Professional Documents

Culture Documents

Final Project Report: Belinda Tomasi Daniel Huff

Final Project Report: Belinda Tomasi Daniel Huff

Uploaded by

Julia Turpo SuarezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Final Project Report: Belinda Tomasi Daniel Huff

Final Project Report: Belinda Tomasi Daniel Huff

Uploaded by

Julia Turpo SuarezCopyright:

Available Formats

Belinda Tomasi

Daniel Huff

Final Project Report

IEE 572 Design of Engineering Experiments

December 4, 2000

1. Recognition and Statement of Problem

!romic acid !as been used for decades "it!in industr# to treat metal surfaces$ T"o

common applications in%ol%ing c!romic acid !a%e been& '( to increase t!e corrosion

resistance of a metal surface and 2( to prepare a metal surface for ad!esi%e bonding$

)lt!oug! processes suc! as t!ese !a%e been %er# useful in industr# and !a%e been used

for decades, c!romic acid possesses !exa%alent c!romium, "!ic! is no" *no"n to be a

carcinogen$ T!erefore, in recent #ears, t!ere !as been significant effort to find alternati%e

processes t!at can be used in place of c!romium+containing processes$

,or non+ad!esi%e bonding applications in%ol%ing aluminum surfaces, t!e use of an

alternati%e, sulfuric acid+based replacement process !as been used successfull# for t!e

past decade$ )lt!oug! t!is process produces an aluminum oxide la#er "it! corrosion

resistance properties comparable to t!ose of t!e c!romic acid process, t!is oxide la#er

does not possess comparable ad!esion properties$ T!erefore, t!e sulfuric acid+based

process cannot be used in place of t!e c!romic acid %ersion for critical ad!esi%e bonding

applications$

Electrol#tic, p!osp!oric acid based treatments are *no"n to -open up. t!e outer surface

in aluminum allo#s and t!e open nature of t!e surface can impro%e ad!esion properties$

/ne of t!ese p!osp!oric acid based processes !as been used successfull# as a deoxidi0er

pretreatment process1 !o"e%er, t!is deoxidi0er process "as de%eloped as a pretreatment

for a different anodi0e process and !as generall# not been used as a pretreatment for t!e

sulfuric acid based anodi0e process described abo%e$ ,urt!ermore, sulfuric acid is

strongl# acidic, and opening up t!e surface ma# lead to a retention of sulfuric acid$ T!is

residual acidit# mig!t interfere "it! t!e curing mec!anisms of ad!esi%e and primers,

t!ereb# reducing o%erall ad!esion properties$

To counter t!e effects caused b# possible residual acidit#, t!e use of a bicarbonate,

neutrali0ing dip after t!e sulfuric acid process can be emplo#ed$ T!is surface

neutrali0ation tec!ni2ue !as been used successfull# in ot!er industrial processes

in%ol%ing strong acids$

,inall#, t!e application of certain silicon+based coupling agents !as been *no"n to

impro%e ad!esion and ot!er properties on %arious inorganic materials$ ertain titanium,

0irconium, and aluminum+based c!emicals !a%e also been used, sometimes in

con3unction "it! t!e silicon+based coupling agents$

B# combining t!e sulfuric acid based anodi0e process "it! t!e deoxidi0er pretreatment,

t!e neutrali0er post treatment, and t!e application of ad!esion promoting coupling agents,

preliminar# ad!esion studies !a%e s!o"n excellent ad!esion properties under most test

conditions$ Ho"e%er, results of tests performed at cold temperatures 4+55

o

,( !a%e

ex!ibited extreme %ariabilit#1 in some instances, cold temperature results "ere %er# poor$

2

Due to t!ese poor results at lo" temperature, it "as decided to perform a designed

experiment on t!is combination process to determine if parameters could be ad3usted to

impro%e cold temperature ad!esion properties$

2. Choice of factors, levels and ranges

In creating t!is combination process, note t!at t!e %arious indi%idual steps ++ t!e

deoxidi0er pretreatment, t!e sulfuric acid based anodi0e process, t!e bicarbonate

neutrali0ation step, and t!e application of a coupling agent treatment ++ "ere extracted

from ot!er processes$ T!ese indi%idual procedures !ad not pre%iousl# been used in

combination "it! eac! ot!er$ onse2uentl#, in t!e preliminar# studies in%ol%ing t!is

combination of process factors 4prior to t!is designed experiment(, le%els of t!e

indi%idual factors "ere set at t!e standard %alues normall# used in t!e ot!er processes$

,or t!is designed experiment, t!e center points "ere assumed to be t!ese same standard

le%els, and lo" and !ig! points "ere selected from eac! side of t!e center points$

In t!is experiment, parameters related to t!e sulfuric acid anodi0e "ere not %aried since

t!is process must meet ot!er re2uirements 4e$g$, corrosion resistance(, and %ariation of t!e

parameters related to t!is process mig!t affect t!ose properties$ Ho"e%er, factors related

to t!e ot!er t!ree process steps 4t!e deoxidi0er, t!e neutrali0ation, and t!e coupling agent

application steps( "ere %aried and are s!o"n in T)B6E I$

TA!" #. $escriptions of "%perimental Factors.

Factor $escription

&ain

Factor

$esignation

!o'

!evel

()*

Center

Point

+igh

!evel

(,*

Time used in p!osp!oric acid+based

pretreatment process 4prior to sulfuric

acid process(

) 7 min '0 min '7 min

8oltage used in p!osp!oric acid+based

pretreatment process 4prior to sulfuric

acid process(

B 5 %olts 7$5 %olts '0 %olts

oncentration of sodium bicarbonate

neutrali0ing solution 4used after

sulfuric acid+based process(

2$09 5$09 :$09

Time soa*ing in sodium bicarbonate

neutrali0ing solution 4used after

sulfuric acid+based process(

D 5 sec 55 sec '05 sec

)mount of silicon+based coupling

agent in ad!esion+promoting solution

E 5 ml '0 ml '5 ml

)mount of 0irconium+based coupling

agent in ad!esion+promoting solution

, 2$5 ml 5$0 ml 7$5 ml

Immersion time of panel in mixed

4silicon;0irconium( coupling agent

< 70 sec '20

seconds

2'0 sec

7

solution

4

-. Selection of the Response .ariable

)s mentioned abo%e, "e !a%e pre%iousl# obtained good ad!esion results on sulfuric acid

processed surfaces b# using t!e p!osp!oric acid deoxidi0er pretreatment and b# using

bicarbonate neutrali0ing bat! and organosilane+based coupling agent treatments as post

treatments$ Ho"e%er, "e !a%e !ad extreme %ariabilit# of our ad!esion results "!en t!ese

surfaces "ere tested under cold conditions$ =ince acceptable ad!esion properties at cold

temperature !a%e been difficult to obtain, t!is experiment specificall# focused upon t!e

ad!esion peel strengt! 4using a standard, )=T> D 7'57 test procedure( performed under

cold temperature conditions 4+55

o

,($

/. Choice of "%perimental $esign

T!e experiment "as performed using a 2

7+7

fractional factorial design 4?esolution I8( in

t"o confounded bloc*s, as s!o"n in T)B6E II belo"$ T"ent# total runs "ere

performed, "it! eac! bloc* of ten runs performed on a separate da#$ 4) -run. is defined

in t!e next section$( Bloc*s "ere defined b# t!e sign of t!e )BD interaction term$

@it!in eac! bloc*, runs "ere performed in random order, except for t!e first and last run

of eac! da#Abloc*, "!ic! "ere center point runs$

TA!" ##. "%perimental $esign.

?un

ID B ) B D

E C

)B

, C

BD

< C

)D

Block

=ABD

Run

Order

Day #1

Run

Order

Day #2

' + + + + + + + + 5

2 ; + + + ; + ; ; 4

7 + ; + + ; ; + ; :

4 ; ; + + + ; ; + 4

5 + + ; + ; ; ; + 7

5 ; + ; + + ; + ; 5

7 + ; ; + + + ; ; 7

: ; ; ; + ; + + + '

D + + + ; + ; ; ; 7

'0 ; + + ; ; ; + + 2

'' + ; + ; ; + ; + D

'2 ; ; + ; + + + ; D

'7 + + ; ; ; + + ; 2

'4 ; + ; ; + + ; + :

'5 + ; ; ; + ; + + 5

'5 ; ; ; ; ; ; ; ; 5

'7 0 0 0 0 0 0 0 '

': 0 0 0 0 0 0 0 '0

'D 0 0 0 0 0 0 0 '

5

20 0 0 0 0 0 0 0 '0

0. Performing the "%periment

In t!is experiment, a -run. consisted of t!e treatment of one E0$025. x 4. x D. aluminum

panelF and one E0$057. x 4. x :. aluminum panelF processed toget!er at t!e appropriate

factor le%els s!o"n in t!e table abo%e$ T!ese t"o panels "ere t!en bonded toget!er "it!

an ad!esi%e and cut longitudinall# into t!ree '."ide strips$ Gsing a mec!anical test "it!

temperature+controlled c!amber set to H55

o

,, eac! '. "ide strip "as tested b# positioning

in a separating, roller+t#pe apparatus, "!ic! "as placed inside a cold 4+55

o

,( test c!amber

and attac!ed to mec!anical test mac!ine grips$ )fter a '0+minute soa* period at H55

o

,,

t!e specimen "as peeled apart in t!e cold c!amber using a constant speed of motion, and

t!e a%erage force re2uired to peel t!e specimen apart "as determined$ T!is a%erage %alue

is called t!e -peel strengt!. of t!e specimen, "it! units of Epounds per inc! "idt!F$

@it! t"ent# runs and t!ree specimens per run, sixt# indi%idual peel strengt! specimens

"ere generated and tested$ =ince it "as not possible to test all t!ese specimens "it!in a

single time period, testing "as performed on t!ree separate da#s$ T!e t!ree specimens

obtained from eac! run "ere separated into t!ree different test groups, and eac! group of

t"ent# specimens "as tested on a different da# in random order$

T!erefore, for eac! run, t!e a%erage of t!e t!ree test specimens 4tested on separate da#s(

"as t!e response %ariable for t!e run$

=ufficient planning, preparation and care "ere used prior to and during t!e experiment so

problems could be a%oided, and fortunatel#, no significant problems "ere encountered

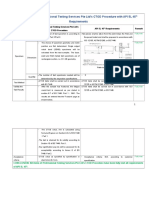

during t!e experiment$ T!e run c!art used during t!is experiment is s!o"n in ,igure '$

5

Fig1re 1. R1n Chart 2sed d1ring "%periment.

7

Factors A, B, C, D, E, F & G to be varied as follows

Day 1

Run

Order

Std.

Alkaline

Clean

Deox.

A (H

3

PO

4

pretreatment

soak time)

Deox.

B (H

3

PO

4

pretreatment

olta!e)

"SAA

Anodi#e

(1$%)

&eutrali#ation

C (&aHCO

3

'on'.)

&eutrali#ation

D (&aHCO

3

soak time)

Couplin! A!ents

E & F (amount o( 'ouplin!

a!ents)

Couplin! A!ents

G ('ouplin! a!ent

soak time)

Apply

"ond

Primer

1 $ min 1) min. *.$ % +) min $, $$ se'. (1) 1) m- Si . $ m- /r 10) se'. 113 mil

+ 2 13 min. $ % 2 +, 1)$ se'. (2) 1$ m- Si . *.$ m- /r 3) se'. 2

3 2 13 min. 1) % 2 0, $ se'. (3) 1$ m- Si . +.$ m- /r 3) se'. 2

4 2 13 min. 1) % 2 +, $ se'. (4) $ m- Si . *.$ m- /r 3)) se'. 2

$ 2 * min. 1) % 2 0, 1)$ se'. (4) $ m- Si . *.$ m- /r 3) se'. 2

3 2 * min. $ % 2 +, $ se'. (5) $ m- Si . +.$ m- /r 3) se'. 2

* 2 * min. $ % 2 0, $ se'. (2) 1$ m- Si . *.$ m- /r 3)) se'. 2

0 2 13 min. $ % 2 0, 1)$ se'. (5) $ m- Si . +.$ m- /r 3)) se'. 2

4 2 * min. 1) % 2 +, 1)$ se'. (3) 1$ m- Si . +.$ m- /r 3)) se'. 2

1) 2 1) min. *.$ % 2 $, $$ se'. (1) 1) m- Si . $ m- /r 10) se'. 2

Day +

Run

Order

1 $ min 1) min. *.$ % +) min $, $$ se'. (1) 1) m- Si . $ m- /r 10) se'. 113 mil

+ 2 * min. $ % 2 0, 1)$ se'. (3) 1$ m- Si . +.$ m- /r 3) se'. 2

3 2 * min. 1) % 2 0, $ se'. (5) $ m- Si . +.$ m- /r 3)) se'. 2

4 2 13 min. $ % 2 +, $ se'. (3) 1$ m- Si . +.$ m- /r 3)) se'. 2

$ 2 13 min. $ % 2 0, $ se'. (4) $ m- Si . *.$ m- /r 3) se'. 2

3 2 13 min. 1) % 2 0, 1)$ se'. (2) 1$ m- Si . *.$ m- /r 3)) se'. 2

* 2 * min. $ % 2 +, 1)$ se'. (4) $ m- Si . *.$ m- /r 3)) se'. 2

0 2 * min. 1) % 2 +, $ se'. (2) 1$ m- Si . *.$ m- /r 3) se'. 2

4 2 13 min. 1) % 2 +, 1)$ se'. (5) $ m- Si . +.$ m- /r 3) se'. 2

1) 2 1) min. *.$ % 2 $, $$ se'. (1) 1) m- Si . $ m- /r 10) se'. 2

3. Statistical Anal4sis of the $ata

Experimental test results are s!o"n in T)B6E III$

TA!" ###. "%perimental Res1lts5 )30

o

F Peel Test.

?un ID B

Test B'

4test da# '(

Test B2

4test da# 2(

Test B7

4test da# 7(

)%erage Ieel

=trengt! 4pi"(

=tandard

De%iation

4pi"(

' 7$7 5$4 D$0 7$77 '$:2

2 25$4 25$' 70$4 27$0 2$D:

7 25$0 27$7 25$5 25$7 '$'7

4 ':$5 :$5 ''$' '2$7 5$'5

5 24$4 '4$4 24$7 2'$2 5$:5

5 25$4 '5$7 24$D 22$5 5$45

7 27$: 25$D 72$4 2:$7 7$74

: 'D$: '7$D 2'$5 'D$7 '$:0

D 27$' 27$4 77$7 2D$7 7$2:

'0 ''$7 7$0 '4$4 '0$D 7$72

'' 'D$D :$2 ':$: '5$5 5$45

'2 25$: 27$D 25$D 25$5 '$52

'7 25$7 20$D 25$2 24$' 2$:4

'4 '7$7 '5$5 '5$0 '5$D '$2'

'5 20$' 'D$5 27$0 20$D '$:4

'5 77$0 2:$5 40$5 75$4 5$'5

'7 D$D '5$0 D$7 ''$4 7$'7

': '0$5 :$: '7$2 '0$D 2$2'

'D 2D$2 'D$D 'D$' 22$7 5$5'

20 2'$5 '7$2 ':$5 'D$' 2$'D

:

Design Expert =oft"are "as used to anal#0e t!e data$ Jormal probabilit# plots "ere

used to select possible significant factors and interactions$ )fter selecting a combination

of main factors and t"o factor interactions, Design Expert "as used to perform an

)J/8) anal#sis of t!e data and to generate %arious measures of model ade2uac#$

T)B6E I8 s!o"s se%eral main factor and interaction combinations "it! corresponding

model ade2uac# measurement %alues$

TA!" #.. &odel Ade61ac4 &eas1res of .ario1s &odel Combinations.

Based upon t!e model ade2uac# %alues s!o"n in T)B6E I8, t!e model

EB,,D,E,,,<,B,B<,,F appears to be t!e best model$ In t!is model, main effect )

4Deoxidi0er time( does not appear to be significant$ )fter remo%ing ,actor ), t!e

experiment pro3ects into a 2

7+2

design 4also ?esolution I8($ )ssuming 7+factor

interactions are insignificant, t!is frees t!e B and B< 2+factor interactions from ot!er

aliases 4alt!oug! t!e 2+factor interaction , is still aliased "it! anot!er 2+factor

interaction, E<($

D

Cobi!atio!

" of #ers

i! $odel

$odel

%&'al(e

)ac* of Fit

%&'al(e +&,-(ared

Ad./

+&

,-(ared

%red/

+&,-(ared

C(rvat(re

%&'al(e

"5 C5 65 75 "7 $ ).)))3 ).43+3 ).0)33 ).*+13 ).$*34 ).)))0

"5 C5 65 85 75 "7 3 ).)))$ ).$331 ).0$+4 ).**14 ).31*$ ).)))$

"5 C5 D5 65 85 75 "7 * ).)))3 ).$0*$ ).0043 ).0)33 ).33*3 ).)))4

"5 C5 65 85 75 "C5 "7 * ).)))3 ).3$00 ).4)+$ ).0343 ).*)$* ).)))+

A5 "5 C5 65 85 75 "7 * ).))13 ).444$ ).0$$4 ).*$4+ ).$+4$ ).)))0

"5 C5 D5 65 85 75 "C5 "7 0 ).)))+ ).**00 ).4344 ).0*31 ).*0)4 9).)))1

B, C, D, E, F, G, BC, BG, CF 0 1/1113 1/2222 1/0435 1/2225 1/2134 1/1111

All 8a'tors : ;ntera'tions 1$ ).13)) 111 ).4**) ).0)4* &<A ).)334

)ssuming , 4and not E<( is t!is 2+factor interaction, t!e e2uation for t!is model is&

+55

o

, peel strengt! C 7$:'742 ; '$0D'424B( H 0$57D5:4( ; 0$0'52754D( ; 0$2'5504E(

; 0$052:774,( ; 0$05D'554<( ; 0$'27574B( H 0$005D'254B<(

; 0$0557774,(

"!ere& B C deoxidi0er %oltage

C bicarbonate concentration

D C bicarbonate soa* time

E C silicon+based coupling agent concentration

, C 0irconium additi%e concentration

< C soa* time in coupling agent solution

B C 2+factor interaction bet"een B and

B< C 2+factor interaction bet"een B and <

, C 2+factor interaction bet"een and ,

)dditional experimentation could be performed to free t!e ,CE< alias1 !o"e%er, ot!er

considerations s!ould be explored furt!er before committing more time and effort to t!e

next experiment$ ,or example, t!e anal#ses indicate t!at t!e use of !ig!er order terms or

data transformations s!ould possibl# be considered in c!aracteri0ing t!e model$ T!e

cur%ature I+%alues s!o"n in T)B6E I8 indicate a lo" probabilit# t!at t!e cur%ature is

not present 4i$e$, t!ese %alues indicate a !ig! probabilit# t!at cur%ature is present($

,urt!ermore, man# of t!e residuals %s$ main factor plots 4e$g$, residuals %s$ deoxidi0er

%oltage, residuals %s$ bicarbonate soa* time, residuals %s$ silane coupling agent

concentration, and residuals %s$ coupling agent soa* time( indicate a slig!t -coning.

effect$ )not!er interesting fact is t!at if t!e mean of t!e four center point runs is

compared "it! t!e mean of t!e ot!er sixteen +A; le%el runs and also "it! t!e !ig!est %alue

of all t!e runs, t!e follo"ing differences are obser%ed&

mean %alue of center point runs& '5$0 pi"

mean %alue of all ot!er runs& 2'$4 pi"

!ig!est %alue 4?un B'5(& 75$4 pi"

?ecall t!at t!e center point le%els of t!e different factors are t!e le%els used "!en t!ese

indi%idual procedures are used in t!eir more+traditional roles as part of ot!er processes$

It "as initiall# assumed "!en t!ese factors "ere combined for t!e ne" process discussed

in t!is report, t!e same standard le%els 4as used in ot!er processes( s!ould also be used to

obtain t!e best peel strengt! %alues$ Ho"e%er, in comparing t!e %alues abo%e, it is

ob%ious t!ese standard le%els do not gi%e optimum results for t!is ne" process$ @it!in

t!e combinations of factors and le%els t!at "ere performed "it!in t!is experiment, t!e

!ig!est response %alue 4s!o"n abo%e, from ?un B'5( "as obtained "!en all factors "ere

set at t!eir !ig! 4;( le%el$ T!is is enlig!tening as to "!# suc! poor results "ere obser%ed

in preliminar# studies of t!is process 4prior to t!is designed experimental stud#($

'0

T!erefore, before additional experiments are carried out to define t!e model furt!er,

certain response surface met!ods s!ould be performed to determine if factor le%els are

e%en "it!in t!e %icinit# of t!eir optimum le%els$

Bloc* effects

T!e center point runs "ere performed as t!e first and last run of eac! da#Abloc*, and t!e

test results of t!ese runs indicate a significant bloc* effect&

Ieel strengt!, center point run B'+' 4da# B', 'st run(& ''$4 pi"

Ieel strengt!, center point run B'+'0 4da# B', last run(& '0$D pi"

Ieel strengt!, center point run B2+' 4da# B2, 'st run(& 22$7 pi"

Ieel strengt!, center point run B2+'0 4da# B2, last run(& 'D$' pi"

T!erefore, t!e inclusion t!e t"o confounded bloc*s "it!in t!e experimental design "as

beneficial for t!e anal#sis of t!e data$ Jote t!at "it!in eac! bloc*, t!ere is good

agreement bet"een t!e results of t!e t"o center point runs$

?esiduals plots&

)lt!oug! se%eral of t!e residuals %s$ factor le%el plots ex!ibited a -coning. effect, and

alt!oug! t!ere appeared to be a bloc* effect bet"een t!e '

st

and 2

nd

da#, ot!er residual

plots did not ex!ibit an# strange patterns$ T!ese include&

Jormal probabilit# plot of t!e residuals

?esiduals %s$ predicted %alues

?esiduals %s$ run order

T!e Design Expert )J/8) anal#sis and t!e %arious plots mentioned abo%e are attac!ed

in t!e )IIEJDIK$

''

7. Concl1sions and Recommendations

B# performing t!is experiment and stud#ing %arious factors related to t!e ad!esion

strengt! of anodi0ed surfaces, an excellent model 4e$g$, ?

2

C0$D4:1 ad3usted ?

2

C0$::D(

"as de%eloped$ T!e e2uation of t!is model is&

+55

o

, peel strengt! C 7$:'742 ; '$0D'424B( H 0$57D5:4( ; 0$0'52754D(

; 0$2'5504E( ; 0$052:774,( ; 0$05D'554<(

; 0$'27574B( H 0$005D'254B<( ; 0$0557774,(

"!ere& B C deoxidi0er %oltage

C bicarbonate concentration

D C bicarbonate soa* time

E C silicon+based coupling agent concentration

, C 0irconium additi%e concentration

< C soa* time in coupling agent solution

B C 2+factor interaction bet"een B and

B< C 2+factor interaction bet"een B and <

, C 2+factor interaction bet"een and ,

)lt!oug! t!e experiment and anal#sis "as able to create an excellent model, t!e anal#ses

s!o"ed !ig!er order terms and data transformations mig!t be useful in c!aracteri0ing t!e

model furt!er$

enter point le%els, "!ic! "ere assumed to be t!e initial best estimates for optimum

factor le%els, "ere s!o"n to produce poor results$ T!is agrees "it! t!e !ig! %ariabilit#

and poor results obser%ed in preliminar# studies of t!is process prior to t!is designed

experiment, in "!ic! onl# t!e center point le%els "ere used to perform t!e process$

@it!in t!e combinations of factors and le%els t!at "ere performed in t!is experiment, t!e

!ig!est response %alue "as obtained "!en all factors "ere set at t!eir !ig! 4;( le%el$

T!e use of t"o confounded bloc*s "it!in t!e experimental design "as !elpful in

accounting for t!e effect of t!e particular da# in "!ic! runs "ere performed$

?esponse surface met!ods "ould be useful for determining if t!e factors are in t!eir

optimum region and for performing general optimi0ation of t!is process$

'2

APP"8$#9

Design Expert )J/8) anal#sis

?esidual Ilots

/ne factor at a time and interaction grap!s

'7

You might also like

- Changed Teachings of The WatchtowerDocument5 pagesChanged Teachings of The WatchtowerJay Smith100% (2)

- The Effect of Electroless Ni-P Coatings On The Fatigue Life of Al 7075-T6 Fastener Holes With Symmetrical Slits PDFDocument9 pagesThe Effect of Electroless Ni-P Coatings On The Fatigue Life of Al 7075-T6 Fastener Holes With Symmetrical Slits PDFSunil KumbarNo ratings yet

- Savage Worlds MLP EditionDocument66 pagesSavage Worlds MLP EditionCarsten_Curren_7854100% (8)

- Corrosion of Aluminum and Its Alloys: Forms of CorrosionDocument3 pagesCorrosion of Aluminum and Its Alloys: Forms of CorrosionInternational Journal of computational Engineering research (IJCER)No ratings yet

- MIL-Q-9858 Quality Program RequirementsDocument11 pagesMIL-Q-9858 Quality Program RequirementsJay MillerNo ratings yet

- Influence of Aging Treatment On Mechanical Properties of 6061 AlumDocument4 pagesInfluence of Aging Treatment On Mechanical Properties of 6061 AlumMohamed NasrNo ratings yet

- Choosing The Right Conformal Coating The Facts & MythsDocument4 pagesChoosing The Right Conformal Coating The Facts & Mythssdfdfs7253No ratings yet

- Austenitic Chromium-Nickel-Silicon Alloy Steel Seamless and Welded PipeDocument4 pagesAustenitic Chromium-Nickel-Silicon Alloy Steel Seamless and Welded PipeJosé Ramón GutierrezNo ratings yet

- Astm E1558.24503Document13 pagesAstm E1558.24503Juan Shevchenko100% (1)

- Tool ListDocument4 pagesTool ListFred WilpenNo ratings yet

- Impedance Spectroscopy: Theory, Experiment, and ApplicationsFrom EverandImpedance Spectroscopy: Theory, Experiment, and ApplicationsEvgenij BarsoukovNo ratings yet

- Treatment of An Anodizing Waste To Water Quality-Based Effluent LimitsDocument6 pagesTreatment of An Anodizing Waste To Water Quality-Based Effluent LimitsbaneNo ratings yet

- Malate Construction Development Corporation v. Extraordinary Realty Agents & Brokers Cooperative, G.R. No. 243765, January 5, 2022Document2 pagesMalate Construction Development Corporation v. Extraordinary Realty Agents & Brokers Cooperative, G.R. No. 243765, January 5, 2022Metsuyo Barite100% (1)

- Review On Automotive Body Coating ProcessDocument4 pagesReview On Automotive Body Coating ProcessIJEMR JournalNo ratings yet

- Chara Dasha Calculation of Mahadasha Anthar Dasha and Prati Anthar DashDocument6 pagesChara Dasha Calculation of Mahadasha Anthar Dasha and Prati Anthar DashSunil RupaniNo ratings yet

- A 915 - A915m - 93 R98 Qtkxns05m1i5oa - PDFDocument3 pagesA 915 - A915m - 93 R98 Qtkxns05m1i5oa - PDFMung Duong XuanNo ratings yet

- Conducting Cyclic Potentiodynamic Polarization Measurements For Localized Corrosion Susceptibility of Iron-, Nickel-, or Cobalt-Based AlloysDocument5 pagesConducting Cyclic Potentiodynamic Polarization Measurements For Localized Corrosion Susceptibility of Iron-, Nickel-, or Cobalt-Based AlloysTeymur Regenmaister100% (1)

- Adiabatic Shear Localization: Frontiers and AdvancesFrom EverandAdiabatic Shear Localization: Frontiers and AdvancesBradley DoddNo ratings yet

- Vassar Industries EEs Union v. Estrella (1978)Document2 pagesVassar Industries EEs Union v. Estrella (1978)GR100% (1)

- Corrosion Resistance of Aluminum and Magnesium Alloys: Understanding, Performance, and TestingFrom EverandCorrosion Resistance of Aluminum and Magnesium Alloys: Understanding, Performance, and TestingNo ratings yet

- Study Data of Passivation - of - Zinc PDFDocument11 pagesStudy Data of Passivation - of - Zinc PDFvkmsNo ratings yet

- Astm Standard Specification For Chemical Pasivation Treatments For Stainless Steel A967Document7 pagesAstm Standard Specification For Chemical Pasivation Treatments For Stainless Steel A967ramquimicaNo ratings yet

- Orifice Plate Calculator Pressure Drop CalculationDocument6 pagesOrifice Plate Calculator Pressure Drop Calculationlutfi awnNo ratings yet

- CoatedDocument3 pagesCoatedmatteo2009No ratings yet

- Porous Anodic Metal OxidesDocument20 pagesPorous Anodic Metal Oxidescargetoianu2357No ratings yet

- ENLS Meningitis and Encephalitis ProtocolDocument20 pagesENLS Meningitis and Encephalitis ProtocolFransiskus MikaelNo ratings yet

- Brazing Allloy Cusil ABADocument12 pagesBrazing Allloy Cusil ABADheeraj SharmaNo ratings yet

- D1005Document3 pagesD1005meealsoNo ratings yet

- Solidification and CrystallizationFrom EverandSolidification and CrystallizationDieter M. HerlachNo ratings yet

- Data Sheet AluminaDocument10 pagesData Sheet AluminaXin EnNo ratings yet

- PRC 5006 CurrentDocument10 pagesPRC 5006 CurrentHoang TanNo ratings yet

- Preparation of Surfaces of Plastics Prior To Adhesive BondingDocument3 pagesPreparation of Surfaces of Plastics Prior To Adhesive BondingShaker QaidiNo ratings yet

- Astm D4496Document5 pagesAstm D4496Sampath WeragodaNo ratings yet

- T-1046.02 (Qqz-325 Type II Class II)Document2 pagesT-1046.02 (Qqz-325 Type II Class II)jazz reyNo ratings yet

- Corrosion Science: ArticleinfoDocument9 pagesCorrosion Science: ArticleinfoalbertoNo ratings yet

- A Comparison of Laboratory Abrasion and Field Wear ResultsDocument11 pagesA Comparison of Laboratory Abrasion and Field Wear ResultschrisnnnNo ratings yet

- New Galvanizing TechnologyDocument4 pagesNew Galvanizing Technologywmaddoxmec100% (1)

- Chromic Acid Lanxess-MSDS PDFDocument10 pagesChromic Acid Lanxess-MSDS PDFyuk ming wongNo ratings yet

- ASTM G 50 - 76 r97 - Rzuwltc2ujk3rteDocument5 pagesASTM G 50 - 76 r97 - Rzuwltc2ujk3rteSamuel EduardoNo ratings yet

- Evolution of Siloxane Epoxy CoatingsDocument10 pagesEvolution of Siloxane Epoxy Coatingsant29539432No ratings yet

- Mil DTF 5541fDocument12 pagesMil DTF 5541fMarcos PerezNo ratings yet

- Bolt STD ChartDocument7 pagesBolt STD ChartVishal G ChipkarNo ratings yet

- AISI 430 Ferritic Stainless Steel MicrostuctureDocument7 pagesAISI 430 Ferritic Stainless Steel MicrostuctureAid Farhan MaarofNo ratings yet

- Stress Corrsion Cracking Behavion of Austenitic Stainless Steel PDFDocument5 pagesStress Corrsion Cracking Behavion of Austenitic Stainless Steel PDFJEISON CONTRERAS HOYOSNo ratings yet

- 101 Metal Repair Paste PS PDFDocument2 pages101 Metal Repair Paste PS PDFhemnNo ratings yet

- A867-03 (2013) Standard Specification For Iron-Silicon Relay SteelsDocument4 pagesA867-03 (2013) Standard Specification For Iron-Silicon Relay SteelsdcardonasterNo ratings yet

- A Review - Weight Loss Studies On The Corrosion Behavior of Some Metals in Various MediaDocument8 pagesA Review - Weight Loss Studies On The Corrosion Behavior of Some Metals in Various MediaRonald GarciaNo ratings yet

- Composite Materials Test MethodsDocument3 pagesComposite Materials Test MethodsVinoth KumarNo ratings yet

- Runge, Jude M. - Enhancing Anodic Aluminum Oxide For Bonding ApplicationsDocument13 pagesRunge, Jude M. - Enhancing Anodic Aluminum Oxide For Bonding ApplicationsLuis Gustavo PachecoNo ratings yet

- A554-15a Standard Specification For Welded Stainless Steel Mechanical TubingDocument5 pagesA554-15a Standard Specification For Welded Stainless Steel Mechanical TubingChuthaNo ratings yet

- 55 Aluminum-Zinc Alloy Coated Steel Technical Bulletin 6 - Cut Edge Protection v20153Document2 pages55 Aluminum-Zinc Alloy Coated Steel Technical Bulletin 6 - Cut Edge Protection v20153Syed Raja AdeelNo ratings yet

- Hydroclear Spec SheetDocument4 pagesHydroclear Spec Sheetamitleck100% (1)

- Surface Protection External Coating of Claas ProductsDocument1 pageSurface Protection External Coating of Claas ProductsTomaszNo ratings yet

- Inclusion Analysis As Per ASTM E45Document2 pagesInclusion Analysis As Per ASTM E45PULKIT AGGARWALNo ratings yet

- FAQ Processes For Surface Hardening of Stainless Steels Bodycote S3PDocument4 pagesFAQ Processes For Surface Hardening of Stainless Steels Bodycote S3PSinan YıldızNo ratings yet

- AL 6XN SourceBookDocument56 pagesAL 6XN SourceBookdrbeyerNo ratings yet

- Simple Static Oxidation Testing: Standard Practice ForDocument4 pagesSimple Static Oxidation Testing: Standard Practice ForTeymur Regenmaister100% (2)

- Mil PRF 46010HDocument17 pagesMil PRF 46010HGoogle UserNo ratings yet

- Zinc Phosphating - Zinc Phosphate Coating - Zinc PhosphatizingDocument2 pagesZinc Phosphating - Zinc Phosphate Coating - Zinc Phosphatizingpuri16No ratings yet

- Foil Catalogue Web VersionDocument44 pagesFoil Catalogue Web VersionNeeraj SinghalNo ratings yet

- C692Document7 pagesC692dinhtung2210100% (1)

- ADocument2 pagesAMinh Vuong TranNo ratings yet

- Outokumpu Corrosion Management News Acom 3 2014Document11 pagesOutokumpu Corrosion Management News Acom 3 2014Joshua WalkerNo ratings yet

- Atomic Radiation and Polymers: International Series of Monographs on Radiation Effects in Materials, Vol. 1From EverandAtomic Radiation and Polymers: International Series of Monographs on Radiation Effects in Materials, Vol. 1No ratings yet

- Shallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceFrom EverandShallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceNo ratings yet

- Strength of Metals and Alloys (ICSMA 7): Proceedings of the 7th International Conference on the Strength of Metals and Alloys, Montreal, Canada, 12–16 August 1985From EverandStrength of Metals and Alloys (ICSMA 7): Proceedings of the 7th International Conference on the Strength of Metals and Alloys, Montreal, Canada, 12–16 August 1985H. J. McQueenNo ratings yet

- Auger Electron SpectroscopyFrom EverandAuger Electron SpectroscopyC. L. BriantRating: 3.5 out of 5 stars3.5/5 (2)

- Thread CuttingDocument7 pagesThread CuttingJulia Turpo SuarezNo ratings yet

- Putt or ChipDocument21 pagesPutt or ChipJulia Turpo SuarezNo ratings yet

- How To Plant A Successful Winter Lawn: IEE 572 D E EDocument26 pagesHow To Plant A Successful Winter Lawn: IEE 572 D E EJulia Turpo SuarezNo ratings yet

- Design of Experiments IEE 572 Factors Affecting Radish Growth Carol Lynn SulDocument17 pagesDesign of Experiments IEE 572 Factors Affecting Radish Growth Carol Lynn SulJulia Turpo SuarezNo ratings yet

- IEE 572 Term Project: Executive SummaryDocument15 pagesIEE 572 Term Project: Executive SummaryJulia Turpo SuarezNo ratings yet

- Factors Influencing The Optimization of SpeedDocument24 pagesFactors Influencing The Optimization of SpeedJulia Turpo SuarezNo ratings yet

- Cupcake HeightDocument20 pagesCupcake HeightJulia Turpo SuarezNo ratings yet

- Calorie LossDocument22 pagesCalorie LossJulia Turpo SuarezNo ratings yet

- Op Tim IzationDocument8 pagesOp Tim IzationJulia Turpo SuarezNo ratings yet

- Pengembangan Sumber Daya Manusia Terhadap Kualitas Dan Kinerja Karyawan GIANT Pulosari MalangDocument15 pagesPengembangan Sumber Daya Manusia Terhadap Kualitas Dan Kinerja Karyawan GIANT Pulosari MalangTOMY ARJUNESNo ratings yet

- Relative Reconstructions: Caroline Heycock Can We Arrive at A Unified Picture?Document26 pagesRelative Reconstructions: Caroline Heycock Can We Arrive at A Unified Picture?ayydatboiNo ratings yet

- Cursul II Jean-Ovide Decroly - CareerDocument5 pagesCursul II Jean-Ovide Decroly - CareerTimea UrdaNo ratings yet

- Racism in HODDocument6 pagesRacism in HODKashaf RiazNo ratings yet

- Chapter - 1 Rational - NumbersDocument21 pagesChapter - 1 Rational - NumbersAditya GawandeNo ratings yet

- Fulltext 01Document54 pagesFulltext 01Shafayet UddinNo ratings yet

- 20 - Hrg. - Parties - Dtd. - 01.09.2023. Parties Dtd. 01.09.2023Document2 pages20 - Hrg. - Parties - Dtd. - 01.09.2023. Parties Dtd. 01.09.2023Sanket SakhareNo ratings yet

- ds93 Unit 8 Summative AssessmentDocument3 pagesds93 Unit 8 Summative Assessmentapi-110789702No ratings yet

- EE Theory de GustibusDocument16 pagesEE Theory de GustibusWilliam BallNo ratings yet

- Journal of Cleaner Production: Christina Maria Dües, Kim Hua Tan, Ming LimDocument8 pagesJournal of Cleaner Production: Christina Maria Dües, Kim Hua Tan, Ming LimAnass CherrafiNo ratings yet

- Introduction To Attitude and MotivationDocument192 pagesIntroduction To Attitude and MotivationHoney AliNo ratings yet

- Meghan Quinn Books in Order ChecklistDocument3 pagesMeghan Quinn Books in Order ChecklistGuadalupe Mendez CraveroNo ratings yet

- GATCE 2015 Exam TimetableDocument2 pagesGATCE 2015 Exam TimetableDennisEudesNo ratings yet

- Fluid Mechanics Question Bank CE8394Document34 pagesFluid Mechanics Question Bank CE8394Bala Mettur100% (1)

- Copy of Medical Errors - IVDocument3 pagesCopy of Medical Errors - IVst25scampasNo ratings yet

- Chapter 04Document19 pagesChapter 04erza scarletNo ratings yet

- Physics 2 PTDocument12 pagesPhysics 2 PTKatrina NuegaNo ratings yet

- Multinational Finance Solutions Chapter 1Document3 pagesMultinational Finance Solutions Chapter 1fifi_yaoNo ratings yet

- Key Concepts and Ideas of FilipinoDocument23 pagesKey Concepts and Ideas of Filipinotanny100% (1)

- White Fang: I. Read The StoryDocument2 pagesWhite Fang: I. Read The StoryNang SuNo ratings yet

- Passive Voice (Theory IMANOL)Document5 pagesPassive Voice (Theory IMANOL)Aitor Soto RuizNo ratings yet

- Bio Assessment 1 Term 1Document6 pagesBio Assessment 1 Term 1turirirNo ratings yet