Professional Documents

Culture Documents

Example Problem: Frames at 5 MC/C D

Uploaded by

Hilary WatsonOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Example Problem: Frames at 5 MC/C D

Uploaded by

Hilary WatsonCopyright:

Available Formats

Design of Steel Structures Prof. S.R.Satish Kumar and Prof. A.R.

Santha Kumar

Indian Institute of Technology Madras

Example Problem

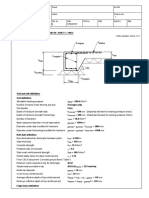

An Industrial building of plan 15m30m is to be constructed as shown in Fig.E1.

Using plastic analysis, analyse and design the single span portal frame with gabled roof.

The frame has a span of 15 m, the column height is 6m and the rafter rise is 3 m and

the frames are spaced at 5 m centre-to-centre. Purlins are provided over the frames at

2.7 m c/c and support AC sheets. The dead load of the roof system including sheets,

purlins and fixtures is 0.4 kN/m

2

and the live load is 0.52 kN/m

2

. The portal frames

support a gantry girder at 3.25 m height, over which an electric overhead travelling

(EOT) crane is to be operated. The crane capacity is to be 300 kN and the crane girder

weighs 300 kN while the crab (trolley) weight is 60 kN.

Fig. E1 Details of an Industrial Building

1.0 Load Calculations

1.1 Dead Load of roof given as 0.4 kN/m

2

Dead load/m run on rafter =0.4 * 5 2.0 kN/m

1.2

Live Load given as 0.52 kN/m

2

Live load/m run on rafter =0.52 * 5 2.6 kN/m

15 m

3

0

m

Frames at 5

m c / c

3

m

6

m

3

.

2

5

m

15 m

0

.

6

m

0

.

6

m

A

B

C

D

E

F

G

300 kN

300 kN

60 kN

B

B

F

F

Frame Elevation Plan

Design of Steel Structures Prof. S.R.Satish Kumar and Prof. A.R.Santha Kumar

Indian Institute of Technology Madras

1.3 Crane Load

The extreme position of crane hook is assumed as 1 m from the centre line of

rail. The span of crane is approximately taken as 13.8 m. And the wheel base along

the gantry girder has been taken as 3.8 m

1.3.1 Vertical load on gantry

The weight of the crane is shared by two portal frames At the extreme position of

crab, the reaction on wheel due to the lifted weight and the crab can be obtained by

taking moments about the centreline of wheels (point B).

To get maximum wheel load on a frame from gantry girder BB', taking the gantry

girder as simply supported.

Centre to centre distance between frames is 5 m c/c.

Assuming impact factor of 25%

Maximum wheel Load @ B =1.25 (242 (1 +(5-3.8)/5)

=375 kN.

Minimum wheel Load @ B =(88 /242)*375

=136.4 kN

13.8 m

1 m

(300 + 60)/2

300/2

B

F

6.9 m

R

B

= 242 kN R

F

= 88 kN

242 kN

242 kN

3.8 m

5 m

B'

B

R

B

1

= 136.4

R

B

=375 kN

Design of Steel Structures Prof. S.R.Satish Kumar and Prof. A.R.Santha Kumar

Indian Institute of Technology Madras

1.3.2 Transverse Load (Surge):

Lateral load per wheel =5% (300 +60)/2 =9 kN

(i.e. Lateral load is assumed as 5% of the lifted load and the weight of the crab acting

on each rail).

Lateral load on each column *375

242

9

= =13.9 kN

(By proportion)

1.4 Wind Load

Design wind speed, V

z

=k

1

k

2

k

3

V

b

From Table 1; IS: 875 (part 3) 1987

k

1

=1.0 (risk coefficient assuming 50 years of design life)

From Table 2; IS: 875 (part 3) 1987

k

2

=0.8 (assuming terrain category 4)

k

3

=1.0 (topography factor)

Assuming the building is situated in Chennai, the basic wind speed is 50 m

/sec

Design wind speed, V

z

= k

1

k

2

k

3

V

b

V

z

=1 * 0.8 *1 * 50

V

z

= 40 m/sec

Design wind pressure, P

d

=0.6*V

z

2

= 0.6 * (40)

2

=0.96 kN/m

2

Design of Steel Structures Prof. S.R.Satish Kumar and Prof. A.R.Santha Kumar

Indian Institute of Technology Madras

h

w

w

plan

elevation

1.4.1. Wind Load on individual surfaces

The wind load, W

L

acting normal to the individual surfaces is given by

W

L

=(C

pe

C

pi

) A*P

d

(a) Internal pressure coefficient

Assuming buildings with low degree of permeability

C

pi

= 0.2

(b) External pressure coefficient

External pressure coefficient for walls and roofs are tabulated in Table 1 (a) and Table

1(b)

1.4.2 Calculation of total wind load

(a) For walls

h/w =6/15 =0.4

L/w =30/15 =2.0

Exposed area of wall per frame @ 5 m

c/c is A =5 * 6 =30 m

2

Wind load on wall / frame, A p

d

=30 * 0.96 =28.8 kN

Table 1 (a): Total wind load for wall

C

pe

C

pi

C

pe

C

pi

Total wind(kN)

(C

pe

-C

pi

)Ap

d

Wind

Angle

Wind-

ward

Lee-

ward

Wind

ward

Lee

ward

Wind

ward

Lee

ward

0.2 0.5 -0.45 14.4 -12.9 0

0

0.7 -0.25

-0.2 0.9 -0.05 25.9 -1.4

0.2 -0.7 -0.7 -20.2 -20.2 90

0

-0.5 -0.5

-0.2 -0.3 -0.3 -8.6 -8.6

Design of Steel Structures Prof. S.R.Satish Kumar and Prof. A.R.Santha Kumar

Indian Institute of Technology Madras

15 m

(b) For roofs

Exposed area of each slope of roof, per frame (5m length) is

For roof, Ap

d

=38.7 kN

Table 1 (b): Total wind load for roof

Pressure Coefficient C

pe

C

pi

Total Wind

Load(kN)

(C

pe

C

pi

) Ap

d

C

pe

C

pe

Wind

ward

Lee

ward

Wind

ward

Lee

ward

Wind

angle

Wind Lee

C

pi

Int. Int.

-0.328 -0.4 0.2 -0.528 -0.6 -20.4 -23.2 0

0

-0.328 -0.4 -0.2 -0.128 -0.2 -4.8 -7.8

-0.7 -0.7 0.2 -0.9 -0.9 -34.8 -34.8 90

0

-0.7 -0.7 -0.2 -0.5 -0.5 -19.4 -19.4

2.1 Dead Load

Replacing the distributed dead load of 2kN/m on rafter by equivalent

concentrated loads at two intermediate points corresponding to purlin locations on each

rafter,

kN

6

15 * 2.0

W

D

5 = =

2.2 Superimposed Load

Superimposed Load =2.57 kN/m

Concentrated load , kN 6.4

6

15 * 2.57

W

L

= =

( ) ( )

2 2 2

m 40.4 7.5 3.0 * 5 A = + =

2kN/m

C E

W

W

W

W

W

W / 2

W / 2

D

Design of Steel Structures Prof. S.R.Satish Kumar and Prof. A.R.Santha Kumar

Indian Institute of Technology Madras

kN

2

eaves @

2

w

0 . 3

6

= =

2.3 Crane Load

Maximum Vertical Load on columns =375 kN (acting at an eccentricity of 600

mm from column centreline)

Moment on column =375 *0.6 =225 kNm.

Minimum Vertical Load on Column =136.4 kN (acting at an eccentricity of 600 mm)

Maximum moment =136.4 * 0.6 =82 kNm

3.0 Partial Safety Factors

3.1 Load Factors

For dead load,

f

=1.5

For leading live load,

f

=1.5

For accompanying live load,

f

=1.05

3.2 Material Safety factor

m

=1.10

4.0 Analysis

In this example, the following load combinations is considered, as it is found to

be critical. Similar steps can be followed for plastic analysis under other load

combinations.

(i) 1.5D.L +1.5 C .L +1.05 W.L

4.1. 1.5 D.L + 1.5 C.L+ 1.05 W.L

4.1.1Dead Load and Wind Load along the ridge (wind angle = 0

o

)

(a) Vertical Load

w @ intermediate points on windward side

w =1.5 * 5.0 1.05 *(4.8/3) cos21.8

=6 kN.

w @ intermediate points on leeward side

w =1.5 * 5.0 1.05 * 7.8/3 cos21.8

=5.0 kN

Design of Steel Structures Prof. S.R.Satish Kumar and Prof. A.R.Santha Kumar

Indian Institute of Technology Madras

kN

2

eaves @

2

w

5 . 2

0 . 5

= =

Total vertical load @ the ridge =3.0 +2.5 =5.5 kN

b) Horizontal Load

H @ intermediate points on windward side

H =1.05 * 4.8/3 sin 21.8

=0.62 kN

H/2 @ eaves points =0.62/2

=0.31 kN

H @ intermediate purlin points on leeward side

=1.05 * 7.8 /3 sin 21.8

=1 kN

H/2 @ eaves =0.5 kN

Total horizontal load @ the ridge =0.5 - 0.31 =0.19 kN

Table 3: Loads acting on rafter points

Vertical Load (kN) Horizontal Load (kN)

Windward Leeward Windward Leeward Intermediate

Points

5.2 4.2 0.62 1.0

Eaves 2.6 2.1 0.31 0.5

Ridge 4.7 0.19

4.1.2 Crane Loading

Moment @ B =1.5 * 225 =337.5 kNm

Moment @ F =1.5 * 82 =123 kNm

Horizontal load @ B & @ F =1.5 * 13.9 =20.8 kN

Note: To find the total moment @ B and F we have to consider the moment due to the

dead load from the weight of the rail and the gantry girder. Let us assume the weight of

rail as 0.3 kN/m and weight of gantry girder as 2.0 kN/m

Design of Steel Structures Prof. S.R.Satish Kumar and Prof. A.R.Santha Kumar

Indian Institute of Technology Madras

Dead load on the column = acting at e=0.6m

Factored moment @ B & F =1.5 * 5.75 * 0.6 =5.2 kNm

Total moment @B =337.5 +5.2 =342 kNm

@ F =123 +5.2 =128 kNm

Factored Load (1. 5D.L+1.5 C.L +1.05 W.L)

4.2 1.5 D.L + 1.5 C.L + 1.05 L.L

4.2.1 Dead Load and Live Load

@ intermediate points on windward side =1.5 * 5.0 +1.05 * 6.4

=14.2 kN

@ ridge =14.2 kN

@ eaves =14.2 / 2 7.1 kN.

kN 5.75 5 *

2

0.3 2

=

+

15 m

3 m

6 m

3.25 m

20.8 kN 20.8 kN

343 128

27.2 kN 1.5 kN

1.0 kN

1.0 kN

0.5 kN

0.19 kN

5.5 kN

5 kN

5 kN

2.5 kN

0.62 kN

0.62 kN

6 kN

6 kN

3 kN

0.31 kN

Design of Steel Structures Prof. S.R.Satish Kumar and Prof. A.R.Santha Kumar

Indian Institute of Technology Madras

4.2.2 Crane Load

Moment @ B =342 kNm

Horizontal load @ B =20.8 kN

Moment @ F =128 kNm

Horizontal load @ F =20.8 kN

Factored Load (1. 5D.L+1.5 C.L +1.05 W.L)

4.3 Mechanisms

We will consider the following mechanisms, namely

(i) Beam mechanism

(ii) Sway mechanism

(iii) Gable mechanism and

(iv) Combined mechanism

(v) Beam Mechanism

15 m

3 m

6 m

3.25 m

20.8 kN 20.8 kN

343 128

27.2 kN

1.5 kN

1.0 kN

1.0 kN

0.5 kN

0.19 kN

5.5 kN

5 kN

5 kN

2.5 kN

0.62 kN

0.62 kN

6 kN

6 kN

3 kN

0.31 kN

Design of Steel Structures Prof. S.R.Satish Kumar and Prof. A.R.Santha Kumar

Indian Institute of Technology Madras

(1) Member CD

Case 1: 1.5 D.L +1.5 C.L +1.05 W.L

Internal Work done, Wi =M

p

+M

p

(/2) +M

p

( +/2)

=M

p

(3)

External Work done, W

e

=6 * 2.5 - 0.62 * 1 * +6 * 2.5 * /2 0.62 * 1 * /2

=21.6

Equating internal work done to external work done

W

i

=W

e

M

p

(3) =21.6

M

p

=7.2 kNm

Case 2: 1.5 D.L +1.5 C.L +1.05 L.L

Internal Work done,

W

i

=M

p

3 (as in case 1)

External work done, W

e

=14.2 * 2.5 +14.2 *2.5 / 2

=53.3

D

C

5.5 kN

0.62 kN

6 kN

0.62 kN

0.31 kN

6 kN

0.19 kN

3 kN

/2

M

p

=7.2kNm

14.2 kN

14.2 kN

14.2 kN

7.1 kN

/2

M

p

= 17.8kNm

Design of Steel Structures Prof. S.R.Satish Kumar and Prof. A.R.Santha Kumar

Indian Institute of Technology Madras

Equating W

i

=W

e

,

M

p

(3) =53.3

M

p

=17.8 kNm

Note: Member DE beam mechanism will not govern.

(2) Member AC

Internal Work done,

External Work done,

Equating W

i

=W

e

, we get

3.69 M

p

=383.9

M

p

=104.1 kNm.

(3) Member EG

Internal Work done,

External Work done,

Equating W

i

=W

e

, we get

p

M 3.69

13

11

p

M

13

11

p

M

p

M

i

W

=

+ + =

C C

A

p

M 3.69

13

11

p

M

13

11

p

M

p

M

i

W

=

+ + =

* * * * *

383.9

13

11

3.25 27.2

2

1

13

11

342

13

11

3.25 20.8 W

e

=

+ + =

428.3

13

11

3.25 * (21.2)

2

1

* 342

13

11

* 3.25 * 20.8

e

W

=

+ + =

E

F

G

20.8 kN

342 kNm

27.2 kN

11 /13

M

p

= 104.1kNm

20.8 kN

342 kNm

21.2 kN

11 /13

F

G

M

p

= 116.1kNm

Design of Steel Structures Prof. S.R.Satish Kumar and Prof. A.R.Santha Kumar

Indian Institute of Technology Madras

3.69 M

p

=428.3

M

p

=116.1 kNm

For members AC & EG, the 1

st

load combination will govern the failure mechanism.

4.3.1 Panel Mechanism

Case 1: 1.5 D.L +1.5 C.L +1.05 W.L

Internal Work done, W

i

=M

p

() +M

p

() +M

p

() +M

p

()

=4M

p

External Work done, W

e

W

e

= 1/2 (27.2) * 6 +20.8 * 3.25 +342 - 0.31 * 6 - 0.62 * 6 - 0.62

(6)+0.19 * 6 +1.0 *6 +1.0 * 6 +0.5 * 6+1/2 (1.5) * 6 +

20.8 * 3.25 - 128 *

= 442.14

Equating W

i

=W

c

, we get

4M

p

=442.14

M

p

=110.5 kNm

The second load combination will not govern.

Design of Steel Structures Prof. S.R.Satish Kumar and Prof. A.R.Santha Kumar

Indian Institute of Technology Madras

14.2

14.2

14.2

14.2

7.1

14.2

20.8 kN 20.8 kN

342 kNm 128 kNm

7.1

4.3.3 Gable Mechanism

Case 1: 1.5 D.L +1.05 W.L +1.5 C.L

Internal Work done = M

p

+M

p

2 +M

p

(2) +M

p

=6M

p

External Work done, W

e

=

-0.62 * 1 * - 0.62 * 2 * +0.19 * 3 * +1.0 * 4 * +1.0 * 5 * +0.5 * 6 * +6 * 2.5 * +6 * 5 * +5.5 *

7.5 * +5 * 5 * +5 * 2.5 * + * 1.5 * 6 +20.8 * 3.25 * - 128*

W

e

=78.56

Equating W

i

=W

e

, we get

6M

p

=78.56

M

p

=13.1 kNm.

Case 2: 1.5 D.L +1.05L.L +1.5 C.L

M

p

=37.3kNm

1.0

1.0

0.5

0.19

5.5

5

5

2.5

0.62

0.62

6

6

3

0.31

20.8 kN

342 kNm

20.8 kN

128 kNm

27.2 kN 1.5 kN

M

p

=13.1kNm

Design of Steel Structures Prof. S.R.Satish Kumar and Prof. A.R.Santha Kumar

Indian Institute of Technology Madras

Internal Work done, W

i

=M

p

+M

p

(2) +M

p

(2) +M

p

=6M

p

External Work done, W

e

=14.2 * 2.5* +14.2 * 5 * +14.2 * 7.5 +14.2 * 5 * +14.2 * 2.5 -

128 * +20.8 * 3.25

=223.6

Equating W

i

=W

e

, we get

6M

p

=223.6

M

p

=37.3 kNm

4.3.4 Combined Mechanism

Case1: 1.5 D.L +1.05 W.L +1.5 C.L

(i)

Internal Work done, W

i

=M

p

( ) +M

p

( +/2) +M

p

(/2 +/2) +M

p

(/2)

=M

p

( + +/2 +/2 +/2 +/2 +/2)

=4 M

p

External Work done, W

e

=

1/2 * 27.2 * 6 +20.8 * 3.25* +342 - 0.31 * 12 * /2 - 0.62 * 11 * /2

- 0.62 * 10 */2 +0.19 * 9 * /2 +1.0 * 8 * /2 +1.0 * 7 * /2 +0.5 * 6* /2 +1/2 (1.5) *

6/2 +20.8 * 3.25 * /2 - 128 * /2 6 * 2.5 * /2 6 * 5.0 * /2 5.5 * 7.5 * /2 5 * 5 *

/2 5 * 2.5 * /2

=402.86

Equating W

i

=W

e

4M

p

=402.86

M

p

=100.7 kNm

M

p

= 100.7

Design of Steel Structures Prof. S.R.Satish Kumar and Prof. A.R.Santha Kumar

Indian Institute of Technology Madras

6 1.5

2

1

128 3.25 20.8

2

2.5

2

5.0

2

12 0.5

2

11 1.0

2

10 1.0

2

7.5

2

5.0

2

2.5

2

9 0.19

2

8 0.62

2

7 0.62

2

6 0.31

2

6 27.2

2

1

2

342

2

3.25 20.8 W

e

* *

* * * * 5 * * 5 * * * *

* * * * 5 . 5 * * 6 * * 6 * * * *

* * * * * * * * *

+

+ + + + +

+ + + + +

+ + =

(ii) Internal work done, W

i

=M

p

/2 +M

p

( /2 +/2) +M

p

( /2 + )

+M

p

W

i

= 4M

p

External Work done,

=300.85

Equating W

i

=W

e

, we get

4M

p

=300.85

M

p

=75.2 kNm

Similarly analysis can be performed for hinges occurring at purlin locations also

but they have been found to be not critical in this example case

/2

/2 /2

20.8 kN

342 kNm

20.8 kN

128 kNm

27.2 kN 1.5 kN

1.0

1.0

0.5

0.19

5.5

5

4.2

2.1

0.62

0.62

6

6

3

0.31

12 m

M

p

= 75.2

Design of Steel Structures Prof. S.R.Satish Kumar and Prof. A.R.Santha Kumar

Indian Institute of Technology Madras

From all the above analysis, the largest value of M

p

required was for member EG

under

1.5 DL +1.5 CL +1.05 WL

Therefore the Design Plastic Moment =116.1 kNm.

5.0 DESIGN

For the design it is assumed that the frame is adequately laterally braced so

that it fails by forming mechanism. Both the column and rafter are analysed assuming

equal plastic moment capacity. Other ratios may be adopted to arrive at an optimum

design solution.

5.1 Selection of section

Plastic Moment capacity required=116 kNm

Required section modulus, Z

p

=M

p

/ f

yd

ISMB 300 @ 0.46 kN/ m provides

Z

p

=683 * 10

-3

mm

3

b =140 mm

T

i

=13.1 mm

A =5.87 * 10

3

mm

2

t

w

=7.7 mm

r

xx

=124 mm

r

yy

=28.6 mm

( )

3 3

10 * 4 . 510

0

mm

1.1

250

116*10

6

=

=

Design of Steel Structures Prof. S.R.Satish Kumar and Prof. A.R.Santha Kumar

Indian Institute of Technology Madras

y 1

f

f

136

T

b

=

8.6 5.34

13.1

70

T

b

1

f

< = =

kN

x5.87*10

1.1

250

3

1334

0

=

=

5.2 Secondary Design Considerations

5.2.1 Check for Local buckling of flanges and webs

Flanges

b

f

=140/2 =70 mm

T

1

=13.1 mm

t =7.7 mm

Web

5.2.2 Effect of axial force

Maximum axial force in column, P =40.5 kN

Axial load causing yielding, P

y

=f

yd

* A

Therefore the effect of axial force can be neglected.

y y y

1

P

P

f

1600

f

1120

t

d

( )

K O. Hence 68, 38.9

0.27

250

1600

250

1120

7.7

300

y y

0.15 0.03

1

40.5

P

P

y

< = =

334

Design of Steel Structures Prof. S.R.Satish Kumar and Prof. A.R.Santha Kumar

Indian Institute of Technology Madras

5.2.3 Check for the effect of shear force

Shear force at the end of the girder =P- w/2

=40.5 -6.8 kN

=33.7 kN

Maximum shear capacity V

ym

, of a beam under shear and moment is given by

V

ym

=0.55 A

w

* f

yd

/ 1.10

=0.55 * 300* 7.7* 250/1.10

=289 kN>>33.7 kN

Hence O.K.

You might also like

- Structural Steel Design to Eurocode 3 and AISC SpecificationsFrom EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNo ratings yet

- Bracings For Portal FramesDocument6 pagesBracings For Portal FramesJulianNo ratings yet

- Design of Steel Baseplate To BS 5950 - PHILLIPS CONSULTING ENGINEERS LTDDocument4 pagesDesign of Steel Baseplate To BS 5950 - PHILLIPS CONSULTING ENGINEERS LTDLavanyan SatchithananthanNo ratings yet

- Apex ConnectionDocument9 pagesApex ConnectionMihnea OrzaNo ratings yet

- Portal Frame SampleDocument70 pagesPortal Frame SampleVincent 20200% (1)

- Elastic Analysis of A Single Bay Portal FrameDocument31 pagesElastic Analysis of A Single Bay Portal Framelanmark100% (1)

- Ribbed Slabs: Design ConsiderationsDocument6 pagesRibbed Slabs: Design ConsiderationsAwadNo ratings yet

- Portal Frame Stablity CheckDocument2 pagesPortal Frame Stablity CheckAlma M. LaraNo ratings yet

- Peb Shed StaadDocument22 pagesPeb Shed StaadShashank PatoleNo ratings yet

- Inclined ColumnDocument6 pagesInclined ColumnRabindraUpretiNo ratings yet

- Steel Column Axial LoadsDocument2 pagesSteel Column Axial LoadsGihan Chathuranga100% (1)

- Analysis of Portal Frame BuildingDocument36 pagesAnalysis of Portal Frame BuildingTaofik Kay Lawal100% (4)

- Design of A CanopyDocument31 pagesDesign of A CanopyPratiwi KusumaNo ratings yet

- Hollow Pot Design WorksheetDocument7 pagesHollow Pot Design Worksheetpatrick chegeNo ratings yet

- Timber Beam DesignDocument5 pagesTimber Beam DesignnurulselangorNo ratings yet

- Manual of Purlin and Girt DesignDocument64 pagesManual of Purlin and Girt DesigntitlesaengNo ratings yet

- Minimum Edge Distances As Identified in BS 5950Document1 pageMinimum Edge Distances As Identified in BS 5950Jagdish DhanuskarNo ratings yet

- Raft Foundation DesignDocument10 pagesRaft Foundation DesignGautam PaulNo ratings yet

- Portal Frame Practice ProblemsDocument10 pagesPortal Frame Practice ProblemsBoyzz ChinNo ratings yet

- Example Flat Slab Design - CarDocument31 pagesExample Flat Slab Design - CarRayGaintNo ratings yet

- Design Procedure For Steel Frame Structures According To Bs 5950Document46 pagesDesign Procedure For Steel Frame Structures According To Bs 5950Ali Gaffar100% (2)

- Design of A UbDocument8 pagesDesign of A UbGihan Chathuranga100% (1)

- Design Example-Beam Compact SectionDocument13 pagesDesign Example-Beam Compact SectionManoj RautNo ratings yet

- Design of Portal FramesDocument35 pagesDesign of Portal FramesPranav Prabhakar100% (2)

- Steelwork Design Guide To BS 5950 Vol 1 Part B1 Dimensions & PropertiesDocument56 pagesSteelwork Design Guide To BS 5950 Vol 1 Part B1 Dimensions & PropertiessubamanivelNo ratings yet

- Example 3.2 - Continuous Beam-Updated 010812Document15 pagesExample 3.2 - Continuous Beam-Updated 010812Muhammad Farhan Gul100% (2)

- Design of Steel StructuresDocument8 pagesDesign of Steel StructuresCharan ReddyNo ratings yet

- Slab With OpeningDocument16 pagesSlab With OpeningTomislav Šimag100% (1)

- Add An Extra DL and Revise - 0.15 PSFDocument1 pageAdd An Extra DL and Revise - 0.15 PSFsharif uddinNo ratings yet

- 2 - Portal FramesDocument19 pages2 - Portal FramesLesego Matojane100% (2)

- Steel Staircase DesignDocument4 pagesSteel Staircase DesignSenthooran MahendranNo ratings yet

- Clean Copy Metal Building Foundation Rev 2.1Document14 pagesClean Copy Metal Building Foundation Rev 2.1jurieskNo ratings yet

- Load Calculation For Portal Framed Shed With Wind Asce 7-10Document10 pagesLoad Calculation For Portal Framed Shed With Wind Asce 7-10msb100% (1)

- Notes Structural Design 1-2Document182 pagesNotes Structural Design 1-2Athiyo Martin75% (4)

- Structural Engineering - Slab Design To BS 8110Document4 pagesStructural Engineering - Slab Design To BS 8110Gladson Js100% (2)

- Wind Loads UK Portal Frame WEDocument31 pagesWind Loads UK Portal Frame WEmandregomes100% (1)

- Design Provisions of BS 5950 Part 1Document21 pagesDesign Provisions of BS 5950 Part 1ISMAEL SHAIK86% (7)

- Shear Wall Design EurocodeDocument22 pagesShear Wall Design EurocodeYemi Eshetu MeeNo ratings yet

- Slab DesignDocument87 pagesSlab Designshamen amarasekaraNo ratings yet

- Balcony Slab To BS 8110Document5 pagesBalcony Slab To BS 8110gaza manNo ratings yet

- Reinforced Concrete Design 2: Frame AnalysisDocument100 pagesReinforced Concrete Design 2: Frame AnalysisAhmad Ubaidillah Abdul Rani67% (3)

- Z Purlins TigerDocument9 pagesZ Purlins TigerabuthahirNo ratings yet

- Compare BS and ACI CodeDocument12 pagesCompare BS and ACI CodeMiski45100% (1)

- BS5950 Vs EC3Document146 pagesBS5950 Vs EC3Ali Gaffar100% (1)

- Portal Frame CalculationDocument57 pagesPortal Frame CalculationFaizal Imran100% (4)

- Lecture 6 - Design of RC SlabsDocument21 pagesLecture 6 - Design of RC SlabsTuan Jalai100% (1)

- Strip Footing 3 Columns Bsi 8110 - 2Document11 pagesStrip Footing 3 Columns Bsi 8110 - 2Magdy Bakry100% (2)

- Longterm Deflection Comparison With EtabsDocument6 pagesLongterm Deflection Comparison With EtabsArnel Dodong100% (1)

- Structural Analysis ReportDocument3 pagesStructural Analysis ReportLandz GanzonNo ratings yet

- Example Flange Beam PDFDocument17 pagesExample Flange Beam PDFFarhana HussinNo ratings yet

- Portal Frame Design-Worked ExampleDocument30 pagesPortal Frame Design-Worked Examplesanjeevkr82% (17)

- CraneDocument36 pagesCraneGautam Paul100% (2)

- TutorialDocument27 pagesTutorial朱星宇No ratings yet

- Gable FrameDocument45 pagesGable FrameKamran JamilNo ratings yet

- Reinforced Concrete Lecture Notes University of HongKongDocument32 pagesReinforced Concrete Lecture Notes University of HongKongApril Ingram100% (4)

- Chapter 36 WexDocument30 pagesChapter 36 WexCaesarAbdullahNo ratings yet

- WarehouseDocument51 pagesWarehouseAnonymous q0irDXlWAm100% (2)

- Section4 3 PDFDocument13 pagesSection4 3 PDFRavi ShankarNo ratings yet

- 25m Single Lane Bridge Design Calculations LatestDocument16 pages25m Single Lane Bridge Design Calculations Latestntah84100% (4)

- GRE NotesDocument21 pagesGRE NotesMatheus Loss LizeNo ratings yet

- Gradhb18 0Document178 pagesGradhb18 0deua2004No ratings yet

- PPPPDocument23 pagesPPPPdeua2004No ratings yet

- 2017 GSAS FinancingGradStudyFINAL Web ReadyDocument12 pages2017 GSAS FinancingGradStudyFINAL Web Readydeua2004No ratings yet

- PPPPDocument23 pagesPPPPdeua2004No ratings yet

- Studysheet For GREDocument15 pagesStudysheet For GREMuqarraulAhmadNo ratings yet

- 'Sri Krishna Public School, Bistupur: This Question Paper Consists of 4 PagesDocument5 pages'Sri Krishna Public School, Bistupur: This Question Paper Consists of 4 Pagesdeua2004No ratings yet

- Indian Forest Act 1927Document24 pagesIndian Forest Act 1927Sidharth SudNo ratings yet

- 3 Types of RocksDocument35 pages3 Types of RocksJulieta Bias100% (4)

- Law Collage Dhanbad PDFDocument1 pageLaw Collage Dhanbad PDFdeua2004No ratings yet

- LL B I Year SyllabusDocument42 pagesLL B I Year Syllabusdeua2004100% (1)

- Adv Arto Tsi2016Document10 pagesAdv Arto Tsi2016deua2004No ratings yet

- Types of RockDocument5 pagesTypes of Rockdeua2004No ratings yet

- Previouspaper BSSC Graduate Level Main Exam 2010 GKDocument48 pagesPreviouspaper BSSC Graduate Level Main Exam 2010 GKJay Prakash PatelNo ratings yet

- DEC Salary Slip of GsDocument1 pageDEC Salary Slip of Gsdeua2004No ratings yet

- Law Collage DhanbadDocument1 pageLaw Collage Dhanbaddeua2004No ratings yet

- 9561 155 PVC C 534Document1 page9561 155 PVC C 534deua2004100% (1)

- Digitally Signed by V.P.Johari Date: 2010.08.24 09:41:10 GMT+05:30 Reason: CAT I Location: NtpceocDocument1 pageDigitally Signed by V.P.Johari Date: 2010.08.24 09:41:10 GMT+05:30 Reason: CAT I Location: Ntpceocdeua2004No ratings yet

- Conveyor Calculations Based On Is: 11592: Input SheetDocument2 pagesConveyor Calculations Based On Is: 11592: Input Sheetdeua2004No ratings yet

- Bangalore To Mumbai 18 March 2014 (Perhaps Not Travveled)Document1 pageBangalore To Mumbai 18 March 2014 (Perhaps Not Travveled)deua2004No ratings yet

- PLS Furnish Pointwis E Reply To All OUR Comment S: FE EDDocument1 pagePLS Furnish Pointwis E Reply To All OUR Comment S: FE EDdeua2004No ratings yet

- Power Cal. TSL 3.0 MtpaDocument8 pagesPower Cal. TSL 3.0 Mtpadeua2004No ratings yet

- 9561-155-PVM-B-046-02 (Cat-1)Document1 page9561-155-PVM-B-046-02 (Cat-1)deua2004No ratings yet

- TS 1Document17 pagesTS 1deua2004No ratings yet

- NSE-20150422-equityonsms.com.txtDocument32 pagesNSE-20150422-equityonsms.com.txtDhawan SandeepNo ratings yet

- Comparison of Old Scope To New Scope of JSPL Package6Document2 pagesComparison of Old Scope To New Scope of JSPL Package6deua2004No ratings yet

- For More Inquire (: We Believe in The Strength of Teamwork and Innovative ThinkingDocument1 pageFor More Inquire (: We Believe in The Strength of Teamwork and Innovative Thinkingdeua2004No ratings yet

- Sanjeet UpdatedDocument3 pagesSanjeet Updateddeua2004No ratings yet

- NSE-20150422-equityonsms.com.txtDocument32 pagesNSE-20150422-equityonsms.com.txtDhawan SandeepNo ratings yet

- Annexure - I Priority Circuit As Per Mom Dated 28Th May' 2010 To 31St May' 2010 DRG No. Drawing Description SL. NO Submitted ON Approval StatusDocument1 pageAnnexure - I Priority Circuit As Per Mom Dated 28Th May' 2010 To 31St May' 2010 DRG No. Drawing Description SL. NO Submitted ON Approval Statusdeua2004No ratings yet