Professional Documents

Culture Documents

SAIC-A-2023 - 2010ed

Uploaded by

mubs997Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SAIC-A-2023 - 2010ed

Uploaded by

mubs997Copyright:

Available Formats

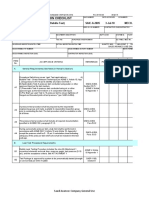

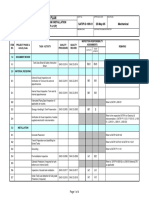

SAUDI ARAMCO ID/PID - 2/19/05 - REV 0 (Standards Cutoff - August 2004)

SAUDI ARAMCO INSPECTION CHECKLIST

Pressurization for Leak Testing

SAIC NUMBER

DATE APPROVED

SAIC-A-2023

PROJECT TITLE

WBS / BI / JO NUMBER

EQUIPMENT ID NUMBER(S)

EQUIPMENT DESCRIPTION

LAYOUT DRAWING NUMBER

REV. NO.

SCHEDULED INSPECTION DATE & TIME

ACTUAL INSPECTION DATE & TIME

25-May-05

QR NUMBER

MECH.

CONTRACTOR / SUBCONTRACTOR

EQPT CODE

SYSTEM ID.

PURCHASE ORDER NUMBER

PLANT NO.

EC / PMCC / MCC NO.

QUANTITY INSP.

MH's SPENT

TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER

SAUDI ARAMCO ACTIVITY NUMBER

SAUDI ARAMCO INSPECTION LEVEL

CONTRACTOR INSPECTION LEVEL

ITEM

No.

ACCEPTANCE CRITERIA

REFERENCE

A. General:

A1

Proponent has thoroughly inspected the equipment/system to be tested.

All piping components included in the limits of the test as shown in the

Test diagram are completely re-instated in accordance with the P&ID.

NOTE: All designated "YES" items in the MCC Punchlist were

completed or corrected.

A2

An approved leak test procedure shall be available at the site prior to

commencing the leak testing activities. (G.I.-2.102, Para. 5.2).

NOTE: Additional checkpoints specifically described in the test

procedure shall be written as supplementary checkpoints.

SAES-A-004,

Para. 7.1.1

A3

Pressure gages and pressure recorders shall be calibrated before the

tests.

SAES-A-004,

Para. 7.1.5

A4

A minimum of two pressure gages are required for the test system. One

pressure gage shall be on the test pump and the other(s) on the test

system. Their accuracy shall be within 5% of one another.

SAES-A-004,

Para. 7.1.5 c

A5

During the application of the test pressure, all in-line valves if not used as

test isolation valves are in an open position.

SAES-A-004,

Para 8.1.3

A6

All flange joints are taped and a hole punched for detection of leak.

A7

Proper test medium (inert gas or steam) is used as specified in the

approved leak test procedure.

G.I.-2.102,

Para. 5.3

A8

Means of control for access to site is in place.

G.I.-2.102,

Para. 5.11

A9

Control pressure rise: Check for leaks at 25 psig or 50% of the test

pressure whichever is lower.

G.I.-2.102,

Para. 5.16

Control pressure rise: After preliminary checks for leaks, increase the

pressure (for inert gas or other gas as test medium) in steps no greater

A10

than one-tenth of the test pressure with at least 10 minute holds at each

step to check for leaks and weaknesses.

G.I.-2.102,

Para. 5.16

A11 Depressurize the system before stopping or repairing leaks.

G.I.-2.102,

Para. 5.17

A12 (Additional Check Points per approved procedure)

Page 1 of 2

G.I.-2.102,

Para. 5.1

WORK PERMIT REQUIRED?

PASS

FAIL

N/A

RE-INSP DATE

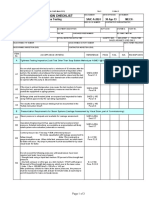

SAUDI ARAMCO ID/PID - 2/19/05 - REV 0 (Standards Cutoff - August 2004)

SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Pressurization for Leak Testing

SAIC-A-2023

PROJECT TITLE

ITEM

No.

DATE APPROVED

WBS / BI / JO NUMBER

ACCEPTANCE CRITERIA

REFERENCE

QR NUMBER

25-May-05

MECH.

CONTRACTOR / SUBCONTRACTOR

PASS

FAIL

N/A

RE-INSP DATE

REMARKS:

REFERENCE DOCUMENTS:

1. SAES-A-004, General Requirements for Pressure Testing, (30 June, 2003)

2. G.I.-2-102, Pressure Testing Safely, (22 July, 2002)

Contractor / Third-Party

Saudi Aramco

Construction Representative*

PMT Representative

Work is Complete and Ready for Inspection:

Name, Initials and Date:

T&I Witnessed

QC Record Reviewed

Work Verified

T&I Witnessed

QC Record Reviewed

Work Verified

T&I Witnessed

QC Record Reviewed

Work Verified

Name, Initials and Date:

QC Inspector

PID Representative

Performed Inspection

Work / Rework May Proceed

Name, Initials and Date:

Name, Initials and Date:

QC Supervisor

Proponent and Others

Quality Record Approved:

Name, Sign and Date:

Name, Organization,

Initials and Date:

*Person Responsible for Completion of Quality Work / Test

Y = YES

Page 2 of 2

N = NO F = FAILED

You might also like

- SAIC-A-2013 Rev 0Document2 pagesSAIC-A-2013 Rev 0philipyapNo ratings yet

- SAUDI ARAMCO PNEUMATIC TEST CHECKLISTDocument3 pagesSAUDI ARAMCO PNEUMATIC TEST CHECKLISTரமேஷ் பாலக்காடுNo ratings yet

- Saic A 2011Document5 pagesSaic A 2011Anonymous 4e7GNjzGWNo ratings yet

- Saudi Aramco Inspection Checklist: 1-Dec-06 Mech. Review of Leak Test Procedure (Bubble Test) SAIC-A-2005Document3 pagesSaudi Aramco Inspection Checklist: 1-Dec-06 Mech. Review of Leak Test Procedure (Bubble Test) SAIC-A-2005ரமேஷ் பாலக்காடுNo ratings yet

- SAIC-A-2024 Rev 2Document2 pagesSAIC-A-2024 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- SAIC-A-2009 Rev 0Document3 pagesSAIC-A-2009 Rev 0philipyapNo ratings yet

- SAIC-A-2015 Rev 0Document1 pageSAIC-A-2015 Rev 0philipyapNo ratings yet

- Saic A 2005Document10 pagesSaic A 2005karthi51289No ratings yet

- SAIC-A-2015 Rev 2Document9 pagesSAIC-A-2015 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- SAIC-A-2015 Rev 7Document8 pagesSAIC-A-2015 Rev 7Bebin Mathew0% (1)

- SAIC-A-2016 Rev 0Document2 pagesSAIC-A-2016 Rev 0philipyapNo ratings yet

- SATIP-A-004-01 Rev 7Document2 pagesSATIP-A-004-01 Rev 7Bebin Mathew100% (1)

- SATR-J-6512 - Rev 0 PDFDocument5 pagesSATR-J-6512 - Rev 0 PDFAdel KlkNo ratings yet

- SAIC-A-2005 Rev 8Document4 pagesSAIC-A-2005 Rev 8Syed ImranNo ratings yet

- Saudi Aramco Inspection Checklist: Flow - Positive Displacement Meter - Material Receiving SAIC-J-6108 1-Oct-05 InstDocument3 pagesSaudi Aramco Inspection Checklist: Flow - Positive Displacement Meter - Material Receiving SAIC-J-6108 1-Oct-05 InstAdel KlkNo ratings yet

- Saudi Aramco Inspection Checklist: Inspection of Leaks For Tightness Testing SAIC-A-2024 3-Jul-18 MechDocument3 pagesSaudi Aramco Inspection Checklist: Inspection of Leaks For Tightness Testing SAIC-A-2024 3-Jul-18 Mechkarthi51289100% (1)

- SAIC-A-2009 Rev 6 Test EquipmentDocument5 pagesSAIC-A-2009 Rev 6 Test Equipmentpookkoya thangalNo ratings yet

- Saudi Aramco Inspection Checklist: Visual Inspection of Pneumatic Test SAIC-A-2021 25-May-05 MechDocument1 pageSaudi Aramco Inspection Checklist: Visual Inspection of Pneumatic Test SAIC-A-2021 25-May-05 MechphilipyapNo ratings yet

- SAIC-A-2005 Rev 5 Leak TestDocument4 pagesSAIC-A-2005 Rev 5 Leak Testpookkoya thangalNo ratings yet

- Saudi Aramco Inspection Checklist: Level - Magnetic Gauges / Switches-Material Receiving. SAIC-J-6302 1-Oct-05 InstDocument2 pagesSaudi Aramco Inspection Checklist: Level - Magnetic Gauges / Switches-Material Receiving. SAIC-J-6302 1-Oct-05 InstAdel KlkNo ratings yet

- Saudi Aramco Inspection Checklist: Mech-Review Procedure - Lay-Up of Piping Systems or Vessels SAIC-A-2007 1-Dec-06Document23 pagesSaudi Aramco Inspection Checklist: Mech-Review Procedure - Lay-Up of Piping Systems or Vessels SAIC-A-2007 1-Dec-06ரமேஷ் பாலக்காடுNo ratings yet

- SAIC-A-2009 Rev 7Document4 pagesSAIC-A-2009 Rev 7sajidazmi.amuNo ratings yet

- Saudi Aramco Inspection Checklist: Reqmts Are Listed in Attachment 1Document6 pagesSaudi Aramco Inspection Checklist: Reqmts Are Listed in Attachment 1sureshNo ratings yet

- Saudi Aramco Inspection Checklist: Verify Test Equipment (Safety Assessment) SAIC-A-2009 31-Dec-14 MechDocument4 pagesSaudi Aramco Inspection Checklist: Verify Test Equipment (Safety Assessment) SAIC-A-2009 31-Dec-14 MechpravinNo ratings yet

- Saudi Aramco Inspection Checklist: Pressurization For Bubble Leak Test (Using Air, Inert Gas) SAIC-A-2023 30-Apr-17 MechDocument5 pagesSaudi Aramco Inspection Checklist: Pressurization For Bubble Leak Test (Using Air, Inert Gas) SAIC-A-2023 30-Apr-17 Mechkarthi51289No ratings yet

- Satr S 4001Document1 pageSatr S 4001mahdi_gNo ratings yet

- Saudi Aramco Piping ChecklistDocument3 pagesSaudi Aramco Piping ChecklistphilipyapNo ratings yet

- Saudi Aramco Inspection Checklist: Pressurization of Pneumatic Test (Strength & Service) SAIC-A-2020 3-Jul-18 MechDocument4 pagesSaudi Aramco Inspection Checklist: Pressurization of Pneumatic Test (Strength & Service) SAIC-A-2020 3-Jul-18 Mechkarthi51289No ratings yet

- Satip A 004 03Document3 pagesSatip A 004 03Anonymous 4e7GNjzGW100% (1)

- Saudi Aramco Inspection Checklist: Review Procedure - Pressure Testing (All Applications) SAIC-A-2001 1-Dec-06 MechDocument30 pagesSaudi Aramco Inspection Checklist: Review Procedure - Pressure Testing (All Applications) SAIC-A-2001 1-Dec-06 Mechரமேஷ் பாலக்காடு86% (7)

- Reviewing Lay-Up Procedures for Piping SystemsDocument12 pagesReviewing Lay-Up Procedures for Piping Systemsimrankhan22No ratings yet

- SATIP S 070 02 Irrigation PipingDocument2 pagesSATIP S 070 02 Irrigation PipingMuhammad Farukh ManzoorNo ratings yet

- SAIC-A-2001 Rev 3 Review Procedure Pressure Testing (All Applications)Document15 pagesSAIC-A-2001 Rev 3 Review Procedure Pressure Testing (All Applications)imrankhan2250% (2)

- 26 Saic A 2009Document5 pages26 Saic A 2009Naveed ShahNo ratings yet

- SAUDI ARAMCO INSPECTION CHECKLIST FOR LEAK TESTINGDocument3 pagesSAUDI ARAMCO INSPECTION CHECKLIST FOR LEAK TESTINGpookkoya thangalNo ratings yet

- Saudi Aramco pneumatic test checklistDocument5 pagesSaudi Aramco pneumatic test checklistpookkoya thangalNo ratings yet

- Verify Saudi Aramco Test Equipment SafetyDocument6 pagesVerify Saudi Aramco Test Equipment SafetyEagle SpiritNo ratings yet

- SAUDI ARAMCO INSPECTION CHECKLIST FOR PRESSURE VESSELSDocument2 pagesSAUDI ARAMCO INSPECTION CHECKLIST FOR PRESSURE VESSELSkarthi51289No ratings yet

- SAIC-L-2042 Rev 6 Field Hydrostatic Testing of Isolation ValvesDocument6 pagesSAIC-L-2042 Rev 6 Field Hydrostatic Testing of Isolation ValvesAhdal NoushadNo ratings yet

- Saudi Aramco Exhaust Fan ChecklistDocument2 pagesSaudi Aramco Exhaust Fan ChecklistBilalNo ratings yet

- SAIC-A-2026 Rev 2Document5 pagesSAIC-A-2026 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- SAUDI ARAMCO CENTRIFUGAL PUMP INSPECTION PLANDocument3 pagesSAUDI ARAMCO CENTRIFUGAL PUMP INSPECTION PLANJithuJohn100% (1)

- Satip G 005 01Document2 pagesSatip G 005 01Anonymous 4e7GNjzGWNo ratings yet

- 1 SATIP-D-109-01 Shop Fab Storage Tank PDFDocument4 pages1 SATIP-D-109-01 Shop Fab Storage Tank PDFJithuJohnNo ratings yet

- SAIC-A-2015 Saudi Aramco Inspection ChecklistDocument8 pagesSAIC-A-2015 Saudi Aramco Inspection Checklistkarthi51289No ratings yet

- SAIC-A-2015 Saudi Aramco Inspection ChecklistDocument8 pagesSAIC-A-2015 Saudi Aramco Inspection Checklistkarthi51289No ratings yet

- SATR-J-6913 Rev 0 PDFDocument6 pagesSATR-J-6913 Rev 0 PDFAdel KlkNo ratings yet

- SAIC-L-2095 Rev 7Document6 pagesSAIC-L-2095 Rev 7Jaseel KanhirathingalNo ratings yet

- SAIC-N-2042 Rev 0Document2 pagesSAIC-N-2042 Rev 0philipyapNo ratings yet

- SAUDI ARAMCO PNEUMATIC TEST INSPECTIONDocument4 pagesSAUDI ARAMCO PNEUMATIC TEST INSPECTIONpookkoya thangalNo ratings yet

- 00 Saip 06Document4 pages00 Saip 06Selvakpm06No ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistDilshad AhemadNo ratings yet

- SATR-J-6001 Rev 0 PDFDocument5 pagesSATR-J-6001 Rev 0 PDFAdel KlkNo ratings yet

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1From EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Rating: 3.5 out of 5 stars3.5/5 (3)

- 737 Performance Reference Handbook - EASA EditionFrom Everand737 Performance Reference Handbook - EASA EditionRating: 4.5 out of 5 stars4.5/5 (3)

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationFrom EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationNo ratings yet

- Airman Certification Standards: Remote Pilot - Small Unmanned Aircraft Systems (2024): FAA-S-ACS-10BFrom EverandAirman Certification Standards: Remote Pilot - Small Unmanned Aircraft Systems (2024): FAA-S-ACS-10BNo ratings yet

- Piping and Ducting SupportDocument7 pagesPiping and Ducting SupportphilipyapNo ratings yet

- Saudi Aramco Tent Structure SpecificationsDocument5 pagesSaudi Aramco Tent Structure SpecificationsphilipyapNo ratings yet

- Sealant and CaulkingDocument8 pagesSealant and CaulkingphilipyapNo ratings yet

- Finish CarpentryDocument17 pagesFinish CarpentryphilipyapNo ratings yet

- DuctworksDocument7 pagesDuctworksphilipyapNo ratings yet

- Exterior LightingDocument8 pagesExterior LightingphilipyapNo ratings yet

- Fire Protection SysytemDocument5 pagesFire Protection SysytemphilipyapNo ratings yet

- Panel BoardDocument7 pagesPanel BoardphilipyapNo ratings yet

- Resilent FlooringDocument7 pagesResilent FlooringphilipyapNo ratings yet

- Low Voltage Wires and Cables SpecificationDocument9 pagesLow Voltage Wires and Cables SpecificationphilipyapNo ratings yet

- Saudi Aramco Tent Structure SpecificationsDocument5 pagesSaudi Aramco Tent Structure SpecificationsphilipyapNo ratings yet

- Raceway Selection GuideDocument10 pagesRaceway Selection GuidephilipyapNo ratings yet

- Saudi Aramco Ductwork SpecificationsDocument5 pagesSaudi Aramco Ductwork SpecificationsphilipyapNo ratings yet

- Chilled Water PumpDocument6 pagesChilled Water PumpphilipyapNo ratings yet

- Variable Air UnitDocument4 pagesVariable Air UnitphilipyapNo ratings yet

- Fan Coil UnitsDocument3 pagesFan Coil UnitsphilipyapNo ratings yet

- SignageDocument4 pagesSignagephilipyapNo ratings yet

- FanDocument7 pagesFanphilipyap100% (1)

- DuctworksDocument7 pagesDuctworksphilipyapNo ratings yet

- Metal FramesDocument4 pagesMetal FramesphilipyapNo ratings yet

- Metal FramesDocument4 pagesMetal FramesphilipyapNo ratings yet

- Sheet Membrance Water ProofingDocument6 pagesSheet Membrance Water ProofingphilipyapNo ratings yet

- Plumbing SpecialitiesDocument4 pagesPlumbing SpecialitiesphilipyapNo ratings yet

- Control SystemDocument21 pagesControl SystemphilipyapNo ratings yet

- Roof and Deck InsulationDocument3 pagesRoof and Deck InsulationphilipyapNo ratings yet

- Glass and GlazingDocument8 pagesGlass and GlazingphilipyapNo ratings yet

- G.furniture & FixturesDocument2 pagesG.furniture & FixturesphilipyapNo ratings yet

- 03210-Epoxy Coated Conc ReoDocument7 pages03210-Epoxy Coated Conc ReophilipyapNo ratings yet

- Floor MatsDocument3 pagesFloor MatsphilipyapNo ratings yet

- Swimming PoolDocument4 pagesSwimming PoolphilipyapNo ratings yet

- Be Sem 5 TTDocument11 pagesBe Sem 5 TTMasterNo ratings yet

- Mod BDocument32 pagesMod BRuwina Ayman100% (1)

- April 2014 1396445255 131fa 88 PDFDocument2 pagesApril 2014 1396445255 131fa 88 PDFkavithaNo ratings yet

- Account Statement As of 26-08-2022 18:16:42 GMT +0530Document4 pagesAccount Statement As of 26-08-2022 18:16:42 GMT +0530jagapriya sivaraman6897100% (1)

- Technical Specification Clamp Nut BoltDocument20 pagesTechnical Specification Clamp Nut Boltpiyush_123456789No ratings yet

- N P Rajeswara Reddy: Ummary of KillsDocument2 pagesN P Rajeswara Reddy: Ummary of KillskiranNo ratings yet

- SQM Lecture3 Org Structure Roles&RespDocument19 pagesSQM Lecture3 Org Structure Roles&Respjayanto_mayankNo ratings yet

- LINCOLN Lubrication Centro - MaticDocument53 pagesLINCOLN Lubrication Centro - Maticrmartinf2527No ratings yet

- Container BLDGS 1ST Edition PDFDocument65 pagesContainer BLDGS 1ST Edition PDFfcjjcfNo ratings yet

- Clearing Pending TransactionsDocument10 pagesClearing Pending TransactionsVinay ChughNo ratings yet

- Why Do You Say That Project Management Is The Best Method of Implementing ChangeDocument10 pagesWhy Do You Say That Project Management Is The Best Method of Implementing ChangeFaisal HameedNo ratings yet

- Guide To Stability Design Criteria For Metal Structures-6ed Zeiman 2010 1117pDocument1,117 pagesGuide To Stability Design Criteria For Metal Structures-6ed Zeiman 2010 1117pcgingenieros94% (31)

- Job planning and process preparationDocument11 pagesJob planning and process preparationNiza JamilNo ratings yet

- Pampanga Rule78 ProblemsDocument63 pagesPampanga Rule78 ProblemsCrizza Joyce CruzNo ratings yet

- A Way To Deal With The Project Crashing Problem: Hamdjatou Kane Gilbert NkubiliDocument14 pagesA Way To Deal With The Project Crashing Problem: Hamdjatou Kane Gilbert Nkubilimangalam manjuNo ratings yet

- BTDSynchronous Servomotors GuideDocument72 pagesBTDSynchronous Servomotors GuideDubravko BituhNo ratings yet

- Steam Nozzles: Prepared by Venkat Chintala Asst. Prof. S.G. Mechanical Engg. Deptt., UPESDocument50 pagesSteam Nozzles: Prepared by Venkat Chintala Asst. Prof. S.G. Mechanical Engg. Deptt., UPESRaj NarayanNo ratings yet

- Radiography Examination Procedure For Asme Boiler, Pressure Vessel and PipingDocument15 pagesRadiography Examination Procedure For Asme Boiler, Pressure Vessel and PipingEko Kurniawan100% (1)

- Faurecia Automotive Maneser NSF Project Time Plan PS Trails (6152)Document2 pagesFaurecia Automotive Maneser NSF Project Time Plan PS Trails (6152)Tushar KohinkarNo ratings yet

- 1-M Vib Meas Hwp-A MotorDocument3 pages1-M Vib Meas Hwp-A MotorNovindra PutraNo ratings yet

- China Vaseline White Petroleum Jelly - Snow White Vaseline - China Vaseline White, Petroleum Jelly PDFDocument3 pagesChina Vaseline White Petroleum Jelly - Snow White Vaseline - China Vaseline White, Petroleum Jelly PDFIstianah Achy HaeruddinNo ratings yet

- Project 3Document18 pagesProject 3Jay ParekhNo ratings yet

- Honda International ManagementDocument29 pagesHonda International ManagementTanumoy Sengupta100% (1)

- Lesson 28 DFD and Er DiagramDocument10 pagesLesson 28 DFD and Er DiagramSelect dsouzaNo ratings yet

- Design Qualification TemplateDocument5 pagesDesign Qualification Templateavinash peddintiNo ratings yet

- Extended Warehouse Management - Flyer - ENDocument2 pagesExtended Warehouse Management - Flyer - ENsapabap403No ratings yet

- 0001 0 General Nobel DentonDocument50 pages0001 0 General Nobel DentonPeyman MznNo ratings yet

- Fluid Flow Mean Velocity and Pipe Diameter For Known Flow RateDocument10 pagesFluid Flow Mean Velocity and Pipe Diameter For Known Flow Ratefaisal mahmood azamNo ratings yet

- Human Factors EngineeringDocument54 pagesHuman Factors Engineeringganeshrams88No ratings yet

- Woodward Speed Setting MechDocument6 pagesWoodward Speed Setting Mechmanuel1122No ratings yet