Professional Documents

Culture Documents

Song Hong Co., Ltd Welding Procedure Specification

Uploaded by

Trinh DungOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Song Hong Co., Ltd Welding Procedure Specification

Uploaded by

Trinh DungCopyright:

Available Formats

Song Hong Co.

, Ltd

,

SONG HONG CO.,LTD.

Add: 698 Thon:: Nhat Str., Ward 3.

Vung Tau Cit)', S.R. Viet Nam.

Tel: 84 64 3839585 Fax: 84 64 38.19586

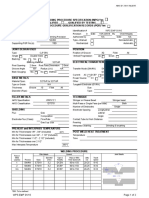

WELDING PROCEDURE SPECIFICA TION(WPS)

~ Email: son2.hong@~hcnL,,'nn."n

ISO 9001:2008

Comp~_!lame

Weldin~J~~oc..:dur.eSpecification No.

Revision No.

Song H0!lK~o., Ltd .__

SH-02-FC-3G

I __ ~~

....J..

Supporting PQR No.

.----. -.-.----.--

__ lJQ/05120~_

----

.---

.. ....

-=C-.--- . PQR-SH-02-FC-3G

By ~g..l.!yen Duc Hanh

d Rev.1

-

.

--

--------_.-

Welding Process(es) FCA W T e(s)' C:~mi - Automatic

yp. (Manual, Semi - Automatic, Machine, Automatic)

Code AWS Dl.l:2010

JOINT

Type

Weld type

Backing

I D~uble- V, Fillet, or any groove detail conforming with

I the requirements oL3.12 or 3.13, excep~ua~!..~ove.

I Full and patical penentration butt welds,

! Fillet welds

Yes

__

I Details

I

'\

~

"I

i/ n

"C" ~~J

(j'?

~ (TRAC'l NHI

Backing Material Weld metal

~

~I

Back Gouging

BASE METALS

--'-'-,

Yes

I

POSITION

---_ ..

~

~07':'

"'1U-T.

._'"------

~terial SEec S355J2G3 or equivalent Welding Position 3G, See table Below

Group I to Group I, Group I to Group II, Welding Progression Uphill It] I Downhill 0

Qualified Metarial

Group II to GrouE II Other - !

Thickness: I CJP I 3 mm to 28 mm P1P/Fillet I All

Diameter (pipe) I I 1 POST WELD HEAT TREATMENT

Other

-_._---_. - ____ ._._.,._ .._ ..__ .._._._.ww .._____ ._. =i~~p'~~~~!!.re

-

Time

---=:L:------------.--.

FILLER METALS FCAW Other I~

AWS Specification A5.20 or A5.29 GAS

AWS Classification E71T-IC or equivalent ~osition Flow Rate

Size of Filler Metal (mm) 1.2,1.6 Shielding_ I C02 99.9% 15 - 20 I/min

J:Y..Eeof Electrode Flux core wire

..- ----- -_ .. Trailing I -

-

Flux - Electrode(Class) -

. -----_._ .._--_ ..

Backing I ------- --_._._._--_.-

Flux - Type - Gas Cup Size 15.8 mm(or 5/8")

Trade Name - Other -

Weld Metal thickness 28 mm Max

-

.-------.-.-----=r----..

-..----.--.------

.. ..--_ ....--.--... ---==r

Other TECHNIQUE

--- String or weave bead I Strin2

PERHEAT _M~~ass ~~~~gJ.~p'as~per sid~...M..':!!!P.~~ _______

!S

Preheat Temperature Min per table 3.2 AWS DJ.l 2010

Number of Electrode

Oscillation

11

-

I

Interpass Temperature Max

Preh.:~~_maintenance Temperature

Method

liii----=--====

I 250°C

Gas heati,!g ___

DistanceC~ntact Tube/Work !,-iece

Method of back gou~ing

15-25mm

I Gouging.pass one

Method of Preparation and Cleaning ! Grinding/BrushinL

Method of Temp. Measurement I Thermometer, tempilstik Other 1-

ELECTRIAL CHARACTERISTICS

I

Pass or

weld I

Welding ..

Filler metal

Size

Type of j

- curent I Amps(A) Voltage

Travel

Speed I Head input I Welding Sequences

I

Layers iI

Process (V) (Kl/mm)

I (mm) Porlarity I

Class mm/min

, i

Root ! FCAW E7IT-IC I 1,2 DCEP -- I 97 - 130 19-22 61.60 ~..!..8~ - 2~"!.2-

-H~--T FCAW ...- E7IT-IC I 1,2 DCEP II 163 - 175 21-25 I 136.36 ___ -L..!.:51-J...93 I

-

Fill ! ----- ----- .•..........I -_._-

FCAW E7IT-IC 1,2 -=QCE~_] 166 - 180 2:~=~~_J. ___ ..25.2~ I~:~!...=~

--.-- -T--

Cap I FCAW _ E7IT-IC

-..-----1--- ----- I

I,~--- DCEP

----

I

---r-----

135-185 _..?.3_~}5

-t.-~Q.2.3....?...::..24~?-9-F

0.76-2.59 I

Tungsten Electrode(GT AW) - Transfer Mode for GMA W -

Power Scoure CC 0 CV 0 A(/;}

tf'S

PQR No: PQR-SH-02-FC-3G Rev.I Page 1 of2

Song Hong Co., Ltd

OTHER

Plate Pi e Box tube

Butt Joint T-. Yo, K- Butt Joint T-, Y., K

Position

F H V 0 H All F H V 0 H All F H V 0 H All F H V 0 H All F H V 0 H All

as table

CJP 0 0000 0 0 0000 0 0 0000 0 0 0000 0 0 0000 0

4.1

pJp 0 0000 0 0 0000 0 00000 0 0 0000 0 0 0000 0

Fillet F 0 H 0 V Ii] OH 0 All 0

CLIENT

Name Name

Signature Signature

Position Position

Date Date

PQR No: PQR-SH-02-FC-3G Rev.1 Page 2 of2

Song Hong Co., Ltd

SONG HONG CO.,LTD.

Add: 6911Thong .'hal Str .• Ward 3.

Vung Tau CiI)', S.R. VI., ~am. PROCEDURE QUALIFICA nON RECORD ( PQR)

1'.1: l\.I 6-13839585 Fax: 846-13839586

Email: 50ng-huog@hcm.\'Dn.\'n

ISO 9001:2008

Company name Song Hong Co., Ltd

Procedure Qualifica.tie>,nRecord No.

,--r---,-"..

"...

,-.--------

PQR-SJ-!-02-FC-3G Rev.l

...

,

.~ Date 0:

01"0512013

..-

pWPS No. SH-FC-STR-3G-Ol Rev.O

Welding Process(es) FCA W , Type(s): I Semi-Automatic ..

~anual, Semi -Automatic, Machine, Automatic)

Code lAWS D1.1:2010

JOINT DESIGN WELDING SEQUENCES

Joint design Single Yee

Backing N/A

Backing

material t.>.]~e

Method

Other

N/A

..~~~__ y_~~_. ._._

_~~.~9~.~

N/A

f W }]

Type Single Vee

BASE METALS POST WELD HEAT TREATMENT

M~erial S;;;-------rEN 10025 ---.-. Temperature

Type or Grade i S355'J2G3 or equivale~t Time

Thickness ' I 14 mm Heating Rate

Test coupon I 500 x 180 mm( L x W) Cooling Rate

Heat No II SB78855 ...

Other

~~etifi.~.~l?n ~? j}-Q.Q.I! ..~:.~~.~-=-O.!!~-OO-I---.--,- ...-.-.

Other !- _ GAS

I Gas(es) Comp-osition Flow Rate

FILLER METALS FCAW Shielding C02 99.9% 15 - 20l/min

AWS Specification A5.20 Trailing-

AWS Classification E 71T-IC _' _ , Backil!g -

Size of Filler Met.~i~'!!l._ 1.2 ...Q.~sC~E...~~._ ....._t -

_T_yp_e_-_E_le_c_tr_o_d_e ..__ !!_ux_c_o_d~wire _ Other I

Flux - Electrode(Class) I- ELECTRICAL CHARACTERISTICS

Flux - Type I- Current AC 0 DC 0 I

Brand - Name ---r

K-71T Polarity DC-EP

Lot No. I 203110 Power Source CC 0 I CY0

~cate No. __" j~12o.3-0204-01 Mode of Metal Tranfer for GMA W

Weld Metal thickness I 14 mm Shorting -Circuiting 0 Globular 0 Spray 0

Other I- Tungsten Electrode Side- Type

POSITION Amps i 97 - 185 Yolts 19 - 25

Welding Position 3G Heat input .l

_Vi elding ..!2~!1l~~~~~_.._ .. ~ p!~i!I. ~ ,..._I?,Cl.~~~!ILg .._,......_,____,Q!he~. L _

Other -

PERHEAT TECHNIQUE

Preheat Temperature Mini 23°C String or Weave Bead I Weaeving no greater than I2mm

Interpass Temperature Max I 250°C Mutipass or Single pass(per side) I Mutipass

_Post-heating ,--,---,---t..:.------.------,- _.~umber of Electrode ~ 1

~reh~_~'!"'f!1~~ten~nc~_!!~e..erature_ ..__ _+-=--------- ...--,- ...9.3~iIlatio_r::

__ ,__ .. I-

Method . ]I..Q~heati'!g Di.stance Cont~!_~~e/Work Piece i 15 - 25mm

Method ofTefl!perature Measu!:.t:ment .Thermometer Method of~~~ration and, Cleaning I Grinding/Brushing_

Other I- Other I - p //.

t/yY

PQR No: PQR-SH-02-FC-3G Rev.l Page I of3

Song Hong Co., Ltd

PROCEDURE QUALIFICATION RECORDS ( PQR)

PQR No. PQR-SH-02-FC-3G Rev. I

Welder name Nguyen Van Hung Stamp No. WD - 0 I

Filler Metal Current Travel Interpass

Weld Volt Heat Input

Layer Process Speed Temperture

Type/ Ampere (V) kJ/mm

pass Class Diameter (mm/min) ( 0c)

Polarity (A)

I FCAW K-7IT 1.2 DCEP 97 - 130 19-22 61.60 1.80 - 2.79 37

LI

- 1.51 - 1.93

I

100

L2 2 FCAW K-7IT 1.2 DCEP 163 - 175 21 -25 136.36

.-

23 -24 95.24 DCEP 166 - 180 2.41- 2.72 130

L3 3 FCAW K-7IT 1.2 _._--_.

DCEP 165 - 185 24 -25 120.97 1.96- 2.29 110

4

---

FCAW

---

K-7IT

----_ 1.2 -_._. "---'--~- ._._--- ----- ._--

L4

__

..

5 FCAW K-7IT 1.2 DCEP 161 - 184

---_ 23 -24 102.39-_._.~...... - 2.17 - 2.59 135

"'R' ___

-- ._..- ._----_. ---_. ... -- .,

6 FCAW K-7IT 1.2 DCEP 135 - 168 23 -24 245.90 0.76 - 0.98 100

L5

7 FCAW K-7IT 1.2 DCEP 137- 148 23 -24 150.00 1.26 - 1.42 205

---- ._-_._._- -_._-_. _.__ ._ _- ---_ _--_

.. .. .. ._----- ._"--_._-- -

-- ----_. --_._---- ------ ----- -

~

-2

" ... _- ~ 'C

'<"..•••

-- ------ _ "------_.- -----

.. ------ ._,--- ---- IY '1

--- -- -----_. -------- ----- _._---_.__

. ----- ._----_ .... ------ "._- ' l.Iill H~N

TTr:,. "1

HV1I •.•

I"

..;:

-----:

:on

_. -:::;

--

----- ----_. --

---- ---- ---_._--- ----- ._----_.

.. .. _

_._._-_. __ _._---_.- ---,-_._--- -.__ ._--_ _-_.," ._- ....._ ... ....__ .__ .._--_. -_ .... __ ._.- .._._-"--_.-_. __ - _._

... .... _. ----_. __ _ .. ..........

__

----- --,-- --_. . --_._--_. _.__ ._--_. -_._---- _ ... __ ._--

.-

--_ ..__ . _--_.- ---_._._--

...

-'--- -_ .._- -----. -_ _ .._._ ..._-- _. __ ._----_._. -----_.

... ---_._ --_.__ . _._---~-_._-_..~.-

.. ...~.---_._--_.

---- --- ---- ------_. -----_. -'-_ _-

-- _--

.. .. _._--- --------

CLIENT CA(DNV)

Name Name

Signature Signature

Position Position

Date Date

PQR No: PQR-SH-02-FC-3G Rev.1 Page 2 of3

Song Hong Co" Ltd

PROCEDURE QUALIFICATION RECORDS (PQR)

TEST RESULTS

POR No' POR-SH-02-FC-3G Rev 1

MECHANICAL

Tensile Tests

S '

p~:en

12.137.18

d TESTING

Dimension

Thk x Width (mm)

13.3 x 19.9 265.0

Temperature: (23 + 5) DC

---

UI~imate

TensIle Load

~N)

-_.-_

154.8

••

I UltimateTensil~

---.-----

S

tress

(MP )

a

585.0

Humidity

Fracture LocatIon

._--

Base metal

(55 + 5) %RH

~I

I

Result

Accepted

12.137.19 I 13.6 x 19.9 271.0 154.6 57\.0 Base metal Accepted

Bend Tests

Former diameter: 50.8mm

I

Specimen No.

Dimension

(Width x Thk. mm)

Type of Bend J'i Bend Angle

(D)

Result Rmarks

.. _-------_ ..... - 111

12.137.20 13x10 Side bend 180 Accepted

12.137.21 13 x 10 Side bend 180 Accepted

12.137.22 13 x 10 I Side bend 180 Accepted

12.137.23 13 x 10 Side bend 180 Accepted

Impact Tests Type: Transverse specimen Requirement: Min. Average

Min. Individual

i

Impact Value (1)

Specimen No V-Notch location

Specimen Temp. I Average

Remarks

Size (mm) (DC) (J)

I 2 3

I

12.137.26 + 28 Weld Metal 10 x 10 -20 ! 50.9 56.7 46.0 5\.2

.---::20-t 107.6--'

~._-_ 97.8

12.137.72.;.74

12.137.29+31

Fusion Line

Fusion Line +1

10 x 10

10 x 10 -20 I 176.1

... _--_.-

190,8

78.3

176.1

94.6

181.0

1-

,

i

12.137.32 + 34 I Fusion Line + 5 10 x 10 -20

1 137.0 18\.0 200.5 172.8

I

Macroscopic Examination -)

Specimen No : Dimension (mm) Result

-------_._-----_

12.137.25

..

N/A -I --_._-----

Accepted

Hardness tests Type/load: Test load 10kg Specimen No: 12.137.24

Heat Affect

Line Base Metal Heat Affect Zone(HAZ) Weld metal Base Metal

I Zone(HAZ)

A 206 210;248;280 I 233;220;231 300;273;242 202

B 209 210;240;320 rn2; 244; 242 327;278;234 195

Other test-

Test Conducted by VSP - OCD Lab (VILAS 184) Laboratory Test No: 12.137.2/4

NON-DESTRUCTIVE TESTING

Visual Inspection Radiograpic/Utrasonic examination

Result Accepted RT Report No: CA-12/074-RT-02 Result: Accepted

Test date 28/09/0212 Test Conducted by: : CA NOT Co., Ltd

Witnessed by DNV Penetrant/Magnetic Praticle

Other tests MPI Report No: .

Test conduted by Result:

Welder's name Nguyen Van Hung Stamp No. : WD - 01

Acceptance Standard AWS Dl.I:2010 ~

Manufacture Of Contractor Som'HonlJ Co/l'tlt" ~~

Date of test Certified by ~ 1¥IQA/QC ~)

Pham Van Do - QNQC Manager ~ .• /,jl

PQR No: PQR-SH-02-FC-3G Rev.l Page 3 of3

You might also like

- ASME IX-Welder Performance Qualification (WPQ) : Welding and NDT Purposed FormatDocument1 pageASME IX-Welder Performance Qualification (WPQ) : Welding and NDT Purposed FormatArshadAliNo ratings yet

- CMG STARS Guide PDFDocument1,136 pagesCMG STARS Guide PDFAastha91% (11)

- Sample API 1104 WpsDocument3 pagesSample API 1104 WpsMuhammadShabbir0% (1)

- WPS Api 1104Document3 pagesWPS Api 1104miguelNo ratings yet

- WPS List For Piping: (Asme Section Ix)Document2 pagesWPS List For Piping: (Asme Section Ix)Ali MoosaviNo ratings yet

- Stainless steel welding procedure qualification recordDocument1 pageStainless steel welding procedure qualification recordchandraNo ratings yet

- PQR Sample PrintoutDocument2 pagesPQR Sample PrintoutDhewo Rachmad Yansyah100% (3)

- RT Acceptance Para. 9.4Document4 pagesRT Acceptance Para. 9.4Yan Ferizal100% (1)

- PQR 01 PDFDocument2 pagesPQR 01 PDFVijay BhaleraoNo ratings yet

- Welder Qualification Test Certificate: Weld Test Details Range of ApprovalDocument1 pageWelder Qualification Test Certificate: Weld Test Details Range of ApprovalRamkunwar YadavNo ratings yet

- I-963 Welder Certificate Smaw-Gtaw-1Document1 pageI-963 Welder Certificate Smaw-Gtaw-1nivedithdigitals onlineservices100% (1)

- Dobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingDocument3 pagesDobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingBiswajit DeyNo ratings yet

- Welder Qualification Test RequestDocument1 pageWelder Qualification Test RequestgoguluNo ratings yet

- Dep 30.10.60.32 - Welding of Metals, Based On Iso StandardsDocument76 pagesDep 30.10.60.32 - Welding of Metals, Based On Iso StandardsPablo PazNo ratings yet

- Sample API 1104 WpsDocument1 pageSample API 1104 Wpsippon_osoto100% (1)

- Poposed Welding Procedure Specification (PWPS) : ASME Section IX, ASME Boiler and Pressure Code Ed.2015Document12 pagesPoposed Welding Procedure Specification (PWPS) : ASME Section IX, ASME Boiler and Pressure Code Ed.2015MulPXNo ratings yet

- API Recommended Practice 2SIM: Structural Integrity Management of Fixed Offshore StructuresDocument4 pagesAPI Recommended Practice 2SIM: Structural Integrity Management of Fixed Offshore StructuresTrinh Dung0% (1)

- Welding Procedure 6GDocument5 pagesWelding Procedure 6GTrinh DungNo ratings yet

- ASME IX QW (Welding General Requirements)Document12 pagesASME IX QW (Welding General Requirements)Ariq Fauzan100% (1)

- Guided Bend Test Jig Dimension ASME 9Document3 pagesGuided Bend Test Jig Dimension ASME 9esamhamad50% (2)

- AWS D1.1 (2020) - Essential Variable For WPS & WeldersDocument7 pagesAWS D1.1 (2020) - Essential Variable For WPS & WeldersFouad OudinaNo ratings yet

- WPS Steps of MakingDocument51 pagesWPS Steps of MakingSaut Maruli Tua Samosir100% (1)

- 004 Gtaw P5aDocument16 pages004 Gtaw P5aMuhammad Fitransyah Syamsuar Putra100% (1)

- Procedure Qualification Record (PQR) : Jl. Brigjend Katamso KM 5.6 Tanjung Uncang - Batam IndonesiaDocument2 pagesProcedure Qualification Record (PQR) : Jl. Brigjend Katamso KM 5.6 Tanjung Uncang - Batam IndonesiaMulPXNo ratings yet

- STD 1104 - Welding of Pipelines and Related FacilitiesDocument38 pagesSTD 1104 - Welding of Pipelines and Related FacilitiesGishnu SunilNo ratings yet

- Aws d1.1 Tubular Vs Non TubularDocument1 pageAws d1.1 Tubular Vs Non TubularrendraNo ratings yet

- Welder Qualification Form for Rana Pratap ChouhanDocument1 pageWelder Qualification Form for Rana Pratap ChouhanMahendra singhNo ratings yet

- IRATA Rope Access Training and Qualification Requirements R1Document9 pagesIRATA Rope Access Training and Qualification Requirements R1Trinh Dung100% (1)

- Sample API 1104 WpsDocument6 pagesSample API 1104 Wpsjacquesmayol100% (2)

- 1 5 1Document5 pages1 5 1daemsalNo ratings yet

- Wps Emp 01-16 s275jr - s275jr BW P Smaw Awsd1 1Document2 pagesWps Emp 01-16 s275jr - s275jr BW P Smaw Awsd1 1Touil HoussemNo ratings yet

- WPS Resrvoire Sous Pression Smaw SawDocument6 pagesWPS Resrvoire Sous Pression Smaw SawDanem HalasNo ratings yet

- Lab Manual Rock & AggregateDocument75 pagesLab Manual Rock & AggregateBatepola BacNo ratings yet

- Finite Element Method Chapter 4 - The DSMDocument17 pagesFinite Element Method Chapter 4 - The DSMsteven_gogNo ratings yet

- Wps 1010 IfrDocument28 pagesWps 1010 IfrSyed Mahmud Habibur RahmanNo ratings yet

- WPQ-1083 3G PDFDocument2 pagesWPQ-1083 3G PDFduendex360100% (1)

- WPS Pipe 08'' SHD 40 SMAW REV02Document2 pagesWPS Pipe 08'' SHD 40 SMAW REV02Amine MaalejNo ratings yet

- Medieval Warm Period RussiaDocument13 pagesMedieval Warm Period RussiaAntiKleptocratNo ratings yet

- Symbol of Weld PDFDocument28 pagesSymbol of Weld PDFSyarif IrwantoNo ratings yet

- Major equipment failures causing shut-downs in ammonia plantsDocument17 pagesMajor equipment failures causing shut-downs in ammonia plantsrobertionNo ratings yet

- PQR Is7307Document1 pagePQR Is7307Tridib Dey100% (1)

- WPS PQR PDFDocument23 pagesWPS PQR PDFtomj9104No ratings yet

- Earthquake Resistant Design of StructuresDocument36 pagesEarthquake Resistant Design of StructuresghchgNo ratings yet

- Offshore Containers Guide E-Dec17Document83 pagesOffshore Containers Guide E-Dec17Kelvin XuNo ratings yet

- Welding Procedure Specification for SMAW of Carbon Steel Butt JointsDocument2 pagesWelding Procedure Specification for SMAW of Carbon Steel Butt JointstayyabNo ratings yet

- Quiz 1 - Group 1Document5 pagesQuiz 1 - Group 1Kim OpenaNo ratings yet

- Control of Welding Rejection Rate and NDT Backlog in MEGA ProjectDocument10 pagesControl of Welding Rejection Rate and NDT Backlog in MEGA ProjectMubeenNo ratings yet

- Mohamed Ashim: Mechanical InspectorDocument5 pagesMohamed Ashim: Mechanical InspectorMad TahaNo ratings yet

- 6GR RequirementsDocument1 page6GR Requirementswalitedison100% (1)

- Aws D1.1 - WPS - Smaw-Fcaw PDFDocument1 pageAws D1.1 - WPS - Smaw-Fcaw PDFThe Welding Inspections CommunityNo ratings yet

- WPS & PQR (E Co Cr-E)Document3 pagesWPS & PQR (E Co Cr-E)HossamSAshourNo ratings yet

- WPS - Api 5L X52 - Codigo Api1104Document1 pageWPS - Api 5L X52 - Codigo Api1104Cristhian Camilo Quiroga WalterosNo ratings yet

- WPQ WELDER QUALIFICATION 16MM PLATE SMAWDocument1 pageWPQ WELDER QUALIFICATION 16MM PLATE SMAWniket0No ratings yet

- WPQ Sample PrintoutDocument1 pageWPQ Sample PrintoutKannan VelNo ratings yet

- Weld Summary: SATIP-W-011-01 SATR-W-2008 30/apr/13 19/04/2020Document3 pagesWeld Summary: SATIP-W-011-01 SATR-W-2008 30/apr/13 19/04/2020bishalNo ratings yet

- Sample Forms WPS PQRDocument22 pagesSample Forms WPS PQRGMNo ratings yet

- B H e L Limited RTDocument13 pagesB H e L Limited RTbhavin17850% (2)

- Sample WPS 1Document13 pagesSample WPS 1waqas pirachaNo ratings yet

- Welding Procedure Specification For GTAW & GMAWDocument4 pagesWelding Procedure Specification For GTAW & GMAWanh thoNo ratings yet

- PFI ES-1-1992 Internal Machining and Solid Machined Backing Rings For Circumferential Butt Welds PDFDocument8 pagesPFI ES-1-1992 Internal Machining and Solid Machined Backing Rings For Circumferential Butt Welds PDFfatapia74No ratings yet

- PT Kuwera Karya Me: PanduDocument2 pagesPT Kuwera Karya Me: PanduGalang Pratama PutraNo ratings yet

- Welding SA210 GR CDocument2 pagesWelding SA210 GR Cabet_singkong8930No ratings yet

- OCS Engineering & Construction Visual Inspection ReportDocument1 pageOCS Engineering & Construction Visual Inspection ReportvinothNo ratings yet

- 625 CRO - SAW Study - Final Report PDFDocument21 pages625 CRO - SAW Study - Final Report PDFAnouar AbdelmoulaNo ratings yet

- PQR - 152Document3 pagesPQR - 152MAT-LIONNo ratings yet

- QW-403 6Document1 pageQW-403 6Solikhul HarisNo ratings yet

- D1.5M D1.5 2015 AMD1 Form O 2 FillableDocument1 pageD1.5M D1.5 2015 AMD1 Form O 2 Fillablevikasphopale1No ratings yet

- Name:Murat First Name (S) : WPQ N°: TUR-18-A-931: Essential Variables (QW - 350) Actual Values Qualified Ranges QWDocument2 pagesName:Murat First Name (S) : WPQ N°: TUR-18-A-931: Essential Variables (QW - 350) Actual Values Qualified Ranges QWSabit CirdiNo ratings yet

- Wa0017Document6 pagesWa0017Yaman KomaeniNo ratings yet

- Vector Part 1Document25 pagesVector Part 1Rishi KaulNo ratings yet

- Pdfs 2Document169 pagesPdfs 2Shayan AliNo ratings yet

- Adobe Scan 20 Jul 2023Document4 pagesAdobe Scan 20 Jul 2023Seenam SiddiquiNo ratings yet

- Maintain Reciprocating CompressorsDocument4 pagesMaintain Reciprocating CompressorsCarlos MantillaNo ratings yet

- Carbothane 134 HG PDSDocument4 pagesCarbothane 134 HG PDSAnhera enterpriseNo ratings yet

- No-Skive: 421SN & 301SNDocument2 pagesNo-Skive: 421SN & 301SNTrinh DungNo ratings yet

- U2VG Model - Alco - Valves - Technical Spec.Document2 pagesU2VG Model - Alco - Valves - Technical Spec.Trinh DungNo ratings yet

- MLOG GX CMXA75 v4.05 322985e0 UM-EN PDFDocument342 pagesMLOG GX CMXA75 v4.05 322985e0 UM-EN PDFGandalf cimarillonNo ratings yet

- Certifies 1Document1 pageCertifies 1Trinh DungNo ratings yet

- Commercial Driver's Guide to Operation SafetyDocument122 pagesCommercial Driver's Guide to Operation SafetyTrinh DungNo ratings yet

- Detect magnetic particles with white paintDocument2 pagesDetect magnetic particles with white paintTrinh DungNo ratings yet

- Operation ManualDocument26 pagesOperation ManualengharshNo ratings yet

- Manual-Trunnion Ball ValvesDocument12 pagesManual-Trunnion Ball ValvesTrinh DungNo ratings yet

- Modco Brochure (Figure 500) - Customer Version (3MG) PDFDocument8 pagesModco Brochure (Figure 500) - Customer Version (3MG) PDFTrinh DungNo ratings yet

- Valve Material Specifications: Forged Cast Key Physical PropertiesDocument1 pageValve Material Specifications: Forged Cast Key Physical PropertiesTrinh DungNo ratings yet

- List of Safefsdfty StudyDocument1 pageList of Safefsdfty StudyTrinh DungNo ratings yet

- N 9-32312E General Tolerances For Linear and Angular DimensionsDocument4 pagesN 9-32312E General Tolerances For Linear and Angular DimensionsArlindo CrispimNo ratings yet

- Solution For Tutorial ECH3602Document23 pagesSolution For Tutorial ECH3602Prem KumarNo ratings yet

- Newton's Laws WorksheetDocument2 pagesNewton's Laws Worksheetwade aryanNo ratings yet

- PQ 0802004769Document6 pagesPQ 0802004769alveirohmNo ratings yet

- Mass Transfer Fundamentals: Diffusion CoefficientDocument23 pagesMass Transfer Fundamentals: Diffusion CoefficientAbdur RehmanNo ratings yet

- SA LabDocument10 pagesSA LabArunendra PratapNo ratings yet

- M24 - Thermodynamic PropertiesDocument38 pagesM24 - Thermodynamic Propertieshoghost123No ratings yet

- Viscoplastic Deformation Behaviour of Preloaded Stainless Steel ConnectionsDocument10 pagesViscoplastic Deformation Behaviour of Preloaded Stainless Steel ConnectionsfankenstainNo ratings yet

- Tutorial FastenersDocument2 pagesTutorial FastenersKrm LeoNo ratings yet

- ND: YAG Laser (Yttrium Aluminium Garnet) : (J. E. Geusic Et Al. at Bell Laboratories in 1964)Document32 pagesND: YAG Laser (Yttrium Aluminium Garnet) : (J. E. Geusic Et Al. at Bell Laboratories in 1964)KARTHIKEYA REDDY B SNo ratings yet

- EVAPORATIONDocument11 pagesEVAPORATIONEmmanuel AtakosNo ratings yet

- Recycle PTQDocument6 pagesRecycle PTQremsorNo ratings yet

- KAT7100-0004-E Motor Driven Reels MAG DriveDocument20 pagesKAT7100-0004-E Motor Driven Reels MAG DriveJan IulianNo ratings yet

- Experiment No 2Document5 pagesExperiment No 2saish sakharkarNo ratings yet

- Fourth Year Class: University of Baghdad College of Engineering Department of Civil EngineeringDocument19 pagesFourth Year Class: University of Baghdad College of Engineering Department of Civil Engineeringعبدالله ماجد عامر زغير-B-No ratings yet

- EN1101 - MJE - Part 9 - Phase Diagrams - LCDocument17 pagesEN1101 - MJE - Part 9 - Phase Diagrams - LCnwankwo chubyNo ratings yet

- Synthesis of High Temperature Superconductor Using Citrate Pyrolysis and Observing The Meissner EffectDocument10 pagesSynthesis of High Temperature Superconductor Using Citrate Pyrolysis and Observing The Meissner EffectKufun CocinaNo ratings yet

- Pipe Expansion and Support - International Site For Spirax SarcoDocument8 pagesPipe Expansion and Support - International Site For Spirax SarcoSandi ApriandiNo ratings yet

- Chemical Properties of Soil: pH, CEC & PZCDocument17 pagesChemical Properties of Soil: pH, CEC & PZCHasnat QureshiNo ratings yet

- Numerical Modeling of Geosynthetic-Encased Stone Column-Reinforced GroundDocument11 pagesNumerical Modeling of Geosynthetic-Encased Stone Column-Reinforced GroundPMHNo ratings yet

- 4 Concrete Pavement Monitoring With PPP BOTDA Distributed Strain and Crack SensorsDocument21 pages4 Concrete Pavement Monitoring With PPP BOTDA Distributed Strain and Crack Sensorsabdulsalam yousifNo ratings yet

- Air Cooling System Components and OperationDocument10 pagesAir Cooling System Components and OperationAK KHANNo ratings yet