Professional Documents

Culture Documents

Edition Detail - Glass Construction Manual

Uploaded by

Sebastian Comanescu0 ratings0% found this document useful (0 votes)

226 views326 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

226 views326 pagesEdition Detail - Glass Construction Manual

Uploaded by

Sebastian ComanescuCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 326

Glass

Construction

Manual

BALKOW

SCHITTICH SCHULER

STAIB SOBEK

BIRKHAUSER — PUBLISHERS FOR ARCHITECTURE

BASEL « BOSTON - BERLIN

EDITION DETAIL

MUNCHEN

“The orginal German ection ef this book was concelved and developed by

DETAIL, Revew of Architecture.

Authors:

(Christian Sohiticn

Dipleing, archtect, Chief Eeitor of tho journal DETAIL

Gerda

Prof pling. freelance architect.

Chair of Bulling Structures and Design, Dresden Technical Unversity

Dieter Salow

Dipl.-Ing, publicly appointed Independent expert for glass in buildings and dayllontng

Director oF the Swiss Institute for Glass in Building, Zurich

Matthias Schuler

Dipl-Ing, Managing Partner of Tranesolar Energictechnik, Stutgart

Wamer Sobek

Prot Dring

Head of the incttute for Lightweight Sructures, Stitgat University

Assistants:

Eckhard Holtich, Dip-Ing; Mathias Kutterer, Dip!-ings Anja Wits

Sike Brumm, Ospina: Frademam Kk, Dpi-Ina; Filedrch Sick, Dipl.-Ing. Peter Vor, Dip-Ing

Published by:

Institut fir intemationals Arcitel¢u-Dokurmentation GmbH, Munich

Editoval services:

Christian Scntich, Dip-ing.; Songe Grandi, Dip. -ng. Susanne Funk M.A, Comet Hirt M.A,

Drawings: Sabine Drey, Dpl-lng

Translators (German/Engish!

Peter Groon, Dil. Ach., MunichiLondon (Part $)

Gerd Softer, Pip Tit, Hanover (Pans 1-3)

[AGP catalogue record for this books avalable tom the Library of Congress,

Washington, D.C., USA

Deutsche Biblithek — Cataloging: in-Pubication Data

Gass Construction Merual /[Hrea: Insti fr intemationals Arcttekiur-Dosurrentetion Grol

Minehen

alow. [Red.: Chistian Schitich .. Transl (GermervEng.) Peter Green (part 4); Gerd Sitter,

Phil Tht pars t-3) Zeichn: Sabine Drey]. ~ Basel: Boston; Berin : Birkhauser, 1998

By, Ausg. ud 7: Glasbau-Atas

ISBN 3-7645.0077-1 Basel.)

ISBN 0-8178.6077-1 [Bosten)

“This vexcie eublect to copyright Allrights ara reserved, whether the whole or pat ofthe mate

rials concerne, specifically the righ'so! transtaten, reriting,re-uee efillusttions,resilation,

‘broadcasting. renreducton on microfims or n other ways, and storage in data banks. For any

kn of use, permission ofthe copyright mut te obtaired.

“This bookie also availabe in a Garman language edition #SBN 8-7643-5644-7)

© 1989. Brknauser— Publishers for Archtecturs, P.O. Box, 199, CH-4010 Basel, Switzerland

Printed on eci-tree parr produced from chicrine-tree pulp. TOF =

Printed in Germany

ISBN3-7643-0077-1

ISBNO-8!76-6077-

987054321

Contents

Pest 1 Glass in architecture

‘From the origins to classical modernism

Gerad Stib

he main stages inthe manufacture

of ass

‘The wactional house

The Gomi cathedral

The town house

‘= Seattonal vapaness house

fen —reacting for tne light

Fem wallto skin

Ths destruction o the box

eesing visions with glass

Soh ar. sunstine

‘Glass architecture in the second

‘bait of the 20th contury

rsten Scnitich

Tensparency and ranstucency

The cream ofthe glass house

Sess skyscrapers and curtain walls

Savicht end darkness - aless and licht

The now transparency —

lass as a symbol

Trersusoncy and reflection

yrs tacace a5 cisolay

Devetopments n glass construction

fain walls

Suspended glazing and point fixings

Gaszed nets

(Gisss construction subjected to tension

‘and compression ~ a-giass butlaings

Gessand energy

The daveloprant of passive solar

architecture

oiwelent wals and intelligent facades

Tre doubleveaf fagade

Geodesic shells

a

14

7

18

2

26

2

a

a6

36

4

42

4a

46

8

8

6

58

56

58

Part 2. Principles

Glass as a building material

Distor Ballow

aes - a detirivon

‘Types of glass

Coatings for gass

‘Surface rearrenis

Boge works:

Thermally treated glass

Chemically strenathened glass

Laminated glase

Laminated safety glass

Insulating glace

Lowe gas

Centalling solar radiation

Scattering the light

Rediestng the lgit

Photovollaie modules and! elements

Fire-resistant lass

Comoinctions of special function glaceos

Appications

Glass unrier foot

Physccal phienomene:

Advice on alazina

Cleaning and maintenance

Infuence on functional cata

Designing with glass — strength and

loadboaring behavicur

Werner Sobek and Mathias Kulterer

Buluing with gas

The material

Gonetruction deta

Solely ana design

Structural eysters

Glass and energy construction physics

Mattias Schuler

Gless properties relevant to energy

issues and construction physics

Gaining energy throug glass ~

soler radiation, lignt

Glsee ae thermal irsulstion

Glazing polcationsin buildings

and systems:

8

BAIIVeAssAees

83

95

90

118

128

180

140

Part 3 + Construction details,

Fxngs for glass

poring

Architeotural details

Part 4 - Built example:

Cistian Schitteh, Gerald Staio

But examples in dtail

Examples 1-34

‘Appendix

Standards

References

Subject Incex

Prciue credits

12

153

184

186

187

320

22

ane

27

Preface

Hardly any othar bullcing material can

fraich the currant immense populaity of

glace among architecis and engineers,

Glass has witnessed 2 long patiod of evolu-

tion in arcritecture ~ from the soli. plein

veal to the see-through and light-permeable

outer skin,

‘A material that gives us the chenee to eract

transparent. open and seeminaly weantess

buildings clters the cerraiaton between in

terlor and exterior, the relationship between

humankind, space, ight and nature. itis not

Gifficul to understand why glass has such a

high priority as an architectural medium.

‘The property of being able to “capture” the

warmth of the gun within the bulging was

sill a major problem at the beginning of tho

20th century as new structurel solutions

‘were boing explored and tho dosire arose te

reach beyond the confining walls of our con.

structions. Today we have many diferent

‘options available forthe inteligent control

‘and admission ofthe right amount of ight

‘and heat ito our buildings. And glace io

being increasinaly usec 2s a Icadbearng

element oy the structural angineer ~ consid

erably reducing the proportion of bulky sup-

porting construction.

Glass has very recenty been given en enor-

mous Innovative boos:, We are now in tha

ppasition fo comply with the stringant

‘demands of fire protection and safety. The

latest thin-im coatings render possible low-

emission and solar-contral glasses which at

tho same time parmt optimum transparency,

‘nd yet other echnologies can make glass

alternately translucent cr transparent, oF —

by way of holograms or liguic erysials ~ turn

itinto an information medium

These diverse innovations lead to an enor:

‘mous thirs! for information among architects

and onginesre.

‘This book is intended to quench that thirst.

The sim of the Glass Construction Marual is

to present the mulifarious aesthetic and

engineering possibilities presented by glass

‘a3 a building meterial, Following on in the

tradiion of such "construction manuals”

from Esition Detail, thi book algo takos an

‘overall [cok at the subject. Basics suon as

the properties of glass, its lbadbearing

behaviour, thermal, acoustic and firs

aspects, glass as en eneroy provider and e

systemnatia selection of fixing detalls and

construction forms are all covers hate,

The first part deals with the history of glass,

and illustatee all tho applicetions of the

material from its earliest beginnings ight up

tothe present day.

‘The tinal seoton contains examples intend

‘230/to show, above al, tha inleraation of aas-

‘hatios and engineering, The projects

selected are not ust those where vest

‘expanses of glazing and technical innova~

‘ions are rominent but also everyday sols-

signs, aueh ag the integration of slamentary

windows in a wall of timber or exo0se3 clay

‘acing bricks.

It remaing to nope that this book wil con-

tribute to a beter practical and theoretical

ungerstaning of thls multjpurpose material

perhans evan to inspiring architects and

engineers in shoir cally cuties,

The Authore

\ Nery \i hf ps Uy

i LA ,

\ v\ le) Bs

IO Hf ep. EA

, oN

Ss PER ee 2

aS INS

Gp OE ES

Ce

Part 1 - Glass in architecture

From the origins to clessicel modernism

Gerald Stab

‘Theman stages fr the manufacture of glass ~

a historical perspective

The traditional houss

The Gothic cathedral -“God i light”

Baroque -attermpting to admit the lant

‘Tha town house - the extarnal wail becomes a

permeable sructure

The traditional Japanese nouse

Jron—reashing for the ight

From wal to skin releasing the extemal wall

from ts loedbearing function

‘The destruction of the box - the fluent tran-

‘ition between inside and outeids

(Geeating visions wit glass ~

‘Without a glass palacs, life becomes

a pucn

Light, a, sunshine ~ “the house machine’

Glass architecture in the socond half of the

20th century

(Chrietian Sehitich

‘Transparency and translucency

the glazed skin comes ave

“The dream of the glass house

Giags skyscrapers and outain walls

Deviant anc darkness ~ olass end lignt

The new transparency —

Gassas a symbol

Translucency and reflection

‘Tha fagede as a dsplay—

‘tha glazed alen comes ale

Davalopmants in glass consiructcn

Curain walls

Suspended glazing and point fixings

Glazed nets |

Glass construction suojected to tension anc

‘compression ~al-glase buildings

lass and eneray

‘Tre daveloparent of passive solar architecture

Pelwelent walls and inteligan: facades

The double leat facade

Geodesic shells -

man-made spaces under olass

From the origins to classical modernism

Gerald Stal

‘The main stagos in the manufacture of

lass ~ a historical perspective

“The word lass is derived trom

Germanic term meaning “amber

“shimmer”. The gless jewellery the Romans

impotted closely resembled amber anciwas

consequartly named as auch. In Latin, amber

is glesum or glaesum. The Romans, on the

othar hand, referred to glass ae virur, pro-

viaing the root for the French expressions

vitre for window pane ard vere for glass.

Origins in Mesopotanis ané Eaypt

tis ail uncertain where the manufecture of

lass criginated, An ash discovered by

change when copper wes amelted or when

Clay vasses were free was used 10 gaze

aramios from eary times. Articos showing

guidence of ts and dating back io the Sth

contury BC have been found in Mesopotamia,

while olhars from the early 4th century BO

were excavated in Egypt, When the tems of

Egyptian pharaohs were onered, gresrien

glass beacs that stemmed from around 3500

BBC came to ight, This marks the beginning of

what could be referred 10 as interticnal glass

manufacture, From the midle of fha 2nd

century BC, rings and simall igures, which

had besn produced using bowls as casting

moulds, began to appesr. The core wound

‘echnigue also alowad the production of

‘omall glaeees, vase, ete from the vieoous,

‘opaque melt, A sand core containing clay

wae fxee © 8 10d, dpaed in tha moltan glass

and tamed around its own axis ‘9 create a

thick “class thraadt that adhered ‘oi, This,

‘was subsequenty rolled into @ sutable shape

(ona fle surface and the core removed after

‘opeling, The oldest blueprint for glass

appears on clay tablets nthe great library of

tho Assyrian king Ashurbaninel (638-826 BO)

in Nineven. the inscriptions in cunetferm

read “Take 60 paris o! sand, 160 paris of ash

‘rom marine plants, 5 peris of chak anc! you

will obtain glass", In principle, this is stil cr-

rect today (s0¢ “Composition”, p. 81)

‘The Syrian blowing ron

‘Onyy ater the invention of the blowing iron

‘round 200 BC by Syrian erafiomen in tre

‘Sidon region did it become possible to pro:

‘duce thin-valled hollow vessels in a wide

variety of stapas. The gate’ (blower) gathers

‘molten glass on tne end of a 1.5m hotow roa

and blows this nic a thinwalled vessel,

‘Tho Reman age

Excavations have revealed that glass was

first used as part ofthe bulding envelope in

vilas at Pompeii snd Horoulenoum, and at

public bains, These panes were installed

Sitar without a frame or were given a bronze

tr 09d surround; they measured approx,

300 x 500 mm and were between 30 and

60 mim theck. Although cylinder sheet glass

was known at this time, these panes were

cast and drawn: a viscous paste was frst

oured onto @ amed table sprinkled wrth

end and then strotohed by drawing it with

iron hooks. 4s far as the weathered (ag;

‘ants ciscavarad oan indicate this Roman

wadew glass seems to have been a bluish

‘reen and not particularly transparent

The Mdcle Ages

\With the Romane, this taohniqua of glass pro:

uction aiso spread to northern alpine

regians. After the patie of migration, the

Floman traction was frst revwed by the

Merovingian Frarks. Objects preserved from

the early Middle Ages nicluds inastos ves:

sels, drinking hams and cla beakers. Thase

beaver, tote Francona, 6h ean:

feeischeshism, Wir,

‘Ma

‘mating eee, engrving om Dera meta,

2 beats onmining and motlurgy, Georse

gona (iat 1880) Basel 160?

Utensils continued to be produced right into

the high Middle Ages, elthough glass pro=

‘uston now revolved more and mere eraund

the bulging of churshes and monasteries,

‘he largest alassworks were iovated in

forested areas end along rivere, Le. wherever

there was an abundancs of wae, ‘o provide

snargy end potesh, ane water, fer cooing

and transporting tne sand. Wnen the supply

cof wood in the vietnty was depleted, the

glessworks moved on. Deferestation became

Critical, and glass-making was prohibited in

many arees. Coal did not replace viood as @

fuel until the 18tn century, fay marking the

‘end af forest gleaaworls.

Blewn eynder shee nd erown glace

“The !wo most important production tec

riquse since the early Midala Ages, the

blown oylinder sheet and crown glass

processes, remained the basis of class pro-

‘cuotion until the late 12h and early 20th cen-

tury. While flat class had been produces

TIS]

Fiom the origins to classiea! modsrismm

Using @ blowing iron in the eylinder proses

Inthe 1st century AD, the metnod of procuc-

ing crown glaos wae not slecovorod unt the

4in century AD. tt wes again Syrian crarts-

men who developed bot processes and ois

seminated these during thelr tevels in he

och

In both the Grown glass and! blown cylinder

Gass processes. ¢ blob of melten glass is

avn off with a blowing iron, preformed into

‘around shape and blown into a "balloon,

\whih i centinually roneated to keep it duc-

tik for shaping

In the blown oylincar sheet glass process,

primary applied in Lorraine and along the

River Rina, tha oallocn was shaped inio a

0

oylinder, as long and thin-walles as possi

bie, by Slowing, swinging and roling ton @

taolo. A dampened iron pin, later a diamond,

Was Used to cut off both ends and sit open

the stress-relleved, caoled cylinder Iongth-

wise betore il was reveated in the flattening

furrace and bent into a flat pane. The cimen-

sions of the cylinder, and consequent of

the pane, were limited only by the power of

the blower's lungs! Cylinders measures a

maximum cf 2 mong witha dameter oF

200 mim,

To produce crown glass, the bubble of glass

was “stuck’ tothe iron plate on the glass-

‘maker's pont lion rod) and the élowng ron

ccrackod off; the hole was enlarged to form a

rim. This bell-shaped object was again

feheated anc rotated at speed 12 fom a

die, As i wes uneven, the glass-maker cut

this “crown” glass into smaller rectangles,

rhombuses or hexagons, depending an its

quality. The thick centre, the bul’seeys, anc

smaller panes were scid as bulls-aye panes

without being cut egain, In contrast to cylin

dar glass, the crown gass process pro-

duced more avon, pursr and mare lustrous

Surfaces as the less did) not come into can

tect with the rough, hat floor of the furnace,

This method was still applied until the rid=

1th century, particularly in Normandy - pre-

sumably the ‘eason itis celled verre de

France ~ andl in Englane.

venice

Botioon tho 1th and 17th eanturios, the city

Of Venice was he major producer of glass

‘bows, drinking vassals and minors (panes

of fiat glass backed with an amalgam of tn

land mercury), which were primarly exported

le Germany and France. The suscess of

Venetian alass was dus to its extraordinary

purty and absence of colour, achioved by

adding the ash of a marine plant as well 2s

manganese and white arsoric as decstouriz.

ing agents.

{719/10 century

‘The glass 000M In tne 17% century ~

‘yas ne longer sold sclely to churches anct

monasteries but a'so io dzelers In the cites

for glazing ralaces and housas - and ine

‘less monopoly held by Venice motivates

class-makers 1o seek new metnods of

‘custion. In 1987 the Frenorrran Bernard

Perrot developed a vital innovation, ne cast

gles process, in which the glaze melt was

ourec anio a smacth, ofeheated copp=

table and praseed inte a pana by a water

‘cooled metal oer. The thickness of the

pane depended an the height ofthe sur-

round. The pane, far more even in compar

son to previous arocesses, was Sub-

saquontly ground with eand and water and

polsned witn a paste made trom iron ox

“These so-called grandes giaces or “pate”

glass panes measured up fo 1.20 x2 mand

vere able to be produced in better quality

vith fess manpower, leading fo a reduction

In costs, The true breakthrough, however,

came wih the invention of a casting and

rolling method, ine Bicheroux proce:

Max Bichorcux in 1919 (220 "Early

tury p12).

Daaspite this, window glass continued t be

en expensive material, perty because bath

sides had to be polished. Glass wes so

cious atthe end of the 18th century thst

coach dhivers, for instanca, replaced the

gloss panes in their carriages by wickorwork

at ine and o! tne cay. in Englang, tenants

removad the window glass wen they

house as it dio not constituie part oft

fFxed furnishings,

Industratstion

Gonsigerabie progrese wae made in

realms of glass production in the 137

tury In 1886 Friedrich Siemans patented ar

Improved version of the melting furnace: th

rationalized operations and halved the

riount of fuel required. It boosted eificiency

In production and prices declined. Tre

bblown cylinder sheet glaas process similarly

experienced major develeament:in 1999 the

‘Chanos brotiers succeeded in adapting the

cutting, grinding and pclishing of tho blown

cyinder to reduce breakage and improve the

Surface finish. With the advant ofthis process

2 1850-51 it became possible 1o produce

‘he enormous number of glass penes for the

‘construction oj the Crystal Palace in just 2

few months. Around the turn of the century,

the American, John H. Lubbers, developed a

mechanical otacess to comone blowing anc

Commsis

Dhalepur, Neos

te

The tracitional house

Frontheailgins class

‘The Gothie cathedral ~ “God is light”

the medieval town

the bishop

tne sovereign,

t played on

entience tas something sp

bby a new light

interior end oxteriar, bot

Ittransformed the rays ofthe

al modium.

i able to eon)

Denis int

Architecture and light oe

sprivalzetion and derra

1”

Baroque — attempting to admit the light

rogue architecture wae essentially coe

red wath the rythrric movement an vivid

immediacy of space. focussed and extended

tointiniy.

ht layed a special role in this respect

2 difuse, mystic ight of the Gothic cathed:

.ad been superseded by tright sunlight

steaming in through ample window and door

openings. Light to create space, but elsa

‘a means of dissclung tha limits of

ace. in the interaction with painting anc

plasterwerk, with fight church walls ~ the

abbey church by Balthasar Neuman in

Norasheim (begun in 1745) deserves special

mention here — and mivrers in palaces, space

loses its material characier; t axpands into

infinity, the walls begin to dissolve and dena:

terialze, The soli outer wall separating inter-

i and exterior faces inte the oackarcunc,

Architecture and nature, inside and outside,

merge to become ona, The achievemanis

‘nanlifested In the baroque bulédings oF this

were to gain more and more signit-

The increasing trond tewarde opening

up architecture prompted a huge demand for

lass. The mushrooming glaae industry in the

north was stl working wan traditional metn-

3 his time and with the inherent disad-

12 crown glass and blown cylln-

der sheet olass processes. With the casting

land rolling methed, whicn frst appeared ia

1688, lerger and almost pure panes of glass

became possible, heraicing tha ora of tha

grandes gfaces. These viete combined ina

Fomarkable way wih mirrors, familiar since

antigulty, but sill made of bronze and copper

with a polished surlace and coated with siver

slatinum. Convex mrrors tad been por

duced sinca the 13th century and backed by

lead or terne metal, Venetian mira, coated

wth an amalgam, had been knowin since the

‘ate 15th century an continued to be pro:

Guced inthis way ito the 1St» century, The

Galario das Glacas (1678-84) at tho Palace

of Verseilles by Jules Hardouie-Mansert ang

Cherles Le Brun is an exemplary display of

how class can be combined with mirors, The

facade ofthe long iransverse wing cveriook-

ing the gardone comprieae a long ropotitive

series cf arched windows which almost dis

solve the wall, transforming it into a mers

‘rame. These openings reappear cn the

opposite internal wall as mierars (civided inta

individual ements measuring 020 »

900 mm). The reflections of nature, the tress

and the clouds are continued inthe white

and coloured marble walls. In tne ight

streaming through the large openings, the

reflections in the mirrors and the indescant

materials, the room itself seems almost to

y completely.

Baroque —attemting o admit the light

From the erigins to classical rogernism

‘The town house the external wall

fecomes a permeable structure

house generally

vy, 20d anvelope, The epen-

vent tiny, and were note

sections: an upper part

nt permanently closed by thin,

hides and other materials that

ter, ane a lower part with

at could ba opened. The

yas ofton closed by tho shutters

id by gratings in the sum-

with round panes mounted on

to appear only very grad-

wet, remained rare and pr

ployed, apart from n pale

clusivey in the constuction of

tries. The Gothic era saw

39 In size with pointed arch

fed in groups, not only evident

ile, tvs lificultto

fo produce large open

rehitcture a the proper

"ead brick reed on carty-

ly in compression, Itwas

ee tin the case of timberframe cone

2 distinctionin the struc-

.Sbearing and non-joacbear

made ine arses between te

eSers available for aperings. Within this

nd vertcaltnes, it now 3+

tring together 2 series of

weocows separated by the timber

9 an early style of cantrucus stip

“This generous broakclown and oom.

1088 14 town halls, uid

smeatis houses became

(of the flourishing ‘ouns of the

> century Instone architecture too,

#5 were made to open up the wall as far

is houses were built very close

Dutch towns ilustate this feeture

ter val could be reduced io

ut afew loacbearing ae.

‘led in with large windows Cespite

ry siya, The generous openings to

lotved light to penetrate into the

rooms. Tha external wall vies

‘hard division between nside

itnow became an elemento! the

‘cn; private and public epheres marged.

-odelling a! ths Zone looks backon a

‘on, particulary in th Notherlands.

es 0n glass and windows In Enganc

es the sacly 17h century, and in Franca on

10 windows, led to the development

forms forthe outer wal.

air,

Basra, Amsterdam

‘The town house ~ He external vall becomes a permeable suucture

Hisaes ie

Tate DOE. y

a 0a

From the origins to classical magamism

‘The tracitional Japanese house

“The climatic conattions prevailing inthis

group of islands, the abundance of wood as

2 bulding materiel, the risk of earthquakes

and the strong adherence to cultural and

religious traditions have produced a typo of

house in Japan that has folowed the same.

rule for earturias

The open plan, the bond with the garden, the

lightwalart, opening slements reaching up to

the calling and the {ul length of the well hac

a greet influence on modamist architects ike

Frank Lloyd Wright and Bruno Teut

The tractiona’ Japanese ouse is a Neuse

made of wood, bamboo, frequently clay for

the walls, paper toil in tne sliding elements

‘and otraw tlocre; a skelaton construction with

lgntwaight, mostly siding wall units. All

parts of the house, the wacdan construc-

tions, the wall etements end the sliding

doors, the arrangement and dimensions of

the rooms, the size ofthe straw mets etc. are

all defined exactly. Each part relates to the

other ~a very eary form of eimencicnal

coordination and standardization,

Ae the climate normally requires 8 high

‘degree of permeaballiy, ine skeleton con-

struction allows the wails, spanned with

paper and vansmiting ign, to become st

ing doors, Structure and building envelope

arg clearly demarcated. Consequentiy, the

‘openings in this house are not holes in te

wll, but pact of tha wall, Combined with the

{generous overnang of the roof, providing

protection from sun 2nd rain, and the sur~

rounding veranda, the large sliding walls

‘shai cn the inner side of the veranda, the

oom side, form & deep zone of tranatio.

When thse “walls” are open, garden and

ilerier are linked by tha veranda to croato

an exienced living space.

Sliding stutlers made completely of wood,

later win glass pane's ico, and fied tothe

puter side of ths veranda form a sort of

‘dauble-lea” external wall providing greater

protection from the cold. Sheets and barr

‘00 blinds are hung up to cut out the glare

ofthe sun, An “outer wal” ensues that can

bbe adapted to a whole range of situations

and, inthis way, sable to offer ne most

dveree interaction between inside and

outsige.

1.1.18 Pan ot a drawn fre Jacanese domestc haus

‘ypiealcondricton coals

119 Ketseaoeral la, Kiso, pan, 170

ctu

1

fron ~ reaching for the light

Up unt the 18th century, architecture was

hetly defined by the natural resources

=raiable. Buildings woro made of stone,

Say 2nd wood, Architectural torm wes

Sefned by the properties of these materiale

6 te liitea strangih of humans. As

Sones and clay could anly accommodate

compressive loads, sclid walls and vaults

fxedominaied. In contrast, wood appeared

= erchtecture elther a8 a skeleton {frame-

ork matnod) or as a sclid construction

ung logs).

© ine quest for new Dulkding mater, iron

ss diecovered at an sarly stage, Yet it was

fet abie 10 be used as an indepencent

‘=steril for construction until the late 18th

setury when coe was recognized as sult-

sabi for smelting iton ore, subsequently

easing to better quality ron in larger quanti

fedustrial production, boosted by technical

ecrovements fo the steam engine, the

Seschanical [scm em tha ability {2 produce

est Fon, now finaly blossomed. Iron, with

fs higher load-carrying capacity, its far

‘spotter performance to the materials

eeeloyad praviously, and its abilty to

‘e-commadite tensile loads fer beter than

sy material used up until then, opened up

Seta now horizons fer beth building moth

fos and architectural design. Tne forces

ereously borne by solid stone walls were

Sow concentiaied ina slender skeleton (ist

st ron, later mainly wrought iton) of

Sous and beema: intoriora now became

ecbstructeo, extended and could be

shaped in many ways. With this, the wall lost

‘© ‘sedbearing function and could be

sepiaced by a glace shin to admit the light

Soom, hardly “contined" any longer,

became largar and brighter.

During the cou'se of the enormous secial,

Sectural and industial upheavals of the

2) century, numerous new tacks for erch

Secture 31056, ¢.9. markst nals, cepartmant

S285, railway statons otc. Tho buildings

Ssraled Ne(e are just ¢ few representative

examplee.

‘re laige glass dome

suited or domed constructions made of

Sere 29 well a9 wae flocrs or open rca!

constructions wityaristie wood carvings

ers matneds af covering large, grand inter

ne passage of light through a deme was

Sally defined by the inherent character of

“s constuction and was only possible

‘Svoush the apex (Penthson) or through

smaller openings at the dase of the dome

Hagia Sophia). Vaults could now be oroken

exygen (0) (SiO; tetrahedra) with

estons contained inthe interstices. It glass

peated to 800 ~ 1100°C and this tempara-

see maintained fr a while, then a proves

seoun as devitrfcation hagins. Tais pra-

8 silicon crystals which ere leached out

‘om the glass mass. en effect which leads

so milky, opaque glass.

Natural glass, e.9. obsidian. is produced as

sult ef volcaric ectivity. ti formed by

niense heat in the Earth's core and is,

ected by ths energy of voloanic erations,

Searier times, natural glass was used as

sewellery, for vessele cr for other everyday

stots of manvtastare

About 5000 years ago the Mescpotamians,

Sscovered that whon heated together

900°C), siligon, Ime, sodium cerbonate,

#ossium carbonate end metal oxides

coud be worked into e glessy mass. But this,

Sethod was extremely complicated and so

ess remained a coveted, rare commodity

‘The first written record of a recipe is found

en 8 clay tablet from tha Assyrian king

Ashurbanipal, dated c, 850 EC,

Flat glass panas were already osing pro-

cused by casting during the tine of the

Romans, as wall as blown cylinder sheet

lass. By the 14th century the erovin class

method allowed bul’s-eye glasses to be

produced forthe first time withaut a rim

‘around the circumference.

Improvements in ne 18th century lad to the

Irst large panes produced by the blown

ovlinder sheat glass process

The Englisiimen Alastair Pilkington dever

oped the fost glass meitvad in the 18508

The viscous glass melt is pessed over a

bath of matten tin, floating on the level sur-

face. Owing fo the suriace tensions together

‘uth the viscosities of the glass melt and the

motion tin tho quid glee forme a layor

6 mmihick. The temperature of the moten

tin on tha ilet sida is 1090°C, en the autlat

side €00°C. Alter leaving the bath the glass

is slowly cooled in a carefully controlled

process to ensure no recicual streeaes —

before being cut to size, (See “The main

stagos i the manufacture of glass", p. 9.)

Composition

“The glass produced these days Is made up

as shown in Tab, 21.2, Besides those Iistad

here, smail propsrtions of other substances

‘may be introcuced in order to influence

propertise end selaur. Tha manufacture of

bogy-tited glass requires the adalton of

‘minimal amounts of evtabla adestives:

these do not however alter the mechanical

strength

urabitty

Sode-lime-slice glass is generally resistant

toacids and alkaline solutions. Likewise, the

surface is suticlontly hard (coraien nerd-

ness 6 - 7 on the Wions scale}. This property

‘ascribes the soratch resistance of the

glass surface. Therefore, sharp, Nard

objects. ¢9, small sand particles in claan-

ing water, can cause hailline crecks on the

surfece if adequate care is not taken when

cleaning.

11 fim of water remains stanciing on @

glass surface for a long time, leachings

form, The bond between the silicon and the

‘exygen in tha watar is stronger than thai to

the components in the lattice interstices in

2.1.4 Gantt pha properties of glass

abe

Prope Symbol

Deneve pCa

Harness 6 uns

onthe Mohs eos

acute of osteiy E 7x 10°Pa

Poisson's rato ry 02

6 OTHE TIX)

Chern expanse a 94108"

‘Thormal eoractuiy a 1 Wire

varage rtactive nex

fvhavblerange of

sareerahs

212 Conrestionst ass

tear doi 10) Ta

Calcium ond (Gad) 18

Sadun oxae 0) ia i0%

Nagnesim odo (lg0)—O%- OX

‘Aan do Gh oR 8

This conpestion Fas bee stanearazee fo ope

NEN S72 Fan

243. Race pate!

afcst iss pare

214 Factus patanot

‘aie gasspane

61

215 Fou less carat now nists

us nase Tern

23.85.60m

iam

i25nm

The properiasol cand Foayiinied bal gavsoro

‘Stout in Burgeo eondlard EN S72 Port

28 Ughiwanimusnee vaues oat

ah argon snoatalass

Biase hiewrose

am

com

nm

ven

088

‘097

sen

nm

24,7 Brann shoe! gat is naiibie ese thio

Gass hickness: Taerance

020m

== 20d

Yom =

200m

Diawn stent lassi coverod W Euopeby EWSTE Pans

218 Patered dassisavalabe m ese

frases

Gasihones

S48 6mm

inm

ator lass covere i Eioba by ENT? Pa 5

219 Bocacate gas fe avnabie h Nes

Iicenesses

the glass, to sodium, ealsium and mag-

nasium ions. This means that these ‘orm

solutions with the water more quickly. In tho

minute quantity of weter inthe frm the alka-

ling concentration risae andl attacks the

residual acigic lattice, leading to corrosion

of tha glass surface

Such atiacks on the glass surface do not

‘nermally occur on windows and fecaces

unless water cenaot drain from a horizontal

surface.

Leachings from glaes aro also caused by

‘contact with mineral plasters, wet concrele

or extromely alkaline cleaning agents.

Types of glass

Foo! ass

Today float lass is the most widely used

type of glage and is procuced by way of the

float procass described above (Fig. 2.1.11)

The induetral process rrakes it possible to

produce large quantiles of nigt-quatty

loa glase with virualy flat suriaces in

thicknesses from 2 to 181mm (Tab. 2.1.5).

Mosern faat glass plants turn out anprox.

1900 tof glass @ mm thick each dey. Max

mum ribbon sizes of 82 x 60m are then

avallabie fer further processing (coe EN 672

Part 2)

Float glace can be coloured during the man

Ulacturing process; the ight tansrittance

values aller accerdingly

By choosing the raw materials caretuly,

lower amaunts 0 Fa;Os, itis possible to

reduce of even virtually olminate the natural

‘teen tint of tloat glass, in such cases ine

(giaee ie clmost colourless anc is designated

low-lron or clear-nnite glass. The thermal

tigue resistance is about 40°C (max

420°O). It terrparature zones are present

across the glass surface, the differences

botwoon which lie in this range, the glass

‘can fracture. The warm zone tries to expand

but is prevanted from doing so by tha calc

one, Siesses bulld up which can lead to

breakage, especially # this diference is to a

covered edge. The tracture pattern of float

Glass can be sean in Fig. 21.3 (p. 61).

Drawn sheet glass

“There are sti a few drawn sheet glass

plants producing very thin to (in some

cases) thick glass, These use either the ver:

tical mathod (Fwvented by Emile Fourcaut in

1902) or the horizontal method (Libby

Owens, 1805)

Orawn sheet class and float glass have tne

‘same chomicel aomposition as wall as the

‘same general physical properties. Never-

theless, in comparieon fo float glaes, crawn

sheet glass sxhiois slignt waves and

“pattar" in the surtace porpandicular to the

iraction of drawing, These are sometimes

\isible when looking through the glass, 9

teny case in the distorted reflection.

‘The cht teansmittance values for drawn

heet and flast glacs aro chown in Tab,

216.

“Tho iraciure pattorn of drawn sheet glass is

Iemmical vith that of foal glass (Fig. 2.1.9,

p. 51), The thicknesses available are given

InTeb, 2.17.

Patterned or rolled gles

In the manufacture of patterned or rolled

gloas (Fig. 2.1.12), tha liquid glass melt, Ike

an overfiawung bath, '$ fed between one cr

‘mere pairs of rllers fo Ove ita character's

tic surface texture as required. Therofore,

the glass o€n ba given bvo smooth surfaces,

‘one smooth and one textured surface or two

textured sidas depending on tne design ct

the roll’ or tebio eurfaces,

ellec classes are translucent ~ they cannot

Optend eine

coulng

J q

sus

anecton

lasathicinese Taeance

a4 5,

85. 75mm

16 smn

04/05

2140 Main corsttunt of Bos

‘Seon cove a

Baron ORG

fe

Fotassimonide

‘ures oie

nck

@

ey]

woking

Separate Hot

bangiquasire

U lo —1

uss

‘aresivgiche

21.11 The prinopal stepsinite ma

facture oat lass

Patemed less

°||

ating ari

Fotecs to ae

‘gass ispaten

‘reainglott

Pao Tech gaan sees

reproduce the transparency of float or

drawn sheet, The various surface textures

scatter the light to varying dagrees. This

‘abies interiors to be provided with natural

lighting while maintaining privacy. Certain

surface texlures can direct the ight in a

seecitic direction, 2.9. to brianten the cei-

ing of a room,

The thermal fatgue resistence for patterned

orralied glass 's, ike for float glaes, about

30°C (max, 40°C), The fracture patiern of

iis type of glass is Identical with that of

toa! gless (Fig. 2.1.8, p. 61).

Itis possible to insert a wire mesh into the

glass while itis stil liquid, This is then

krown as wired pattemed olass or, with two

smooth surfaces, simply as wired glass, The

‘hormal fatigue resistance of this glass is

about 20K, The fracture patiem of wired

glass is snown in Fig. 2.7.4 (p. 61). The

thicknesses available are given in

Teb. 2.1.8.

‘The physical properties of patternad and

lical glass are identical, The ultimate bend

ing strength lies slightly oelow that of oat

glass because of the surface pattern,

Boreoicatesleoe

‘This glass contains approx, 7 - 18% boron

oxide, In comparison to drayin sheet andl

oat glass, the coefficient of thermal exoan-

sion is lower and so the thermal fatioue

resistence is considerably higher. Ithas &

high resistance to alkaline solutions and

‘ese days, porosticate glass can ne man:

lfactured like drawn shast and feat glass or

Fhe rolled and cast gass. tis used where

high thermal fatique resistance is neces-

sary, ¢.g. for fire protection, The relevant

processing and installation clrectives must

be atriotly adhered to,

‘The fracture pattern of borosilicate glass is

‘dentica! with that of float glase (Fig. 2.1.3,

9.61). The thicknesses avallable, main con

stituents and light transrritianca valuas of

borcslicate glass ere given intebies 2.1.

2.4.10, 2.1.18 and 2.1.14,

Glass coranies|

Modern mathads alse rendor it possible to

procuce materials with cortrated crystal-

Ization. These are no longer glasses ac

‘such Dut Instead can exhibit a pantie! or

complete microcrystalline structure, while

‘remaining peitectly wansparent

Glass ceramics are produced just like float.

of glass that can he tasted with the mpact

‘body faling from a lower height. A crcp

height of 700 men has esiablished itset 9

practice, Neverthalsss, cletinetions must be

‘mad between the individual applications.

‘A drop he'gat of 1200 mm may algo be usec

for testing alustrade constructions anc

thoir clasees.

‘The sack of lead shot is veplaced in Euro

pean standard prEN 12600 by two smaller

‘ear tyres, one on top of the other. The mass

ff the impact badly may yet be increased by

about § kg in order to take aacount of the

inereesing average weight of the Euopsen

pepulation.

PVE (polyvinyl butyral oll, suitable casting

rosing or other organic or inorganic mater

Fished laminae

salty lass

2192 ‘Te propa tens nthe mentctré nine slaty

sage wih PVB lrayer

lals may be used as the intermesiate layer

provided that, in conjunction with the lass,

the necosaary safety roquiromante aro eats:

ties,

‘The olese units musi be stable with respect

{0 solar radiation. Their macnanical and

‘optical pronertias should not alter during er

alter being subjected lo raciation or a

defined moisture load. When using a PB

interlayer, the fois placed between the

panes and the whole unit pressed together

in-an autoclave under the action of hast and

pressure (Fig. 2.1.32),

The bond at the adga of a laminated safely

gaass with a PVB interlayer can suler I sub-

Jecied to moisture permanently. As the fail is

initially very dry, itcan absorb hurilty end

hence weaken the bond at the edge. There-

fre, ike wth Insulating glass, the edges

must be set ina glass rebate which permits

vapour-preacure equalization and provente

permanent humidity. Neverteless, his

Stfect cannot be entiely rulae aut in the

long term, Even during transport and sior-

age, care must he takan to ensure that he

edges are protected from excess moisture

However. this is only an optical defect and

whole.

The bonding of the gloee reamente ta the

\nterlayar in lamineted (safery) glass is

tested using the matnods laid dawn in

EN 12937 Part

Casting resin can be introduced between

the panes in several ways. Mult-ply compe-

nents cure by themselves or under the

action of UV radiation. Special caro is

required at the exiges wnen using casting

resin, The soiteners in sealing rmaterials can

penetrate the edge cover stips, seep into

tha resin and attack this chemically

Antivendal, antlniruder and bullat-esistnt ola

wing tots ability to bond glass iraoments

logethor and its stueturs comprising ind

vidua! panes with fol In between, laminated

safety glass is ideal for provicing protection

against altacks with blunt objects 01 projec-

tlas fora eartain length of time.

Throwing stones at glass or sriking it with

an axe isa combination of large mass and

‘ow velecity, whereas a bullet from a gun ie

2 combination of small mass and high velo

¥y, acting on a small area af glass. Those

concepts must be considered when choos:

‘9g beth lass and fall When specitying

Such pens itis essemial fo remember that

ine actual olass prapertias of the window

cen only be reclized ifthe construction com:

lies with the requirements and is maicned

tothe glass.

To provide effective protection against

intruders, a window must be designed in

such a way that ii canno! be levered out ent

Laminates safety glass

blo6 oF the panes eemoved without demag-

ing the olaes. External Glazing bars should

rt bs Used. Tho recommendations of craft

German standara DIN V 19054 and drait

European standards prEN 1522 and 1523

should be observed,

Ant-vandat glazing

These class units, classified as tyne “A’, are

Intended to prevent stones thrown at ther

‘rom penetrating the glass, Ins property is

tasted by dropping a 4.11 kg stoo! ball threo

limes in succession onto the glass trem var

‘ous heights. DIN 52290 Part 4 dascribes the

lest. The classifications Ai, AZ and Aa refer

{othe drop heights of 25, 5 and &.6m

respectively and are awarded depending on

‘whether or not the ball penetrates the glass

What this means in practice is that glazing

at ground floor level should be chosen to

provide a high arti-vardal protection level,

indesd evan anti-inirucer protection, while

for upper floors a lowor lovel of protaction is

sufficient, wing to the diminisning impect

energy of a stone which thrown. Laminat-

ec safety glass, including several layers of

foll or a suitable resin, can give the glass

unit an appropriate degree of resistance.

Antiintruder glazing

‘Ihase giass nits, classiied as type "3", are

intended fo prevent an opening larger than

409 x 400 min being smesiied in the gless

with an axe in a short space of time, This

property is tested in accordance with

DIN 52290 Part or prEN 358.

‘The olacsiication dopende on the time taken

{9 produce an opsning 400 x 409 mm

A long-nancled axe fitad ta a machina

simulates the attack conditions end provides

objective, comparable test results. In tha

gless/ll or glsssiresin combinations ths

elastic intermeciate layers are held together

and protected by the glass, The elasticity of

the whole system allows the glass unit to

absorb the ehack o! the impacts.

69

Glass as ¢ buiding material

ax, overreasice Duration

Diretace siaok ofover

Gave bir 33) Bresre

pha rs)

a aT

ras 20 a

1 itarpane

2 toro pane

3 Metal apacer

4 seairgiee!

fpuylsest

5 Descent

© Soalngiovol

polis soa /

Q

2.1.96 Beige sealer nung glass

= i=

21.38. Tro etectot altering ana cust gass nck

nesses en nouitirg lass uns 2. osltof

Srpreceine ustons

Builer-resistant glazing

‘These glass units are classilied as type °C”.

A bullt fired from 8 pistol or rife produces

fa very small mass acting with 2 high velocity

(ona small impact area, Crucial tothe pro:

fective function of the class in ins instance.

is ite mace and not its elasticty. Conse-

‘quant, bullet-rasistant glazing units con

tain 4 high proportion of glass. DIN 52280

Fait 2 and prEN 259 stipulate the test pro

‘cedures which provice comparable results,

‘The classification is based on the type of

vweapen and ammunition used.

Maximum security is achiavad whan tho pro~

Jectle does not panetrate the glass and no

‘plintere cf glace are flung olf irom the rear

face of te glass unit, According to tne the-

‘ory of alaetic mpact, the impact energy is,

‘ransmities through the material anc

rlassec at the ofner end, Additional layers,

cf glass, preferably thermally or chercally

strengthened. as Well as orotective films or

plastic layers can prevert this psling of

fraamerts, Such glass Is dasignated “Zero

spall; glaaces in waish fragments are eject:

‘9d from tne rear of the unit by the force of

projectile are callad “imitediunlimited spall”

as appropriate,

For euch a window or fagade to offer effeo-

tiva resistance, the frame must also comply

‘wilh the same or a higher specitication

Explosionresistant glazing

Those glass unte are classified as type “D

and ate Irtenied to protect against attacks

from cusida using explosive devices. Lam

nated safely glass can be used in euch cir

cumstances.

Testing the propertiaa of the glazing ie cov.

ered by DIN 6220 Fart 8. which assumes a

aphorical proscure wave acting perpendic:

las to the glass. The new European standard

rEN 1099 with is thrae classas £1, E2 and

3 is comparable with DIN 2290 Part 6

The oassifications D1, D2 and 03 to

DIN 52280 Part § depend on the moximum

overpressure of He rellected shock wave for

1 presoribed duration of the overpressure

phase (Tab. 2.1.33). The elastic propery of

glaze, copecially lerrinatod safety olase,

makes isafnoticsable fete, OF course, He

Frame holding the glass must De suitebly

designed and fixed to the masonry or

fagade, During the test the olass is held at

tha edges by the test rig with a presaure of

1423 Nom?

Alarm glass

Fine silver wires can be placed within the

make-up o the laminated safety glass. Ifthe

glass is peretrated or even subjected 10

Sevare deformations, breaking one of thes=

vires vill cause a clroul ib be intemupied

‘and an alarm signal to be triggered. The

“Ohmic resistance of a pane” depends on its

dimensions, The same effact can be

achieves vihon thermally toughonod glass is

provided with a conductive loop in one cor

nor, If the glass ig damaged, than the can-

ductive pane Is mieirupied, The position of

the connacting cable must be carefully

planned and Incorporated so thai the

eainage of tha rebate Is act hindered and

the connection to the glass cannot become

‘wel, Therefore, fis best to incorporate the

leap at the top.

Hosted

Heated glass cen be produced by applying

‘a conductive coating to the surface of the

glass cr by placing a fine wire within the

make-up of the laminated (safety) glass.

‘With the coating method the size of the pane

eterminas the electrical resistance anc

hence the heating capacity. With the wirs

method the heating capacity can be deter-

mined through appropriate dacign ai tho

Serles/parallel Grcut ‘oF the elecirical con

ctor

Insulating gless

coneral

Insulating glass consists of at least two

seperate panes kept apart by spacers fited

around the edge. These deys, the first sea

{s located batween the spacers and the

panes of gless; this prevents moisture from

entering the cavity between the penes. In

‘edilkion, enother ae! is positionad behind

the spacers and between the panes; this

serves ab a secondary seal and as an ache.

sive, keeping the panes and spacers joined

together (Fig. 2.138). Tha spacers contain

an adsorbent substance that dehumicii

‘the cavity, which is harmetically sealed

against the autsice air. This reduces the

dew point oi the enclosed ait to Delow

“90°C, Tha sealing aysioms pravent an

‘exchange o! gases between the cavity and

the outside air and the ingress of moisture

Into the cavity, tthe seals are damaged and

moisture enters the cavity, then the relative

humidity in the cevity rises as soon as the

desiccant is saturated, When the alt cools to

below the dew point, thie damp air condone

8: We say the pane 's “fogged or "steamed

Up". The cieoimiler moisture contents of the

cavity ar and the outside alr give rse to @

high vapour-pressure gracient. Thetefare, i

Is necassary (0 febrigate insulating glass.

Unite with the utmost care and, once

Installed, to make sure that the rebate is not

packed full of sealant but instead remains

free of sealant and dry, achieved by way of

‘a functioning vapour-atessure equalization

‘and drainage arrangement. Permanent

humidity must be avoided at all costs, The

edge seal of an insuleting glass unit if rot

made trom silicone, must ba protected

‘againe! colar radiation, Panos which aco not

‘ited into a rebete wll need to be given an

‘enamel or other type of coating in order fo

provide the necessary shading for ihe seal-

ing system. Edge seal eystoms employing

silicones should mot be used with cavities

filed with, for example. argon, krypton and

xenon as Well as OF, because the perme-

ability of siicane is 100 high for these dases.

‘Cave in the production and inetatatien oF

Insulating glass units, 6.9, rebate tree of

sealant, adequate vapcur-pressure equal-

{zation (no permanent dampness) and no

additional, undefined mechanical losds on

tHe edge seal, ill result in service lives of

20 years or even longer.

‘The air pressure in the cavity corespends

to the atmosoheric pressure prevailing at

the time of manufacture. After installation,

whan the stmospheric pressure rises

bboyond that in the cavity, both panae aro

pressed inwards; when the outside pressure

reps. the panes bulpe outwards (Fig

2.4.85). These movements can be readily

perceived as distortions. Special attention

should be given to this “pumping” action

‘wnen oesigning large panes wit reflective

properties, Merely optimizing the giass

thicknesses in ine wit structural require-

ments is nat encugh to copa with this offact

‘Current methods of calculating the glass

thickness distribute the loads aver both

‘pangs. The result ofthis is that the panes

‘can be thinner, and hence the stiinesses

lower and the pumping movements greater.

Gee wrest ano-festeatremeay ss co make te

Gute ano, og. te ona wih the raflactive

Seaton. thicker and the ier ane thiener.

Pea scsogacyschthn!atteseonatha nied,

‘S eeicsiation. Optimizing the glass thiok-

“Sees Snes not simoly maan salecting the

= pene but, on tbs contrary, employ”

ee Sess thicknesses which are matched to

sry different prysical phenomena that

be e1pecied. More than ever befcre,

seowiedge of specialists, who under

1 te interaction of thase phenomena, is

‘orusial for today’s arplications and combina

tions. Hete tco, the rule is that not everything

that can be produced may be used every

sere witnout restitions,

-Eage seals for insutaing glass units

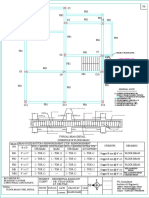

Fig, 2.1.34 shows the customary edge seal

detail of an insulating glass unit. Otver sys:

tems ara also current available:

All-gtass edge seat

Inthe past the usual way of creating an all.

glass edge seal was to weld together the

‘adges of the spaced panes anc fil the cave

ity with dty ar. This croated a rigid edge

seal. The all-glass edge seal might wall

‘become popular again wits the development

of "vacuum insulating glass’, in which 2 cay-

ity of just 0.2 mom ie sufisiort

Buty! adge seal with sufiening

The siitened butyl edge seal nes been

round fer over 20 years. The spacer hare is

ot a tubular proille but stead a thin metal

stip placad perpendicuiar to the glass. The

butyl seal with integral adso:bent is post

tions ground the strip to scak up the meist-

ture in the cavity. The metel strip too sois as

2 caulty seal. Another sealant is added to

provide meshanioal strength (Fig. 2.1.26).

Butyl edae seal without stifening

The solid butyl edge s2el, in use for over 25

veats, has been undergoing something oF 3

cemeback af Iste. The butyl with intogral

adsorbent is injected hot into tne sage, A

second vanqur basrier is applied ‘othe out:

side of ihe seal. This edge seal Is aivays

black (Fig. 2.1.37). The sealant on its own

provides a stable edge.

Physical propertos

The physical oropertics of insulating glass

are cierermined rrom measurements ana car

cculatione snd are subject to the customsry

fluctuations encountered in production. The

mralensio.cl tha nlpsa.oadithetbialnnas. pte

haps with coatings, have a decisive influ

‘ance, The figuras specified should always

be lreated with a eertain amount af aaution,

Thermal ineulation

The thermal Insulaton effect ot nsulating

glass comprising float glass panes is mainly

Uependent on bie cavity anc its fling, anc

in the case of enated float glass on the tyoe

of costing.

Thermal tranemittance value (U-valuo}*

‘Tre thermal transmittance value (U-value) of

an insulating glass unit consisting of two

oat glass panes and a 12 mm cavity is

3.0 Winek. Ifthe cavity is enlarged to

20 mim, then the value drops to 2.8 Wir

Inauatng glass

2137 Buty cope sea!

2.195 Sut adge sea yee

va sien

‘ath sifenee

Insteung gues wn soredge

ass oene

cavty

[Bi eoscer nt ess) wth rere adsorbent

2rclaeolordachecie

etal sets

coreg

(Gass ote:

| Ceomvetin 23

2 eaviwe and

| ius

Het coi

Hee

sanateten a

Heat ater, Heat wanstr,

enemnal ey vier a

2189 Pysicalattorsbpsct te Uaskeitran

Pulating glass wrth oo cai:

1) The herr raranitance aa U bran irsuatng

pssisiaunninad yt folowing raha yScal

Pranorora:

*"oanooton the cat (VU

‘Pamalcencucten mush te aes

* fat ange boteor tha toast

pos nV —depandanton the missy tthe

oats wea)

+ ama venemsser batvenn gs anaouisaw

dear fn a

iceliaedt= UL = Vay

i cain, 14. and bec ager

vale omnale, Teiterma heulaon bet,

n

Glass as # building material

229 Usa varus insu ls units

Doscestion ay wth Trae

rderg gies ri ets

fot ss ae

Emm serv mm at

2ply(teaviy) Ammecaviye Gen 32

Ziyi cauiy) Jomm- 40 %. In

practice, fluctuations in these values

amounting to S ~ S% are irrelevant for the

internal environment. Bedy-tinted glasses

adsor more than highly rellective, costed

‘glasses, although these days absorbent

coatings too are baing employed for soler-

Cortral purposes and for ecleured effects,

‘The spactic values for reflection, catour anc

hence total eneray transmittance for 220"

application depend on which glass surface

‘ig coated, while direct transmission, ie. lint

tranemitance too, remains constant, Values

are calculated in accerdance with preN 410,

land prEN 673,

2.148 Rolenthis heen Uae al misty tor coublenelating amo

Emasly —Thomalancmitenc

ale Usaus)

ar agen Knpton

[msg [iecy_[)

21

49

a0 20

a8

18

v

2:146_Palenship bewseen Usalue ard asst tortie wlezna

Emsavily— Thematirensmitenc

vas Wu)

on

(wn

4

= 108

are we ~*~ oem

Tot ont Gauty Elena

energy Fansmitance theinese

anita

grave ake

198 ton mn

em Om

term mn

re od

Yom mm

36m iim

0% Te tery Bim

Yrm mm

Tot tigi ~Gaviy Element

rancmitance

aaa ae

2x Bem

2xiomm

2x oem

2x Bem)

2x tore

Beem

we we 2x Gem

2x Siam

ene

Detain,

(GvatediBod)-tinied soler-control glass

Solar-cantral glazing comarisas coated or

ody tinted glasses, yihich in our climete

region are used as insulating ajass. Minute

amounts of additives inaduced into the

matt give the glass @ grey, bronze, green or

even blue tnt

The usual methods of coating glass are out-

lined on pp, 64-85.

The glass surface to which the costing can

be applied mainly depends 09 tha nature of

the coating, The physical parameters of

radiation can be dstermned according to

the prineples mentionad above, whereby

the coloration and optical corsistency of the

coating shall be considered besides purely

functional aspects.

Only tha manufacturer can provide dtalls

oon the glass surface and position of tre

ating because cnly ne knows the compe-

sition of the coatings, tholr effecte end thaie

durability. Definitions and methods of test-

ing, to determine coating durabiliy, are

given in draft European standard prEN 1086

Paris 1=A

Ir the coatings are processed with fll or

sting resin to for complete units, the

new bounclary relationships between the

soatings and the faillresin must ba taken

ito account. This applies both to the

appearance of the glass and to the pnysical

parameters ef radiation, Solar contra by

‘means of coatings remains constant ard

enables consistent, unhindered transpar-

fenoy right actoss the whole avea of the

glass. Transmission is reduced by in

creased abeoration oF reflection ever the

entire area,

Printed solar-control glass

The transmission cf adiation can be

reduced by providing some opaque areas

lords), Using silt-sereen printing, an

opaque pattern can be applied to parts of

the glass suriace, 2.0, by “baking-in” an

‘enamel during the manufseture oF tough

ned safety glass.

Solar control, Le. raducing the transmission

bf radiation, is achieved by the glass sur-

face boing shadac by tha pattem Thus,

only part of the glass pane is transparent

and so the area for tanerrittance ol solar

radiation ia reduced. The solar-centre stect,

depencs on the ratio cf transparent to

opaque areas, inotuding their abeoraticn,

Effective external shaving prevents exces-

fe solar eneray from even teaching the

glass and hence penetrating to the room

Deyond. Such shades can be adjusted

mechanically but they can ebstruct the view

ut and, # the shading effect is too extieme,

may necessitate the provision of adcitiona)

Contoling solar radiation

External shading must be able to withstand

the rigors of wind, snow and moisture anc

should rot cause any edditonal wind noise

‘Apart irom that, ithas to be oleanec end

should nat be attached to the glazing

beads. The things for excernal shading

should be joined to the actual fagade in

such @ way thal ro the:rral bridges to the

inside are created,

Fixed shading

Inclined or horizontal louvres can be

arranged in such a way tat they shade the

‘wanspatent areas st a corresponding solar

altiude angle. These louvtes ere usually

projecting and can be made of metal, wood,

plasiic or even glass. Coated glasses, with

Fw transmittance values and sufficiently

durable costings. er body-tinted glasses

can be usad for this in the farm of tough

nod safety glace or a¢ laminated glace.

“They are usuelly gio but can also be pro-

vided as movable louvres, The choice of

toughened or laminated safety class

depends on the figs for the glass as well

as the respeciive additional safety requre-

ments arising from the use of the buildin.

Movable extemal shading

‘A movable external srading aerengement

enables the shade to be adjusted to sult

individual needs. Opaque matsriais in the

form of horizontal sitades, iranslucent fabric

blinds ang even movatle glass elements are

all sullable solutions, With horizontal louvres,

‘minimum selar Fradietion is achieved when

tho louvies aro arranged in such a vay that

‘oni indirect radiation can anter tne room

Howaver, this ean lead to = severely ractrict-

ed view out ane tne nega 1 install additional

arificial lighting. When using translucent

fabric binds it must be ensured that they

are weathar. and wind/-resistant.

Movable glass elements are placed in front

of the windows andl are made from body-

tinted glace or coated glaes with low tne

mitance. When not in use they remain in

front of the epancrel panel and are movad

G703s the windows to provide shad as te

quired. The light transmittance therefcre r2-

mains commensurate with the transparency,

Blinds within the cavity of on inavlating glass

unit

In thia eae tho shading fas in tho plane of

te facade, The absorption campenert is

transmitted parily autwards, also partly

inwards. 4 folding or roller bind is placed

within the cavity ofan insulating glass unit

nd this can be controted individually

‘When inuse. it shades the transaerent area:

suren eloved, the air in the cavity can be

heated up 2s a result ct nigh absorption

caused by solar radistion. Suitable materials

‘must therefore ba chosen because adaition-

Glass as e bulding materia!

omen t

2.147 Sreesosia gst po where hot and cod

=a stacy

by pec pti

Sl ime fee

Sill

is som

Ss ae

ome SPT site eset

es

asus vce

21.48 Lghtredrectng glass

angle ree 00"

2.148) Redrecing me ghiby way af spec aleates

78

‘al trermal loads increase the pressure in tre

‘cavity and hance on the panes. In smell

panos the machanioal stresses in the glass

Increase, altnough this czn be compensated

for in the eclge seals or by using pre:

stressed panes. In large pores this causes

signilicant bowing which can lead to optical

distortion.

In he case of vertical panes, the sunshed:

ing is lowered by moans of it own woight

vith inclined olazing adattional mechanisms

may need to be incorporated to ensure

proper oneration,

It's net possible to replace the sunshading

In insulating glass without replacing the

complete unit, This must be taken into

account in the design

‘The shading arrangement can consist of 2

reflective fol, a translucent foil or horizontal

louyras. There must be suificent clearance

bbowoon the fangs and the shading to allow

for correct operation even If panes cave

inwards as 2 result of pressure flictuations

In the cavity. A fol blind cas heat up severe

ly # it ies in the transparent area when

rolled up; the material mey be damaged as,

aresut,

Fixed fois in the cavity

Rellective [eile can 90 spanned across the

cavity, The actual sheding facilty is placed

in the middle of a wid cavity and divides it

into two narrow cavities, leacing to a lover

thermeltrensmittance value (U-value). The

‘two cavities have to be linked to provent ny

ifterences mn pressure. The fols used

reflect the solar ractatian in 2 selective man-

ret end so Nave cifferent colours depending

cen how they da this. Tha thi surface pro-

Ccuces a reflection when viewed from out

side.

Glasses with ntermediate layers

Spun gleea, nor-woven fabrics, capillary

system's or foams can be integrated

bowser the glass panes. The tharmal trans

mmittance values and the physical pare

‘meters of radiation for the glass unit alter

depending on the materials used. Most of

these scatter the jght depending on therr

sign, The aun glaae and non-woven fab

ries have a high (diffuse) light transmittance

bout at tho camo tims reflect the light and so

else piovide solar-contiol properties. A

direct viow through is net possible. When

they are used as roctlights or in roots, he

sealtered light can be directed deeper inte

tne interior by teilection, for exemple, on the

ceiling or the walls. Capillary layers and

feams ean also be employed as transparent

thermal insulation”. These have very low

U-values (down to approx. 0.8 Were} but

stl allow the passage of lignt albet difuse,

into the room, leading to an eneray gain.

‘The types of glass used are selected

accarding to their application as spandrel

panels of as windows in the form of Inclined

gazing

lnvornal shading

Interral shading is not subjected to cirect

external loads. It can only reflect solar regia.

tion back theaugh the glazing: the enoray i

absorbs remains in tne room An inadequate

Clearance between pane and shading can

lead to a heat build-up which places a thet

rral load an the panes. As the edges of the

panes ~ covered by the frames ~ remain

cooler. toughened or heat-strenathaned

‘91982 may well have to be Used in order 10

attain @ better inermal fatique resisiance

‘and rula aut the pessiollty of fracture (Fig

2aar)

Internal chaging serves more as a form ot

‘glare prevention” to prevent the occupants

{rom being disturbed by direct sunicht

Foil attached to the glass

Roflectve or absorbant ‘oils can b¢ glued to

the outer surlaces of insulating glass. These

‘change the temperature of the pane direct

by way of absorption. Greal care is needed

when attaching fol to existing window

Highly absorsent fois which are attached to

the inner suriaces can cause a huae Dull

lp of hast when subjected ‘o colar radiation

(fig. 2.1.47),

Anigiare protection

A dithase transmitting surface, respective

‘ol whother itis the glase pane itself or inter

nnaliextornal shading elements, can be used

to eoatier daylight asroes the Interior, Thie

reduces tha areat aiferences in tohing

Intensity an werking suriaces and decrsacss

the prysiological glare phencmmencn. No

parsons in the room are subjected to direct

sunlight

Ono-ney glass

A view through only trom one side, ¢.9, from

ine outside to tha inside, is only possible

‘when tooking from the dark sie towards the

bright side. Ifthe lighting relationshio is

reversed, then the direction of view also

changas. This effect s amplified ey adai-

‘ional telleciion or sbeorption, Novertholeas,

itis the aghting trai cetermines the direction

of view, not the glace.

Scattering the light

A trensparont pane of glass aliows e direct

‘ed beam of ight to pass throuah Unaffected.

However, owing te their rough” surfaces,

cifusing olasses, or patterned glasses ipre-

iouely known aa casi), ecettor the boar of

lignt. Tha greater the dagree of scatter, the

more an apjeet behind the glass is cb-

soured, For interiors, a dtusing glass

‘means thet the ineident light is more cr less

scatieted. The brightness levels ate more

yen and ct so cependent on the solar at

tude angle. Glasses fitted wit spun giaae or

ron-vioven fabrics can achieve Identical

effect

Redirecting the light

(One simple method of praviding move day-

ght farher away from the vandows has

'bcon peasibie for many yoare using epecial

coast glasses. During production the Sur-

faces unciergo axtrame shaping so that the

light whic stikes the first glass surface is

deflected towards tne next surface in such a

way that i shines onto the bright ceiling and

‘rom there into the roam. A siooing ceiling

near the windowe can help the light to reech

fever farhar into the eerie. Recentiy, more

‘and mora insulating glaeses have bean

‘developed which enabe the light © be re

cirectad to an even greater extent To do

this, curved plastic elomonts are incornarat

fed which redirect the light up to tha ceiling

(Figs 2.1.48 and 2.1.49), From there it then

radistes deeper into the room. Recirecting

insulating glage unite ara ideal ae fanlighte

because they are desicned in such a way

that as much sunight as possible S cedi-

rected through the elements regardless of

the angle af incidence Fig. 2.1.6

Photoveltais modules ané elements

Solar cole can be installed in the cavity

between two gless panes, These then con-

var the incident solar energy into electe:cal

current. Casting resin is Frequently used as

a tacking material. Either amorphous ar

erystalline solar cells may be used. The

Fire-resictant glass

‘xtornal appzrarce af the amerphous calls

ranges trom red and transparent or cark

grey to opacue, that of the crystaline calle

sblue and opaque with vansparent spaces

‘between tha cells, The photovoltaic modula

fare arranged in such a way that they can be

‘processed like conventional glass or irsulat-

ing giase elements, The degrac of efficiensy

‘depends on the materials used:

8 - 8% for modules produced using thin-film

technology snd approx, 10% for sitcon

rmo-dulas. New developments are concen

tating on 3 higher degree of sfticlency

‘coupled with lower production costs. Photo- = —

voltaic modules can be used in the form of

curtain walls or cold or warm facades.

Fire-resistant glass

Each country has ts oar set of rules ang

assficetions, all of which must pe iia

conserved. Thevetore, European siandards:

on festing and classification are beng C

‘drawn up with the aim of harmonizing te

itferent approaches. in adsiticn, the pas- 2.150 _OsMeuton ong unirgrasrecing demens

‘9890 oF radiation is spocitied separately for ‘te gadeand a ete cela

gazing. The folowing ciassifcation nas

tharaiora been adapted:

F = loadbearing capacity, E = integrity,

W = radiation, [= insulation, § = smoke con-

‘tol end C = self-closing (piEN 957 Part 1).

Glass ‘or fre protection purpaces ia divided

G-glass

This type prevents flames and fumes from

penetrating for 2 specified length of ime:

Faciated heat, however, is not contained,

Feotass

‘This type provents flames and fumes trom

peneivating for 2 specified length of time but

alsa contains the heat radiation produced