Professional Documents

Culture Documents

2AZ-FE Emission Control

2AZ-FE Emission Control

Uploaded by

hienCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2AZ-FE Emission Control

2AZ-FE Emission Control

Uploaded by

hienCopyright:

Available Formats

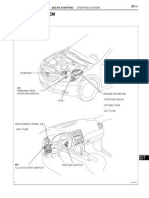

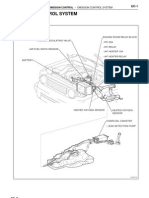

2AZ-FE EMISSION CONTROL EMISSION CONTROL SYSTEM

EC1

EMISSION CONTROL SYSTEM

2AZ-FE EMISSION CONTROL

ENGINE

PARTS LOCATION

VENTILATION VALVE

VACUUM SWITCHING VALVE

EC

CANISTER

HEATED OXYGEN SENSOR

AIR FUEL RATIO SENSOR

FUEL TANK CAP

A135646E03

EC2

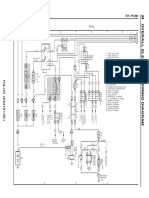

2AZ-FE EMISSION CONTROL EMISSION CONTROL SYSTEM

SYSTEM DIAGRAM

For PZEV :

ECM

Air Cleaner

Intake Manifold

Soak Timer

Air Filter

Canister

EVAP VSV

Service Port

Fuel Cap

Pump Module

Roll-over Valve

EC

Cut-off Valve

Fuel Tank

A128935E01

EC3

2AZ-FE EMISSION CONTROL EMISSION CONTROL SYSTEM

Except PZEV :

ECM

Air Cleaner

Intake Manifold

Soak Timer

Air Filter

Canister

EVAP VSV

Service Port

Fuel Cap

Pump Module

Roll-over Valve

Cut-off Valve

EC

Fuel Tank

A128936E01

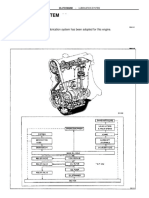

EC4

2AZ-FE EMISSION CONTROL EMISSION CONTROL SYSTEM

N17

Canister Pump Module

ECM

MGND

6

34

A24

MTRB

1

Leak Detection Pump

70

C24 VCPP

VCC

Canister

Pressure

Sensor

71

C24 PPMP

VOUT

3

94

C24 EPPM

SGND

2

Vent Valve

VLVB

42

A24 VPMP

VGND

8

C6 VSV (Purge)

EC

1

C22

Heated Oxgen Sensor

+B

E2

EFI No. 3

C15

Air Fuel Ratio Sensor

HT1B

OX1B

49

C24 PRG

87

C24 EX1B

64

C24 OX1B

47

C24 HT1B

EFI

EFI-MAIN

2

From Battery

+B

HA1A

A1AA1A+

4

3

113

C24 A1A112

C24 A1A+

109

C24 HA1A

44

A24 MREL

A135723E01

EC5

2AZ-FE EMISSION CONTROL EMISSION CONTROL SYSTEM

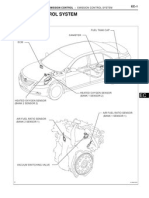

ON-VEHICLE INSPECTION

1.

VISUALLY INSPECT HOSE, CONNECTIONS AND

GASKETS

(a) Check that there are no cracks, leaks or damage.

HINT:

Detachment or other problems with the engine oil

dipstick, filler cap, PCV hose and other

components may cause the engine to run

improperly.

Disconnection, looseness or cracks in the parts

of the air induction system between the throttle

body and cylinder head will allow air suction and

cause an engine failure or engine malfunctions.

If the result is not as specified, replace the parts as

necessary.

2.

INSPECT FUEL CUT RPM

(a) Start and warm up the engine.

(b) Open the throttle valve and keep the engine speed

at 3,000 rpm.

(c) Use a sound scope to check for injector operating

sounds.

(d) Check that when the accelerator pedal is released,

injector operating sounds stop momentarily (at

2,500 rpm) and then resume (at 1400 rpm).

Standard

B000412

Item

Specified condition

Fuel cut off rpm

2,500 rpm

Fuel return rpm

1,400 rpm

If the result is not specified, check the injectors,

wiring and ECM.

A128092

3.

INSPECT LINE AND CONNECTORS

(a) Visually check for loose connections, sharp bends

or damage.

4.

CHECK AIR TIGHTNESS IN FUEL TANK AND FILLER

PIPE

(a) Disconnect the vent line hose from the fuel tank.

(b) Connect the pressure gauge to the fuel tank.

(c) Apply pressure to the fuel tank to create an internal

pressure of 4 kPa (41 gf/cm2, 0.58 psi).

(d) Check that the internal pressure of the fuel tank is

maintained for 1 minute.

(e) Check the connected portions of each hose and

pipe.

(f) Check the installed parts on the fuel tank.

If any malfunctions, damage or other problems are

found, replace the fuel tank and filler pipe.

(g) Reconnect the vent line hose to the fuel tank.

EC

EC6

2AZ-FE EMISSION CONTROL EMISSION CONTROL SYSTEM

5.

REMOVE FUEL TANK ASSEMBLY

(a) Disconnect the vent line hose from the fuel tank.

(b) Connect the pressure gauge to the fuel tank.

(c) Fill the fuel tank with fuel.

(d) Apply pressure of 4 kPa (41 gf/cm2, 0.58 psi) to the

vent port of the fuel tank.

HINT:

Check the amount of fuel in the fuel tank. When the

fuel tank is full, the float valve of the fill check valve

is closed and no air can pass through.

(e) Remove the fuel tank cap, and check that the

pressure drops.

If the pressure does not drop, replace the fuel tank

assembly.

(f) Reconnect the vent line hose to the fuel tank.

6.

REMOVE AIR INLET LINE

(a) Disconnect the air inlet line hose from the charcoal

canister.

(b) Check that air can flow freely into the air inlet line.

If air cannot flow freely into the air inlet line, repair or

replace it.

(c) Reconnect the air inlet line hose to the charcoal

canister.

Fuel Tank Cap

A126204E01

EC

Air Inlet Hose

Air

A128093E02

2AZ-FE EMISSION CONTROL CANISTER

EC7

CANISTER

2AZ-FE EMISSION CONTROL

ENGINE

COMPONENTS

for PZEV:

EC

CHARCOAL CANISTER ASSEMBLY

39 (398, 29)

N*m (kgf*cm, ft.*lbf) : Specified torque

A135649E03

EC8

2AZ-FE EMISSION CONTROL CANISTER

except PZEV:

EC

CHARCOAL CANISTER ASSEMBLY

39 (398, 29)

N*m (kgf*cm, ft.*lbf) : Specified torque

A135648E06

2AZ-FE EMISSION CONTROL CANISTER

EC9

REMOVAL

1.

REMOVE FUEL TANK ASSEMBLY

HINT:

(See page FU-34)

2.

REMOVE CHARCOAL CANISTER ASSEMBLY

(a) Disconnect the fuel tank vent hose from the

charcoal canister.

(1) Push the connector deep inside.

(2) Pinch portion A.

(3) Pull out the connector.

Pinch A

A

Pinch A

Push

A

A132954E01

(b) Disconnect the charcoal canister filter sub-assembly

from the charcoal canister.

(1) Push the connector deep inside.

(2) Pinch portion A.

(3) Pull out the connector.

(c) Disconnect the vapor pressure sensor connector.

(d) Disconnect the wire harness clamp.

(e) Disconnect the purge line hose from the charcoal

canister.

Pinch

A

Pinch

Push

A128095E01

(f)

Remove the 2 bolts, clip and charcoal canister.

A128096

INSPECTION

1.

A112883E01

INSPECT CHARCOAL CANISTER ASSEMBLY

(a) Visually check the charcoal canister for cracks or

damage.

If cracks or damage are found, replace the charcoal

canister assembly.

EC

EC10

2AZ-FE EMISSION CONTROL CANISTER

(b) Check charcoal canister operation.

(1) With the purge port closed, blow 1.10 kPa (11.2

gf/cm2, 0.16 psi) of air into the vent port, and

check that air flows from the air inlet port.

If the result is not as specified, replace the

charcoal canister assembly.

Air

Vent Port

Air Inlet Port

Purge Port

A111044E02

Purge Port

Air Inlet Port

Air

(2) With the vent port closed, blow 1.10 kPa (11.2

gf/cm2, 0.16 psi) of air into the air inlet port, and

check that air flows from the purge port.

If the result is not as specified, replace the

charcoal canister assembly.

Vent Port

A111043E02

EC

Purge Port

Air Inlet Port

(c) Check for air leakage.

(1) With the purge port and air inlet port closed,

apply 19.6 kPa (0.2 kgf/cm2, 2.81 psi) of

pressurized air into the vent port, then confirm

that pressure is retained for 1 minute.

If the result is not as specified, replace the

charcoal canister assembly.

Pressure Gauge

Vent Port

SST

A111042E02

(d) Check the leak detection pump.

(1) Remove the detection pump from the charcoal

canister.

(2) Check that air flows from port A to B.

If the result is not as specified, replace the

charcoal canister assembly.

A

Air

B

A112886E01

2AZ-FE EMISSION CONTROL CANISTER

Valve

7

EC11

(3) Connect the positive (+) lead of the battery to

terminal 7 and the negative (-) lead to terminal

6.

(4) Check that the valve is closed.

If the result is not as specified, replace the

charcoal canister assembly.

(5) Install the detection pump.

Closed

A111047E01

INSTALLATION

1.

INSTALL CHARCOAL CANISTER ASSEMBLY

(a) Install the 2 bolts, clip and charcoal canister.

Torque: 39 N*m (398 kgf*cm, 29 ft.*lbf)

(b) Connect the purge line hose to the charcoal

canister.

(c) Connect the wire harness clamp.

(d) Connect the vapor pressure sensor connector.

(e) Connect the charcoal canister filter sub-assembly to

the charcoal canister.

(f) Connect the fuel tank vent hose to the charcoal

canister.

2.

INSTALL FUEL TANK ASSEMBLY

HINT:

(See page FU-39)

3.

CHECK FOR EXHAUST GAS LEAKS

A128096

EC

EC12

2AZ-FE EMISSION CONTROL VACUUM SWITCHING VALVE

VACUUM SWITCHING VALVE

2AZ-FE EMISSION CONTROL

ENGINE

COMPONENTS

VACUUM SWITCHING VALVE CONNECTOR

VACUUM SWITCHING VALVE

PURGE LINE HOSE

PURGE LINE HOSE

EC

A135652E03

EC13

2AZ-FE EMISSION CONTROL VACUUM SWITCHING VALVE

REMOVAL

1.

REMOVE VACUUM SWITCHING VALVE

(a) Disconnect the vacuum switching valve connector.

(b) Disconnect the wire harness clamp.

(c) Disconnect the 2 purge line hoses from the purge

VSV.

(d) Remove the vacuum switching valve.

A135666

INSPECTION

1.

23 to 26

1

INSPECT VACUUM SWITCHING VALVE

(a) Measure the resistance of the purge VSV.

Standard resistance

Tester Connection

Specified Condition

1-2

23 to 26 at 20C (68F)

1 - Body ground

2 - Body ground

10 M or higher

If the result is not as specified, replace the purge

VSV.

2

10 M or higher

EC

A124791E01

(b) Check the operation of the purge VSV.

(1) Check that air does not flow from port E to port

F.

E

Air

A124792E01

(2) Apply battery voltage across the terminals.

(3) Check that air flows from port E to port F.

If the result is not as specified, replace the

purge VSV.

F

Air

A124793E01

EC14

2AZ-FE EMISSION CONTROL VACUUM SWITCHING VALVE

INSTALLATION

1.

REMOVE VACUUM SWITCHING VALVE

(a) Install the vacuum switching valve onto the air

cleaner hose.

(b) Connect the 2 purge line hoses to the vacuum

switching valve.

(c) Connect the vacuum switching valve connector.

A135666

EC

2AZ-FE EMISSION CONTROL VENTILATION VALVE

EC15

VENTILATION VALVE

2AZ-FE EMISSION CONTROL

ENGINE

COMPONENTS

7.0 (71, 62 in.*lbf)

NO. 1 ENGINE COVER SUB-ASSEMBLY

VENTILATION VALVE SUB-ASSEMBLY

VENTILATION HOSE

EC

N*m (kgf*cm, ft.*lbf) : Specified torque

Precoated part

A135650E03

EC16

2AZ-FE EMISSION CONTROL VENTILATION VALVE

REMOVAL

1.

REMOVE NO. 1 ENGINE COVER SUB-ASSEMBLY

2.

REMOVE VENTILATION VALVE SUB-ASSEMBLY

(a) Disconnect the ventilation hose from the ventilation

valve sub-assmbly.

A097786E01

(b) Using a 22 mm deep socket wrench, remove the

ventilation valve sub-assembly.

22 mm Deep Socket Wrench

EC

A098067E01

INSPECTION

Cylinder Head Side

1.

Clean Hose

A059511E02

INSPECT VENTILATION VALVE SUB-ASSEMBLY

(a) Install a clean hose to the ventilation valve.

(b) Inspect the ventilation valve operation.

(1) Blow air into the cylinder head side, and check

that air passes through easily.

NOTICE:

Do not suck air through the valve.

Petroleum substances inside the valve are

hazardous to your health.

(2) Blow air into the intake manifold side, and

check that air passes through with difficulty.

If the result is not as specified, replace the

ventilation valve.

(c) Remove the clean hose from the ventilation valve.

Intake Manifold Side

Clean Hose

A059512E11

2AZ-FE EMISSION CONTROL VENTILATION VALVE

EC17

INSTALLATION

Adhesive

1.

INSTALL VENTILATION VALVE SUB-ASSEMBLY

(a) Apply adhesive to 2 or 3 threads of the ventilation

valve.

Adhesive:

Toyota genuine adhesive 1324, three bond

1324 or equivalent

A092670E03

(b) Using a 22 mm deep socket wrench, install the

ventilation valve.

Torque: 19 N*m (194 kgf*cm, 14 ft.*lbf)

(c) Connect the ventilation hose.

22 mm Deep Socket Wrench

2.

INSTALL ENGINE COVER SUB-ASSEMBLY

3.

CHECK FOR ENGINE OIL LEAKS

A098067E01

EC

EC18

2AZ-FE EMISSION CONTROL AIR FUEL RATIO SENSOR

AIR FUEL RATIO SENSOR

2AZ-FE EMISSION CONTROL

ENGINE

COMPONENTS

except PZEV :

EC

x4

12 (122, 9)

44 (449, 33)

NO. 1 EXHAUST MANIFOLD

HEAT INSULATOR

AIR FUEL RATIO SENSOR

N*m (kgf*cm, ft.*lbf) : Specified torque

A135654E03

2AZ-FE EMISSION CONTROL AIR FUEL RATIO SENSOR

EC19

for PZEV :

44 (449, 33)

AIR FUEL RATIO SENSOR

EC

N*m (kgf*cm, ft.*lbf) : Specified torque

A132950E02

EC20

2AZ-FE EMISSION CONTROL AIR FUEL RATIO SENSOR

REMOVAL

1.

REMOVE NO. 1 EXHAUST MANIFOLD HEAT

INSULATOR (except PZEV)

(a) Remove the 4 bolts and No. 1 exhaust manifold

heat insulator.

2.

REMOVE AIR FUEL RATIO SENSOR (except PZEV)

(a) Disconnect the air fuel ratio sensor connector and

clamp.

A135682

A135681E01

(b) Using SST, remove the air fuel ratio sensor from the

exhaust manifold converter sub-assembly No. 2.

SST 09224-00010

NOTICE:

Do not damage the air fuel ratio sensor.

EC

SST

A135683E01

3.

REMOVE AIR FUEL RATIO SENSOR (for PZEV)

(a) Disconnect the air fuel ratio sensor connector.

A135685E01

(b) Using SST, remove the air fuel ratio sensor.

SST 09224-00010

NOTICE:

Do not damage the air fuel ratio sensor.

SST

A135686E01

EC21

2AZ-FE EMISSION CONTROL AIR FUEL RATIO SENSOR

INSPECTION

+B

1.

HT

AF-

INSPECT AIR FUEL RATIO SENSOR

(a) Using an ohmmeter, measure the resistance

between terminals 1 (HT) and 2 (+B).

Standard resistance

Condition

Specified Condition

20C (68F)

1.8 to 3.4

AF+

If the result is not as specified, replace the sensor.

A075325E01

INSTALLATION

1.

SST

INSTALL AIR FUEL RATIO SENSOR (for PZEV)

(a) Temporarily tighten the air fuel ratio sensor.

NOTICE:

Do not damage the air fuel ratio sensor.

(b) Using SST, fully tighten the air fuel ratio sensor.

SST 09224-00010

Torque: 44 N*m (449 kgf*cm, 32 ft.*lbf)

A135687E01

(c) Connect the air fuel ratio sensor connector and

clamp.

2.

INSTALL AIR FUEL RATIO SENSOR (except PZEV)

(a) Temporarily tighten the air fuel ratio sensor.

NOTICE:

Do not damage the air fuel ratio sensor.

A135685E01

(b) Using SST, fully tighten the air fuel ratio sensor.

SST 09224-00010

Torque: 44 N*m (449 kgf*cm, 32 ft.*lbf)

SST

A135684E01

(c) Connect the air fuel ratio sensor connector and

clamp.

A135681E01

EC

EC22

2AZ-FE EMISSION CONTROL AIR FUEL RATIO SENSOR

3.

A135682

EC

INSTALL NO. 1 EXHAUST MANIFOLD HEAT

INSULATOR (except PZEV)

(a) Install the exhaust manifold heat insulator with the 4

bolts.

Torque: 12 N*m (122 kgf*cm, 9 ft.*lbf)

2AZ-FE EMISSION CONTROL HEATED OXYGEN SENSOR

EC23

HEATED OXYGEN SENSOR

2AZ-FE EMISSION CONTROL

ENGINE

COMPONENTS

EC

HEATED OXYGEN SENSOR

44 (449, 33)

N*m (kgf*cm, ft.*lbf) : Specified torque

A135656E02

EC24

2AZ-FE EMISSION CONTROL HEATED OXYGEN SENSOR

REMOVAL

1.

REMOVE HEATED OXYGEN SENSOR

(a) Disconnect the heated oxygen sensor connector.

A135678E01

(b) Using SST, remove the heated oxygen sensor from

the exhaust pipe assembly front No. 3.

SST 09224-00010

NOTICE:

Do not damage the heated oxygen sensor.

SST

A135679E01

INSPECTION

EC

+B

HT

1.

A104021E01

INSPECT HEATED OXYGEN SENSOR

(a) Measure the resistance between terminals 1 (HT)

and 2 (+B).

Standard resistance

Condition

Specified Condition

20C (68F)

11 to 16

If the resistance is not as specified, replace the

sensor.

2AZ-FE EMISSION CONTROL HEATED OXYGEN SENSOR

EC25

INSTALLATION

1.

INSTALL HEATED OXYGEN SENSOR

(a) Temporarily tighten the heated oxygen sensor.

NOTICE:

Do not damage the heated oxygen sensor.

(b) Using SST, fully tighten the heated oxygen sensor.

SST 09224-00010

Torque: 44 N*m (449 kgf*cm, 32 ft.*lbf)

SST

A135680E01

(c) Connect the heated oxygen sensor connector.

EC

A135678E01

You might also like

- Benelli TNT300 Service ManualDocument488 pagesBenelli TNT300 Service ManualMaximilianoVilla90% (10)

- Ford Fiesta Mk7 Routine Maintenance Guide (2013 To 2017 Models) - Haynes PublishingDocument7 pagesFord Fiesta Mk7 Routine Maintenance Guide (2013 To 2017 Models) - Haynes PublishinggregNo ratings yet

- Engine D-4S. LexusDocument59 pagesEngine D-4S. LexusThanh DanhNo ratings yet

- Cooling System: Engine - 2Tr-Fe Engine EG-18Document2 pagesCooling System: Engine - 2Tr-Fe Engine EG-18Maxi SardiNo ratings yet

- LS600hL LS600h (Engine)Document36 pagesLS600hL LS600h (Engine)Minh Nhat Phan100% (2)

- Throttle Body Dan TPS Corolla 88-97Document4 pagesThrottle Body Dan TPS Corolla 88-97Fitri Wibowo100% (1)

- Toyota Camry 2014 ABS EWDDocument16 pagesToyota Camry 2014 ABS EWDasfwsvgerNo ratings yet

- Toyota Camry 2006-2011 2AZ-FE ChargingDocument21 pagesToyota Camry 2006-2011 2AZ-FE ChargingMichael MatthewsNo ratings yet

- 2011 Transtar Automatic Transmission CatalogDocument125 pages2011 Transtar Automatic Transmission Catalogshanestarbuck68100% (2)

- CatDocument13 pagesCatDammiam GaticaNo ratings yet

- Diesel Particle Filter Emergency RegenerationDocument4 pagesDiesel Particle Filter Emergency RegenerationBuga BuniciNo ratings yet

- Toyota New Land Cruiser 70 PDFDocument32 pagesToyota New Land Cruiser 70 PDFIngrid Garcia de Jauregui86% (7)

- Toyota Innova BrochureDocument11 pagesToyota Innova BrochureBima GalangNo ratings yet

- 2AZ FE StartingDocument16 pages2AZ FE StartingLuks FernandezNo ratings yet

- 2AZ-FE FuelDocument43 pages2AZ-FE FuelLuks Fernandez100% (1)

- 2AZ FE IntakeDocument7 pages2AZ FE IntakeLuks Fernandez100% (2)

- 2AZ FE LubricationDocument22 pages2AZ FE LubricationLuks Fernandez100% (2)

- 2az-Fe Diagnostic Trouble Code ChartDocument6 pages2az-Fe Diagnostic Trouble Code ChartEdi Farnando100% (3)

- 2AZ FE IgnitionDocument8 pages2AZ FE IgnitionLuks Fernandez100% (3)

- GDIDocument7 pagesGDIlinhda561No ratings yet

- 2AZ FE CoolingDocument35 pages2AZ FE CoolingLuks Fernandez50% (2)

- If Your Vehicle Needs To Be Towed: 5-1. Essential InformationDocument7 pagesIf Your Vehicle Needs To Be Towed: 5-1. Essential InformationxsmartieNo ratings yet

- 013 - Engine - Throttle - Pedal Position Sensor - Switch A Circuit MalfunctionDocument4 pages013 - Engine - Throttle - Pedal Position Sensor - Switch A Circuit MalfunctionMortada AlsonniNo ratings yet

- Compression Test On 2AZ EnginesDocument4 pagesCompression Test On 2AZ EnginesOlatunde OnakoyaNo ratings yet

- BMC HiaceDocument396 pagesBMC HiaceJerome Maminta100% (1)

- '02 - '04 Camry (2AZ-FE) (Non PZEV) Technical Service BulletinDocument5 pages'02 - '04 Camry (2AZ-FE) (Non PZEV) Technical Service BulletinElvin Domingo100% (1)

- EMISSION CONTROL SYSTEM (2AZ FE) CamryDocument30 pagesEMISSION CONTROL SYSTEM (2AZ FE) CamryRahmat HidayatNo ratings yet

- 1 ZzfeDocument8 pages1 ZzfeScuderia Redin100% (1)

- 5 6215436109652951289Document37 pages5 6215436109652951289Kamrullah ST100% (1)

- Toyota 2AZ-FE Engine Assemblyy InfoDocument10 pagesToyota 2AZ-FE Engine Assemblyy Infomatderis100% (1)

- Engine Cooling Fan Rav 4 2001 2002Document11 pagesEngine Cooling Fan Rav 4 2001 2002mattkidoNo ratings yet

- Automatic Transmission PDFDocument334 pagesAutomatic Transmission PDFAriel MercochaNo ratings yet

- General: Jengine Control SystemDocument29 pagesGeneral: Jengine Control SystemJuan EspinoNo ratings yet

- 1 Hilux (Cont. Next Page) : Starting Power SourceDocument2 pages1 Hilux (Cont. Next Page) : Starting Power SourcewilderNo ratings yet

- 2016 D 2.5 TCI-A2 Schematic Diagrams Engine Electrical System Engine Control System (ETC) Schematic DiagramsDocument1 page2016 D 2.5 TCI-A2 Schematic Diagrams Engine Electrical System Engine Control System (ETC) Schematic DiagramsMAXIMILIANO CASTILLO ANTONIONo ratings yet

- Oxygen Sensor Heater For 2AZFeDocument6 pagesOxygen Sensor Heater For 2AZFelzengunitecNo ratings yet

- Ignition SystemDocument40 pagesIgnition Systemhenisetiawan100% (1)

- GdiDocument22 pagesGdiAnonymous ysrxggk21c100% (1)

- 360 Around View User ManualDocument23 pages360 Around View User ManualaputraNo ratings yet

- Prado Manual SM - 2Document104 pagesPrado Manual SM - 2jeddo2005100% (1)

- ST - 1nz-Fxe Engine StartingDocument84 pagesST - 1nz-Fxe Engine StartingOana MoloceaNo ratings yet

- Toyota Prius 2010 Cruise ControlDocument9 pagesToyota Prius 2010 Cruise ControlBrais Diaz SanchezNo ratings yet

- Supplemental Restraint System (SRS) PDFDocument64 pagesSupplemental Restraint System (SRS) PDFruanm_1No ratings yet

- 01-Distributor Ignition System - Diagnosis and Testing - AutoZoneDocument9 pages01-Distributor Ignition System - Diagnosis and Testing - AutoZoneNato DlAngelesNo ratings yet

- 1 Toyota Fortuner (Cont. Next Page) : Power SourceDocument159 pages1 Toyota Fortuner (Cont. Next Page) : Power SourcerabitosanNo ratings yet

- Multiplex Communication PDFDocument17 pagesMultiplex Communication PDFgandhi permana adjieNo ratings yet

- Greddy E Manage Instalcion en MitsubishiDocument11 pagesGreddy E Manage Instalcion en MitsubishiFelipe Cortes0% (1)

- Toyota Camry IgDocument56 pagesToyota Camry IgKulasekaran Amirthalingam100% (1)

- p5 5S-FE+ENGINE+REPAIR+MANUALDocument23 pagesp5 5S-FE+ENGINE+REPAIR+MANUALkavindaNo ratings yet

- P1012-Fuel Pump Delivery Pressure Too High: Theory of OperationDocument2 pagesP1012-Fuel Pump Delivery Pressure Too High: Theory of OperationYovani AcevedoNo ratings yet

- Hybrid 06Document0 pagesHybrid 06Jorge Eduardo Diaz ValenzuelaNo ratings yet

- Ecs 1azDocument21 pagesEcs 1azjamesNo ratings yet

- LS600hL - LS600h (Hybrid System)Document62 pagesLS600hL - LS600h (Hybrid System)Nguyễn Hoài Nam100% (1)

- Ecs 2azDocument17 pagesEcs 2azRoyer LRNo ratings yet

- Toyota Rav4 Ecu Recall Euc Problem PDFDocument4 pagesToyota Rav4 Ecu Recall Euc Problem PDFرشيد الحربيNo ratings yet

- M6ha Mdwa Baxa MaxaDocument68 pagesM6ha Mdwa Baxa Maxagabriela DiazNo ratings yet

- Meter / Gauge System: PrecautionDocument76 pagesMeter / Gauge System: PrecautionlogammicNo ratings yet

- E Manage Ultimate Wiring Steps For JDM Supra With 2JZ GEDocument7 pagesE Manage Ultimate Wiring Steps For JDM Supra With 2JZ GECosta TsimiklisNo ratings yet

- A140E Automatic Transmission Service and Repair ManualDocument139 pagesA140E Automatic Transmission Service and Repair ManualNon TaschanonNo ratings yet

- ECT and A/T Indicator (1AZ-FSE) ECT and A/T Indicator (1AZ-FSE) ECT and A/T Indicator (1AZ-FSE)Document1 pageECT and A/T Indicator (1AZ-FSE) ECT and A/T Indicator (1AZ-FSE) ECT and A/T Indicator (1AZ-FSE)LuisNo ratings yet

- Maintenance Manual ABS PDFDocument39 pagesMaintenance Manual ABS PDFPedro Emilio Miguez CastrillonNo ratings yet

- 17 Engine and Emission ControlDocument38 pages17 Engine and Emission ControlJoaoBorgesNo ratings yet

- Electronic Throttle Control System-Intelligence (ETCS-i)Document19 pagesElectronic Throttle Control System-Intelligence (ETCS-i)DoDuyBac50% (2)

- Hyundai Chassis EPS - MDPS-Power SteeringDocument99 pagesHyundai Chassis EPS - MDPS-Power SteeringDedi Suwasono100% (2)

- 2GR-FE Emission ControlDocument23 pages2GR-FE Emission ControlLuks FernandezNo ratings yet

- Emission ControlDocument26 pagesEmission ControllogammicNo ratings yet

- Al To Heavyduty CatalogDocument54 pagesAl To Heavyduty CatalogRoberto PerezNo ratings yet

- Hy-Vo Morse Chain CatalogueDocument20 pagesHy-Vo Morse Chain CatalogueLuks FernandezNo ratings yet

- DVK86B PDFDocument8 pagesDVK86B PDFLuks FernandezNo ratings yet

- 2GR FE ExhaustDocument5 pages2GR FE ExhaustLuks FernandezNo ratings yet

- 2GR-FE Engine MechanicalDocument156 pages2GR-FE Engine MechanicalLuks Fernandez100% (7)

- 2AZ FE IgnitionDocument8 pages2AZ FE IgnitionLuks Fernandez100% (3)

- 2GR FE ChargingDocument25 pages2GR FE Chargingmink4uNo ratings yet

- 2GR FE CoolingDocument36 pages2GR FE CoolingLuks FernandezNo ratings yet

- 2GR-FE Emission ControlDocument23 pages2GR-FE Emission ControlLuks FernandezNo ratings yet

- 2AZ FE CoolingDocument35 pages2AZ FE CoolingLuks Fernandez50% (2)

- RT-flex82 Flexview-9520 Rev.00Document64 pagesRT-flex82 Flexview-9520 Rev.00Gaby Cris100% (2)

- Power Train ManualDocument354 pagesPower Train ManualJackson Gonzalez BermudezNo ratings yet

- Disassembly and Assembly: 1106D Industrial EngineDocument185 pagesDisassembly and Assembly: 1106D Industrial EnginefranNo ratings yet

- The 2.0 L 162 KW / 169 KW TSI Engine: Design and FunctionDocument56 pagesThe 2.0 L 162 KW / 169 KW TSI Engine: Design and FunctionAntónio Fernandes100% (1)

- Fuel Injection SystemDocument49 pagesFuel Injection SystemRavi Teja KarumuriNo ratings yet

- Installation Manual: For #60250 2003-2005 Cummins 5.9L Common Rail DieselDocument29 pagesInstallation Manual: For #60250 2003-2005 Cummins 5.9L Common Rail Dieselthanhhai31No ratings yet

- 4 GrfseenDocument4 pages4 GrfseenDustNo ratings yet

- 6135HF485 SDocument2 pages6135HF485 SIrwin JoseNo ratings yet

- MG3 BrochureDocument36 pagesMG3 BrochureReunion St Augustines100% (1)

- U 151eDocument155 pagesU 151emauricio_ch_91100% (5)

- Industrial Diesel Generator Set: Standby Power RatingDocument6 pagesIndustrial Diesel Generator Set: Standby Power RatingJuly E. Maldonado M.No ratings yet

- Vovlo Fuel System PartsDocument7 pagesVovlo Fuel System PartswguenonNo ratings yet

- ManualDocument20 pagesManualpepw67% (3)

- Manual de Partes Del Motor Cat c9Document127 pagesManual de Partes Del Motor Cat c9jalb80% (5)

- MAN 00187 Xylo mDiCRDe Wiring ManualDocument122 pagesMAN 00187 Xylo mDiCRDe Wiring ManualEduardo Antonio Barria OjedaNo ratings yet

- L10 Cummins Info 1 PDFDocument4 pagesL10 Cummins Info 1 PDFpan - panNo ratings yet

- Eendv 110001 - DV11 Engine PDFDocument178 pagesEendv 110001 - DV11 Engine PDFServicios Generales NatividadNo ratings yet

- RtyDocument732 pagesRtyqiuwdhqiwudhqwd0% (1)

- Injectors, Description: Service InformationDocument52 pagesInjectors, Description: Service Informationمحمدابو مهدي العيساوي100% (1)

- 16H Ats PDFDocument37 pages16H Ats PDFMiguel Marquez KongNo ratings yet

- 21 60 03arevDocument4 pages21 60 03arevAdal VeraNo ratings yet

- DV 10 Techical Leaflet PDFDocument12 pagesDV 10 Techical Leaflet PDFbalu9999No ratings yet

- MS 6.3 ECU - 2.8L Engine - v02Document15 pagesMS 6.3 ECU - 2.8L Engine - v02pankituna5487No ratings yet

- Bouncing of The Diesel Injector Needle at The Closing StageDocument10 pagesBouncing of The Diesel Injector Needle at The Closing StageShahfin Ahmed IftiNo ratings yet

- Install and Time Camshaft and Fuel Injection Pump PDFDocument4 pagesInstall and Time Camshaft and Fuel Injection Pump PDFAngela WigleyNo ratings yet