chart

Uploaded by

Kaveri SomasundaramCopyright:

Available Formats

GD&T REFERENCE GUIDE

Form controls

Profle controls

Orientation controls

Location controls

Runout controls

Straightness

Flatness

Circularity

Cylindricity

Profle of a Line

Profle of a Surface

Parallelism

Perpendicularity

Angularity

Position

Concentricity

Symmetry

Circular Runout

Total Runout

NAME SYMBOL

FOR SURFACE

OR F.O.S.?

TOLERANCE ZONE

SHAPE (see below)

CAN USE MMC

OR LMC MODIFIER?

Either

Either

Surface

Surface

Surface

Surface

Surface

Surface

F.O.S.

Either

Either

Either

F.O.S.

F.O.S.

a, b, c

b

e

d

a, d, f

b, e, g

a, b, c

a, b, c

a, b, c

d

e

b, c, h

c

b

Yes, if a F.O.S.

Yes, if a F.O.S.

Yes, if a F.O.S.

Yes, if a F.O.S.

Yes, if a F.O.S.

No

No

No*

No*

Yes

No

No

No

No

DATUM REF?

Never

Never

Never

Never

Usually

Usually

Always

Always

Always

Always

Always

Always

Always

Always

*The datum reference(s) may use

MMC or LMC modifiers, if a F.O.S. datum

Exception: position applied to coaxial holes

a = 2 parallel lines b = 2 parallel planes c = cylinder d = 2 coaxial circles

e = 2 coaxial cylinders f = 2 irregular line boundaries

g = 2 irregular surface boundaries h = sphere

The current standard for GD&T is ASME Y14.5-2009, from the American Society of Mechanical Engineers. It replaces the 1994 version.

The rectangular box that contains a GD&T callout is known as the "feature control frame."

A geometric tolerance shown in a feature control frame is always total, not plus/minus. Depending on how it is used, it may be

centered around a fixed location, or it may float within a given size limit.

The datum references (the letters at the end of a feature control frame) are given in a specific order to show the relative importance of

each (primary, secondary, and tertiary).They do not have to be in alphabetical order, but rather order of precedence.

The modifier M is helpful for clearance fits. It allows the tolerance to increase as the size of the feature varies. It can also be used on

datum references if there might be looseness or "play" on those features.

Datum features should be identified on physical items (surface, hole, pin, etc.) not on an imaginary center line. Even if the true datum

might be a center, the symbol should still appear on the feature from which the center is derived.

Basic dimensions (boxed dimensions) do not have any direct tolerance. Instead, they are indirectly toleranced from a feature control frame.

Basic dimensions are most common in conjunction with position and profile controls.

Concentricity is expensive to inspect. Often, position or runout can be used to achieve the same goal. (Reason: concentricity measures

the centers of every cross-section, but position measures the center of an envelope, and runout measures the physical surface.)

One of the most powerful GD&T symbols is profile of a surface. It controls a shape (which is defined by basic dimensions) by building a

three-dimensional tolerance zone around it. And depending on how it relates to the datums, it can also control orientation and location.

Modifiers to know: M = maximum material condition L = least material condition F = free state

P = projected tolerance zone U = unequal tolerance zone T = tangent plane

Helpful things to remember:

CREATES VIRTUAL

CONDITION?

Yes, if on F.O.S.

No

No

No

No

Yes, if on F.O.S.

Yes, if on F.O.S.

Yes, if on F.O.S.

Yes

Yes

Yes

Yes**

Yes**

**It is not a true "virtual condition" as defined in the standard,

but it does create a "worst-case boundary" that may be

important for assembly or function.

Yes, if on F.O.S.

F.O.S. stands for feature of size (a pin, hole, slot, etc.)

2009 Geometric Learning Systems www.gdtseminars.com

You might also like

- Geometrical Dimensioning and Tolerancing for Design, Manufacturing and Inspection: A Handbook for Geometrical Product Specification Using ISO and ASME StandardsFrom EverandGeometrical Dimensioning and Tolerancing for Design, Manufacturing and Inspection: A Handbook for Geometrical Product Specification Using ISO and ASME StandardsRating: 4.5 out of 5 stars4.5/5 (3)

- Ford GD&T Pocket GuideDocument33 pagesFord GD&T Pocket GuideAnonymous nXmUV4L100% (9)

- Topology - Solutions Sections 51-54Document29 pagesTopology - Solutions Sections 51-54Leonardo Amorim Silva100% (1)

- GD&T PDFDocument49 pagesGD&T PDFnupurvinodNo ratings yet

- GD&T Day 1 Part 1Document22 pagesGD&T Day 1 Part 1harshkallani100% (2)

- GDT Workbook QuestionsDocument82 pagesGDT Workbook Questionsmechlop100% (5)

- GT&D GlossaryDocument10 pagesGT&D GlossaryshawntsungNo ratings yet

- Applications & Interpretation - 1 Page Formula Sheet: IB Mathematics SL & HL - First Examinations 2021Document1 pageApplications & Interpretation - 1 Page Formula Sheet: IB Mathematics SL & HL - First Examinations 2021Zia Silver100% (1)

- Geometric Dimensioning Tolerancing 102Document51 pagesGeometric Dimensioning Tolerancing 102Vidjeane MourthyNo ratings yet

- Counter BoreDocument11 pagesCounter BoreSURYA20051961No ratings yet

- GDNTDocument3 pagesGDNTkevinjaisNo ratings yet

- GD&T Symbols - GD&T Terms - Geometric Dimensioning and Tolerancing Glossary - GD&T Free ResourceDocument5 pagesGD&T Symbols - GD&T Terms - Geometric Dimensioning and Tolerancing Glossary - GD&T Free Resourcebbbsample0% (1)

- GD&T 1Document41 pagesGD&T 1Sai CharanNo ratings yet

- GD & T-2Document29 pagesGD & T-221adNo ratings yet

- Profile ControlDocument9 pagesProfile ControlSahil SharmaNo ratings yet

- Dimension IngDocument6 pagesDimension IngvasantNo ratings yet

- Profile of A SurfaceDocument5 pagesProfile of A SurfacemooninjaNo ratings yet

- ASME Y 14.5: CNC MachiningDocument6 pagesASME Y 14.5: CNC MachiningAnil ETNo ratings yet

- Perpendicularity: GD&T Symbol: Relative To Datum MMC or LMC Applicable: GD&T Drawing CalloutDocument14 pagesPerpendicularity: GD&T Symbol: Relative To Datum MMC or LMC Applicable: GD&T Drawing CalloutanishNo ratings yet

- GD & T PresentationDocument63 pagesGD & T PresentationPuneet Birla100% (2)

- True Position: Special NoteDocument15 pagesTrue Position: Special NoteanishNo ratings yet

- Contatto in ANSYSDocument20 pagesContatto in ANSYSmatteo.daccNo ratings yet

- Geometric TolerancingDocument57 pagesGeometric TolerancingKewell LimNo ratings yet

- GD&T PDFDocument109 pagesGD&T PDFBikash Chandra SahooNo ratings yet

- GD&TDocument10 pagesGD&TShahed FacebookNo ratings yet

- Flat Ness: Our Comprehensive List of GD&T SymbolsDocument29 pagesFlat Ness: Our Comprehensive List of GD&T SymbolsMidhilesh RavikindiNo ratings yet

- Geometric Dimensioning and Tolerancing GD&TDocument17 pagesGeometric Dimensioning and Tolerancing GD&TJusuf ElQudsyNo ratings yet

- NAPA Online Manuals 2009Document26 pagesNAPA Online Manuals 2009Bùi Công LộcNo ratings yet

- Geometric Dimensioning and Tolerancing GD&TDocument17 pagesGeometric Dimensioning and Tolerancing GD&TUS Kuntal50% (2)

- Geometric Dimensioning and Tolerancing GD&TDocument17 pagesGeometric Dimensioning and Tolerancing GD&TaadeshkerNo ratings yet

- GDT GlossaryDocument6 pagesGDT GlossaryNnamdi Celestine NnamdiNo ratings yet

- Geometric Dimensioning and ToleranceDocument25 pagesGeometric Dimensioning and ToleranceJEGAN RAJ NATARAJAN100% (4)

- GD&T Symbols and TermsDocument5 pagesGD&T Symbols and TermsMikeNo ratings yet

- 1-888-TEC-EASE Outside USA: 1-716-785-6015: GD&T Glossary and Resource Symbols and TermsDocument7 pages1-888-TEC-EASE Outside USA: 1-716-785-6015: GD&T Glossary and Resource Symbols and TermsSathishkumar MNo ratings yet

- Profile of A LineDocument6 pagesProfile of A LinemooninjaNo ratings yet

- 2 GD - T True Position SymbolDocument10 pages2 GD - T True Position Symbolteck hock kooNo ratings yet

- GD&TDocument10 pagesGD&TestampariaitupevaNo ratings yet

- Geometric Dimensioning & Tolerancing TrainingDocument5 pagesGeometric Dimensioning & Tolerancing TrainingLokesh NarasimhaiahNo ratings yet

- GD&T Symbols and TermsDocument6 pagesGD&T Symbols and TermsAnand KumarNo ratings yet

- GD&TDocument6 pagesGD&Tdhruv001No ratings yet

- 3 D Toler AncingDocument19 pages3 D Toler AncingErnesto MorettorresNo ratings yet

- Winncad GDT DefinitionsDocument6 pagesWinncad GDT DefinitionsVeera PandiNo ratings yet

- Geometric Dimensioning and Tolerancing GD&TDocument17 pagesGeometric Dimensioning and Tolerancing GD&TAnonymous sfkedkymNo ratings yet

- GD&T Glossary and Resource - GD&T Symbols and TermsDocument4 pagesGD&T Glossary and Resource - GD&T Symbols and TermsMohammed Adil100% (1)

- Common Terms and Definitions: Basic DimensionDocument9 pagesCommon Terms and Definitions: Basic Dimensionswap dNo ratings yet

- Enjoy This Site?Gift The Author A Wordpress Com Plan GiftDocument9 pagesEnjoy This Site?Gift The Author A Wordpress Com Plan GiftSathya DharanNo ratings yet

- Introduction To Datums: Datums Tell Us Where To Measure From. Calling Them Out Clearly and Labelling EachDocument8 pagesIntroduction To Datums: Datums Tell Us Where To Measure From. Calling Them Out Clearly and Labelling Eachmanikantar15No ratings yet

- Geometrical Dimensioning & Tolerancing: Based On The ASME Y14.5M - 1994 Dimensioning and Tolerancing StandardDocument86 pagesGeometrical Dimensioning & Tolerancing: Based On The ASME Y14.5M - 1994 Dimensioning and Tolerancing Standardmohtram1037100% (4)

- Soilin PDFDocument54 pagesSoilin PDFstonerrrockNo ratings yet

- GD & TDocument90 pagesGD & TgurlambaNo ratings yet

- Your Source For GD&T Training and MaterialsDocument6 pagesYour Source For GD&T Training and Materialskharsh23No ratings yet

- Goetsch ch12Document45 pagesGoetsch ch12Vijay RaghavanNo ratings yet

- Geometry of Surfaces: A Practical Guide for Mechanical EngineersFrom EverandGeometry of Surfaces: A Practical Guide for Mechanical EngineersNo ratings yet

- Standard-Slope Integration: A New Approach to Numerical IntegrationFrom EverandStandard-Slope Integration: A New Approach to Numerical IntegrationNo ratings yet

- Level Set Method: Advancing Computer Vision, Exploring the Level Set MethodFrom EverandLevel Set Method: Advancing Computer Vision, Exploring the Level Set MethodNo ratings yet

- A Classification System to Describe Workpieces: DefinitionsFrom EverandA Classification System to Describe Workpieces: DefinitionsW. R. MacconnellNo ratings yet

- Frampton Studies in Tectonic Culture 1995 P 1 12 Email PDFDocument14 pagesFrampton Studies in Tectonic Culture 1995 P 1 12 Email PDFviharlanyaNo ratings yet

- Geometry V2 CDDocument51 pagesGeometry V2 CDChicoletteCadouriCuDichis100% (4)

- Practice Science Questions - Physics Velocity and AccelerationDocument5 pagesPractice Science Questions - Physics Velocity and Acceleration김재명No ratings yet

- Mathematics 1Document11 pagesMathematics 1Marose Villanueva de Guzman100% (6)

- Engineering Mechanics - An Introduction To Dynamics 4th Ed PDF - PDF - Kinematics - VelocityDocument502 pagesEngineering Mechanics - An Introduction To Dynamics 4th Ed PDF - PDF - Kinematics - VelocitySRNo ratings yet

- Word Problem ExamplesDocument18 pagesWord Problem ExamplesselventhiraNo ratings yet

- Jackson 5.1 Homework SolutionDocument3 pagesJackson 5.1 Homework Solutionalex100% (1)

- Introduction To Trigonometry: Section - IDocument48 pagesIntroduction To Trigonometry: Section - IKaranjeet ChauhanNo ratings yet

- Engineering GraphicsDocument48 pagesEngineering GraphicsVictor SenpaiNo ratings yet

- 529-Article Text-1895-1-10-20220430Document16 pages529-Article Text-1895-1-10-20220430Pratiwi Dwi Warih SitaresmiNo ratings yet

- CES3Document2 pagesCES3Achietots CabarioNo ratings yet

- DPP#5 Circular Motion SolutionDocument10 pagesDPP#5 Circular Motion SolutionADARSH KUMAR BEHERANo ratings yet

- Module 4 - Solutions of TrianglesDocument1 pageModule 4 - Solutions of TrianglesHayati Aini AhmadNo ratings yet

- Functions Equations Question BankDocument101 pagesFunctions Equations Question BankParth DesaiNo ratings yet

- Solid Geometry by C SmithDocument268 pagesSolid Geometry by C SmithADITI Library100% (2)

- 5-5 Triangle Inequality TheoremDocument10 pages5-5 Triangle Inequality TheorembiancaNo ratings yet

- The Geometer's Sketchpad Unit 1Document47 pagesThe Geometer's Sketchpad Unit 1henlie10d0008No ratings yet

- Pythagoras Game Card PDFDocument5 pagesPythagoras Game Card PDFmdmemaNo ratings yet

- University of Cambridge International Examinations International General Certificate of Secondary EducationDocument20 pagesUniversity of Cambridge International Examinations International General Certificate of Secondary Educationnisa1673100% (1)

- Physics 101ah - Lesson 3aDocument3 pagesPhysics 101ah - Lesson 3aRonald TantiadoNo ratings yet

- Theory of Relativity ScriptDocument2 pagesTheory of Relativity Scriptzoemin1112No ratings yet

- NMTC-at-Junior-level-IX-X-Standards (Level2)Document6 pagesNMTC-at-Junior-level-IX-X-Standards (Level2)asha jalanNo ratings yet

- Analisis Soalan Trial Add MathDocument3 pagesAnalisis Soalan Trial Add MathTee Pei LengNo ratings yet

- Constructing A Right Angle in Ancient Ways Using StringDocument2 pagesConstructing A Right Angle in Ancient Ways Using StringIrina VasilescuNo ratings yet

- Circle GeometryDocument40 pagesCircle GeometryBimalendu DasNo ratings yet

- Trig EssayDocument4 pagesTrig Essayapi-265366548No ratings yet

- Stefan Tanaka History Without Chronology 02 Cap 1Document31 pagesStefan Tanaka History Without Chronology 02 Cap 1Armando Javier Torres VillarrealNo ratings yet

- Wheel Topology OptimizationDocument5 pagesWheel Topology OptimizationDan Wolf100% (1)