Professional Documents

Culture Documents

Menghitung Roof Ceiling Reflection

Menghitung Roof Ceiling Reflection

Uploaded by

Riski SaraswatiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Menghitung Roof Ceiling Reflection

Menghitung Roof Ceiling Reflection

Uploaded by

Riski SaraswatiCopyright:

Available Formats

LIGHTING DESIGN LIGHTING LEVEL CALCULATIONS

The Zonal Cavity approach to calculate average illumination levels is based on the concept

of dividing any room into three cavities. (1) The space between the ceiling and the luminaires is the ceiling cavity. (2) The space between he luminaires and the work plane is the

room cavity. (3) The space between the work plane and the floor is the floor cavity.

Room Cavity = Volume bounded by walls, luminaire plane and work plane.

hrc = height of room cavity.

Cavity Ratio = Dimensions of Cavity Expressed as Mathematical Relationship;

RCR = Room Cavity Ratio;

CCR = Ceiling Cavity Ratio;

FCR = Floor Cavity Ratio;

Room Cavity Ratio (RCR)

RCR =

5 hrc (L+W)

10 hrc

For Square Rooms RCR =

LxW

2.5 (Cavity Height x Cavity Perimeter)

For Irregular

Shaped Rooms RCR =

Room Surface Reflectances:

pc = Ceiling

pw = Walls

pf = Floor

(L=W)

Area of Cavity Base

Ceiling Cavity Ratio (CCR)

Effective Cavity Reflectances:

The combination of actual reflectances within a given cavity into one reflectance at the

face of the cavity.

pcc = Effective Ceiling Cavity Reflectance

pfc = Effective Floor Cavity Reflectance

5 hcc (L+W)

CCR =

LxW

= RCR

hfc

hrc

Floor Cavity Ratio (FCR)

5 hfc (L+W)

hfc

FCR =

= RCR

LxW

hrc

Coefficient of Utilization: (CU)

Portion of lamp lumens which reach the work plane. Affected by fixture design, room pro- For square rooms or irregular rooms calculate RCR then use the ratio of the cavity heights

portions, and room-surface reflectances.

to determine CCR and FCR.

Light Loss Factor: (LLF)

The approximate average illumination level or number of luminaires may be calculated as

Depreciation of initial lighting level due to Lamp Lumen Depreciation (LLD) and accumulafollows:

tion of dirt on the lamp and luminaire surface (Luminaire Dirt Depreciation LDD).

1. Determine Room Cavity Ratio (RCR)

Affected by fixture design, lamp choice, number of burning hours and type of interior.

2. Determine Reflectances

Ballast Factor: (BF)

The commercial ballast performance relative to reference ballast.

Typical approximate reflectances:

Other Factors:

See IES Lighting Handbook for recurring and non-recurring factors that lead to still greater

accuracy, including the determination of effective cavity reflectances.

Ceiling:

Standard White Paint

Rough White Pain

Rough Light Paint

80%

50%

30%

Walls:

White Paint

Rough Light Paint

80%

30%

Floors:

Dark Concrete

Carpet Average

20%

15%

3. Find Coefficient of Utilization

Knowing the ceiling. walls and floor reflectances and the room cavity ratio (calculated

in step 1), the coefficient of utilization may be found from the manufacturers published

data or typical data found in the current IES Handbook. See Table 1 below for example.

For a room cavity ratio of1.0 and reflectances of 30 (ceiling), 30 (wall), and 20 (floor) the

CU equals 0.63 for this luminaire.

W = Room Width

L = Room Length

Ceiling Cavity = Volume bounded by walls, ceiling and luminaire plane.

hcc = height of ceiling cavity. *For surface mounted or recessed fixtures

4. Compute Average Footcandle Level or Number of Luminaires using formulas A and/or B.

hcc = 0.

Floor Cavity = Volume bounded by walls. floor and work plane.

hfc = height of floor cavity.

B.Maintained

A.Number of

(Maintained Illuminance (FC) Desired) x (Area in Square Feet)

Illuminance (Number of Luminaires) x (Lamp Lumens Per Luminaire) x (CU) x (LLD) x BF)

Luminaires =

(Lamp Lumens/Luminaire) x (CU) x (LLD) x (BF)

(Area in Square Feet)

(FC) =

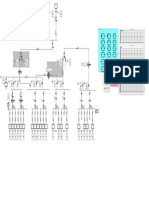

COEFFICIENTS OF UTILIZATION FOR 20 PERCENT EFFECTIVE FLOOR CAVITY REFLECTANCE

Effective Ceiling

Cavity Reflectance

Wall Reflectance

80

50

30

70

10

Room Cavity

1

2

3

4

5

6

7

8

9

10

50

30

50

10

50

30

30

10

10

50

30

10

50

30

10

65

57

49

43

37

33

29

26

24

21

63

53

45

38

32

28

24

21

19

16

61

50

41

34

28

24

20

17

15

12

62

54

47

41

36

32

28

25

23

20

61

51

43

36

31

27

23

20

18

15

59

48

40

33

27

23

20

17

15

12

57

47

38

31

26

22

18

15

13

10

COEFFFICIENTS OF UTILIZATIONZONAL CAVITY

75

64

56

48

42

37

33

29

26

23

71

59

49

41

35

30

26

22

20

17

68

54

44

36

30

25

21

18

15

12

73

63

54

47

41

36

32

29

26

23

69

58

48

40

34

30

25

22

20

17

66

53

43

35

29

25

21

18

15

12

69

60

52

45

39

35

31

27

25

22

66

55

47

39

33

29

25

21

19

16

64

51

42

35

29

24

20

17

15

12

See manufacturers published data for actual coefficients of utilization.

T 12

1/98

You might also like

- Zonal Cavity Method For Indoor CalculationsDocument3 pagesZonal Cavity Method For Indoor CalculationsJoniel Rosal Jayag80% (5)

- Artificial Lighting CalculationDocument40 pagesArtificial Lighting CalculationSonisha Aryal100% (1)

- LED Technology Presentation (Rev Kuwait)Document63 pagesLED Technology Presentation (Rev Kuwait)AV Shrinivas100% (3)

- Cahier Technique: Discrimination With LV Power Circuit BreakersDocument10 pagesCahier Technique: Discrimination With LV Power Circuit BreakersAsanka RodrigoNo ratings yet

- 1-Lumen Method PDFDocument11 pages1-Lumen Method PDFRADHIKANo ratings yet

- TransLine 1 ConclusionDocument2 pagesTransLine 1 ConclusionmultisporkyNo ratings yet

- Illumination AdditionalDocument80 pagesIllumination Additionalbutohpakang100% (1)

- Lumen MethodDocument11 pagesLumen Methodgiziew belay100% (1)

- 10 Lighting - CU and CR CalculationDocument28 pages10 Lighting - CU and CR CalculationNatalie CorpuzNo ratings yet

- Zonal Cavity CalcDocument23 pagesZonal Cavity Calcmaulia farahNo ratings yet

- Zonal Cavity Method For Calculating The Number of Lamps in An AreaDocument9 pagesZonal Cavity Method For Calculating The Number of Lamps in An AreaAbdulyekini Ahmadu100% (1)

- Lighting: CHAPTER - 1: Building Electrical Installation CalculationDocument13 pagesLighting: CHAPTER - 1: Building Electrical Installation CalculationMr NobodyNo ratings yet

- Supplementary ProblemsDocument3 pagesSupplementary Problems白銀0% (1)

- 2 - Low Intensity Discharge Lamps Part 3Document41 pages2 - Low Intensity Discharge Lamps Part 3Miko F. RodriguezNo ratings yet

- Chapter 3Document19 pagesChapter 3Lëlîså DébālkéNo ratings yet

- Electric LightingDocument10 pagesElectric LightingSarah FrazierNo ratings yet

- IlluminationDocument43 pagesIlluminationlee robert olivar67% (3)

- Illumination Engineering: Utilization, Traction, Heating & Drives - Unit-1Document59 pagesIllumination Engineering: Utilization, Traction, Heating & Drives - Unit-1suvo dasNo ratings yet

- ILLUMINATIONDocument12 pagesILLUMINATIONjohncedrixbNo ratings yet

- Calculate Lighting Fixture's Beam Angle and Lumen - Electrical Notes & ArticlesDocument5 pagesCalculate Lighting Fixture's Beam Angle and Lumen - Electrical Notes & ArticlesRahul ItaliyaNo ratings yet

- Lighting Design by Lumen MethodDocument11 pagesLighting Design by Lumen MethodAmos Korme100% (1)

- Zonal CavityDocument32 pagesZonal CavityarkidechNo ratings yet

- Zonal Cavity & Lumen MethodDocument36 pagesZonal Cavity & Lumen MethodAnanda DuttaNo ratings yet

- Illumination EngineeringDocument7 pagesIllumination EngineeringSumit GawareNo ratings yet

- Illumination NotesDocument16 pagesIllumination NotesANIL KUMAR100% (1)

- Thesis of JhoweeDocument25 pagesThesis of JhoweeTrüth SeekerNo ratings yet

- 0501 Eu1 RJR PPT IllumDocument17 pages0501 Eu1 RJR PPT IllumAlexNo ratings yet

- Lumen Method Lighting CalculationDocument9 pagesLumen Method Lighting CalculationAdisuNo ratings yet

- Lighting DesignDocument2 pagesLighting DesignKhay SaadNo ratings yet

- Zonal Cavity RatioDocument3 pagesZonal Cavity RatioPrecious AdeboboyeNo ratings yet

- Calculations and The Laws of IlluminationDocument3 pagesCalculations and The Laws of Illuminationbrijesh varshneyNo ratings yet

- IlluminationDocument130 pagesIlluminationsavvymovNo ratings yet

- Interior Lighting: M CM V FDocument33 pagesInterior Lighting: M CM V FHassen LazharNo ratings yet

- AdU Illumination Problem Set 1Document1 pageAdU Illumination Problem Set 1Andrew NibungcoNo ratings yet

- Solar GeometryDocument55 pagesSolar GeometrySwamy Venkata Udayagiri100% (2)

- Statistical Intervals For A Single SampleDocument31 pagesStatistical Intervals For A Single SampleBui Tien DatNo ratings yet

- Low Intensity Discharge Lamps: Group 1Document69 pagesLow Intensity Discharge Lamps: Group 1Ronald James DiazNo ratings yet

- Swes Unit 3Document64 pagesSwes Unit 3pradeepNo ratings yet

- Light System and Design Calculations ExampleDocument9 pagesLight System and Design Calculations ExampleMark Anthony GarciaNo ratings yet

- Lighting Design BasicsDocument25 pagesLighting Design BasicsPooja PundeerNo ratings yet

- Chapter 12Document9 pagesChapter 12m_michael_cNo ratings yet

- Lighting Building Service SystemsDocument5 pagesLighting Building Service SystemsPrincess Morales TyNo ratings yet

- Lecture Notes For Illumination EngineeringDocument30 pagesLecture Notes For Illumination EngineeringVishal Narkhede83% (12)

- Lecture - 4 - Artificial - Lighting - CalculationDocument40 pagesLecture - 4 - Artificial - Lighting - Calculationsamuel seyoumNo ratings yet

- Revision Qns 2Document1 pageRevision Qns 2Colesha BarukaNo ratings yet

- D'Alembert's Principle: REF Ma REF W GDocument2 pagesD'Alembert's Principle: REF Ma REF W GGianne Karl AlmarinesNo ratings yet

- Chapter 2Document23 pagesChapter 2Melkamu BirlewNo ratings yet

- Elementary Idea of The Special Features Required andDocument13 pagesElementary Idea of The Special Features Required andnikhil100% (1)

- FinalDocument21 pagesFinalMohammed Arshad AliNo ratings yet

- Lumen Method: Illuminance: The Quantity of Light Reaching A Certain Surface. It'sDocument15 pagesLumen Method: Illuminance: The Quantity of Light Reaching A Certain Surface. It'sSarah Al-MutlaqNo ratings yet

- Sheet2 - SolutionsDocument17 pagesSheet2 - SolutionsMöstafa MohamedNo ratings yet

- Engineering Mechanics (Statics) : A B A B A B BDocument2 pagesEngineering Mechanics (Statics) : A B A B A B BMallene EhurangoNo ratings yet

- SolutionDocument9 pagesSolutionDaaniyyee Abdiisaa100% (1)

- VejigDocument2 pagesVejigMiner TPNo ratings yet

- Zonal Cavity Method: Laguna State Polytechnic University Sta Cruz, LagunaDocument12 pagesZonal Cavity Method: Laguna State Polytechnic University Sta Cruz, LagunaEeeeeeNo ratings yet

- GROUP-9 - 2.8-Lighting Application and Design (REVISED)Document58 pagesGROUP-9 - 2.8-Lighting Application and Design (REVISED)Von ToledoNo ratings yet

- Reading The CU TableDocument1 pageReading The CU TableelectworldNo ratings yet

- Lumen Man!Document18 pagesLumen Man!bukit_guestNo ratings yet

- Lighting Calculation PresentationDocument9 pagesLighting Calculation PresentationSuhandri AndryNo ratings yet

- Cavity Method VirtudazoDocument25 pagesCavity Method VirtudazoJoshua TupasNo ratings yet

- Lumen Method Calculation WorksheetDocument1 pageLumen Method Calculation WorksheetDonald Gabriel100% (1)

- 10 Piano-2023-2024-Grade-1Document1 page10 Piano-2023-2024-Grade-1Asanka RodrigoNo ratings yet

- 7 Piano-2023-2024-Grade-1Document1 page7 Piano-2023-2024-Grade-1Asanka RodrigoNo ratings yet

- 6 Piano-2023-2024-Grade-1Document1 page6 Piano-2023-2024-Grade-1Asanka RodrigoNo ratings yet

- 2 Piano-2023-2024-Grade-1Document1 page2 Piano-2023-2024-Grade-1Asanka RodrigoNo ratings yet

- Transportation Research Procedia 25 (2017) 4529-4543Document1 pageTransportation Research Procedia 25 (2017) 4529-4543Asanka RodrigoNo ratings yet

- 3 Discrimination With Power Circuit-BreakersDocument9 pages3 Discrimination With Power Circuit-BreakersAsanka RodrigoNo ratings yet

- Techno-Economic Analysis of Intermittent Renewable Energy Penetration With The Proposed India-Sri Lanka HVDC InterconnectionDocument13 pagesTechno-Economic Analysis of Intermittent Renewable Energy Penetration With The Proposed India-Sri Lanka HVDC InterconnectionAsanka RodrigoNo ratings yet

- 4 Examples of Circuit-Breaker Selections For An LV InstallationDocument9 pages4 Examples of Circuit-Breaker Selections For An LV InstallationAsanka RodrigoNo ratings yet

- SL Energy Policy 2019Document3 pagesSL Energy Policy 2019Asanka RodrigoNo ratings yet

- Color Measurements: RGB Value Tristimulus Value Chromaticity Coordinate CCTDocument3 pagesColor Measurements: RGB Value Tristimulus Value Chromaticity Coordinate CCTAsanka RodrigoNo ratings yet

- Lightning: 1% of Strokes Exceed 200 KaDocument1 pageLightning: 1% of Strokes Exceed 200 KaAsanka RodrigoNo ratings yet

- Colorimetry & StandardsDocument4 pagesColorimetry & StandardsAsanka RodrigoNo ratings yet

- Radiant Energy: Capable of Exciting The Retina and Producing A Visual SensationDocument1 pageRadiant Energy: Capable of Exciting The Retina and Producing A Visual SensationAsanka RodrigoNo ratings yet

- Transient Over VoltagesDocument5 pagesTransient Over VoltagesAsanka RodrigoNo ratings yet

- Semester 1: Curriculum - B.Sc. Engineering Honours in Electrical EngineeringDocument3 pagesSemester 1: Curriculum - B.Sc. Engineering Honours in Electrical EngineeringAsanka RodrigoNo ratings yet

- Non Linear Model For Bi-Color LED: Two LED Sets From Two Different Colors Warm White and Cool WhiteDocument4 pagesNon Linear Model For Bi-Color LED: Two LED Sets From Two Different Colors Warm White and Cool WhiteAsanka RodrigoNo ratings yet

- RH TechPaperIESL Oct06Document9 pagesRH TechPaperIESL Oct06Asanka RodrigoNo ratings yet

- 1-2006Document8 pages1-2006Asanka RodrigoNo ratings yet

- Writing Tips: Thesis: Which SectionsDocument4 pagesWriting Tips: Thesis: Which SectionsAsanka RodrigoNo ratings yet

- The Benefits of Applying 61000-5-2 To Cable Shield Bonding and Earthing, 21 May 04Document6 pagesThe Benefits of Applying 61000-5-2 To Cable Shield Bonding and Earthing, 21 May 04Asanka RodrigoNo ratings yet

- Overcurr Ent Protection: Location 2 Phase A Instantaneous Cur Rent I 1aDocument1 pageOvercurr Ent Protection: Location 2 Phase A Instantaneous Cur Rent I 1aAsanka RodrigoNo ratings yet