Professional Documents

Culture Documents

F-8739 Line Proportioner PDF

F-8739 Line Proportioner PDF

Uploaded by

fajaraminwahyullahOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

F-8739 Line Proportioner PDF

F-8739 Line Proportioner PDF

Uploaded by

fajaraminwahyullahCopyright:

Available Formats

FOAM SYSTEMS LINE PROPORTIONERS

Data/Specifications

APPLICATION

DESCRIPTION

ANSUL line proportioners are designed to introduce a controlled flow of

foam concentrate into a pressurized water stream. They provide an inexpensive foam proportioning means for systems requiring fixed flow rates

and where available water supply pressures are adequate. Depending

on specific foam systems design, line proportioners may operate with

inlet pressures as low as 80 psi (552 kPa). However, in most systems a

water pressure between 125 psi and 200 psi (862 and 1379 kPa) is

required. The flow rate and operating pressure required at the foam

making device are of primary importance in determining the required line

proportioner inlet pressure. The line proportioner must match the flow

rate of the foam making discharge device.

ANSUL model PL line proportioners can be used with all types of foam

concentrates. The proportioners are available in a wide range of sizes

for fixed foam system applications. These applications also require an

atmospheric foam concentrate storage tank as shown in the Typical Line

Proportioning System schematic.

Portable line proportioners with fire hose thread connections (typically

for use with matched handline nozzles) are also available for the PL-60

through PL-350 sizes.

Each ANSUL line proportioner consists of a body, jet, throat, and metering orifice all of which are corrosion-resistant brass.

The line proportioner body is designed with a female NPT threaded inlet

and a male NPT threaded outlet (see Line Proportioner Dimensions).

The proportioner body is clearly marked with a flow direction arrow and

the designed concentration percentage.

The inlet jet is secured by a stainless steel retaining ring on models

PL-60 through PL-350; the inlet jet is threaded in place on models

PL-420 through PL-730. The metering orifice or adjustable metering

valve is sized according to the type and percentage of foam concentrate

used. The metering orifice is secured with a stainless steel retaining ring

to enable ease of change-over to other concentrate percentages.

In fixed systems the line proportioner may be mounted at a maximum

distance of 8 ft (2.4 m) above the minimum foam liquid surface.

SPECIFICATIONS

Typical applications include use by municipal fire departments and CFR

type vehicles, or with fixed systems, for protecting flammable liquid

storage tanks, loading racks, dike areas, and anywhere flammable

liquids are used, stored, processed, or transported.

The line proportioner body, jet, and throat shall be of brass construction.

Retaining rings for both the inlet jet and the metering orifice shall be

stainless steel.

Typical Line Proportioning System

The line proportioner body shall have a female NPT inlet and male NPT

outlet (see Line Proportioner Dimensions). The body shall be clearly

marked with a flow direction arrow and the percentage of foam concentrate that the proportioner was designed to provide.

Pipa ke foam monitor

LINE

PROPORTIONER

The convergent inlet jet shall have a rounded inlet and a smooth

machined finish to ensure minimum friction loss. It shall be retained by a

stainless steel retaining ring or shall be threaded in place. The inlet jet

shall terminate in the foam concentrate annulus chamber, and shall be

concentric with and set back from the throat and pressure recovery

section. Line proportioner outlet pressure recovery shall be 65% of the

inlet pressure. The line proportioner shall be approved for mounting up

to a maximum height of 8 ft (2.4 m) above the minimum foam liquid

surface.

CHECK

VALVE

WATER

SUPPLY

VALVE

FOAM

CONCENTRATE

SHUT-OFF VALVE

8 FT MAXIMUM

(2.4 m)

FOAM

CONCENTRATE

STORAGE TANK

(ATMOSPHERIC TYPE)

The foam concentrate metering orifice shall be machined to the proper

diameter for the agent. It shall rest on a machined surface to prevent

leakage and shall be secured by a removable stainless steel retaining

ring.

ORDERING INFORMATION

001184

Line Proportioner Cross Section

FOAM CONCENTRATE

INLET

JET

RETAINING RING

FOAM

SOLUTION

DISCHARGE

THROAT

BODY

WATER

INLET

METERING ORIFICE

001185

Line

Proportioner

Model

__________

Part No.

With

3% Concentrate

Orifice

_____________

Part No.

With

6% Concentrate

Orifice

_____________

Approximate

Shipping

Weight

(kg)

lb

_________

PL-60

PL-95

PL-120

PL-210

PL-240

PL-280

PL-350

PL-420

PL-480

PL-550

PL-600

PL-660

PL-730

75650

75662

75674

75684

76890

75694

75704

71508

71518

71528

71538

71548

71558

75656

75668

75679

75689

76895

75699

75709

71504

71514

71524

71534

71544

71554

7

7

12

19

19

19

19

24

24

24

29

29

29

(3.2)

(3.2)

(5.4)

(8.6)

(8.6)

(8.6)

(8.6)

(10.9)

(10.9)

(10.9)

(13.2)

(13.2)

(13.2)

Flow Rate at Given Pressure

Line Proportioner

K Factor

Model

Water

__________

_____

4.8

7.3

9.2

16.2

18.2

21.2

27.0

32.5

37.2

42.6

46.8

52.0

57.3

PL-60

PL-95

PL-120

PL-210

PL-240

PL-280

PL-350

PL-420

PL-480

PL-550

PL-600

PL-660

PL-730

Formula:

Q = (K

K Factor

3%

_____

K Factor

6%

_____

5.0

7.6

9.5

16.8

18.9

22.1

28.0

33.7

38.7

44.3

48.5

53.9

58.8

5.1

7.7

9.7

17.1

19.3

22.5

28.6

34.4

39.4

45.1

49.5

55.0

60.7

INSTALLATION REQUIREMENTS

1. The line proportioner must not be mounted more than 8 ft (2.4 m)

above the minimum foam concentrate liquid level as shown in Figure

1.

2. Downstream pipe, fittings, elevation head, and discharge devices

must not result in line proportioner outlet backpressure in excess of

65% of line proportioner inlet pressure. (Consult with the system

designer to verify.)

3. A check valve must be installed in the foam concentrate line with the

direction of flow from the foam concentrate storage tank to the line

proportioner. (See Figure 1.)

4. A shutoff valve in the foam concentrate line is recommended to

enable flush out of foam solution piping or allow for water only

discharge. (See Figure 1.)

P)

5. Piping to foam concentrate inlet must be sized to match the foam

concentrate inlet piping size. (See Figure 2, Dimension B.)

Example: Find flow of PL-350 @ 180 psi (1241 kPa) when used with

a 3% foam concentrate:

PL-350 3% K Factor

Square root of 180 psi

FLOW RATE

6. ANSUL recommends that the foam concentrate inlet line not exceed

11 ft (3.4 m) of pipe, two 90 elbows, one swing check valve, and one

nonrestricting shutoff valve.

28.00

13.41

_____

375 gpm @ 180 psi

(1420 Lpm @ 1241 kPa)

NOTICE

Exceeding foam concentrate line limitations or using pipe

sizes smaller than the foam concentrate inlet of the line

proportioner may reduce concentration percentages.

LINE PROPORTIONER DIMENSIONS

MODELS PL-420 THROUGH PL-730

G

MODELS PL-60 THROUGH PL-350

F

G

H (HEX)

H (HEX)

E

D

K

001186

E

D

001187a

001187b

Dimensions Inches (cm)

PL-60

PL-95

PL-120

PL-210

PL-240

PL-280

PL-350

PL-420

PL-480

PL-550

PL-600

PL-660

PL-730

A

1 1/2 11 1/2

NPT

1 1/2 11 1/2

NPT

2 1/2 8

NPT

2 1/2 8

NPT

2 1/2 8

NPT

2 1/2 8

NPT

2 1/2 8

NPT

2 1/2 8

NPT

2 1/2 8

NPT

2 1/2 8

NPT

38

NPT

38

NPT

38

NPT

B

1/2 14

NPT

1/2 14

NPT

1/2 14

NPT

1 11 1/2

NPT

1 11 1/2

NPT

1 11 1/2

NPT

1 11 1/2

NPT

1 11 1/2

NPT

1 11 1/2

NPT

1 11 1/2

NPT

1 1/4 11 1/2

NPT

1 1/4 11 1/2

NPT

1 1/4 11 1/2

NPT

C

1 1/2 11/12

NPT

1 1/2 11/12

NPT

2 1/2 8

NPT

2 1/2 8

NPT

2 1/2 8

NPT

2 1/2 8

NPT

2 1/2 8

NPT

38

NPT

38

NPT

38

NPT

48

NPT

48

NPT

48

NPT

D

2.50

(6.35)

2.50

(6.35)

3.56

(9.04)

3.75

(9.53)

3.75

(9.53)

3.75

(9.53)

3.75

(9.53)

4.03

(10.24)

4.03

(10.24)

4.03

(10.24)

4.38

(11.13)

4.38

(11.13)

4.38

(11.13)

E

1.59

(4.04)

1.59

(4.04)

2.38

(10.80)

2.69

(6.83)

2.69

(6.83)

2.69

(6.83)

2.69

(6.83)

2.97

(7.54)

2.97

(7.54)

2.97

(7.54)

3.21

(8.15)

3.21

(8.15)

3.21

(8.15)

F

10.00

(25.40)

10.25

(26.04)

14.25

(36.20)

16.00

(40.64)

16.00

(40.64)

16.00

(40.64)

16.00

(40.64)

18.38

(46.69)

18.38

(46.69)

18.38

(46.69)

20.19

(51.28)

20.19

(51.28)

20.19

(51.28)

G

2.47

(6.27)

2.63

(6.68)

2.88

(7.32)

4.25

(10.80)

4.25

(10.80)

4.25

(10.80)

4.25

(10.80)

4.75

(12.07)

4.75

(12.07)

4.75

(12.07)

5.06

(12.85)

5.06

(12.85)

5.06

(12.85)

H

1.25

(3.18)

1.38

(3.51)

2.00

(5.08)

2.63

(6.68)

2.63

(6.68)

2.63

(6.68)

2.63

(6.68)

3.00

(7.62)

3.00

(7.62)

3.00

(7.62)

3.25

(8.26)

3.25

(8.26)

3.25

(8.26)

I

2.47

(6.25)

2.63

(6.68)

2.88

(7.32)

4.25

(10.80)

4.25

(10.80)

4.25

(10.80)

4.25

(10.80)

J

5.00

(12.70)

5.00

(12.70)

8.00

(20.32)

8.50

(21.59)

8.50

(21.59)

8.50

(21.59)

8.50

(21.59)

K

3.50

(8.89)

3.50

(8.89)

3.50

(8.89)

4.00

(10.16)

4.00

(10.16)

4.00

(10.16)

4.00

(10.16)

L

.281

(.714)

.281

(.714)

.281

(.714)

.343

(.87)

.343

(.87)

.343

(.87)

.343

(.87)

NOTICE

Mounting feet are not provided with

models PL-420 through PL-730.

ANSULis a trademark of Ansul Incorporated or its affiliates.

Ansul Incorporated

Marinette, WI 54143-2542

715-735-7411

www.ansul.com

Copyright 2007 Ansul Incorporated

Form No. F-8739-1

You might also like

- Kids Box New Generation 3 Pupils BookDocument97 pagesKids Box New Generation 3 Pupils BookMicaela Corado Dedo100% (5)

- Anatomy and Physiology Chapter 1 Practice TestDocument13 pagesAnatomy and Physiology Chapter 1 Practice TestDani AnyikaNo ratings yet

- Signature AssignmentDocument11 pagesSignature AssignmentHugoNo ratings yet

- Cameron Ball ValvesDocument31 pagesCameron Ball ValvesJosé Roberto Alejo MirandaNo ratings yet

- Classic Range Dn60 To 2000Document48 pagesClassic Range Dn60 To 2000binunalukandamNo ratings yet

- PIPESIM FundamentalsDocument206 pagesPIPESIM FundamentalsphantanthanhNo ratings yet

- Chem 145.1 FR 2Document8 pagesChem 145.1 FR 2Shaina CerveraNo ratings yet

- Monitoring Training PDFDocument264 pagesMonitoring Training PDFDiego Rojo100% (6)

- Rationalizati ON: Prefinal Practical ExamDocument22 pagesRationalizati ON: Prefinal Practical ExamOsannah Irish InsongNo ratings yet

- Catalogs Proporcionadores EspumaDocument10 pagesCatalogs Proporcionadores EspumaPoncho RmzNo ratings yet

- 01 Installation of Ratio Flow ControllersDocument1 page01 Installation of Ratio Flow ControllersBrandon TrocNo ratings yet

- FM 200Document1 pageFM 200Md Hossain KhondakarNo ratings yet

- Diaphragm Control Valve Solutions - BrochureDocument20 pagesDiaphragm Control Valve Solutions - BrochureMusaab AliNo ratings yet

- Data Sheet Rosemount Tank Gauging System en 104590Document46 pagesData Sheet Rosemount Tank Gauging System en 104590Alejandro LopezNo ratings yet

- FB 1200Document52 pagesFB 1200Eduardo AlvarezNo ratings yet

- Emergency Shut Down Valve:: Actuated Valve Partial or Total Process ShutdownDocument3 pagesEmergency Shut Down Valve:: Actuated Valve Partial or Total Process ShutdownPrasanna kumar subudhiNo ratings yet

- Varec Automatic Tank GaugeDocument18 pagesVarec Automatic Tank GaugeNeilNo ratings yet

- Buckling Pin Pressure Relief Technology PDFDocument12 pagesBuckling Pin Pressure Relief Technology PDFfkboulosNo ratings yet

- Grundfosliterature 1563Document60 pagesGrundfosliterature 1563Montoya SantiagoNo ratings yet

- SS 4C 1,3Document1 pageSS 4C 1,3عدیل الررحمنNo ratings yet

- Plantpax Process Automation Solution For Oil and GasDocument24 pagesPlantpax Process Automation Solution For Oil and GaszkaticNo ratings yet

- Control Valve SourcebookDocument218 pagesControl Valve SourcebookJuanita JitomateNo ratings yet

- OMV E&P Philosophy: TitleDocument29 pagesOMV E&P Philosophy: TitleamdatiNo ratings yet

- Motor Driven Pumps Process Pumps ProMinent Product Catalogue 2017 Volume 3Document220 pagesMotor Driven Pumps Process Pumps ProMinent Product Catalogue 2017 Volume 3carlosmilfontNo ratings yet

- BMID Hydrant Test FormDocument2 pagesBMID Hydrant Test FormSheikh Faiz RockerNo ratings yet

- How Accurate Is Accurate Parts 1-2-3Document10 pagesHow Accurate Is Accurate Parts 1-2-3wlmostiaNo ratings yet

- Elster-Instromet M2000 FCDocument0 pagesElster-Instromet M2000 FCsaid_rahmansyah4750No ratings yet

- MSRL To PP+FRP ComparisonDocument1 pageMSRL To PP+FRP Comparisonprateek_bhoirNo ratings yet

- Subsea Production Control Systems: 1 ForewordDocument25 pagesSubsea Production Control Systems: 1 ForewordBSFNo ratings yet

- 00022443the Application of A Continuous Leak Detection System To Pipelines and Associated EquipmentDocument4 pages00022443the Application of A Continuous Leak Detection System To Pipelines and Associated EquipmentFaizal AbdullahNo ratings yet

- Air Ejector PDFDocument66 pagesAir Ejector PDFSebastianNo ratings yet

- Desmoke System p.155-173Document19 pagesDesmoke System p.155-173Just RysdanNo ratings yet

- Process Control (Level)Document12 pagesProcess Control (Level)Gino GalanoNo ratings yet

- Conectores 15000 Psi MS-02-335Document10 pagesConectores 15000 Psi MS-02-335Pierre MejiaNo ratings yet

- DP Transmitter Interface Level Measurement Principle, Limitations, Selection, Installation, Design & CalibrationDocument12 pagesDP Transmitter Interface Level Measurement Principle, Limitations, Selection, Installation, Design & CalibrationsubbaraoNo ratings yet

- Selection Guide EmersonDocument16 pagesSelection Guide Emersonmmrjbi9412No ratings yet

- Hydrocyclones DeoilingDocument2 pagesHydrocyclones DeoilingJ SlaterNo ratings yet

- 02-A Kinetico Owners Manual - Commercial Plus Softener SeriesDocument32 pages02-A Kinetico Owners Manual - Commercial Plus Softener SeriesCastoriadisNo ratings yet

- Pipe SwabsDocument2 pagesPipe SwabsadammzjinNo ratings yet

- Metering Pumps Components Metering Systems ProMinent Product Catalogue 2016 Volume 1Document198 pagesMetering Pumps Components Metering Systems ProMinent Product Catalogue 2016 Volume 1kambiadoNo ratings yet

- Comparison of The Design of Water Treatment Plant by Manual and by Software MethodDocument4 pagesComparison of The Design of Water Treatment Plant by Manual and by Software MethodChan KianNo ratings yet

- Flow Metering Tutorial Part 4 Ultrasonic Flow MetersDocument4 pagesFlow Metering Tutorial Part 4 Ultrasonic Flow MetersSenthil KumarNo ratings yet

- Asco Valve 8262h 8263h GP Spec r3Document4 pagesAsco Valve 8262h 8263h GP Spec r3Anonymous 6VCG1YRdNo ratings yet

- (SB007A3) Smith Meter® AccuLoad® III Controller and Microload - Net™Document3 pages(SB007A3) Smith Meter® AccuLoad® III Controller and Microload - Net™Roberto Carlos TeixeiraNo ratings yet

- Det-Tronics - 92-1037-06Document4 pagesDet-Tronics - 92-1037-06Javierfox98No ratings yet

- Pumps, Valves, and PipingDocument50 pagesPumps, Valves, and PipingSikandar HayatNo ratings yet

- Upply INE Anitization: Operation & Maintenance Manual Demineralization Water Treatment SystemDocument11 pagesUpply INE Anitization: Operation & Maintenance Manual Demineralization Water Treatment SystemHedi Ben MohamedNo ratings yet

- DPT Smart Pressure TransmitterDocument15 pagesDPT Smart Pressure Transmitterprasanta_bbsrNo ratings yet

- Installation & Troubleshooting Guidelines For API Seal Flush PlansDocument132 pagesInstallation & Troubleshooting Guidelines For API Seal Flush PlansP_I_P_HNo ratings yet

- Pump Design - 2Document1 pagePump Design - 2kapsarcNo ratings yet

- AVK Pneumatic Gate Valves BrochureDocument2 pagesAVK Pneumatic Gate Valves BrochureCuong Nguyen ChiNo ratings yet

- Shutdown ValvesDocument2 pagesShutdown Valvesnazury2kNo ratings yet

- ITP - 031 (Earthing)Document2 pagesITP - 031 (Earthing)mohamed wahebNo ratings yet

- Flow-X Flow ComputerDocument12 pagesFlow-X Flow ComputerKuan Yue ChanNo ratings yet

- Hvac Plant Do'S and Don'Ts Air Handling UnitDocument1 pageHvac Plant Do'S and Don'Ts Air Handling UnitSYED SHAHBAZNo ratings yet

- Product List: Pressure MeasurementDocument6 pagesProduct List: Pressure MeasurementSr FarezNo ratings yet

- TechnicalSpec CustodyTransferMeterDocument10 pagesTechnicalSpec CustodyTransferMeterXarly Polite Jr.No ratings yet

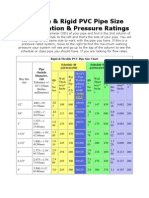

- Flexible & Rigid PVC Pipe Size IdentificationDocument4 pagesFlexible & Rigid PVC Pipe Size IdentificationAziz Khan KakarNo ratings yet

- MIS-M-DS-04052 50m3 Treated Water Tank Data Sheet (T-04320) - CDocument2 pagesMIS-M-DS-04052 50m3 Treated Water Tank Data Sheet (T-04320) - Chappale2002No ratings yet

- Fire Protection Engineering Fall 2001Document35 pagesFire Protection Engineering Fall 2001Hany RifaatNo ratings yet

- BASICS of Process ControlDocument31 pagesBASICS of Process ControlMallikarjun ManjunathNo ratings yet

- Catalogue PlantpAxDocument16 pagesCatalogue PlantpAxaharnishaNo ratings yet

- Ciu Plus & Ciu PrimeDocument8 pagesCiu Plus & Ciu Prime91665111No ratings yet

- ANSUL Between Flanged ProportionersDocument2 pagesANSUL Between Flanged ProportionersAngel Mendieta100% (1)

- Bombas Dosificadoras Milton Roy Lmi CDocument2 pagesBombas Dosificadoras Milton Roy Lmi CErikLjNo ratings yet

- 02 110 BPS Foam Pump Skid With Foam Pump and RC ControllerDocument8 pages02 110 BPS Foam Pump Skid With Foam Pump and RC Controllerarachman297988No ratings yet

- Cyclone Performance and DesignDocument23 pagesCyclone Performance and DesignpsycopaulNo ratings yet

- About Fieldwire: Company Fact SheetDocument2 pagesAbout Fieldwire: Company Fact SheetpsycopaulNo ratings yet

- Overfill White PaperDocument48 pagesOverfill White PaperpsycopaulNo ratings yet

- BLOWDOWN Webinar Presentation PDFDocument47 pagesBLOWDOWN Webinar Presentation PDFpsycopaulNo ratings yet

- Zwick Whitepaper 2 PDFDocument9 pagesZwick Whitepaper 2 PDFpsycopaulNo ratings yet

- Handbook PentairDocument233 pagesHandbook PentairpsycopaulNo ratings yet

- Chemical Engineering April 2015Document86 pagesChemical Engineering April 2015XuanTung0% (1)

- PFD&PID With AUtoCAD P&ID PDFDocument7 pagesPFD&PID With AUtoCAD P&ID PDFihllhmNo ratings yet

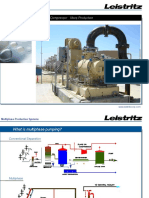

- Leistritz Multiphase Pumping SystemDocument30 pagesLeistritz Multiphase Pumping SystempsycopaulNo ratings yet

- Techical Emerson - PCV SizingDocument21 pagesTechical Emerson - PCV SizingpsycopaulNo ratings yet

- Engineering Standards: Enron Gas Pipeline Composite Index GroupDocument1 pageEngineering Standards: Enron Gas Pipeline Composite Index GrouppsycopaulNo ratings yet

- Compresor Thomas PDFDocument4 pagesCompresor Thomas PDFpsycopaulNo ratings yet

- CEP - Industrial Scale Flare TestingDocument5 pagesCEP - Industrial Scale Flare TestingpsycopaulNo ratings yet

- Hira Sweets PPT KhushiDocument12 pagesHira Sweets PPT Khushikhushichugh616No ratings yet

- Daa Unit-1Document44 pagesDaa Unit-1passion jobNo ratings yet

- Modicon M251 - Programming Guide EIO0000003089.02Document270 pagesModicon M251 - Programming Guide EIO0000003089.02mariookkNo ratings yet

- Professor Manihar THESISDocument183 pagesProfessor Manihar THESISSatyabhama SanasamNo ratings yet

- Summative Test-Quarter 2Document19 pagesSummative Test-Quarter 2JocelynNo ratings yet

- Needs Assessments Processes, Methods and Examples - Annotated Bibliography - Extension - University of Nevada, RenoDocument3 pagesNeeds Assessments Processes, Methods and Examples - Annotated Bibliography - Extension - University of Nevada, RenoSatish UlliNo ratings yet

- Automobile Tire Life Prediction Based On Image Processing and Machine Learning TechnologyDocument14 pagesAutomobile Tire Life Prediction Based On Image Processing and Machine Learning TechnologyLê Gia MinhNo ratings yet

- Coral Reef Restoration A Guide To EffectDocument56 pagesCoral Reef Restoration A Guide To EffectDavid Higuita RamirezNo ratings yet

- University of Mumbai: (Computer Systems and ApplicationsDocument21 pagesUniversity of Mumbai: (Computer Systems and ApplicationsManish YadavNo ratings yet

- Merge 02Document18 pagesMerge 02Kartiki KodeNo ratings yet

- Yaya Maimouna RizalDocument5 pagesYaya Maimouna RizalKriselle Ann CalsoNo ratings yet

- VW - tb.17!06!01 Engine Oils THat Meet VW Standards VW 502 00 and VW 505 01Document8 pagesVW - tb.17!06!01 Engine Oils THat Meet VW Standards VW 502 00 and VW 505 01SlobodanNo ratings yet

- LEO Small-Satellite Constellations For 5G and Beyond-5G CommunicationsDocument10 pagesLEO Small-Satellite Constellations For 5G and Beyond-5G CommunicationsZakiy BurhanNo ratings yet

- New PODocument9 pagesNew POredz00No ratings yet

- Karishma Project Front PageDocument5 pagesKarishma Project Front PageRohan GargNo ratings yet

- The Mystery of Time - SAL RACHELEDocument287 pagesThe Mystery of Time - SAL RACHELEgheorghe.mihaela1369No ratings yet

- Multiple Integrals: Example 3 SolutionDocument15 pagesMultiple Integrals: Example 3 SolutionshivanshNo ratings yet

- 1test PDFDocument2 pages1test PDFPaul John Garcia RaciNo ratings yet

- Old Offshore Scheme: Frequently Asked QuestionsDocument18 pagesOld Offshore Scheme: Frequently Asked QuestionsIgorNo ratings yet

- Mitsubishi Forklift Edr13n 24v Esr18n 24v Esr20n 24v Ess15n 24v Ess20n 24v Operation Maintenance Manual enDocument23 pagesMitsubishi Forklift Edr13n 24v Esr18n 24v Esr20n 24v Ess15n 24v Ess20n 24v Operation Maintenance Manual enmichellejackson130187gcq100% (125)

- WA 05 Unit Test 01 Listening ScriptsDocument1 pageWA 05 Unit Test 01 Listening ScriptsEden GamaNo ratings yet

- Purdue Pharma-Mass. AGDocument312 pagesPurdue Pharma-Mass. AGWews WebStaff100% (1)

- ATV61 Communication Parameters en V5.8 IE29Document126 pagesATV61 Communication Parameters en V5.8 IE29Anonymous kiyxz6eNo ratings yet

- 13 Vassileva Pediatric DRLDocument57 pages13 Vassileva Pediatric DRLLavinia BaracNo ratings yet