Professional Documents

Culture Documents

Rig Maintenance Plan

Rig Maintenance Plan

Uploaded by

klibiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rig Maintenance Plan

Rig Maintenance Plan

Uploaded by

klibiCopyright:

Available Formats

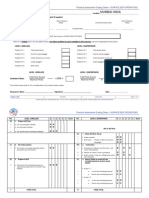

RIG MAINTENANCE REPORT #1 of 12

Rig#:

Drilling Crew:

Make/Model:

Serial #:

Service Technician:

Inspection Date:

Location:

Component:

OK

Needs repair

Get maintenance and safety data from suppliers with lube data on:

rig, mud pump, compressor, truck, engine, transmission, all clutches,

all hydraulic items (pumps, motors, filters), swivel, etc.

Steam clean equipment. Visually inspect for broken members,

cracks in welds, leaks of power transmission boxes, leaks of

hydraulic fluid and fuel leaks.

Hold safety meeting around the rig, pay special attention to the

new comers in our field. Never allow horseplay ever!

Duplex. Check oil and grease. Note what oil is used in power end.

Use a synthetic (white) grease that is water resistant on all lube

points. Check drain plugs, remove during freezing. Adjust packing

glands. Inspect power end components, fluid end parts.

Prime pump properly, start up and listen with equipment stethoscope

for proper internal sounds. Check for leaks. Note piston size and

SPM. Note rod taper type and valve type.

Inspect the shear relief valve (safety valve) for proper operation and

correct nail size. Inspect the pressure gauge and flowline valves and

hoses. Inspect the mudhose safety chains for proper installation and

inspect the surge chamber. Look at the hammer unions.

Replace quick coupler seal on suction line, inspect suction hose, foot

valve and strainer. Review your suction pit design.

Swivel. Inspect and adjust bearings. Lube swivel with water

resistant synthetic lube. Inspect seal rings or packing set. Adjust

packing properly according to manufacturers guidelines.

Check swivel mounting assembly and lube track roller bearings if

installed.

Inspect wash down/mud mixing hose. Inspect and clean the mud

hopper. Review system to hold the suction strainer off the bottom of

the pit.

Centrifugal Pump: Inspect the main shaft seal. Lubricate with

synthetic water resistant grease. Adjust packing set carefully. Too

tight will burn shaft and seal. Lube the shaft bearings with the same

grease.

Note: Vertically installed pumps that operate at 2000 RPM or above

will need oilbath lubrication.

Remove the involute and inspect the impellar for proper condition.

Use new gaskets on flanges.

Check the duplex and/or centrifugal pump drive. Inspect hydraulic

motor, mounting and chain coupling. Lube coupling. Make sure all

rotating parts are covered by heavy guard.

Chart creation by John LEspoir, President of Enid Drill Systems, Inc. (EDSI). For additional

information, contact EDSI by phone 580-234-5971 or fax 580-234-5980 or purchase your copy

of Transfer of Technology today.

LUBE OFTEN

WORK SAFE!

RIG MAINTENANCE REPORT #2 of 12

Rig#:

Drilling Crew:

Make/Model:

Serial #:

Service Technician:

Inspection Date:

Location:

Component:

OK

Needs repair

Centrifugal pump priming system. Check cut-off valves to be

airtight. Foot valve to be water tight. Check diaphragm air pump

and hose connections. If rig is equipped with an air compressor,

consider installation of an air primer system.

Drill Stem: Inspect those threads. All of them! Kelly, subs, drill

pipe, drill collars, and bits. Kelly to swivel sub may be LH or RH. If

righthand, this connection may be spot welded. Check this.

Chemically clean and wire brush threads. Inspect, cover boxes and

pins with pipe dope compound. Do not use grease. Check all

hoisting plugs.

Check drill pipe for tooljoint OD wear and check midbody tube for

worn spots. Check drillpipe and collars to be straight.

Check elevators and links for wear. Lube all pins.

Confirm that elevators match the drillpipe style. Do not ever lift 18

shoulder pipe with square shoulder elevators.

Check break-out tongs, consider oversize pins to correct wear in

jaws. Lube all pins. Clean, inspect, or replace the tong dies.

Clean, inspect all pipe wrenches. Lube the threads with a silicon dry

spray. Replace worn heels and jaws.

Check slips and replace rollers or slipdogs if needed.

Check the master bushing for wear in the taper.

Check snatch block and lifting block bearings and pins for wear.

Check sheave grooves to match wireline size. Lube the bearings.

Check the kelly drive bushing and pins or keys for wear. Replace

pins frequently.

Dis-assemble roller type kelly drive bushings and inspect roller size,

bearings, and pins. Lube bearings. Note make, model, and size.

Rotary tables: Drain lube, inspect for contamination. Check end

play of pinion bearings. Check back lash of gear set. If water and

sand is found in table, dis-assemble the table. Check all bearings for

wear. Replace all seals and inspect seal surfaces. Repair if worn.

Do not pre-load the tapered roller bearings. Caution: Threads above

the ring gear are generally left hand. Do not use EP style gear lube

if the table has brass components. Fill with fresh oil and lube all

grease fittings. Note lube specifications.

Chart creation by John LEspoir, President of Enid Drill Systems, Inc. (EDSI). For additional

information, contact EDSI by phone 580-234-5971 or fax 580-234-5980 or purchase your copy

of Transfer of Technology today.

LUBE OFTEN

WORK SAFE!

RIG MAINTENANCE REPORT #3 of 12

Rig#:

Drilling Crew:

Make/Model:

Serial #:

Service Technician:

Inspection Date:

Location:

Component:

Inspect the wireline. Note the size and construction and length for

each drum below.

Size

Length

OK

Needs repair

Construction

Kelly Drum

Trip Drum

Sandreel

Winch #1

Winch #2

Pulldown

Tong C Balance

Guy Lines

Recommended Construction

Kelly and Trip Lines: 19x7

Bailing Line: 6x19 or 6x26 with wire center

Winch Lines: 6x36 with wire center

Guylines: 6x36 with wire center

Wireline clips. Check for proper installation clip size, number of

clips, turn back of ropes and torque in ft. lbs. Never put a saddle on

a dead horse! All saddles go on the long end and the U-bolts go

around the short end. Threads must be dry.

Size

3/8

7/16

9/16

5/8

7/8

1

Quantity

2

2

3

3

3

4

4

5

Turnback

7

7

12

12

12

18

19

26

Torque Ft Lbs

45

65

65

95

95

130

225

225

Check the wireline drum anchors.

Chart creation by John LEspoir, President of Enid Drill Systems, Inc. (EDSI). For additional

information, contact EDSI by phone 580-234-5971 or fax 580-234-5980 or purchase your copy

of Transfer of Technology today.

LUBE OFTEN

WORK SAFE!

RIG MAINTENANCE REPORT #4 of 12

Rig#:

Drilling Crew:

Make/Model:

Serial #:

Service Technician:

Inspection Date:

Location:

Component:

OK

Needs repair

Crownblock: Inspect the mounting of the crown. Nuts, bolts, or

welds. Inspect sheaves for wear in groove and check groove size.

Side wear indicates a side load. Disassemble all sheaves, inspect

bearings, and pins. Reassemble and lube. Install sheave guards.

Mast: Inspect all mast pins for wear and correct installation. If

rusted, remove, clean, and install pins. Lube before installation.

Mast hardware nuts and bolts. Torque check all bolts. This

equipment operates above your head. Only use grade 5 nuts/bolts.

Inspect all components mounted inside the mast. Hydraulic

cylinders, wireline anchors, swinging tong brackets. Pulldown

components and racking platforms. Check platform pipe spacer bars

for cracked welds. Check all mast member welds and replace bent or

missing mast members. Never use pipe to repair the mast. Check

with your OEM to get steel and welding specs. Look close for

wireline cuts and repair at once. Once again, check mud/air flow

lines, safety chains. Lube often.

Electric wiring. Check all wiring in the mast and on the rig. Repair

or replace damaged wires. Electric sparks, even from 12 Volt

systems, can and will start fires.

Check electric connections. Especially in coastal areas. Clean

connections and spray with a protective coating such as PDRP

(Sprayon #710). Check supply of spare fuses.

Check mast/ladder structure and safety climbing device. Inspect

body harness.

When drilling near any airport, check on regulations requiring a red

flashing light on top of your mast. Install if required.

Check and service the weight indicator.

Note mast hookload capacity and number of lines strung to the

block: Hookload cap _______________lbs on __________ lines.

Note date of weight indicator calibration:

Instruct driller, helper, and tool pusher on proper way to raise and

lower a mast.

Inspect mast locking devices for proper operation.

Inspect the mast supporting structure: hinge post, drill frame,

mechanical jack system, and hydraulic jacks. Replace rusted load

support members to avoid structural failure.

Drawworks: Inspect drum clutches. A clutch that needs a cheater

pipe needs immediate repair. Smell for burned plates. After

disassembly, check that hub and back plate friction surface is exactly

square 90 with the centerline. Take skim cut if required. Inspect

splines.

Chart creation by John LEspoir, President of Enid Drill Systems, Inc. (EDSI). For additional

information, contact EDSI by phone 580-234-5971 or fax 580-234-5980 or purchase your copy

of Transfer of Technology today.

LUBE OFTEN

WORK SAFE!

RIG MAINTENANCE REPORT #5 of 12

Rig#:

Drilling Crew:

Make/Model:

Serial #:

Service Technician:

Inspection Date:

Location:

Component:

OK

Needs repair

On mechanical clutches, check and lube sliding cones, brass collars,

engagement rollers and adjusting ring threads. Check guards.

On air clutches, check the air tube or diaphragm. Check for proper

adjustment of clutch and check pneumatic system for leaks. Check

air pressure at nearest point to clutch. Note ___________ PSI.

On drawworks clutches, make sure that the sliding cone is a NONLOCKING style. Never use a locking cone on a drawworks clutch.

Check the clutch for oil or grease contaminants. Find the source and

fix the leak. On equipment with oil in the drum to lube the drum

bearings, clean the assembly and use double sealed bearings as

replacement. These do not require oil in the drums.

Clutch linkage. Adjust linkage for best mechanical advantage.

Replace worn pins and consider drilling the yokes to use oversize

pins. Double check the installation of cotter pins.

Inspect the brake bands for adequate and efficient friction material.

Replace grease or oil soaked linings.

Inspect brake drums for smooth surface. Check diameter for

adequate flange thickness and roundness. A wobble on the brake

lever indicates a warped or egg shaped drum.

Inspect brake linkage same as clutch linkage.

Inspect equalizer mechanism for dual band brakes and anchor bolt of

single bands. Lube all pins with dry spray-on lube. Clean off all

grease that may get onto friction surface.

Disc brakes. Inspect pads for proper thickness and condition.

Inspect rotors for smooth surface.

Auxiliary brakes. Water brakes, Parmacs, Hydromatic, etc. Check

for external leakage. Check operating temperature. A cool brake

does not absorb energy. Replace internal rotors and stators. A good

brake gets up to 200F with 100F or less input water temperature.

Check shaft bearings for endplay. Check grease lube and seals.

Replace worn bearings and seals. Do not preload tapered roller

bearings. Check brake internal pressure. This must be less than 25

PSI.

Install guards over all rotating drivelines and chain drives.

Check the jaw clutch teeth and sliding splines on shaft.

Chart creation by John LEspoir, President of Enid Drill Systems, Inc. (EDSI). For additional

information, contact EDSI by phone 580-234-5971 or fax 580-234-5980 or purchase your copy

of Transfer of Technology today.

LUBE OFTEN

WORK SAFE!

RIG MAINTENANCE REPORT #6 of 12

Rig#:

Drilling Crew:

Make/Model:

Serial #:

Service Technician:

Inspection Date:

Location:

Component:

OK

Needs repair

Electric retarders. Check electric connections and potentiometer.

Check if coils get extremely hot. Lube bearings on shaft. Install

expanded metal guards over the retarder. Do not block air flow.

Check input drive to auxiliary brake. Lube drive lines and check for

balance. Check lube in one-way overriding clutch or check inline

clutch for proper condition.

Check to be sure that hydromatic supply line valve has a hole

drilled through to avoid total cut-off. Make sure there is no cut-off

valve in the discharge line from the brake.

Catheads. Check the drum for groove. Turn the drum smooth. Do

not weld grooves for repair. The harder material will grab your rope.

Check the condition of the rope splitter (divider). Inspect catline

ropes, chains, and wirelines.

Inspect cathead wireline drum (chain drum). Check the clutch and

clutch operating mechanism.

Check the cathead mounting and the drive mechanism and jaw clutch

Bevel gear boxes or right angle drives. Used on drawworks,

pulldowns, etc. Check for endplay of pinion shaft. Drain lube and

inspect for contamination. If you find steel or brass shavings, disassemble the box and inspect gear set, bearings and seals. Check

shaft seal surfaces. Inspect the wear pattern of the gear set. Do not

pre-load the tapered roller bearings. Fill with fresh lube to level.

Make sure the vent system works properly on all enclosed drives.

Installation of bevel gear box in between two drums of two clutches.

Typically the gear box is mounted to the frame and the two shaft

ends are held by pillow blocks. This must be perfectly aligned and

shimmed. The bolts must slide in without pulling on the shaft. Once

bolted in, the shaft must rotate without friction. Shaft end bearings

can not have any play radially. Lube all pillow blocks.

Drawworks chains. Check for stretched or worn chains and

sprockets. Chains need to be snug but not tight. Use a dry moly type

lube on chain and sprockets. Check master links.

Inspect drawworks frame or mounting structure for damage by

sloppy chains. Repair cut frame parts today.

Check chain idler assemblies or other chain tightening device.

Torque check the mounting bolts that bolt the drawworks to the rig

frame.

Guard. Repair the drawworks guard and replace missing parts. The

guard should cover all rotating parts and also cover the brake bands

to keep them dry.

Chart creation by John LEspoir, President of Enid Drill Systems, Inc. (EDSI). For additional

information, contact EDSI by phone 580-234-5971 or fax 580-234-5980 or purchase your copy

of Transfer of Technology today.

LUBE OFTEN

WORK SAFE!

RIG MAINTENANCE REPORT #7 of 12

Rig#:

Drilling Crew:

Make/Model:

Serial #:

Service Technician:

Inspection Date:

Location:

Component: SAFETY SAFETY SAFETY SAFETY

OK

Needs action

Inspect rig before clean-up. Make notes of leaks. Steam clean and

inspect with drilling crew.

Inspect crews safety gear. Hard hats, shoes, glasses, ear plugs,

gloves, and mast climbing system. Check uniforms or normal work

clothing.

Inspect special safety gear such as plastic cover-alls, boots, oxygen

mask, etc.

Check truck emergency gear, flares and fire extinguisher. Trailer

units must have one on the trailer.

Check the emergency first aid kit located on the rig and check the

water container and cups to be absolutely clean.

Check the communication system for proper condition, phones, twoway radios, or other. Check on spare batteries.

Check hand tools for proper condition, inspect hammer and shovel

handles, pipe wrenches, etc. Inspect punches and chisels. Look at

slip handles, kelly bushing rings, etc.

Check start, kill, and emergency kill controls on the rig daily.

Inspect heavy equipment lifting aids such as a hydraulic winch.

Check warning and caution plates and control function data plates to

be legible, then assure that the control and plate match.

Check the night working lights.

Check control panel gauges to be in working order.

Inside the office, conduct a safety meeting. Review the past accident

records. Have printed meeting program for every attendant to sign

and date at end of meeting. As a meeting guide refer to: Drilling

Safety Guide booklet by NDA; Video on safe drilling by MobileForemost; Chapter 28 of Transfer of Technology by John

LEspoir; Chapter 7&8 of Basic Procedures by Will Acker III

Inspect safety latches on block hooks, rod hooks, and snatch blocks.

Inspect safety locks/latches on toolboxes, auger racks, platforms, and

mud pans. Check mud hose safety chains.

Relief valves: Mud pump, compressors, Hydraulics, pneumatics

Heat shields/guards over mufflers, coolers, exhaust systems

Wireline and clips. Do a torque check.

All guards over rotating or moving equipment.

Mast crown light, crown cover, and mast locks.

Grease lines/hoses, check other end.

Hydraulic tank cut-off valve locks.

Battery box covers and battery straps and posts.

Air compressor dump valve muffler

Seals on flanged or dual-wall drill pipe

Chart creation by John LEspoir, President of Enid Drill Systems, Inc. (EDSI). For additional

information, contact EDSI by phone 580-234-5971 or fax 580-234-5980 or purchase your copy

of Transfer of Technology today.

LUBE OFTEN

WORK SAFE!

RIG MAINTENANCE REPORT #8 of 12

Rig#:

Drilling Crew:

Make/Model:

Serial #:

Service Technician:

Inspection Date:

Location:

Component:

OK

Needs repair

Check the drawworks cooling fans to cool the brakes for proper

installation and operation.

Inspect all hydraulic winches. Drain the gear lube and inspect it for

contaminants. If water or shavings are found, take the winch apart

and check for internal damage.

Inspect the internal spring applied, hydraulic released brake discs. A

winch will brake only in one direction, make sure wireline is spooled

correct way.

Inspect the winch mounting bolts to the frame. Check seals for

leakage.

Hydraulics. Inspect the fluid for proper level in tank. Take fluid

sample and have it inspected by a lab. Check tank, hoses, valves,

filters for leaks. Replace worn or frayed hoses. Note number of

filters and elements. Replace elements frequently.

Check relief valves to be operational and note the relief setting.

While in normal drilling operation take temperature of the system

and check flowline items temps, especially the control valves and

relief valves. A bypassing valve will get extremely hot. Fix or

replace this problem item at once, 225 F is very hot.

Check control valves for leaks around spools and for proper action.

Spool seals are o-rings. The detent or spring centering cartridges

may need replacement. Check handles, replace broken levers.

Inspect fitting leaks closely. Are the threads matching threads? Pipe

threads need to be cleaned and a sealing compound is recommended.

JIC fittings do not require a sealing compound.

Check all hydraulic gauges to be operational with clean lenses.

Record normal operating pressures and or temps.

Check tank cut-off valves. Gate valves must be fully open and wire

locked to avoid closing of the valve caused by vibration. A partially

closed valve will starve your pump. Fully junk in 2 minutes.

Bundle all hydraulic hoses and keep them away from rotating

drivelines, chains, sprockets, and truck tires. Note that tires can

move up and down and sideways too!

Check hoses that connect sliding items such as rotary tables and

tilting items such as mast cylinders, to be clear and free in both

extreme positions.

Hydraulic leaks. Find all of them and fix them.

Chart creation by John LEspoir, President of Enid Drill Systems, Inc. (EDSI). For additional

information, contact EDSI by phone 580-234-5971 or fax 580-234-5980 or purchase your copy

of Transfer of Technology today.

LUBE OFTEN

WORK SAFE!

RIG MAINTENANCE REPORT #9 of 12

Rig#:

Drilling Crew:

Make/Model:

Serial #:

Service Technician:

Inspection Date:

Location:

Component:

OK

Needs repair

Hydraulic pumps and motors. Check seal cavity drainline. It must

be open and flow below 15 PSI. At 25 PSI, the shaft seals will blow

out.

Hydrostat systems. Note pump, motor, and filter part numbers. Note

type of fluid used. Locate the charge pump pressure gauge and note

operating pressure. If charge pressure drops too low, the pump

de-strokes. Service all filters in this system: in-tank suction screen,

charge flow filter, and return line filter.

Check, lube, and adjust mechanical linkage to hydrostatic pump.

Check component and tank temperatures on the hydrostat circuits.

Pneumatics. Check the air control system for leaks. First build up

pressure and turn all engines off. Listen. Then operate one control

at a time and listen for the air to flow and stop. Upon release of the

control, the pressure bleeds off. On drum clutches, the QRV quick

release valve or dump valve will release the internal clutch air fast.

This is very noisy. Note the system pressure.

Check the safety valve for proper operation.

On units that use the truck air brake system as an air supply, check

for installation of a pressure protection valve on the air tank.

Drain the air tank into a clear container and inspect the fluid for rust,

oil or other contaminants. Condensation water is clear.

Check the lube in the compressor.

Check the drive belts, lower drive and the compressor mounting

hardware.

Inspect inline components such as cut-off valve, pressure regulator,

inline oiler, and antifreezer. Check the airline filter.

Inspect all control valves for proper function. Inspect air cylinders

for operation and make linkage adjustments as needed.

Electrical. Check batteries of deck engines and or truck engine.

Check battery disconnect switch and battery cables. Check battery

box and mounting.

Lifelines. Check cable switches or other emergency kill switches

daily for proper operation.

Check supply of fuses for truck and rig equipment.

Inspect the compressor drive assembly.

Chart creation by John LEspoir, President of Enid Drill Systems, Inc. (EDSI). For additional

information, contact EDSI by phone 580-234-5971 or fax 580-234-5980 or purchase your copy

of Transfer of Technology today.

LUBE OFTEN

WORK SAFE!

RIG MAINTENANCE REPORT #10 of 12

Rig#:

Drilling Crew:

Make/Model:

Serial #:

Service Technician:

Inspection Date:

Location:

Component:

OK

Needs repair

Drill air compressor. Screw type. Only use synthetic fluid. Check

fluid for contaminants. Inspect coalescent filter, make sure

grounding system is correct. Inspect and or replace the air intake

filter and fluid filters. Check the safety valve for proper operation.

Inspect all gauges and the safety shut-down system. Inspect the air

intake throttling system. Clean the cooling core throroughly.

Drill air compressor. Piston type. We recommend to use a synthetic

lubricant. Check lube oil for contaminants. Inspect or replace air

intake filters and lube oil filter. Check the safety valve. Clean the

cooling core thoroughly.

Check the inline oiler system for DTHH drilling. Only use an

approved vegetable oil. Do not use petroleum products.

Check the water/foam injection system for proper operation. Check

the valves for rust.

Deck engines. Drain the lube oil and inspect for contaminants.

Check coolant fluid for level and freezing point. Change all filters:

air, fuel, and lube. Inspect all gauges. Note operating temperature

and lube oil pressure. Check throttle linkage.

Inspect and adjust mechanical PTO clutch.

Inspect fluid level in fluid coupling or torque convertor. Inspect for

leaks.

Trucks. Engines see above. Inspect transmissions, clutch and

differentials for proper lube. Grease all suspension items. Check

tires. Inspect brakes and running lights. Check the steering systems

components. Check exhaust system.

Trailers. Inspect tires. Check air brakes, hoses, valves, and glad

hands. Replace leaking seals. Inspect wheel bearings for proper

lube. Check running lights.

Auger rigs. Check augers for worn or torn flights. Inspect the auger

pins, drive caps, complete lead assembly and connecting bolts for

proper length. Check the auger drive coupling. Lube the bearings.

Inspect the MOYNO pump, drive and plumbing for proper operation.

Inspect the frame slides, sideways and fore and aft. Lube often.

Inspect the high torque part of the mast and auger drive.

Reverse drilling. Inspect the water swivel and air inlet swivel or

combination thereof. Lube those packing sets.

Replace the seals on flanged pipe and inspect that the flange surfaces

are 100% flat. Replace bent bolts.

Inspect the vacuum chamber nozzles for wear. Inspect the inside of

this tapered housing for washouts.

Chart creation by John LEspoir, President of Enid Drill Systems, Inc. (EDSI). For additional

information, contact EDSI by phone 580-234-5971 or fax 580-234-5980 or purchase your copy

of Transfer of Technology today.

LUBE OFTEN

WORK SAFE!

RIG MAINTENANCE REPORT #11 of 12

Rig#:

Drilling Crew:

Make/Model:

Serial #:

Service Technician:

Inspection Date:

Location:

Component:

OK

Needs repair

Inspect the ODEX or TUBEX components used to drill and set

casing simultaneously.

Check dual wall drillstring seals.

Inspect casing hammers, mounting, controls, and plumbing.

Core drilling. Inspect the core drill string, core barrels, and core bits.

Check the weight control system to have a constant weight on the bit.

Note rotary speeds during normal core drilling.

Lube and inspect high speed swivel, rotary table, or top drive.

Power-Take-Off: Drain the lube oil and check for contamination. If

water or steel shavings are found, disassemble the units and inspect

the bearings. Replace all seals.

Inspect the chain and sprockets. Check splines, sliding fork, and

shifting collar. Inspect the poppet detent to work properly. On a

gear type PTO check the gears.

Check the PTO shifting mechanism and adjust linkage as necessary.

In case of air shift, check the cylinders for proper plumbing and

adjustments.

For 3TA92 auxiliary transmission with PTO provide lock to avoid

shifting the wrong way.

Drivelines, universal joints. Lube all journal bearings and inspect for

wear. Torque check all nuts and bolts. Threads must be NF

(National Fine) type. Lube splines and inspect for excessive wear

especially on long stroke slip joints.

Check drivelines for balancing weights and timing marks.

Check all transfer boxes, gear boxes, reversing gear boxes, etc. for

external leaks, change lube oil and inspect backlash on gears or chain

slap in chain boxes. Check for vibration, knocking, or other noises.

Tension all V-belt drives. Inspect individual belts or bands for hard

spots and cracks. Check all pulleys for proper wear on groove sides.

Lube idler bearings and adjust idler roller positioning. Lube

overhung load adapter.

Check that all drivelines, V-belt drives, and open chain drives are

properly guarded.

Topdrive rigs. Inspect the topdrive swivel and gear box. Change

lube, inspect pivot points, and lube all grease zerks.

Inspect the hoist/lowering system of the topdrive. Inspect all

cylinders: hoist, jib boom, transverse slide, head tilt and more.

Inspect the pipe handling system such as carrousel and single joint

loader systems very critically. Inspect lifting slings/chains.

Chart creation by John LEspoir, President of Enid Drill Systems, Inc. (EDSI). For additional

information, contact EDSI by phone 580-234-5971 or fax 580-234-5980 or purchase your copy

of Transfer of Technology today.

LUBE OFTEN

WORK SAFE!

RIG MAINTENANCE REPORT #12 of 12

Rig#:

Drilling Crew:

Make/Model:

Serial #:

Service Technician:

Inspection Date:

Location:

Check lube supplies on rig and in yard:

OK

Order

Please follow OEM instruction: Following are our general lube

recommendations. Go find the old oilcans, use them.

ENGINE OIL: 10W40 or 20W50 Detergent Oil All engines, truck,

deckmounted, gen sets, pump units. Use old oil to lube wirelines.

CHAIN OIL: Do NOT use multi viscosity or detergent oils. Use only

straight weights SAE 30; SAE 40; SAE 50. All chain drives, or combo

chain/gear boxes, chain PTOs, chain driven mud pumps ends, transfer and

compound cases. High speed centrifugal pumps.

GEAR OIL: SAE 85/140 Do not use EP classified lubes in boxes with

brass parts. All gear drives, transmission, rear-ends or trucks, rotary tables,

pulldown transmissions, bevel gear boxes, gear driven mud pump ends,

triplex pumps. Planetary gear drives, winches, drillheads, worm gear

drives, truck steering systems, and axles. Overhung load adapters.

DTHH Lubrication: Do NOT use Rock Drill Oil or other petroleum

products, only use vegetable based oils, such as MATEX RDO 302. All

down the hole hammers and bits. Also use this on pump suction hose quick

coupler seals.

PISTON COMPRESSOR: Synthetic such as Mobil Rarus 827 SHC. Leroi

compressors, IR and other piston type compressors.

SCREW COMPRESSORS: Synthetic such as Mobil Rarus 824 SHC

Sullair screw compressors, all other screw compressors.

OTHER SYTHETICS:

Mobil SHC 626: Hub City gear boxes, Gear PTOs and hyd. systems

Mobil SHC 630: High speed topdrives, chain boxes, gear boxes

Mobil Jet Oil II: One way clutches

DEXRON III Funk transmissions, Allison convertors/transmission

HYDRAULIC SYSTEMS: Conoco Super Hydraulic MV 32 Medium and

low pressure hydraulic systems

HYDROSTATIC SYSTEMS: Conoco Super Hydraulic 46 High pressure

hydraulics for topdrives, rotaries, centrifugal drives etc

PNEUMATIC CONTROL AIR SYSTEMS:

Winter: Methyl alcohol

Summer: SAE 10W oil

Air Clutch controls, air throttle systems, fluid couplings on engines

GREASE: Water resistant synthetic grease. Swivel bearings and packing

sets. Mud pump lubricated glands, centrifugal pump shaft seals. Kelly

bushing rollers, Moyno pumps and Parmac brakes.

GREASE: Excellent quality grease only. All grease zerks, except those

mentioned above. Chain couplings, crown blocks, pillow blocks, sliding

control rods, rotating brake shafts. Spline shaft adapter cavities.

PIPE DOPE: Use BESTOLIFE products or equal. Do not use grease on

drillpipe threads on water wells. Drillpipes, collars, subs, bits, kelly.

SPRAY ON DRY LUBE: LPS Force 842 Dry Moly Lube Kelly pins,

open chain and sprockets, pulldown chains, pivot pins on tongs, mast hinge

and cylinder pins. Screw jacks. Brake band pins.

WAGNER WF 100 Load cell type weight indicators. Available in quarts.

To install use hand pump #WH 103.

Chart creation by John LEspoir, President of Enid Drill Systems, Inc. (EDSI). For additional

information, contact EDSI by phone 580-234-5971 or fax 580-234-5980 or purchase your copy of

Transfer of Technology today.

LUBE OFTEN

WORK SAFE!

You might also like

- Well Handover CertificateDocument1 pageWell Handover Certificateeng7mohamed7hashimNo ratings yet

- Neonatal Care Pocket Guide For Hospital Physicians PDFDocument319 pagesNeonatal Care Pocket Guide For Hospital Physicians PDFelmaadawy2002100% (7)

- Cat III Inspection Mud 2021Document56 pagesCat III Inspection Mud 2021Fāōū ZīNo ratings yet

- Excavator Student ManualDocument25 pagesExcavator Student ManualSamuel Woldemichael Yohannes83% (6)

- Rig IMI Specific Remove Drilling Line On The Drawworks DrumDocument8 pagesRig IMI Specific Remove Drilling Line On The Drawworks Drumsaysamajo100% (1)

- Maintenance Schedule For BOP - 5131086 - 01Document4 pagesMaintenance Schedule For BOP - 5131086 - 01franko guddiNo ratings yet

- Maintenance Manual Varco ST 80 Roughneck 2 PDFDocument42 pagesMaintenance Manual Varco ST 80 Roughneck 2 PDFNAMRAJ SHARMANo ratings yet

- Operation and Maintenance Manual: Triplex Mud Pump - Skid MountedDocument118 pagesOperation and Maintenance Manual: Triplex Mud Pump - Skid MountedrolandNo ratings yet

- Oil Whirl in Floating Ring SealsDocument11 pagesOil Whirl in Floating Ring SealsMuhammad Irfan AnwarNo ratings yet

- Honda Gx35Document1 pageHonda Gx35kelumpj8479100% (1)

- Idc 37 Rig Move PlanDocument15 pagesIdc 37 Rig Move PlanKarim Lehtihet100% (1)

- HH-Rotary Table ZP175 - ZP205 PDFDocument3 pagesHH-Rotary Table ZP175 - ZP205 PDFYosed L SantosNo ratings yet

- Units of Competence: Driller Level - 8Document18 pagesUnits of Competence: Driller Level - 8Ben BieberNo ratings yet

- Extreme Frac PlugDocument19 pagesExtreme Frac Plugmsebag86No ratings yet

- Moduspec ChecklistDocument64 pagesModuspec Checklistbehnam197100% (8)

- #12 Rig Up and Run CasingDocument1 page#12 Rig Up and Run Casingkhurram100% (1)

- Elsharnoby Pediatric Made EasyDocument160 pagesElsharnoby Pediatric Made Easyelmaadawy20020% (1)

- 1-11-B 1. Tools and Equipment: Deadline Anchor MaintenanceDocument2 pages1-11-B 1. Tools and Equipment: Deadline Anchor MaintenanceAbdul Hameed Omar100% (1)

- B+V Manual - CLS 100-150 - 621100-Y-BC-D Rev 005Document30 pagesB+V Manual - CLS 100-150 - 621100-Y-BC-D Rev 005Leonardo Rachen RodriguezNo ratings yet

- BS EN 60811-1-1 1995 FileDocument28 pagesBS EN 60811-1-1 1995 Fileelmaadawy2002100% (3)

- Slips Maintenance, Inspection, & Wear Data PDFDocument3 pagesSlips Maintenance, Inspection, & Wear Data PDFcorsini999100% (2)

- 803 Subsea L4 EquiptDocument25 pages803 Subsea L4 EquiptKen ANo ratings yet

- Job 3395-Emsco FB1600 PumpDocument123 pagesJob 3395-Emsco FB1600 PumpCristian BoselliNo ratings yet

- TA Elevators MaintenanceDocument8 pagesTA Elevators MaintenanceBahman MatouriNo ratings yet

- Hawkjaw Jr. Manual 65K-950JR Serial Numbers 72 To 223Document155 pagesHawkjaw Jr. Manual 65K-950JR Serial Numbers 72 To 223MASAGUS MANGKU GAMANo ratings yet

- Oil Based Rig Inspection ChecklistDocument4 pagesOil Based Rig Inspection Checklistelmaadawy2002100% (1)

- TubingDocument3 pagesTubingjose vargasNo ratings yet

- 14P220 Triplex Mud Pump Spec SheetDocument1 page14P220 Triplex Mud Pump Spec SheetWHWENNo ratings yet

- Um199021 eDocument104 pagesUm199021 eForos IscNo ratings yet

- B+V ELEVATOR Slip Type BVT Tubing VS11 A4Document2 pagesB+V ELEVATOR Slip Type BVT Tubing VS11 A4AhmedNo ratings yet

- Well Intervention Pressure Control Syllabus - Level 3 4Document52 pagesWell Intervention Pressure Control Syllabus - Level 3 4ryaneschultzhotmail.comNo ratings yet

- Mast and Dwks Lowering ChecklistDocument5 pagesMast and Dwks Lowering Checklistjinyuan74No ratings yet

- Arabian Drilling Company Rig Specific Procedure AD - 32 Pick Up Drill PipeDocument4 pagesArabian Drilling Company Rig Specific Procedure AD - 32 Pick Up Drill Pipehosam aliNo ratings yet

- Colombia Guide PDFDocument115 pagesColombia Guide PDFLeonardo Olarte0% (1)

- Parker Drilling Rig 258Document2 pagesParker Drilling Rig 258Nathan Thillai100% (2)

- Check List For SOBM Take On BoardDocument5 pagesCheck List For SOBM Take On BoardVimal SinghNo ratings yet

- HHF-1600L Drilling Pump Set Parts ListDocument21 pagesHHF-1600L Drilling Pump Set Parts ListAhmed SaeedNo ratings yet

- Righill Brochure Catalogue - Exclusive IssueDocument4 pagesRighill Brochure Catalogue - Exclusive IssueMukul Sapre100% (1)

- Auto DrillerDocument2 pagesAuto DrillersrpadronNo ratings yet

- 02 Operation ManualDocument30 pages02 Operation ManualramiNo ratings yet

- IR-BOP Test ProcedureDocument6 pagesIR-BOP Test ProcedureHeris Sitompul50% (2)

- Mast and Dwks Raising ChecklistDocument4 pagesMast and Dwks Raising Checklistjinyuan74No ratings yet

- ChecklistDocument3 pagesChecklistAndy Noven KrisdiantoNo ratings yet

- Units of Competence: Assistant Driller Level - 7Document17 pagesUnits of Competence: Assistant Driller Level - 7Ben BieberNo ratings yet

- 1000HP SpecificationDocument107 pages1000HP SpecificationAl Manar Petroleum100% (1)

- AC-0020 Practical Assessment Grading Sheet - Surface BOP OperationsDocument7 pagesAC-0020 Practical Assessment Grading Sheet - Surface BOP OperationsManash Hazarika100% (2)

- Checklist RigDocument104 pagesChecklist RigKiryaki Francis100% (2)

- HH220 Electric Package Tech SpecDocument28 pagesHH220 Electric Package Tech SpecRobertoVitorianoNo ratings yet

- Controll Cabin OEM PDFDocument47 pagesControll Cabin OEM PDFOvRrj AhmedNo ratings yet

- Preventive Maintenance System: It's A Marriage - Man and Machine - and They Have To Get AlongDocument27 pagesPreventive Maintenance System: It's A Marriage - Man and Machine - and They Have To Get Alongsrinath saiNo ratings yet

- Checklist (For Any Land Rig)Document13 pagesChecklist (For Any Land Rig)Kachur Aleksey100% (1)

- Prometric Questions OrthoDocument13 pagesPrometric Questions OrthoFaisal Mushtaq64% (11)

- Cementing Job Standard ChecklistsDocument10 pagesCementing Job Standard ChecklistsalizareiforoushNo ratings yet

- SOP GTC 100-02-012 Lower The MastDocument2 pagesSOP GTC 100-02-012 Lower The Mastakv9005No ratings yet

- Driller Controller User ManualDocument12 pagesDriller Controller User ManualYahya BA100% (1)

- Oisd 169Document27 pagesOisd 169Anonymous 70lCzDJv100% (3)

- (Ins) YORK JTOH080 960VPE (U, F, R) PDFDocument100 pages(Ins) YORK JTOH080 960VPE (U, F, R) PDFLesly Yisset Landazabal Rodriguez100% (3)

- 10 Work On Mud PumpsDocument5 pages10 Work On Mud PumpsdraghiceanuNo ratings yet

- BOP and Control SystemDocument79 pagesBOP and Control SystemRanjith Kumar RaviNo ratings yet

- Piping Design Criteria Gd-006 - 000pgd006 0 20040909Document28 pagesPiping Design Criteria Gd-006 - 000pgd006 0 20040909Felipe Eduardo Guzmán SilvaNo ratings yet

- TECHNICAL AND ECONOMIC Evaluation of Compact Drilling Rigs PDFDocument82 pagesTECHNICAL AND ECONOMIC Evaluation of Compact Drilling Rigs PDFKolawole Adisa100% (2)

- Mechanical Engineering Interview Questions and Answers Set3 - Preparation For EngineeringDocument9 pagesMechanical Engineering Interview Questions and Answers Set3 - Preparation For EngineeringRajneesh Patel100% (1)

- Cost Effective Integrated Gas Plant Design Sulfinol MDocument2 pagesCost Effective Integrated Gas Plant Design Sulfinol Mamirho3ein100% (1)

- ChecklistDocument2 pagesChecklistdassayevNo ratings yet

- Process STD 104Document53 pagesProcess STD 104Augusto ManuelNo ratings yet

- FLOORMAN Sign-Off WorkbookDocument16 pagesFLOORMAN Sign-Off WorkbookBen BieberNo ratings yet

- Draw WorksDocument3 pagesDraw WorksUsman AhmedNo ratings yet

- 750HP DW PDFDocument6 pages750HP DW PDFilkerkozturkNo ratings yet

- CP-MP-001 Mud PumpsDocument6 pagesCP-MP-001 Mud PumpsEd CalheNo ratings yet

- Valve Seat Inspection and LappingDocument3 pagesValve Seat Inspection and LappingCristian BoselliNo ratings yet

- Baoji Engineering YM-16IIF Hydraulic Cathead Operations ManualDocument22 pagesBaoji Engineering YM-16IIF Hydraulic Cathead Operations ManualDhrubajyoti BoraNo ratings yet

- Dsa4 Side DoorDocument24 pagesDsa4 Side DoorДудла СтаніславNo ratings yet

- 81W173047 (P13069) PDFDocument435 pages81W173047 (P13069) PDFharounNo ratings yet

- Scope of Wok As Per Cat IV Rig InspectionDocument1 pageScope of Wok As Per Cat IV Rig InspectionAsia BelmontNo ratings yet

- Activity Report Nov.23 Nov.30Document1 pageActivity Report Nov.23 Nov.30elmaadawy2002No ratings yet

- How To Probability Distribution by MaadawyDocument3 pagesHow To Probability Distribution by Maadawyelmaadawy2002No ratings yet

- Student Handbook ULgDocument11 pagesStudent Handbook ULgKaliya PerumalNo ratings yet

- MSW Winter10 Online PDFDocument91 pagesMSW Winter10 Online PDFelmaadawy2002No ratings yet

- DOH Airport Schedules PDFDocument354 pagesDOH Airport Schedules PDFelmaadawy2002No ratings yet

- Physician PDFDocument1 pagePhysician PDFelmaadawy2002No ratings yet

- Equipment ProceduresDocument1 pageEquipment Procedureselmaadawy2002No ratings yet

- Mail/Fax Order FormDocument2 pagesMail/Fax Order Formelmaadawy2002No ratings yet

- Design of Steel Strctures IIDocument3 pagesDesign of Steel Strctures IIRajiv SawaruthNo ratings yet

- Welding VocabularyDocument35 pagesWelding Vocabularymail_younes6592No ratings yet

- AVEVA Marine - Tribon ComparisonDocument13 pagesAVEVA Marine - Tribon Comparisonelmaadawy2002No ratings yet

- 15832, Sewage Treatment WEBDocument4 pages15832, Sewage Treatment WEBelmaadawy2002No ratings yet

- Collection and Conveyance of Raw Water From Source: Intake StructuresDocument3 pagesCollection and Conveyance of Raw Water From Source: Intake StructuresAllana Grace RevecheNo ratings yet

- Natural Gas Briefing 1 PDFDocument15 pagesNatural Gas Briefing 1 PDFHelena KosanovićNo ratings yet

- 30 Running in OilDocument2 pages30 Running in OilBennie BarnardNo ratings yet

- Catalyst Cracking of NapthaDocument9 pagesCatalyst Cracking of Napthasswoo3868No ratings yet

- ILECO II CertificationDocument1 pageILECO II CertificationWilfredo Gabata SinoyNo ratings yet

- The Octane Numbers of Ethanol Blended With Gasoline and Its SurrogatesDocument13 pagesThe Octane Numbers of Ethanol Blended With Gasoline and Its Surrogatesely_hernandez2010No ratings yet

- SV80-100 Eng Data1-1996Document9 pagesSV80-100 Eng Data1-1996Bala Krishnan NataNo ratings yet

- Cutback Bitumen MC 70Document2 pagesCutback Bitumen MC 70JivaAliNo ratings yet

- Iocl FireDocument4 pagesIocl Fireshona2rockNo ratings yet

- Energy Assignment 3Document4 pagesEnergy Assignment 3aukitNo ratings yet

- Bombas de Cavidad ProgresivaDocument8 pagesBombas de Cavidad ProgresivaJohanna RojasNo ratings yet

- Fuel Burn To Overhaul Model - En.esDocument6 pagesFuel Burn To Overhaul Model - En.esDAnielNo ratings yet

- Buoyancy, Stability and Masses Subjected To AccelerationDocument12 pagesBuoyancy, Stability and Masses Subjected To AccelerationandreinaNo ratings yet

- Climate Change RevDocument6 pagesClimate Change RevMichelle MalabananNo ratings yet

- Quick and Self-Closing ValvesDocument2 pagesQuick and Self-Closing ValvesMarcoDekkerNo ratings yet

- Proposal For Bank-MGDocument7 pagesProposal For Bank-MGRanjit Roy100% (1)

- Iffco Aonla PresentationDocument16 pagesIffco Aonla PresentationDivya Prakash SrivastavaNo ratings yet

- Variable Priority Flow DividersDocument8 pagesVariable Priority Flow DividersMichael DavenportNo ratings yet

- Cam Less EngineDocument10 pagesCam Less EngineSridhar DineshNo ratings yet

- Organic Sub-Part 1Document16 pagesOrganic Sub-Part 1ahsaanahmadNo ratings yet

- Energy Recovery Atlas CopcoDocument3 pagesEnergy Recovery Atlas CopcoSergio LinNo ratings yet