Professional Documents

Culture Documents

2011'potential Reuse of Plastic Waste in Road Construction - Review PDF

Uploaded by

ambujlovesuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2011'potential Reuse of Plastic Waste in Road Construction - Review PDF

Uploaded by

ambujlovesuCopyright:

Available Formats

21/11/2014

Potential Reuse of Plastic Waste in Road Construction: A Review - I. Kumarswamy and P. Ramanareddy

Potential Reuse of Plastic Waste in Road

Construction: A Review

By Amol S. Bale

April 2011

The author is Assistant Professor in the Department of Chemical Engineering,

Bharati Vidyapeeth Deemed University, College of Engineering, Pune,

Maharashtra, India

Abstract

Now-a-days Plastic is everywhere in todays lifestyle. The disposal of plastic

wastes is a great problem. These are non-biodegradable product due to

which these materials pose environmental pollution and problems like breast

cancer, reproductive problems in humans and animals, genital abnormalities

and even a decline in human sperm count and quality. In recent years,

applications of plastic wastes have been considered in road construction with

great interest in many developing countries. The use of these materials in

road making is based on technical, economic, and ecological criteria. Several

million metric tons plastic wastes are produced in India every year. If these

materials can be suitably utilized in highway road construction, the pollution

and disposal problems may be partly reduced. Keeping in mind the need for

bulk use of these wastes in India, it was thought expedient to test these

materials and to develop specifications to enhance the use of plastic wastes

in road making, in which higher economic returns may be possible. The

possible use of these materials should be developed for construction of lowvolume roads in different parts of our country. A review of various plastic

wastes for use in the construction of roads has been discussed in this paper.

Index Terms: Polyethylene (PE), Polypropylene (PP) and Polystyrene (PS), Plastic Wastes,

Bitumen, Asphalt etc.

Introduction

Plastic is everywhere in todays lifestyle. It is used for packaging, protecting, serving, and even

disposing of all kinds of consumer goods. With the industrial revolution, mass production of

goods started and plastic seemed to be a cheaper and effective raw material. Today, every

vital sector of the economy starting from agriculture to packaging, automobile, building

construction, communication or InfoTech has been virtually revolutionized by the applications

of plastics. Use of this non-biodegradable (according to recent studies, plastics can stay

unchanged for as long as 4500 years on earth) product is growing rapidly and the problem is

what to do with plastic-waste. Studies have linked the improper disposal of plastic to problems

as distant as breast cancer, reproductive problems in humans and animals, genital

abnormalities and even a decline in human sperm count and quality. If a ban is put on the use

of plastics on emotional grounds, the real cost would be much higher, the inconvenience much

more, the chances of damage or contamination much greater. The risks to the family health

and safety would increase and, above all the environmental burden would be manifold. Hence

http://www.eco-web.com/edi/110430.html

1/6

21/11/2014

Potential Reuse of Plastic Waste in Road Construction: A Review - I. Kumarswamy and P. Ramanareddy

the question is not plastics Vs no plastics but it is more concerned with the judicious use and

re-use of plastic-waste.

In recent years, applications of plastic wastes have been considered in road construction with

great interest in many developing countries. The use of these materials in road making is

based on technical, economic, and ecological criteria. The lack of traditional road materials

and the protection of the environment make it imperative to investigate the possible use of

these materials carefully India has a large network of metro cities located in different parts of

the country and many more are planned for the near future. Several million metric tons plastic

wastes are produced every year in India.

Traditionally soil, stone aggregates, sand, bitumen cement etc. are used for road construction.

Natural materials being exhaustible in nature, its quantity is declining gradually. Also, cost of

extracting good quality of natural material is increasing. Concerned about this, the scientists

are looking for alternative materials for highway construction, and plastic wastes product is

one such category. If these materials can be suitably utilized in highway construction, the

pollution and disposal problems may be partly reduced. In the absence of other outlets, these

solid wastes have occupied several acres of land around plants throughout the country.

Keeping in mind the need for bulk use of these solid wastes in India, it was thought expedient

to test these materials and to develop specifications to enhance the use of these plastic

wastes in road making, in which higher economic returns may be possible. The possible use

of these materials should be developed for construction of low-volume roads in different parts

of our country. The necessary specifications should be formulated and attempts are to be

made to maximize the use of solid wastes in different layers of the road pavement

On heating at 100 - 160C, plastics such as polyethylene, polypropylene and polystyrene,

soften and exhibit good binding properties. Blending of the softened plastic with bitumen

results in a mixed that is amenable for road laying. The mixed has been used to lay roads of

length up to 1,500 km in the state of Maharashtra. Other states like Tamil Nadu, Karnataka,

Pondicherry, Kerala and Andhra Pradesh have also laid test roads. These roads have

withstood loads due to heavy traffic, rain and temperature variation

Preparation of Polymer-Aggregate-Bitumen Mix

Cleaned and dried plastic wastes (e.g.: disposed carry bags, films, cups and thermocole)

with a maximum thickness of 60 microns is shredded into small pieces (2.36 mm - 4.75

mm size). PVC is not suitable for this process.

Aggregate is heated to 165C in a mini hot mix plant

Shredded plastic is added to the hot mix. The plastic gets softened and coated over the

surface of the aggregate giving an oily look in 30 - 60 sec.

Hot Bitumen (heated up to a maximum of 160C to ensure good binding) is added

immediately and the contents are mixed well.

The mix, when cooled to 110 - 120C can be used for road laying using 8 ton capacity

road roller. As the plastics are heated to a maximum temperature of 165C, there is no

evolution of any gas. When heated above 270C, the plastics get decomposed and

above 750C they get burnt to produce noxious gases.

Enhanced Properties of the Mix

http://www.eco-web.com/edi/110430.html

2/6

21/11/2014

Potential Reuse of Plastic Waste in Road Construction: A Review - I. Kumarswamy and P. Ramanareddy

Coating of plastic over aggregate to the tune of 10 - 15% by weight of bitumen improves the

binding properties of the mix:

Higher softening point and lower penetration point due to interlinking of polymer

molecule with bitumen.

Lesser moisture absorptive capacity due to coating of plastics at the surface.

Better ductility, higher Marshall Stability value.

Better stripping value (No stripping on soaking in water for 72 hrs)

High compressive strength (>100mpa) and high flexural strength (>450 Kg/cm with

respect to the binding property)

The roads are twice as strong as normal roads and resistant towards water stagnation

and lesser bleeding during

Polymer blended Bitumen shows higher Softening point, lower penetration point, and better

ductility. Polymer coated aggregate blended with Bitumen shows higher Marshall value and

better stripping value showing that the mix is more suited for road laying.

Process of Road Laying

Using PolymerAggregate-Bitumen Mix

Flow Chart showing method for construction of Road Raw material

The plastic waste (bags, cups,

Thermocole) made out of PE, PP, &

PS are separated, cleaned if needed

and shredded to small pieces (passing

through 4.35mm sieve) The aggregate

(granite) is heated to 170C in the Mini

hot Mix Plant and the shredded plastic

waste is added, it gets softened and

coated over the aggregate.

Immediately the hot Bitumen (160C)

is added and mixed well. As the

polymer and the bitumen are is the

molten state (liquid state) they get

mixed and the blend is formed at

surface of the aggregate. The mixture

is transferred to the road and the road

is laid. This technique is extended to

Central Mixing Plant too.

Salient Features of the

Polymer-Waste-Bitumen Mix Road

Road strength is twice stronger than normal roads;

Resistance towards water stagnation i.e. no potholes are formed;

Less bleeding during summer;

http://www.eco-web.com/edi/110430.html

3/6

21/11/2014

Potential Reuse of Plastic Waste in Road Construction: A Review - I. Kumarswamy and P. Ramanareddy

Burning of plastics waste could be avoided

It doesnt involve any extra machinery;

It doesnt increase cost of road construction; and

It helps to reduce the consumption of bituminous mix vis--vis reduce cost

It is observed that addition of plastics waste up to 10 - 15% by weight of bitumen resulted into

higher values of softening point and lower values of penetration, which are appreciable

improvements in the properties of the binder. This has resulted and withstood higher traffic

load and high temperature variation. Several experimental stretches have been laid in more

than 15 locations in Tamilnadu using both Mini hot-mix and central mixing plants.

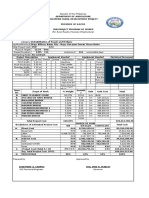

Economics of Road Construction

Laying of Bitumen Road Indian Roads Congress (IRC) Specifications

There are different types of bitumen roads. They are, Dense Bituminous Macadam,

Bituminous Macadam. These roads differ in 3-ways i.e. 1. Composition of the aggregate; 2.

Type of bitumen used; and 3. Thickness of layer. Bitumen is an useful binder for road

construction. Different grades of bitumen like 30/40, 60/70, and 80/100 are available on the

basis of their penetration values and these grades can be used as IRC Specifications. Waste

plastics (10% in place of bitumen) can be used for these different types of bitumen roads. The

technology of road laying is very much the same as prescribed by the Indian Roads Congress

(Section 500, IV revision) Specifications. A detailed description of the material required for

laying of Semi Dense Bituminous Concrete (SDBC) 25 mm road (on existing road) is

described below:

a) Materials:

Conventional Bitumen Road

Battered By Heavy Rain

For 1000M x 3.75M (25mm) Road:

11.250 tons (60/70 grade) bitumen needed

Shredded Plastics Required : 10% by weight

(passing 4.74mm sieve & retaing 2.36 mm).

Bitumen replaced (saved) by 10% Plastics : 1.125

tons

Actual Bitumen Required : 10.125 tons

Aggregate (11.2mm) : 70.875 m

Aggregate (6.7mm) : 43.125 m

Aggregate Dust : 23.625 m

b) Cost:

The total cost including material as mentioned above, labour charge etc. (at Madurai) is

approx. 5.00 lakh, however, the cost may be different from place to place and have to be

calculated accordingly. The cost break-up is given below:

1. Collection of littered plastics : Rs. 0.50 lakh

http://www.eco-web.com/edi/110430.html

4/6

21/11/2014

Potential Reuse of Plastic Waste in Road Construction: A Review - I. Kumarswamy and P. Ramanareddy

2. Cost of shredder and other equipment : Rs. 0.50 lakh

3. Laying of road with material, labour etc. :Rs. 4.00 lakh

4. Total : Rs. 5.00 lakh

Comparison

Polymer-Aggregate-Bitumen Mix Road

Undamaged By Heavy Rain

The durability of the roads laid out with shredded plastic

waste is much more compared with roads with asphalt

with the ordinary mix. Roads laid with plastic waste mix

are found to be better than the conventional ones. The

binding property of plastic makes the road last longer

besides giving added strength to withstand more loads.

While a normal 'highway quality' road lasts four to five

years it is claimed that plastic-bitumen roads can last up

to 10 years. Rainwater will not seep through because of

the plastic in the tar. So, this technology will result in

lesser road repairs. And as each km of road with an

average width requires over two tones of polyblend,

using plastic will help reduce non-biodegradable waste.

The cost of plastic road construction may be slightly

higher compared to the conventional method. However, this should not deter the adoption of

the technology as the benefits are much higher than the cost. Plastic roads would be a boon

for Indias hot and extremely humid climate, where temperatures frequently cross 50C and

torrential rains create havoc, leaving most of the roads with big potholes. Already, a kilometer

long test-track has been tested in Karnataka using this technology. The government is keen

on encouraging the setting up of small plants for mixing waste plastic and bitumen for road

construction. It is hoped that in near future we will have strong, durable and eco-friendly roads

which will relieve the earth from all type of plastic-waste.

Conclusion

Plastics will increase the melting point of the bitumen. The use of the innovative technology

not only strengthened the road construction but also increased the road life as well as will help

to improve the environment and also creating a source of income. Plastic roads would be a

boon for Indias hot and extremely humid climate, where temperatures frequently cross 50C

and torrential rains create havoc, leaving most of the roads with big potholes. It is hoped that

in near future we will have strong, durable and eco-friendly roads which will relieve the earth

from all type of plastic-waste.

References

1. Mroueh, U. M., and Wahlstrom, M. (2002). By-Products and Recycled Materials in Earth

Construction in Finland An Assessment of Applicability. Resources, Conservation and Recycling,

No. 35,2002, pp. 117-129

2. IRC:SP:20-2002. Rural Roads Manual, Indian Roads Congress

3. Report on Demonstration Project for Aggregate-Free Pavement Technology using Fujibeton for

Rural Road Construction, NCCBM, New Delhi, India

4. Gianni A.K. Modi, A.J., Bio Enzymatic Soil Stabilizers for Construction of Rural Roads,International

Seminar on Sustainable Development in Road Transport, New Delhi-India 8-10 November 2001

http://www.eco-web.com/edi/110430.html

5/6

21/11/2014

Potential Reuse of Plastic Waste in Road Construction: A Review - I. Kumarswamy and P. Ramanareddy

5. Sherwood, P. T. (1995). Alternative materials in road construction.Thomas Telford Publications,

London, 1995

6. Dr Satish Chandra, Shiv Kumar & Rajesh Kumar Anand, Soil Stabilization with Rice Husk Ash and

line Sludge, India Highways, Indian Roads Congress, vol33 No. 5, May 2005, pp.87-98

7. Dr. S.S. Verma, Road from Plastic waste., ScienceTech Enterpreneur, March 2008

8. Tara Sen, Umesh Mishra, Usage of Industrial Waste Products in Village Road Construction,

International Journal of Environmental Science and Development, Vol. 1, No. 2, June 2010

9. Wes Heidenreich, Recycled plastic in highway construction and maintenance. State Research

report #525,July 1997

***

Copyright 2011, ECO Services International

http://www.eco-web.com/edi/110430.html

6/6

You might also like

- 5.1 AASHTO and DPWH Design of Rigid PavementsDocument32 pages5.1 AASHTO and DPWH Design of Rigid PavementsJefferson R. Vallente Jr.100% (2)

- Calculation of Safe Bearing Capacity of Soil: - Based On IS: 6403Document31 pagesCalculation of Safe Bearing Capacity of Soil: - Based On IS: 6403sourabh_gupta_54100% (1)

- Work Activity Base Production Rates: Grade ItemsDocument3 pagesWork Activity Base Production Rates: Grade ItemsroldskiNo ratings yet

- Asphalt Emulsions STP1079-EB.30067 PDFDocument117 pagesAsphalt Emulsions STP1079-EB.30067 PDFSri RamyaNo ratings yet

- Vision 5200 2 VOGELEDocument16 pagesVision 5200 2 VOGELERobinson Guaneme100% (1)

- Plastic RoadsDocument30 pagesPlastic RoadsNigam Meher100% (14)

- Plastic Roads: Presented By-Akash Chakole (First Year MBBS, GMC Nagpur)Document27 pagesPlastic Roads: Presented By-Akash Chakole (First Year MBBS, GMC Nagpur)Chandu CKNo ratings yet

- CulvertsDocument14 pagesCulvertsrameshbabu_1979No ratings yet

- USE OF Plastic Waste in Road ConstructionDocument19 pagesUSE OF Plastic Waste in Road ConstructionAbhishek PawarNo ratings yet

- Paper On Plastic To RoadDocument6 pagesPaper On Plastic To RoadSumskrutha Kosgi ShroffNo ratings yet

- Use of Plastic Waste in Bituminous Road ConstructionDocument5 pagesUse of Plastic Waste in Bituminous Road ConstructionIJSTE100% (1)

- Plastic Roads - Akashchakole PDFDocument27 pagesPlastic Roads - Akashchakole PDFAnn CruzNo ratings yet

- Pavement Design ManualDocument295 pagesPavement Design ManualkonstantanolNo ratings yet

- Mini Project Advance PavementsDocument39 pagesMini Project Advance PavementsSD TECHNo ratings yet

- Use of Waste Plastic in Construction ofDocument10 pagesUse of Waste Plastic in Construction ofAnjali chilakalaNo ratings yet

- Plastic Waste Recycling For Development of Bito-PlDocument14 pagesPlastic Waste Recycling For Development of Bito-PlmominspsNo ratings yet

- A Major ProjectDocument16 pagesA Major ProjectRajuNo ratings yet

- Use of Waste Plastic in Construction of Bituminous RoadDocument5 pagesUse of Waste Plastic in Construction of Bituminous RoadTanmay SethiNo ratings yet

- Seminar Report Plastic Road PDFDocument13 pagesSeminar Report Plastic Road PDFAbhinav YadavNo ratings yet

- Utilization of Plastic Waste in Bituminous RoadsDocument9 pagesUtilization of Plastic Waste in Bituminous RoadsDeepankar DaburNo ratings yet

- 2 Animesh Kashyap PPT On Plastic RoadDocument23 pages2 Animesh Kashyap PPT On Plastic RoadANIMESH KASHYAPNo ratings yet

- J0704047981 PDFDocument3 pagesJ0704047981 PDFShuddhashil GhoshNo ratings yet

- Presentation 1Document22 pagesPresentation 1AwAis ABidNo ratings yet

- Animesh Kashyap PPT On Plastic RoadDocument23 pagesAnimesh Kashyap PPT On Plastic RoadANIMESH KASHYAPNo ratings yet

- Polymer Waste PaperDocument16 pagesPolymer Waste PaperMahesh ghorpadeNo ratings yet

- Plastic Use in Roads ConstructionDocument6 pagesPlastic Use in Roads Constructionபுருஷோத்தமன் சரவணன்No ratings yet

- Plasticroads 140415203620 Phpapp02Document27 pagesPlasticroads 140415203620 Phpapp02Piyush KumarNo ratings yet

- Civil Engineering: Khammam Institute of Technology and SciencesDocument31 pagesCivil Engineering: Khammam Institute of Technology and Sciencesramesh ankathiNo ratings yet

- SL No. Chapters Pg. No.: Use of Waste Plastic For Road ConstructionDocument11 pagesSL No. Chapters Pg. No.: Use of Waste Plastic For Road Constructionvinay kumar h sNo ratings yet

- Guidelines For The Use of Plastic Waste in Rural Roads ConstructionDocument5 pagesGuidelines For The Use of Plastic Waste in Rural Roads ConstructionGanesh BhisteNo ratings yet

- PROJECT b11Document17 pagesPROJECT b11mohammadnawab098No ratings yet

- USE OF Plastic Waste in Road ConstructionDocument19 pagesUSE OF Plastic Waste in Road ConstructionAbhishek PawarNo ratings yet

- Igit SarangDocument15 pagesIgit SarangSoumya ranjan MahabhoiNo ratings yet

- Use of Plastic Waste in Flexible Pavements: Volume 2, Issue 4, April 2013Document13 pagesUse of Plastic Waste in Flexible Pavements: Volume 2, Issue 4, April 2013International Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- c1 c5 CompleteDocument44 pagesc1 c5 CompleteAbdulaziz KhalilNo ratings yet

- Review Paper On Plastic Road: Er. Ravi Kamboj, Er. Ashok Anand, Er. Vipin KumarDocument6 pagesReview Paper On Plastic Road: Er. Ravi Kamboj, Er. Ashok Anand, Er. Vipin KumarPoornima PNo ratings yet

- A Review Report On The Utilization of Plastic Wastes in Road ConstructionDocument9 pagesA Review Report On The Utilization of Plastic Wastes in Road ConstructionPoornima PNo ratings yet

- Plastic Roads (Ang)Document17 pagesPlastic Roads (Ang)Feryani DoniaNo ratings yet

- Irjet V5i1240Document8 pagesIrjet V5i1240Aman raj singhNo ratings yet

- Master Thesis Proposal: Use of Waste Plastic in Flexible PavementsDocument7 pagesMaster Thesis Proposal: Use of Waste Plastic in Flexible PavementsFortiter FysproNo ratings yet

- Penetration DecreaseDocument5 pagesPenetration DecreaseBeatrice KunguNo ratings yet

- USE OF Plastic Waste in Road ConstructionDocument19 pagesUSE OF Plastic Waste in Road ConstructionAbhishek PawarNo ratings yet

- Studies On The Improvement of Characteristics of Bitumen With Use of Waste PlasticDocument6 pagesStudies On The Improvement of Characteristics of Bitumen With Use of Waste PlasticAnurag TiwariNo ratings yet

- Report Black BookDocument54 pagesReport Black BookSanket ChaudhariNo ratings yet

- Use of Plastic Waste in Construction of Bituminous RoadDocument6 pagesUse of Plastic Waste in Construction of Bituminous RoadJatinderpal SinghNo ratings yet

- PROJECT PPT (New)Document41 pagesPROJECT PPT (New)Mitali Parkhiya83% (6)

- 321-Article Text-520-1-10-20190425Document12 pages321-Article Text-520-1-10-20190425Ahmed khushalNo ratings yet

- Plastic Roads A Seminar Report SubmittedDocument18 pagesPlastic Roads A Seminar Report SubmittedritikNo ratings yet

- For Greening Our Constructions: By-Pavan Rathode Av Venkatesh BDocument21 pagesFor Greening Our Constructions: By-Pavan Rathode Av Venkatesh Bhemanth gandreddiNo ratings yet

- Wearing Surface Technology Individual Project: Recycling Plastic Into Hotmix AsphaltDocument10 pagesWearing Surface Technology Individual Project: Recycling Plastic Into Hotmix AsphaltOpaqueNo ratings yet

- Plastic Road 35pageDocument35 pagesPlastic Road 35pageME A 04 AvisekNo ratings yet

- Assessment of Suitability of Plastic Waste in Bituminous Pavement ConstructionDocument6 pagesAssessment of Suitability of Plastic Waste in Bituminous Pavement ConstructionSMALLETNo ratings yet

- 804 811V10N8CTDocument9 pages804 811V10N8CTDIVIN KURUPNo ratings yet

- A Presentation On Plastic RoadsDocument23 pagesA Presentation On Plastic RoadsRaki GowdruNo ratings yet

- Edit Final Thesis of ProjectDocument54 pagesEdit Final Thesis of ProjectAshok KumarNo ratings yet

- Use of Plastic Waste in Bituminous Pavement: International Journal of Chemtech Research January 2017Document9 pagesUse of Plastic Waste in Bituminous Pavement: International Journal of Chemtech Research January 2017sulemanNo ratings yet

- Mba Report BhawnaDocument46 pagesMba Report BhawnaAtul BhardwajNo ratings yet

- Roads Made Out of Plastic WasteDocument2 pagesRoads Made Out of Plastic WasteEunice PagadorNo ratings yet

- Vijay Project 2Document60 pagesVijay Project 2Srinivas KosuriNo ratings yet

- Performance Evaluation of Environmentally Sustainable Waste Polythene Fiber Reinforced Bituminous Mix For RoadsDocument6 pagesPerformance Evaluation of Environmentally Sustainable Waste Polythene Fiber Reinforced Bituminous Mix For RoadsEditor IJTSRDNo ratings yet

- Study of Recent Trendes in Road ContructionDocument9 pagesStudy of Recent Trendes in Road Contructionfaizan shaikhNo ratings yet

- Plastic Waste: It'S Use in Construction of Roads: Kurmadasu Chandramouli, Allipilli Satyaveni, Mallampalli - Ch. G.SubashDocument6 pagesPlastic Waste: It'S Use in Construction of Roads: Kurmadasu Chandramouli, Allipilli Satyaveni, Mallampalli - Ch. G.SubashMAHESH A VNo ratings yet

- Waste Plastic GoooodDocument12 pagesWaste Plastic GoooodAngel AngelNo ratings yet

- The Sustainable Solution: Plastic Granulate Production in Action: Money from trashFrom EverandThe Sustainable Solution: Plastic Granulate Production in Action: Money from trashNo ratings yet

- Eco-efficient Rendering Mortars: Use of Recycled MaterialsFrom EverandEco-efficient Rendering Mortars: Use of Recycled MaterialsNo ratings yet

- Recycled Polyester: Manufacturing, Properties, Test Methods, and IdentificationFrom EverandRecycled Polyester: Manufacturing, Properties, Test Methods, and IdentificationNo ratings yet

- S.No. Well Dia (M) Depth (Below The Existing B.H Level) Allowable Bearing Capacity in kg/m2 T/MDocument2 pagesS.No. Well Dia (M) Depth (Below The Existing B.H Level) Allowable Bearing Capacity in kg/m2 T/Msourabh_gupta_54No ratings yet

- Format No. PL/TR/21 Test ReportDocument1 pageFormat No. PL/TR/21 Test Reportsourabh_gupta_54No ratings yet

- 05 Fine Aggregate Gradation, WA & SPGDocument1 page05 Fine Aggregate Gradation, WA & SPGsourabh_gupta_54No ratings yet

- Boring ReportDocument8 pagesBoring Reportsourabh_gupta_54No ratings yet

- Cement Suppliers in IndoreDocument10 pagesCement Suppliers in Indoresourabh_gupta_54No ratings yet

- Cement & Chemical Storage 200sq FT Office 220sq FT Finished Blocks 530 SQ FTDocument1 pageCement & Chemical Storage 200sq FT Office 220sq FT Finished Blocks 530 SQ FTsourabh_gupta_54No ratings yet

- S.No. Material TestDocument1 pageS.No. Material Testsourabh_gupta_54No ratings yet

- Scan 1Document1 pageScan 1sourabh_gupta_54No ratings yet

- Material Transfer VehiclesDocument16 pagesMaterial Transfer VehiclesEliezerChirinos100% (1)

- EstimationDocument15 pagesEstimationnafrisqsNo ratings yet

- Hot Ashalt Mix Desing System MOTDocument48 pagesHot Ashalt Mix Desing System MOTAnonymous a3K3WgNo ratings yet

- Construction of Access RoadsDocument13 pagesConstruction of Access RoadsThandabantu MagengeleleNo ratings yet

- CTR 335 598 Priced BoQ Phase IVDocument153 pagesCTR 335 598 Priced BoQ Phase IVmenso100% (1)

- The Concrete Producer Article PDF - Interlocking Concrete Pavers - The Manufacturing ProcessDocument4 pagesThe Concrete Producer Article PDF - Interlocking Concrete Pavers - The Manufacturing ProcessderoryNo ratings yet

- ABCs of Pavement PreservationDocument8 pagesABCs of Pavement PreservationLuis Miguel Gutierrez KlinskyNo ratings yet

- Railway EngineeringDocument48 pagesRailway EngineeringZineb BoulahiatNo ratings yet

- 10-28 Pow PRDP Fortuna-DaquioagDocument197 pages10-28 Pow PRDP Fortuna-DaquioagMarielle MenorNo ratings yet

- Characterization of Warm Mix Asphalt (WMA) Performance in DiffereDocument247 pagesCharacterization of Warm Mix Asphalt (WMA) Performance in DiffereLatasha SotoNo ratings yet

- Transportation Engineering.....Document0 pagesTransportation Engineering.....www.bhawesh.com.npNo ratings yet

- Vol 2 FinalDocument434 pagesVol 2 FinalSunil ShindekarNo ratings yet

- IRC CodesDocument14 pagesIRC CodesSagar Jha67% (3)

- Flexible Pavement Overlay Design Using Cumulative Difference Approach of Homogeneous SectionDocument11 pagesFlexible Pavement Overlay Design Using Cumulative Difference Approach of Homogeneous Sectionmspark futuristicNo ratings yet

- Schedule of Rates: All Prices Shall Include GSTDocument11 pagesSchedule of Rates: All Prices Shall Include GSTKailas Suresh AnandeNo ratings yet

- Quality Assurance Hand Book For Rural Roads VolumeIIDocument256 pagesQuality Assurance Hand Book For Rural Roads VolumeIIfrozen_07No ratings yet

- 02-1 - (English) Solutions of Infrastructure MaintenanceDocument28 pages02-1 - (English) Solutions of Infrastructure MaintenanceIntan YuniartiNo ratings yet

- Highway Engineering Week 3, FinalsDocument69 pagesHighway Engineering Week 3, FinalsONIFA NAHYOMI ELLOISA M.No ratings yet

- Flexible PavementDocument21 pagesFlexible PavementEugene Odullada MangaringNo ratings yet

- Ottankadu - Punalvasal - SafeDocument6 pagesOttankadu - Punalvasal - SafeRenugopalNo ratings yet

- Coto Coto: TMH 9 Manual For Visual Assessment of Road Pavements Part B: Flexible PavementsDocument60 pagesCoto Coto: TMH 9 Manual For Visual Assessment of Road Pavements Part B: Flexible PavementsNico GroblerNo ratings yet

- Level-III MC of Rigid and Flexible Road SurfacingDocument75 pagesLevel-III MC of Rigid and Flexible Road Surfacingfenta mucheNo ratings yet

- D4429 7542 Standard Test Method For CBRDocument7 pagesD4429 7542 Standard Test Method For CBRDayana HernandezNo ratings yet

- Properties of Asphalt Materials: Variation of Consistency With TemperatureDocument7 pagesProperties of Asphalt Materials: Variation of Consistency With Temperaturetrjirew3No ratings yet