Professional Documents

Culture Documents

Recycling Hard Disk Drive Motors

Uploaded by

Prabhat Sagar0 ratings0% found this document useful (0 votes)

25 views2 pagesrecycle

Original Title

137064246 Recycling Hard Disk Drive Motors

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentrecycle

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

25 views2 pagesRecycling Hard Disk Drive Motors

Uploaded by

Prabhat Sagarrecycle

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Developments in the computing industry progress

rapidly. Last years expensive acquisitions are

already no longer usable for running modern software. However, old computers, or at least parts of

them, need not always end up as electronic

scrap. Lets look at the motors found in old hard

disk drives, for example

By H. Neumann and E. Mller

recycling hard disk

drive motors

1

Hard disk drives with

capacities of 20 to

40 MB can often be

found in discarded computers (in the basement

or at flea markets). The

data stored on these

devices is surely of no

interest to anyone, but

each one contains two

motors, for which some

useful applications might

still be found. In addition

to the stepper motor,

which

moves

the

read/write heads, the

actual drive motor is an

interesting item. In the

case of the drives investigated by the authors,

this is a d.c. motor with

electronic commutation.

An example is shown in

Figure 1. Our objective

here is to see how such

a motor can be brought

back to life.

Before you can do anything with the motor, you

must first disassemble

the drive. Start by

removing the enclosure

cover and the printed

circuit

board.

The

proper tool for removing

the screws is a Torx

screwdriver, but a sturdy

slot-type screwdriver

can also be pressed

into service if necessary.

After the cover and the

board

have

been

removed, you will see

PC TOPICS

the two motors (Figure 2). You can now

dismount the head drive motor (Figure 3) and the platter assembly (Figure 4). Finally, remove the fixing screws

for the drive motor (Figure 5), and you

can extract the desired object.

The motor has six leads, three of which

are connected to its windings. These

leads can be easily identified with the

help of an ohmmeter. The winding resistance will measure around 3 or 6 ,

depending on whether you measure

across one or both windings. You can

thus directly figure out which leads are

the winding leads. The three other

leads are connected to a Hall-effect

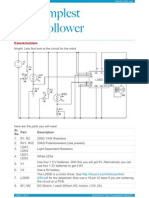

sensor IC, and the measured resistances between these leads will be significantly higher. With the test circuit

shown in Figure 6, you can easily sort

out which of these leads is connected

to what. In the worst case, you will have

to connect each of the three leads to

earth in turn while the other two are

connected to +12 V via series resistors

and LEDs. Turn the rotor of the motor

slowly. If the proper lead is connected

to earth, one of the LEDs will be constantly on; the associated lead is then

connected to the power supply terminal of the IC. The other LED will blink as

the rotor is turned; its lead is thus the

signal output of the IC.

Now you have completed the necessary preparations in order to be able to

use the motor. For this, you will need a

circuit as shown in Figure 7, which can

be quickly constructed on a bit of prototyping board. The Hall sensor built into

the motor has an open-collector output. If the output transistor is switched

on, transistor T1 is cut off. Resistors R2

and R3 then supply enough current to

Elektor Electronics EXTRA

15 - 11/99

Figures 1 through 5. How to take apart a hard disk drive.

R4

L1

L2

180

R2

180

R1

3k3

switch on T2. This in turn supplies base

current to T3 via R4, and T3 is also

switched on. A magnetic field is created in coil L1, and this causes the permanent-magnet rotor to rotate slightly.

The Hall sensor is now exposed to the

opposite magnetic polarity, so that its

output transistor is switched off. The

base of T1 now receives current via R1,

and it switches on. Since the voltage at

the collector of T1 is now very low, the

current flowing through R3 is not sufficient to keep T2 switched on. Consequently, T3 is also no longer switched

on, and current no longer flows through

L1. However, since T1 is switched on, T4

is supplied with a base current via R2,

and it switches on. L2 thus receives a

current and produces a magnetic field,

which in turn causes the rotor to rotate

a bit further. This sequence repeats itself

over and over again as long as an

adequate supply voltage is present.

Diodes D1 and D2 protect T3 and T4

against induced voltages. If you want

to reverse the motors direction of rotation, simply exchange the L1 and L2

leads.

R3

T2

1k

(992039-1)

BC547

T3

D1

T1

1k

1k

12V

Hall-effect

IC

BD243

BC547

1N

4007

T3

BD243

D2

1N

4007

992042 - 11

992042 - 12

Figure 6. This test circuit can be used to

determine the connection scheme of

the motor.

16 - 11/99

Elektor Electronics EXTRA

Figure 7. Control circuit for an electronically commutated motor.

PC TOPICS

You might also like

- ZapperDocument3 pagesZapperawemetal0% (1)

- Power Supply Projects: A Collection of Innovative and Practical Design ProjectsFrom EverandPower Supply Projects: A Collection of Innovative and Practical Design ProjectsRating: 3 out of 5 stars3/5 (2)

- Parts ListDocument7 pagesParts Listnguyencongthanh2011No ratings yet

- Dashboard Digital VoltmeterDocument7 pagesDashboard Digital VoltmetercrashoveriteNo ratings yet

- Schema Circuitului Bistabil Licurici (THE FLIP FLOP) .OdtDocument5 pagesSchema Circuitului Bistabil Licurici (THE FLIP FLOP) .OdtvladareanucatalindanNo ratings yet

- Bible Names and Their MeaningsDocument45 pagesBible Names and Their MeaningsPrabhat Sagar75% (8)

- ElectricalDocument33 pagesElectricalRABISH KumarNo ratings yet

- BASIC Electronics PartsDocument9 pagesBASIC Electronics PartsChakravartyNo ratings yet

- Hardware InterfacingDocument65 pagesHardware Interfacingrajan palaNo ratings yet

- This Is An Electrical Circuit Protection Device Sound DisappearedDocument9 pagesThis Is An Electrical Circuit Protection Device Sound DisappearedRaushan Kumar SinghNo ratings yet

- 2013 CDS FinalDocument130 pages2013 CDS FinalMz4f45No ratings yet

- R - 11 - Robots Page 11Document5 pagesR - 11 - Robots Page 11straf238No ratings yet

- Driving Relays With stm32f407vgtx Microcontroller Using Uln2003 Relay DriverDocument12 pagesDriving Relays With stm32f407vgtx Microcontroller Using Uln2003 Relay DriverAnonymous Nlaa5HNo ratings yet

- Build a simple DIY solar tracker circuit with an ArduinoDocument8 pagesBuild a simple DIY solar tracker circuit with an ArduinoAnonymous MbqTZHLNR9No ratings yet

- R 07 Robots Page7Document4 pagesR 07 Robots Page7straf238No ratings yet

- How Relays Provide Electrical IsolationDocument4 pagesHow Relays Provide Electrical IsolationFaiz RahmanNo ratings yet

- The Simplest Line Follower: ConstructionDocument5 pagesThe Simplest Line Follower: Constructionapi-115728880No ratings yet

- How Things Work - Relay SwitchesDocument4 pagesHow Things Work - Relay SwitchessaurabhdabasNo ratings yet

- Line Follower ROBOT Micro Controller 8051Document28 pagesLine Follower ROBOT Micro Controller 8051Rohit XavierNo ratings yet

- It Would Be Useful To Be Able To Run A Motor in Either Direction Using H BridgeDocument51 pagesIt Would Be Useful To Be Able To Run A Motor in Either Direction Using H BridgeatulhinduNo ratings yet

- Touch Switch Project ReportDocument13 pagesTouch Switch Project ReportGaurav Kumar60% (15)

- Electronics - Schematic Circuits For The HobbyistDocument159 pagesElectronics - Schematic Circuits For The HobbyistrispNo ratings yet

- 3.1 Block Diagram & Components Description:: Fig: 3.1 Block Diagram of Cyclo-Converter Using MicrocontrollerDocument10 pages3.1 Block Diagram & Components Description:: Fig: 3.1 Block Diagram of Cyclo-Converter Using MicrocontrollerSwamyNo ratings yet

- E I (EC 323) : Lectrical NstallationsDocument38 pagesE I (EC 323) : Lectrical NstallationsMalith DeemanthaNo ratings yet

- RelayDocument7 pagesRelayNithin JohnNo ratings yet

- A Versatile 12-Channel Infrared Remote ControlDocument5 pagesA Versatile 12-Channel Infrared Remote ControlMeraz AhmedNo ratings yet

- Remove noise from DC motors with an LC filterDocument7 pagesRemove noise from DC motors with an LC filterbill_gator20059105No ratings yet

- I2C Faq: What Is The Maximum Distance of The I2C Bus?Document7 pagesI2C Faq: What Is The Maximum Distance of The I2C Bus?Krishanu Modak100% (1)

- Basic Electronic Components - SneiderDocument5 pagesBasic Electronic Components - SneiderSNEIDER HERNANDEZ MOTTANo ratings yet

- Proyectos de Electronica.Document27 pagesProyectos de Electronica.saiworNo ratings yet

- Experiment #04: Introduction To Relay and Its Application (Controlling of 220v Using 5v Relay)Document8 pagesExperiment #04: Introduction To Relay and Its Application (Controlling of 220v Using 5v Relay)Ayaz FaisalNo ratings yet

- Relays: TransistorDocument12 pagesRelays: TransistorvgmanjunathaNo ratings yet

- Man TechDocument2 pagesMan Techbeauty senseNo ratings yet

- New Open Document TextDocument12 pagesNew Open Document TextOpris CosminNo ratings yet

- RelaysDocument3 pagesRelaysAnkur SharmaNo ratings yet

- Cheap 220V AC Mobile Charger Circuit DiagramDocument3 pagesCheap 220V AC Mobile Charger Circuit DiagramBhadreshkumar SharmaNo ratings yet

- RelaysDocument4 pagesRelaysSathya AyhtasNo ratings yet

- Three Simple Ways to Blink an LEDDocument9 pagesThree Simple Ways to Blink an LEDDada AlbertNo ratings yet

- Electronic Card Lock System Final Year Ece Project ReportDocument17 pagesElectronic Card Lock System Final Year Ece Project ReportSunny Prasanth100% (3)

- Detect Underground Cable Faults Using ArduinoDocument19 pagesDetect Underground Cable Faults Using ArduinoPrajjwal SrivastavaNo ratings yet

- Home Garden Elektor 303 DIY Project CircuitsDocument77 pagesHome Garden Elektor 303 DIY Project CircuitsTurkogluNo ratings yet

- Tut Relay FinalDocument10 pagesTut Relay FinalAravind KaraNo ratings yet

- Digital Outputs and Relays Control GuideDocument10 pagesDigital Outputs and Relays Control GuideTipanagiri kumar RajuNo ratings yet

- Info RelaysDocument10 pagesInfo RelaysT. Kumar RajuNo ratings yet

- Work Shop MoterDocument23 pagesWork Shop Moterbelacheweshetu222No ratings yet

- Using The 555 TimerDocument5 pagesUsing The 555 TimerMauriceNo ratings yet

- 2 Useful Energy Saver Solder Iron Station CircuitsDocument7 pages2 Useful Energy Saver Solder Iron Station CircuitsΔημητριος ΣταθηςNo ratings yet

- Automatic Night Light Circuit Using SCR: Semester ProjectDocument10 pagesAutomatic Night Light Circuit Using SCR: Semester ProjectNasheed AhmedNo ratings yet

- Introductio1Document12 pagesIntroductio1Khamkar GaneshNo ratings yet

- Single Chip Electronic Dice: (1) ResistorDocument7 pagesSingle Chip Electronic Dice: (1) Resistormohsankayani3462No ratings yet

- Qa 00177 Automatic Street Light ControlDocument10 pagesQa 00177 Automatic Street Light Controlashley_rodrigues_20No ratings yet

- Interfacing Relays Using The Parallel Port: ContentsDocument11 pagesInterfacing Relays Using The Parallel Port: ContentsAgoi GilbertNo ratings yet

- DC Motor Lab: 1.1 The ExperimentDocument9 pagesDC Motor Lab: 1.1 The ExperimentTammanurRaviNo ratings yet

- Projects: Magnetically Operated Gun With NE555Document14 pagesProjects: Magnetically Operated Gun With NE555PedrobarrozoNo ratings yet

- Project of Electronics SubjectDocument14 pagesProject of Electronics SubjectDarren Troy Lingao MayorNo ratings yet

- Automatic Emergency TourchDocument2 pagesAutomatic Emergency TourchchakralabsNo ratings yet

- Power Electronics Guide: Soft Starters ExplainedDocument10 pagesPower Electronics Guide: Soft Starters ExplaineddcasdcNo ratings yet

- In Industrial Process, Speed As A Variable Refers To The ReDocument71 pagesIn Industrial Process, Speed As A Variable Refers To The Reapi-19786583No ratings yet

- Modular Circuits: Μmodule H-BridgeDocument8 pagesModular Circuits: Μmodule H-BridgeAyadNo ratings yet

- 300watt Driver Circuit DiagramDocument1 page300watt Driver Circuit DiagramPrabhat SagarNo ratings yet

- Uniform ApplicationDocument10 pagesUniform ApplicationMinal ParapannawarNo ratings yet

- Excel Payroll Process With AttandanceDocument35 pagesExcel Payroll Process With AttandancePrabhat SagarNo ratings yet

- Portal Enrollment for New BidderDocument28 pagesPortal Enrollment for New BidderPrabhat SagarNo ratings yet

- Bid PreparationDocument38 pagesBid PreparationPrabhat SagarNo ratings yet

- Acspl: Si. No. Material Description Recived Stock Damage Stock Used Stock Balance StockDocument3 pagesAcspl: Si. No. Material Description Recived Stock Damage Stock Used Stock Balance StockPrabhat SagarNo ratings yet

- 12V Auto Cut Off Charger Circuit by Hawkar FariqDocument12 pages12V Auto Cut Off Charger Circuit by Hawkar FariqPrabhat SagarNo ratings yet

- Vehicle Letter June 2017Document1 pageVehicle Letter June 2017Prabhat SagarNo ratings yet

- Reader So 2017Document11 pagesReader So 2017Prabhat SagarNo ratings yet

- Working Auto IrrigationDocument12 pagesWorking Auto IrrigationPrabhat SagarNo ratings yet

- Led Solar Street LightDocument2 pagesLed Solar Street LightPrabhat SagarNo ratings yet

- Plant IrrigationDocument1 pagePlant IrrigationSidhant BansalNo ratings yet

- Daily Work Plan FormDocument1 pageDaily Work Plan FormPrabhat SagarNo ratings yet

- Led Solar Street LightDocument2 pagesLed Solar Street LightPrabhat SagarNo ratings yet

- 4 - Syllabus For LDCO16Document1 page4 - Syllabus For LDCO16Prabhat SagarNo ratings yet

- Professional 1Document1 pageProfessional 1Prabhat SagarNo ratings yet

- 8 - Bank Instruction-Ldco16)Document4 pages8 - Bank Instruction-Ldco16)Prabhat SagarNo ratings yet

- Application Form of Scholarship 2016 2017Document7 pagesApplication Form of Scholarship 2016 2017Prabhat SagarNo ratings yet

- PaceDocument1 pagePacePrabhat SagarNo ratings yet

- Led Solar Street LightDocument2 pagesLed Solar Street LightPrabhat SagarNo ratings yet

- Temporary Faculty ADV. 12-07-2016Document6 pagesTemporary Faculty ADV. 12-07-2016Prabhat SagarNo ratings yet

- Reg Theory PDFDocument6 pagesReg Theory PDFPrabhat SagarNo ratings yet

- Component ListDocument1 pageComponent ListPrabhat SagarNo ratings yet

- 8051 TutorialDocument95 pages8051 TutorialPrabhat SagarNo ratings yet

- Micro Based Safty Gaurd For BlindsDocument6 pagesMicro Based Safty Gaurd For BlindsPrabhat SagarNo ratings yet

- ACS712Document14 pagesACS712Hery Tjah KakoiNo ratings yet

- Solar Pumping Systems for Drinking WaterDocument6 pagesSolar Pumping Systems for Drinking WaterrenuNo ratings yet

- TCRT5000Document12 pagesTCRT5000Richard James Yap TanNo ratings yet