Professional Documents

Culture Documents

Lumber Horse

Uploaded by

Mike MoultonCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lumber Horse

Uploaded by

Mike MoultonCopyright:

Available Formats

ChaMpion

the

LuMber

horse

All photos Mike Abbott, except main picture above Penny Rose.

Mike Abbott describes how to make a modern shaving horse from recycled

wood, so you can ride off into the sunset and get green woodworking!

fter thirty years or more

of using shaving horses,

the occasion arose to

have a total rethink of their

design. I had always based my

shaving horses on a 1.2 metre

(4ft) length of log, about 30cm

(1ft) in diameter, but I was

aware this is not the sort of

thing that most people have

lying around the workshop.

For some time I had wanted

to come up with a design that

used easily obtainable materials

for people without access

to woodlands. While recently

erecting a new workshop I

discovered the effectiveness of

using cordless drills to drive

modern coachscrews into

softwood beams. I had also

40

Permaculture Magazine

No. 61

www.permaculture.co.uk

www.permaculture.co.uk

spent a few hours that summer

chatting to Owen Jones, a

swill-basketmaker, while he was

sitting astride his shaving horse

designed for gripping thin

slivers of oak. It had a central

arm slotted through a horizontal

platform and I had been interested in exploring this design.

Despite my lifelong mission

to persuade people of the

advantages of cleft, unseasoned

hardwoods, I ended up with

a design made out sawn softwood beams. It needed a name

and when I used the term

lumber horse, it rung a

bell from my childhood TV

viewing Champion the

Wonder Horse and the name

Champion the Lumber Horse

Above:

Heres one we

made earlier.

Champion the

lumber horse

in use at the

Sustainability

Centre.

Below:

Mike Abbott.

No. 61

has stuck. It consists mainly

of four 2.4 metre (8ft) lengths of

sawn, seasoned 100mm x 40mm

(4 x 2in) softwood. The only

other ingredients are a 50cm

(20in) length of roofing batten,

a 40cm (16in) length of hazel

rod and 35 M6 turbo coach

screws, 90mm long (although

ordinary screws or nails would

be possible but far less fun).

It can be made in less than a

couple of hours by almost

anybody, as can be seen by the

photos taken at a session of

our youth club in our local

village, Bishops Frome.

In future, I intend to use

locally grown Western Red

Cedar, which should work as

well, if not better than the stock

Permaculture Magazine

41

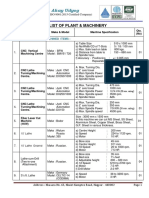

Stage 1: Fix a bed section to front leg, riser and spacer.

Stage 5: Fix the rear leg brace to the rear spacer.

Stage 2: Fix the first part of the platform.

Stage 6: Fix the rear leg brace to the rear legs.

Stage 3: Fix second part of the bed and platform.

from the timber yard. My

assistant Tom assures me that

a ten minute sortie through the

skips along most urban streets

would easily yield sufficient

raw materials for the job. There

are no precise joints needed

and the only woodworking

skills involved are the ability to

wield a hand-saw and a drill.

I suggest you use the sequence

illustrated but theres no reason

why you shouldnt assemble it

any way that takes your fancy.

Making Champion

the Lumber Horse

Pre-drilling the holes:

You are going to need several

25mm (1in) holes in the platform and arms of the horse.

If you have the use of a pillar

drill and/or a bench vice, you will

probably find it easier to drill the

holes before assembly, in which

case drill two holes in each

section of the platform and three

in each arm as illustrated. You

may rather drill these holes once

the horse has been assembled,

Stage 4: Fix the rear seat section.

42

Permaculture Magazine

No. 61

which is fairly easily done with

an electric drill, a brace and bit

or a bar auger.

Assembling the main body:

1. Fix one section of the bed to

the front leg, the central riser

and the back spacer, using just

one screw at each joint.

2. Fix one of the platform

sections to the tops of the front

leg and the riser so that it is

about parallel with the body

section. The holes in the platform

should be positioned as illustrated.

Stage 7: Fix the rear legs to the seat.

3. Turn the whole assembly over

and lay it down with the riser

about square to the bed and with

the front leg sloping. Fix

the other sides of the bed and the

platform with a couple of screws

at each joint. Take care that the

screws are not right at the end

of any components, as they

would be likely to split the wood.

4. Fix the rear seat component

to the back of the body.

www.permaculture.co.uk

Stage 8: Fix the remaining seat sections.

www.permaculture.co.uk

No. 61

Permaculture Magazine

43

8. Fix the remaining seat components into place.

and the arms should be smaller

than 25mm.

9. Screw the top bar onto the

arms so that the gap between

the arms is about a couple of

centimetres wider than the

width of the platform. Now

fix the footrest (which could

be another 50cm length of

4 x 2in, a strong length of 2 x

1in or anything in between).

If you need to transport the

horse, the rear leg assembly can

be easily removed by simply

removing the few screws that

hold the tops of the legs to

the seat and the leg brace to the

rear spacer.

10. Lift up the front of the horse,

slide the frame into place and

pivot it with a short hazel

rod, a length of dowelling,

a length of broom-handle or a

specially made 21mm (7/8in)

wooden pin. This should be

tapered at one end to make it

easier to poke in when adjusting

the gap.

5. Fix the leg brace to the rear

spacer against the underside

of the body.

6. Stand the horse up in the air

onto the two back legs with the

tops of the legs just protruding

above the seat and fix the leg

brace to the legs with one screw

at each joint.

7. Stand the horse on its feet

and fix the top of each leg to

the end of the seat component.

Then making sure the legs are

splaying equally, drive another

screw through each leg into the

leg brace.

Previous page:

Main lumber

horse frame

construction

diagram and

standard twin

swinging arm

diagram.

Above:

Alternative

single swinging arm

construction

diagram.

tooLs neeDeD:

An electric drill, mains or cordless (or a brace or a bar auger)

25mm (1in) drill bit

8mm (5/16in) hex nut driver

(or a hammer if using nails)

Handsaw

notes

An accomplice (Roy Rogers)

to hold things, or a good cramp

Tape measure

Pencil

A couple of low benches

All photos S & G Anderson

Mike Abbott runs regular green

woodworking and chairmaking

courses (see advert page 64).

He is the author of Living

Wood, a book which details

many of his improved woodworking devices and projects.

It is available from The Green

Shopping Catalogue, price

16.95 + p&p. 01730 823 311

www.green-shopping.co.uk

Stage 9: Fix the top bar and footrest to the arms.

Stage 10: Pin the arm in place and youre done.

44

Permaculture Magazine

No. 61

IN PERMACULTURE

You could trim the angles off

the tops and bottoms of the legs

but the tops of the back legs can

be very handy as a bench-stop

when the horse is in use.

And now you can ride off into

the sunset, ready to make a whole

host of wooden artefacts.

An alternative is to use a single

arm ( see illustration top left),

best held together with strong

bolts partly for strength and

also so that it can be taken to

bits to fit into the platform. The

arm will also need to be planed

a few millimetres thinner to

move freely.

Another alternative is to pivot

the arms with a metal pin or

large coach screws, in which

case the holes in the platform

LES PORCS

www.permaculture.co.uk

Stuart and Gabrielle Anderson share their experience of raising pigs

and how you too can be as happy as pigs in permaculture.

ave you a place for pigs in your

permaculture plan? As meat

eaters ourselves, we want our

food to have been as ethically, sustainably

and humanely raised and slaughtered

as possible. Whilst local organic and

free-range meat is available weve taken

the next step and now keep our own

animals. As well as enabling us to be responsible for their raising and slaughter,

its given us a deeper understanding

of all thats involved in putting meat

on the table and learning how their

needs, habits and outputs fit into our

permaculture design.

Raising animals doesnt inevitably

require acres of land. Both chickens

and rabbits can be humanely kept in a

town garden and the responsibility for

larger animals could be shared with

others in terms of both time and space.

Pigs are the archetypal smallholders

beast could you imagine yourself

going the whole hog?

www.permaculture.co.uk

GETTING STARTED

As permaculture pigs, theyll be out

working the land, rather than cooped

up in concrete barns, so they will need

a bit of rough pasture, which could be

rented, rather than owned. You must

have a minimum of two as they are

social creatures and need company.

To their list of other essentials add

housing, fencing, shelter and shade from

wind and sun, drinking water and a

place to wallow. Stock fencing can be

expensive and hard work but many of

the other items are easily created with

a bit of imagination and improvisation.

In return, you will get some of the best

pork youve ever tasted.

Assembling a network of knowledge

and assistance is invaluable and a good

vet essential. In Europe, its obligatory

to register with the local office of the

animal health and welfare organisation

(DEFRA in the UK) even for a private

person keeping just a couple of farm

animals. These two provide a conduit

for dispensing official advice and information and coordinating action; absolutely

essential when you consider epidemics

like foot and mouth. There are some good

books, such as Starting With Pigs by Andy

Case and Blacks Veterinary Dictionary

but we have still been faced with many

questions and weve benefited from

forging friendships with other local

pig keepers, including farmers.

INPUTS & OUTPUTS

To justify including pigs in our permaculture design, we should analyse their

inputs and outputs honestly. The most

difficult aspect is their diet, as pigs

are conventionally fattened up eating

cultivated cereals. As we enjoy pork and

bacon, our challenge is to reduce the

pigs reliance on such food.

For beginners, buying weaners is

the way to go. We take delivery of ours

in the spring, so over the months that

No. 61

Permaculture Magazine

45

You might also like

- Antique Woodworking Tools A Guide To The Purchase, Restoration and Use of Old Tools For Today's ShopDocument197 pagesAntique Woodworking Tools A Guide To The Purchase, Restoration and Use of Old Tools For Today's ShopAnonymous PcUOts100% (1)

- Junior Backhoe: Half-Pint Sidewalk Superintendents Will Go Ape For This Boy-Size, Rugged, Easy-To-Build DiggerDocument5 pagesJunior Backhoe: Half-Pint Sidewalk Superintendents Will Go Ape For This Boy-Size, Rugged, Easy-To-Build Diggermagatsu2099No ratings yet

- Home Made Faceting MachineDocument7 pagesHome Made Faceting MachineGianluca Salvato100% (4)

- Toys of Early America ... You Can Make, by Reba Ann DunmireDocument84 pagesToys of Early America ... You Can Make, by Reba Ann DunmireJeff JeffersonNo ratings yet

- Sliding Bookrack: Woodworks: Intermediate ProjectDocument8 pagesSliding Bookrack: Woodworks: Intermediate ProjectEucap Mdz100% (1)

- Shaving Horse PlanDocument38 pagesShaving Horse PlanJohn Sartor100% (3)

- Rubber Band BullroarerDocument6 pagesRubber Band BullroarerSimone B.No ratings yet

- Free Plan Small CabinetDocument9 pagesFree Plan Small CabinetAlexandre R. PeixotoNo ratings yet

- JT3020 Jt4020atDocument16 pagesJT3020 Jt4020atfrancis0511No ratings yet

- Matching Letter Opener and Desk SetDocument8 pagesMatching Letter Opener and Desk Set- yAy3e -No ratings yet

- Sash PlanesDocument5 pagesSash PlanesBlakdawg15100% (1)

- A Cordage Backed BowDocument9 pagesA Cordage Backed BowGuillermo Bustos100% (1)

- SpokeshaveDocument6 pagesSpokeshavestuckinthestudioNo ratings yet

- PWW 234 Derevyannoe KruzhevoDocument74 pagesPWW 234 Derevyannoe KruzhevoSergio Larraguibel100% (1)

- Sec Roc Drill Pipe and AdaptersDocument16 pagesSec Roc Drill Pipe and AdaptersSerkanAl50% (2)

- Compact SPT CartDocument14 pagesCompact SPT CartmytizplickyNo ratings yet

- Portable WorkshopDocument7 pagesPortable WorkshopJose PichardoNo ratings yet

- Router JigsDocument2 pagesRouter JigsIlberto Fortuna100% (1)

- Basic Scribing TechniquesDocument6 pagesBasic Scribing TechniquesLen S100% (1)

- 10 Best Handscrew Tips PDFDocument5 pages10 Best Handscrew Tips PDFMad CowNo ratings yet

- USDA - Crosscut Saw Guide - Saws That SingDocument71 pagesUSDA - Crosscut Saw Guide - Saws That SingSurvivItNo ratings yet

- Week 2 - Making A Lap Joint and Dovetail Lap JointDocument6 pagesWeek 2 - Making A Lap Joint and Dovetail Lap JointAndy Joseph StotenNo ratings yet

- PG Gland Thread Sizes PDFDocument2 pagesPG Gland Thread Sizes PDFArvind Kumawat100% (6)

- Short MODU Specs of Cuu LongDocument2 pagesShort MODU Specs of Cuu LongThem Bui XuanNo ratings yet

- PWM Economaki SquareDocument7 pagesPWM Economaki SquareYamil PaladinoNo ratings yet

- Quick Canoe Made From PlywoodDocument43 pagesQuick Canoe Made From PlywoodKades100% (1)

- Block PlaneDocument1 pageBlock PlaneSanela Ljubičić100% (4)

- Arts & CraftsDocument29 pagesArts & CraftsMary Charisse SandroNo ratings yet

- An Illustrated Guide to Making Mobile Toys - Scooter, Tricycle, Two Utility Carts and Wooden Land RoverFrom EverandAn Illustrated Guide to Making Mobile Toys - Scooter, Tricycle, Two Utility Carts and Wooden Land RoverNo ratings yet

- Three Sided Lidded Box: Woodturning ADocument11 pagesThree Sided Lidded Box: Woodturning AGustavo RuizNo ratings yet

- Home Made Wooden TripodsDocument7 pagesHome Made Wooden Tripodskorki777No ratings yet

- So You Want To Make A Shave Horse - PrintableDocument11 pagesSo You Want To Make A Shave Horse - PrintableTom Sturner100% (1)

- H Frame Folding Tabletop Easel PlanDocument25 pagesH Frame Folding Tabletop Easel PlanFiorenzoAlbatrosNo ratings yet

- FW1124 - Rodriguez Tilt Top Table PDFDocument9 pagesFW1124 - Rodriguez Tilt Top Table PDFbarbara100% (1)

- Bow SawDocument6 pagesBow Sawkhunchaiyai100% (2)

- Analysis of Rates For Estimate of DPRDocument34 pagesAnalysis of Rates For Estimate of DPRAnamika SinghNo ratings yet

- The Pole Lathe: Part One - A Complete HistoryDocument18 pagesThe Pole Lathe: Part One - A Complete HistoryEvie BeeNo ratings yet

- Woodworker's Journal - Vol.01 No.1 Jan-Feb 1977Document16 pagesWoodworker's Journal - Vol.01 No.1 Jan-Feb 1977BeingNo ratings yet

- Build Your Own LatheDocument3 pagesBuild Your Own LatheNICOLASNo ratings yet

- Tabletop ArtistryDocument5 pagesTabletop ArtistrysossieNo ratings yet

- Showcase Cabinets: The Delicate Interplay of Glass and WoodDocument7 pagesShowcase Cabinets: The Delicate Interplay of Glass and WoodAdrian Cocis100% (1)

- Advanced Project Oak Pie SafeDocument9 pagesAdvanced Project Oak Pie SafeMark_Voigt_4580No ratings yet

- Shooting Board, How To Build.Document21 pagesShooting Board, How To Build.eduelocoNo ratings yet

- Lee Valley - Using A Bench ChiselDocument7 pagesLee Valley - Using A Bench Chiselzedric100% (1)

- Fifty Lessons in Wood Working - 1892Document120 pagesFifty Lessons in Wood Working - 1892workshopcarpintaria100% (3)

- Drilling Operations l3 NotesDocument21 pagesDrilling Operations l3 Notesishimwe kwizera willyNo ratings yet

- Hand Planes and Uses of EachDocument17 pagesHand Planes and Uses of Eachsunyjim100% (1)

- Benchcrafted Moxon ViseDocument12 pagesBenchcrafted Moxon VisexlotoxNo ratings yet

- Foot-Powered Scroll SawDocument8 pagesFoot-Powered Scroll SawJan Steinman100% (1)

- A Little Book of Vintage Designs and Instructions for Making Dainty Gifts from Wood. Including a Fitted Workbox, a Small Fretwork Hand Mirror and a Lady's Brush and Comb Box: Including a Fitted Workbox, a Small Fretwork Hand Mirror and a Lady's Brush and Comb Box.From EverandA Little Book of Vintage Designs and Instructions for Making Dainty Gifts from Wood. Including a Fitted Workbox, a Small Fretwork Hand Mirror and a Lady's Brush and Comb Box: Including a Fitted Workbox, a Small Fretwork Hand Mirror and a Lady's Brush and Comb Box.No ratings yet

- Traditional Casement WindowsDocument9 pagesTraditional Casement Windowsbuckley1212085No ratings yet

- 03 Simba M6Document5 pages03 Simba M6AlejandoNo ratings yet

- Cutting A Bridle JointDocument6 pagesCutting A Bridle JointMario BerronesNo ratings yet

- Method StatementDocument13 pagesMethod StatementGrace tpplNo ratings yet

- How To Make A Meat SafeDocument5 pagesHow To Make A Meat SafeChristian Theriault100% (1)

- PMOct 54 Compact Workbench 1Document1 pagePMOct 54 Compact Workbench 1JimNo ratings yet

- Iron WorkingDocument2 pagesIron WorkingRedeemerBoyNo ratings yet

- The Power of Ducks: Source: Takao FurunoDocument1 pageThe Power of Ducks: Source: Takao FurunopeterNo ratings yet

- How To Build A Japanese Hand PlaneDocument8 pagesHow To Build A Japanese Hand PlaneTASSIO LEIVANo ratings yet

- Buying A Used Shopsmith Mark VDocument5 pagesBuying A Used Shopsmith Mark VendgameNo ratings yet

- Moulding PlanesDocument8 pagesMoulding PlanesJohan Jacobs100% (1)

- PDFDocument44 pagesPDFBaSzarNo ratings yet

- Pedal Power in Work Leisure and TransportationDocument143 pagesPedal Power in Work Leisure and Transportationtariq76No ratings yet

- Let's Build A Can Stirling Engine Step 1 - Material Preparation and StructureDocument6 pagesLet's Build A Can Stirling Engine Step 1 - Material Preparation and Structureulises sosaNo ratings yet

- Sharp ChiselDocument1 pageSharp ChiselAnonymous xEKsRmtjONo ratings yet

- Notes, Parts List & Drawings: Easy DIY Biomass GrinderDocument16 pagesNotes, Parts List & Drawings: Easy DIY Biomass GrinderCalfos SaririNo ratings yet

- Icdt April10 Skansen BenchDocument2 pagesIcdt April10 Skansen Benchapi-239142091100% (1)

- Lie-Nielsen Studio BenchDocument2 pagesLie-Nielsen Studio BenchSameh SamehNo ratings yet

- An Introduction to the Seasoning of Timber: Pergamon Series of Monographs on Furniture and TimberFrom EverandAn Introduction to the Seasoning of Timber: Pergamon Series of Monographs on Furniture and TimberW. J. KapeNo ratings yet

- 05) - Process Flow Diagram For 11190722 - DDocument2 pages05) - Process Flow Diagram For 11190722 - DMONISHRAJNo ratings yet

- Drilling of GFRP Composites To Achieve oDocument4 pagesDrilling of GFRP Composites To Achieve oanaya KhanNo ratings yet

- Machine Tools (Tk103n)Document20 pagesMachine Tools (Tk103n)noragarcia76No ratings yet

- Balanced Bumper SubsDocument18 pagesBalanced Bumper SubsJuanchoNo ratings yet

- MAK4462 Machine - Tools Lecture - Notes 3Document126 pagesMAK4462 Machine - Tools Lecture - Notes 3muhammet çalımNo ratings yet

- AU Plant and Machinery & Testing EquipmentsDocument5 pagesAU Plant and Machinery & Testing Equipmentsajaykumar MeshramNo ratings yet

- Boomer E3/E4 Series: Hydraulic Face Drilling Rigs For Medium To Large Drifts and Tunnels With Cross Sections Up To 205 MDocument8 pagesBoomer E3/E4 Series: Hydraulic Face Drilling Rigs For Medium To Large Drifts and Tunnels With Cross Sections Up To 205 MTOLEDO GARVIZO JAIRO GERM�NNo ratings yet

- BR Service-Bookazine 90092605 20211214 enDocument35 pagesBR Service-Bookazine 90092605 20211214 enRahul SukumaranNo ratings yet

- European Technical Assessment ETA 17/0185: Technical and Test Institute For Construction PragueDocument12 pagesEuropean Technical Assessment ETA 17/0185: Technical and Test Institute For Construction PragueLi Juen GamNo ratings yet

- TTP HARD Drills Bits Are Officially Certified As HARDDocument2 pagesTTP HARD Drills Bits Are Officially Certified As HARDPR.comNo ratings yet

- Raise Boring HorizontalDocument54 pagesRaise Boring HorizontalPercyNo ratings yet

- Catalog 60Document34 pagesCatalog 60judas1432No ratings yet

- YCM GT SeriesDocument30 pagesYCM GT SeriesCNC SYSTEMSNo ratings yet

- 20 Chap. 2 / Contouring and Contouring TechniquesDocument12 pages20 Chap. 2 / Contouring and Contouring TechniquesNathalia WhiteNo ratings yet

- Manuales Instalacion Sellos BTE - AMSETEC LTDADocument24 pagesManuales Instalacion Sellos BTE - AMSETEC LTDAermides garciaNo ratings yet

- Drilling Large Diameer Holes: Swa1RoolDocument20 pagesDrilling Large Diameer Holes: Swa1RoolPa1 Kumar MNo ratings yet

- CatalogueDocument162 pagesCatalogueiLLeno 23No ratings yet

- Operating Instructions and Parts Manual - Mod - JDP-17MF PDFDocument24 pagesOperating Instructions and Parts Manual - Mod - JDP-17MF PDFVicente Capistrán GómezNo ratings yet

- Build Drill Press ViseDocument23 pagesBuild Drill Press Viseمبارك السبيعيNo ratings yet