Professional Documents

Culture Documents

WPS Dan PQR Form AWS N-1 (Recovered 1) (Recovered 1) PDF

WPS Dan PQR Form AWS N-1 (Recovered 1) (Recovered 1) PDF

Uploaded by

M Agus SaparudinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WPS Dan PQR Form AWS N-1 (Recovered 1) (Recovered 1) PDF

WPS Dan PQR Form AWS N-1 (Recovered 1) (Recovered 1) PDF

Uploaded by

M Agus SaparudinCopyright:

Available Formats

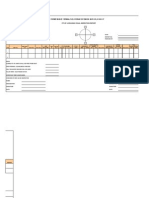

ANNEX N

AWS D1.1/D1.1M:2008

WELDING PROCEDURE SPECIFICATION (WPS) Yes

PREQUALIFIED __________ QUALIFIED BY TESTING __________

or PROCEDURE QUALIFICATION RECORDS (PQR) Yes

Identification # _________________________________

Revision _______ Date __________ By ____________

Authorized by __________________ Date __________

TypeManual

Semiautomatic

Machine

Automatic

Hari Weld's Operation

Company Name _______________________________

GMAW

Welding Process(es) ____________________________

2

Supporting PQR No.(s) __________________________

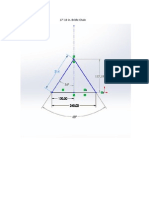

JOINT DESIGN USED

Type:

Single

Double Weld

Backing: Yes

No

Backing: Backing Material:

2

2

Root Opening ______

Root Face Dimension ________

J

80

Groove Angle: ___________

Radius (JU) _________

10

Back Gouging: Yes

No

Method _______

POSITION

5G

Unlimited

Position of Groove: ______________

Fillet: __________

Vertical Progression: Up

Down

ELECTRICAL CHARACTERISTICS

Constan Current

______________________

Transfer Mode (GMAW)

Short-Circuiting

Globular

Spray

Current: AC

DCEP

DCEN

Pulsed

Power Source: CC

CV

Other ________________________________________

Tungsten Electrode (GTAW)

1.8"(3,2mm)

Size: ______________

E6013

Type: ______________

BASE METALS

ASTM A 36

Material Spec. _________________________________

Type or Grade _________________________________

Unlimited

10

Thickness: Groove ____________

Fillet __________

60 cm

Diameter (Pipe) ________________________________

FILLER METALS

A5.18

AWS Specification______________________________

ER70S-6

AWS Classification _____________________________

SHIELDING

CO2

Flux ___________________ Gas _________________

50% CO2

Composition __________

45

55 cfh

Electrode-Flux (Class)_____ Flow Rate ____________

______________________ Gas Cup Size _________

TECHNIQUE

Stringer

Stringer or Weave Bead: _________________________

Multipass

Multi-pass or Single Pass (per side)_________________

1

Number of Electrodes ___________________________

Electrode Spacing

Longitudinal ____________

Lateral_________________

Angle _________________

Contact Tube to Work Distance ____________________

None

Peening ______________________________________

Wire Brush

Interpass Cleaning: _____________________________

PREHEAT

60

Preheat Temp., Min. ____________________________

60

350

Interpass Temp., Min. ___________

Max. _________

POSTWELD HEAT TREATMENT

1100 - 1150 F

Temp. ________________________________________

1 hr/in., 1 hr minimum

Time _________________________________________

WELDING PROCEDURE

Pass or

Weld

Layer(s)

Filler Metals

Process

Class

Diam.

Root

pass

SMAW E7016 3,3

Hot

pass

SMAW

SMAW

filler

caping

Current

Type &

Polarity

Amps or Wire

Feed Speed

Volts

D 110 cv

CE

P

SMAW

Form N-1 (Front)

348

Travel

Speed

Joint Details

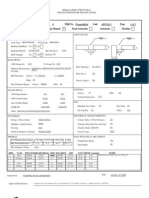

ANNEX N

AWS D1.1/D1.1M:2008

Procedure Qualification Record (PQR) # __________

Test Results

TENSILE TEST

Specimen

No.

Width

Thickness

Area

Ultimate Tensile

Load, lb

Ultimate Unit

Stress, psi

Character of Failure

and Location

GUIDED BEND TEST

Specimen

No.

Type of Bend

Result

Remarks

VISUAL INSPECTION

Appearance___________________________________

Undercut _____________________________________

Piping porosity ________________________________

Convexity_____________________________________

Test date _____________________________________

Witnessed by__________________________________

Radiographic-ultrasonic examination

RT report no.: __________ Result ________________

UT report no.: ___________ Result ________________

FILLET WELD TEST RESULTS

Minimum size multiple pass Maximum size single pass

Macroetch

Macroetch

1. _______ 3. ________ 1. ________ 3. ________

2. _______

2. ________

Other Tests

All-weld-metal tension test

Tensile strength, psi _____________________________

Yield point/strength, psi __________________________

Elongation in 2 in, % ____________________________

Laboratory test no. _________________________

Welders name ________________________________

Clock no. ______________ Stamp no. _____________

Tests conducted by _________________________________________________________ Laboratory

Test number ___________________________________

Per __________________________________________

We, the undersigned, certify that the statements in this record are correct and that the test welds were prepared, welded, and

tested in conformance with the requirements of Clause 4 of AWS D1.1/D1.1M, (__________ ) Structural Welding CodeSteel.

(year)

Signed _______________________________________

Manufacturer or Contractor

By ___________________________________________

Title _________________________________________

Date _________________________________________

Form N-1 (Back)

352

You might also like

- WPS PQR A36.20Document5 pagesWPS PQR A36.20gchaves504100% (2)

- Ilcs-Smaw-D1.3-Deck (G) WPSDocument3 pagesIlcs-Smaw-D1.3-Deck (G) WPSRoss100% (1)

- Welding Machine Calibration ProcedureDocument10 pagesWelding Machine Calibration ProcedureGerman Favela0% (1)

- Sample Welding Procedure Specification (WPS) FormDocument1 pageSample Welding Procedure Specification (WPS) Formfallalovaldes50% (4)

- Welding Procedure Specifica Tion (WPS) : I I I IDocument5 pagesWelding Procedure Specifica Tion (WPS) : I I I ITrinh DungNo ratings yet

- Fit-Up & Welding Visual Inspection ReportDocument11 pagesFit-Up & Welding Visual Inspection ReportRachel Flores71% (7)

- AWS D1.2 GuidesDocument3 pagesAWS D1.2 GuidesTuan DangNo ratings yet

- Atf Wpqr-Blank v1Document1 pageAtf Wpqr-Blank v1lth770310No ratings yet

- Aws D1.6 - SS316 WPSDocument1 pageAws D1.6 - SS316 WPSBoby Thomas0% (1)

- Fit-Up Inspection Report PDFDocument1 pageFit-Up Inspection Report PDFAlfian Imaduddin100% (1)

- Fit-Up Inspection ReportDocument1 pageFit-Up Inspection ReportAlfian ImaduddinNo ratings yet

- WPSDocument2 pagesWPSJuli Agus50% (2)

- Welding Procedure Qualification Certificate EN ISO 15614-1: 2017Document3 pagesWelding Procedure Qualification Certificate EN ISO 15614-1: 2017dcsamaraweera100% (1)

- WPS - D1.1 - Prequalified Procedures QSSLDocument26 pagesWPS - D1.1 - Prequalified Procedures QSSLfazeel mohammedNo ratings yet

- P-WPS 135 - MAG (GR 316)Document9 pagesP-WPS 135 - MAG (GR 316)Tarun PatelNo ratings yet

- Alu WpsDocument4 pagesAlu WpsdselvakuuNo ratings yet

- AWS N-9 Stud Welding Procedure Specification (WPS) FormDocument1 pageAWS N-9 Stud Welding Procedure Specification (WPS) FormNatalia StarkNo ratings yet

- Sample PQRDocument2 pagesSample PQRudaysrp33% (3)

- WPS D1.6 Annex m1 PDFDocument1 pageWPS D1.6 Annex m1 PDFbollascribdNo ratings yet

- WPQR2Document3 pagesWPQR2Thanasis KyrgiazoglouNo ratings yet

- Quick Review On Essential Variables: AWS D1.1 (Structural Welding Code-Steel)Document10 pagesQuick Review On Essential Variables: AWS D1.1 (Structural Welding Code-Steel)Gautam SunnyNo ratings yet

- Reports - QAQC - R0Document10 pagesReports - QAQC - R0talupurumNo ratings yet

- AUT-GMAW-2 Rev.0 PDFDocument5 pagesAUT-GMAW-2 Rev.0 PDFDario100% (1)

- Welding Procedure Specification Register (Structural Steel) : AWS D1.1Document14 pagesWelding Procedure Specification Register (Structural Steel) : AWS D1.1murshid badshah100% (2)

- WQTDocument1 pageWQTRamkunwar YadavNo ratings yet

- Gtaw Smaw 6 Inch 6G CSDocument1 pageGtaw Smaw 6 Inch 6G CSKentDemeterio100% (1)

- WPSDocument6 pagesWPSYASH BARDHAN SinghNo ratings yet

- Welding Procedure Specification (WPS) : FM-87 Issue - 01 Date: Feb, 12,2015 Page 1 of 2Document2 pagesWelding Procedure Specification (WPS) : FM-87 Issue - 01 Date: Feb, 12,2015 Page 1 of 2tayyabNo ratings yet

- Welding Procedure Specification For GTAW & GMAWDocument4 pagesWelding Procedure Specification For GTAW & GMAWanh thoNo ratings yet

- WPS Format For AWS D1.1 - WPS - SMAWDocument1 pageWPS Format For AWS D1.1 - WPS - SMAWThe Welding Inspections CommunityNo ratings yet

- WPS Flow Proceess Chart PDFDocument1 pageWPS Flow Proceess Chart PDFSatish KeskarNo ratings yet

- WPS PQR-09Document11 pagesWPS PQR-09Ranjan KumarNo ratings yet

- Wps Gmaw SawDocument2 pagesWps Gmaw Sawupedro26No ratings yet

- Welding Procedure Specification Joint Venture: Azzawiya Control System Modernization ProjectDocument4 pagesWelding Procedure Specification Joint Venture: Azzawiya Control System Modernization ProjectwentropremNo ratings yet

- Welding Procedure 6GDocument5 pagesWelding Procedure 6GTrinh DungNo ratings yet

- Manual Structural WeldingDocument12 pagesManual Structural WeldingwalitedisonNo ratings yet

- WPS - 024Document4 pagesWPS - 024MAT-LIONNo ratings yet

- Welder: Craftsmen Training Scheme (CTS) NSQF Level-4Document44 pagesWelder: Craftsmen Training Scheme (CTS) NSQF Level-4Loganathan KNo ratings yet

- Specification Type or Grade AWS Group No. Thickness Size (NPS) Schedule DiameterDocument3 pagesSpecification Type or Grade AWS Group No. Thickness Size (NPS) Schedule Diametercentaury2013No ratings yet

- Weld Repair Rate - MFJO542Document2 pagesWeld Repair Rate - MFJO542Salahuddin Farooqui100% (1)

- Alumana Welder IDDocument7 pagesAlumana Welder IDZuberYousufNo ratings yet

- WPS 316 LDocument4 pagesWPS 316 Llaz_k100% (2)

- Welding Procedure Specification (WPS) Yes PREQUALIFIED - Qualified by Testing - or Procedure Qualification Records (PQR) YesDocument4 pagesWelding Procedure Specification (WPS) Yes PREQUALIFIED - Qualified by Testing - or Procedure Qualification Records (PQR) Yesvarun100% (1)

- JushDocument2 pagesJushg6vhdytsyzNo ratings yet

- Aws N-1 WPS-PQR FormDocument2 pagesAws N-1 WPS-PQR FormEdwin MariacaNo ratings yet

- Wps PQR Aws d11 FormDocument2 pagesWps PQR Aws d11 Formflakosisas100% (1)

- Procedure Qualification Record (PQR) NoDocument3 pagesProcedure Qualification Record (PQR) NoMohamed elrefaeyNo ratings yet

- WPS TemplateDocument1 pageWPS TemplateMatt De Hoog100% (1)

- PQR From D17.1-D17.1M-2010Document1 pagePQR From D17.1-D17.1M-2010Mohammed AzizNo ratings yet

- WPS VarillaDocument2 pagesWPS Varillalabingles89No ratings yet

- Form N3 PDFDocument1 pageForm N3 PDFTavo RojasNo ratings yet

- M 3 D1.1 2015 FormDocument1 pageM 3 D1.1 2015 FormĐỗ Văn ChinhNo ratings yet

- B2.1 B2.1M 2014 Amd1 Procedure Qualification Record PQR PDFDocument2 pagesB2.1 B2.1M 2014 Amd1 Procedure Qualification Record PQR PDFNavanitheeshwaran SivasubramaniyamNo ratings yet

- Welding Procedure Specification (WPS) : JointsDocument2 pagesWelding Procedure Specification (WPS) : JointsNavanitheeshwaran SivasubramaniyamNo ratings yet

- Wps Short FormDocument2 pagesWps Short FormsrinivasanNo ratings yet

- D1.5M D1.5 2015 AMD1 Form O 2 FillableDocument1 pageD1.5M D1.5 2015 AMD1 Form O 2 Fillablevikasphopale1No ratings yet

- L2 WPSDocument1 pageL2 WPSBernardo LeorNo ratings yet

- Form N 2 Sample Welding Procedure SpecificationDocument1 pageForm N 2 Sample Welding Procedure SpecificationViswanath SreepadaNo ratings yet

- WPS - Sample - Form D17.1 D17.1M 2010Document1 pageWPS - Sample - Form D17.1 D17.1M 2010Mohammed AzizNo ratings yet

- Astralloy-V: Abrasion and Impact Resistant, Air Hardened Wear SteelDocument2 pagesAstralloy-V: Abrasion and Impact Resistant, Air Hardened Wear SteelJRodengineerNo ratings yet

- Carbon Equivalency (CE) : C Carbon MN Manganese CR Chromium Mo Molybdenum V Vanadium Ni Nickel Cu Copper Si Silicon P Phosphorous Ti ? NB ? SDocument1 pageCarbon Equivalency (CE) : C Carbon MN Manganese CR Chromium Mo Molybdenum V Vanadium Ni Nickel Cu Copper Si Silicon P Phosphorous Ti ? NB ? SJRodengineerNo ratings yet

- A992 After Fire - Display ArticleDocument4 pagesA992 After Fire - Display ArticleJRodengineerNo ratings yet

- Astm A992 Beam: Submit QueryDocument1 pageAstm A992 Beam: Submit QueryJRodengineerNo ratings yet

- Astralloy-V: Abrasion and Impact Resistant, Air Hardened Wear SteelDocument2 pagesAstralloy-V: Abrasion and Impact Resistant, Air Hardened Wear SteelJRodengineerNo ratings yet

- Binder Template (Side)Document1 pageBinder Template (Side)JRodengineerNo ratings yet

- Chief Quality Officer (CQO)Document2 pagesChief Quality Officer (CQO)JRodengineerNo ratings yet

- AWS J1.1-2013 Resistance Weld. ControlsDocument49 pagesAWS J1.1-2013 Resistance Weld. ControlsJRodengineerNo ratings yet

- 17'-10 In. Bridle ChainDocument2 pages17'-10 In. Bridle ChainJRodengineerNo ratings yet

- Ch-1 Introduction To WeldingDocument26 pagesCh-1 Introduction To WeldingJRodengineer100% (2)

- International Accreditation Service, Inc.: Rules of Procedure For Accreditation of Fabricator Inspection ProgramsDocument4 pagesInternational Accreditation Service, Inc.: Rules of Procedure For Accreditation of Fabricator Inspection ProgramsJRodengineerNo ratings yet

- Acute Right Obtuse Straight Reflex AnglesDocument2 pagesAcute Right Obtuse Straight Reflex AnglesJRodengineerNo ratings yet