Professional Documents

Culture Documents

Design and Construction of Pre-Tensioned Sutlej Bridge in Punjab PDF

Design and Construction of Pre-Tensioned Sutlej Bridge in Punjab PDF

Uploaded by

mohan1441Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design and Construction of Pre-Tensioned Sutlej Bridge in Punjab PDF

Design and Construction of Pre-Tensioned Sutlej Bridge in Punjab PDF

Uploaded by

mohan1441Copyright:

Available Formats

Paper No.

524

DESIGN AND CONSTRUCTION OF PRE-TENSIONED SUTLEJ BRIDGE IN PUNJAB

V.N. HEGGADE*, R.K. MEHTA** & R. PRAKASH***

SYNOPSIS

Currently in vogue fast track construction has encouraged the adoption of pre-tension technology for urban flyovers. After having

successfully experimented pretensioned spans for River Bridge upto span of 30 m in Hadakiya Bridge in Gujarat, the technology was first

time extended upto 35m spans for Beas and Sutlej river bridges in Punjab. The inherent peculiarities such as single stage prestressing,

transfer of prestress through bond between concrete and cables by obviation of grouting and sheathing ducts, tensioning of tendons before

the concrete is cast and transfer of prestress after the attainment of required strength in concrete derive certain advantages in favour of

pretensioning in terms of durability, quantity reduction, construction speed, design and construction expediency. However, in the Indian

scenario there are no codal guidelines accounting for these peculiarities for bridges. The enumeration with illustration is intended to

provide basis for formulating guidelines for pretensioning in bridge building. The Paper also deliberates on optimization of beam cross

section in relation to lateral stability during transfer of prestress accounting for casting imperfections, handling and erection of beams

before the beams are transversly stiffened by deck slab which may help the code makers to have fresh look on the guidelines for lateral

stability of the prestressed beams.

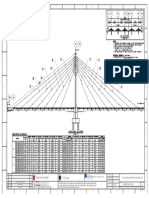

1. DESCRIPTION OF THE PROJECT

The project consisted of design and construction of highlevel bridge across the river Sutlej including approaches and

guide-bunds connecting Nakodar and Jagraon. The

construction of the bridge facilitates in reduction of the distance

between the towns by 50 km, reduction in traffic of NH-1 due to

traffic from Rajkot, Maler Kotla and Jalandar and reduction of

traffic in the city of Ludhiana. The bridge proper, 810 m long

between the inner faces of dirt walls is made up of 23 spans of

35.20 m, while the approaches of lengths 1369 m and 1115 m on

Nakodar side and Jagraon side respectively flanked the bridge

proper.

The main flow is confined and guided through the bridge

linear waterway without causing damage to the bridge and its

approaches by provision of divergent guide-bunds along the

river flow, upstream and downstream on both the banks.

The superstructure of 35.20 m span bridge consisted of 6nos. precast pretensioned concrete beams spaced at 2.15 m

centres and cast-in-situ RCC deck slab. The width of the

carriageway has been kept 7.50 m flanked either side by 2 m

wide cycle track making the total width of the bridge deck to be

12.95 m including crash barriers and steel railings. The vehicular

way is separated from cycle ways by crash barriers while

cyclists are protected by steel railings from being toppled over.

The beams were simply supported on POT-cum-PTFE bearings

having slab steel expansion joints between the spans. The

abutments were solid non spill-through types to go with same

family of plate type piers flaring towards pier cap in the direction

*

**

***

of river flow (transverse) to minimise the size of the RCC cap.

The piers were founded on 6 m dia well foundations while the

abutments were resting on 7 m dia wells. The detail of the

general features of the bridge is given in Fig. 1.

2. DETAILS OF THE CONTRACT

Punjab Infrastructure Development Board, on behalf of

Punjab PWD provided developmental outline proposal with

the condition that the contractor should submit his own

proposal with the approximate dimensions of various

components of the bridge structure to fairly establish that the

technical requirement were met with. The tender proposal of

the contractors were to include certain obligatory conditions

such as length of the bridge, approaches and guide-bunds,

carriageway and cycle track width requirements, linear water

way and vertical clearance and type of foundations, and

formation levels. The departmental outline proposal had the

span of 40.50 m and the variation in span length was permitted

up to 20 per cent. The contractor had to give detailed design

calculations and drawings in support of his proposal after the

award of the work to comply with the design requirements

stipulated in tender documents. Qualified engineers

supplemented by independent quality control consultant in

line with ISO requirements were supervising the execution of

the job.

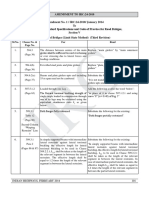

Some of the salient design parameters specified in the tender

documents are as below:

River hydraulics

Head of Technical Mgt.

Gammon India Ltd., Mumbai

Dy. Manager (Tech)

E-mail : vnh@gammonindia.com

Project Manager

Written comments on this Paper are invited and will be received upto 30th Sept., 2006.

HEGGADE, MEHTA & PRAKASH ON

144

Fig. 1. General arrangement of Sutlej bridge

Design discharge

: 18912 Cumecs

Maximum mean velocity

: 4.87 m/sec

High flood level

: RL 227.868

Depth of water at lowest

: 3.0m

water level

Scour level

: RL 204.255

Seismicity

Seismic zone

: IV

Seismic coefficient

: 0075G

Permissible increase in SBC : 25 per cent

Permissible increase in stress : As per IRC: 6

Soil parameter

(dry)

: 1.8 t/m3

(angle of internal friction) : 300

(Friction between soil and face): 200

SBC for well foundation

: 75 t/m2 gross at

founding level.

Material

For condition of exposure

: Moderate

Concrete grades

For pretensioned beams : M40

For well foundation

: M30

Reinforcements

: HYSD bars

conforming to

IS:1786

Loading

Live load

Footpath live load

Cycle track loading

Miscellaneous

Type of bearings

Wearing coat

Cycle track and parapet

Software package

:IRC 70R single lane

or Class-A 2 lanes

: As per IRC: 6

: As per IRC: 6

: POT and POT cum

PTFE

: 25 mm thick mastic

asphalt over 40 mm

thick bituminous

concrete

: As per

departmental

drawing

: STAAD III Release 22.0

3. CONCEPTUALISATION

In many of the river bridges in Punjab upto 45 m spans, the

slab girder system with cast insitu post-tensioned beams are

successfully adopted. Beyond 45 m, upto even 65 m cast insitu

box girders are adopted. However, recently in vogue fast track

DESIGN AND CONSTRUCTION OF PRE-TENSIONED SUTLEJ BRIDGE IN PUNJAB

construction conceptualisation facilitates expeditious

construction. The conventional cast insitu construction and

its expediencies like staging/trestle support for superstructure

in the riverbed is not only time-consuming, also susceptible to

flood damages, consequently reducing productive working

period in a season.

In the recent years, the flyovers in urban areas especially

in metropolitan cities are realised by precast construction. The

various options in segmental and non-segmental technology

is exploited in precast construction using post-tensioning or

pre-tensioning.

In case of Sutlej Bridge, among the various options

available, finally the competition was between post-tensioned

versus pre-tensioned beams. In this particular context, pretensioned beams had certain advantages and also peculiarities

vis--vis its counterpart.

The inherent peculiarities such as single-stage

prestressing, transfer of prestress through bond between

concrete and cables by obviation of grouting, sheathing ducts,

tensioning of tendons before the concrete is cast and transfer

of prestress after the attainment of required strength in concrete,

warrants specially designed casting bed which should be

capable of imparting required quantum of prestressing force.

These peculiarities derive certain advantages in favour of

pretensioned beams in terms of durability, quantity reduction,

construction speed, design and construction expediency. As

the pretensioned girders are manufactured in factory like

environment where the bonding between concrete and tendons

is direct due to the absence of grouting inside the sheathing

duct, the better durability and corrosion resistance is achieved.

The absence of the cables in the web and the elimination of end

blocks and blisters to house the anchorages, allows the section

optimisation from strength criteria alone. This helps in reducing

concrete quantities rendering in lighter beams, facilitating in

attenuation in cost of handling, transportation and erection.

The value engineering carried out during

conceptualisation stage for Sutlej Bridge revealed that for the

same span of 35.40 m and number of beams of six on the cross

section (Fig. 2), the quantities for pre-tensioned girders are

substantially lesser than post-tensioned beams.

145

From the design angle, pre-tensioning uses the prestress

efficiently on smaller sections with higher eccentricities,

reduces the immediate losses like friction, wobble and slip,

reduces initial mass on substructure and foundation due to

seismic and reduces steel congestion in end blocks and

anchorage zones. Construction-wise, the activities associated

with post-tensioning such as threading of cable inside the

sheathing, grouting operation and number of prestressing

operations is eliminated.

Though the pretensioned technology has been used

extensively for flyovers and ROBs for the span range of 18 to

22 m, for the first time for bridge across river Surajbari in Gujarat

the technology was adopted with 26 m spans in India, which

withstood the otherwise catastrophic earthquake in Gujarath

on 26th January 2001. Perhaps, it was but natural for Sutlej and

Beas Bridges in Punjab to extend the span length up to 35 m as

a part of evolutionary process, on the basis of experience gained

through the fast track flyovers and Surajbari Bridge.

4. FOUNDATIONS

Before the award of the job, as a part of tender documents

a thorough soil investigation was carried out by the department

to arrive at soil characteristics, soil bearing capacity and

founding levels along the bridge alignment (Fig. 3). Overall

seven numbers of boreholes were drilled for depths up to 40 m

and standard penetration tests were performed as per IS:2131

to arrive at N values. Silt factors were calculated on the basis

of particle size distribution following the principles of Laceys

silt factor. On the basis of soil investigation, the subsoil strata

were divided into 3 distinct zones.

Around 12 m below the ground level along the alignment a

silty clay strata of average band depth of around 12 m,

designated as Zone-2 was sandwiched between sandy strata

designated as Zone-1 and Zone-3. Average value of sandy

strata was around 340 while clayey strata had undrained shear

strength of around 1.50 kg/cm2 (Cu). On the basis of 75 mm

maximum settlement criteria, the bearing pressure at founding

level in sandy strata after passing through the clayey strata

was specified as 75T/m2 on conservative side. The silt factor

for Zone-1 varied from 0.62 to 1.07 while for Zone-3 the same

was ranging between 0.35 to 1.01. The design scour depths

near the piers and abutments were evaluated on the basis of

maximum discharge, river regime and velocity of the river.

In all 22 numbers of piers were supported on 32 m deep

and 6 m dia well foundations (Fig. 4), consisting of 2.1 m deep

kerb, 1.5 m deep well cap. The steining thickness of 1.05 m is

tapered to 0.75 m at scour depth of around 18 m, below the top

of the well cap.

Fig. 2. Pre-tensioning vis-a-vis post-tensioning VE for Sutlej

bridge

The thickness of the steining was decided by using the

relationship given in IRC:78 to facilitate smooth sinking by

gravity without excessive Kent ledge and damage to steining

146

HEGGADE, MEHTA & PRAKASH ON

Fig. 3. Bore hole details along bridge alignment

Fig. 4. Typical well foundation for Sutlej

DESIGN AND CONSTRUCTION OF PRE-TENSIONED SUTLEJ BRIDGE IN PUNJAB

due to differential earth pressure, sand blow and sudden drop,

etc. it was ensured that the stresses at different levels of steining

during service conditions and construction stage were within

permissible limits. As the well foundations were to be plugged

on soil, the grip for side earth resistance below the scour level

was ensured to be of the maximum depth of scour below the

design scour. As normally, well cannot be sunk to the precise

verticality, the design catered for the cumulative moment effect

of 1 in 80 tilts and 150 mm shift apart from accounting for other

severe load combination. The side earth resistance was

calculated by Bombay Committee Method with the passive

resistance factor of safeties of 2.0 and 1.6 for normal and seismic

conditions respectively. The well cap was designed and detailed

as uniformly thick plate for the external reactions and reaction

components at the bottom of the pier with boundary condition

as partially fixed at supports on well steining all around.

The river bed level varied between RL 222 m to 225.50 m

having deep channel between the pies P3 and P10 with the low

water level being at RL 223.723 m. Up to the deep channel i.e.

P10, the service road was made up to A/R and wells up to P10

were started simultaneously. After the monsoon was over, on

recession of floods, the service road was made on A/L side and

with the help of the site made temporary bridge between P8 and

P10; the wells were tackled in the channel.

Initially, the well sinking was planned with four cranes.

However, the sandwiched clayey strata necessitated overall

eight cranes, as the sinking through the same was consuming

almost 7 to 15 days per metre depth.

147

Since the bed profile was having large variations, almost

all wells were required to be sunk up to 5 m below the ground

level (Photo 2.) and 3.0 m below the water level. The circular

cofferdam except a small flare to accommodate piers was cast

up to water level.

Photo 2. Cofferdam with flare to accomodate pier

Had the well cap level been fixed at ground level or LWL,

the job could have been completed three to four months earlier

and substantial additional expenditure as a consequence of

taking well cap below ground level could have been saved.

As the cofferdam was quite thin compared to steining, the

non-availability of required weight hampered the sinking. This

called for the creation of the sump below the founding level to

facilitate gradual sinking. At P16 location, the sump required

was 3 m to enable last 1.80 m sinking. In the process the well

jumped and sunk by 3.70 m at one go rendering the steining top

almost 8 m (Photo 3.) below bed level.

Most of the well foundations were constructed

conventionally on land, barring a couple in deep channels,

which warranted sand islands.

In the conventional construction (Photo 1.), the cutting

edge fabricated of mild steel was laid on the ground level and

curb with required reinforcements was concreted. The material

inside was gradually scooped out with grabs to facilitate sinking

under its own weight. As the sinking proceeded, the steining

was built up in lifts, normally of around 2.5 m to further the

sinking due to increase in weight.

Photo 3. Construction of well cap below GL

To raise the steining to the required level, the extensive

shoring, continuous dewatering, protection with wire crated

boulders, etc. had to be resorted to apart from stabilising the 6

m deep false walls by adequate structural bracings.

Photo 1. Curb reinforcements & cutting edge

To circumvent the creation of sump to sink last 1.2 m depth

at P3 location, the other measures such as air jetting, water

jetting and Kent ledge on top of false wall were attempted.

Finally after 4 months, the combined effect of 450 t Kent ledge,

5 m excavations outside the well and dewatering yielded the

well to the required depth.

HEGGADE, MEHTA & PRAKASH ON

148

Though the aggregate sinking of 854 m was accomplished

in a short period of 620 days, the good engineering practice of

fixing the well cap at LWL/bed level, would have reduced the

sinking duration, efforts and its financial ramification quite

considerably.

At the every alternative well location, after reaching the

founding level, the soil investigation was carried out up to 9 m

depths to deduce C and values to confirm the soil bearing

capacities. Bottom plugging was carried out by shifting the

concrete from batching plants through buckets and placing

by tremie pipes. After having done the recuperation test for

soundness of plug after 14 days, the sand filling and

intermediate plugs were expedited. With the help of

irrecoverable shuttering supported on precast beams and

cofferdam, each well cap was completed within five to six days

including reinforcement fixing and concreting.

5. PIERS

The RCC piers were of wall type flaring from well cap to

accommodate the pier cap, with the concrete characteristic

strength of 35 N/mm2. Though the grade of the concrete is

same as that of used for well cap, the mix had to be made little

richer with higher workability in order to enable smooth

placement of concrete for the thin sections. A system of

formwork consisting of steel channels and shuttering was used

in piers, which was concreted in two stages (Photo 4).

Photo 4. Shuttering Arrangement for Pier

The height of the first lift was 3.25 m and after concreting

the first lift, the balance second lift shuttering was fixed

immediately in 3 to 5 hours. The grout leakage through the

joints of shuttering was totally avoided by judicious planning

during the fabrication of shuttering such as overlapping of

plates, etc. The concreting for each lift was carried out in

continuous operation without the cold joint. By virtue of large

shuttering and minimum number of lifts in concreting, the surface

texture of the concrete pier has been of excellent quality.

6. SUPERSTRUCTURE

6.1 Choice of Cross Section

Due to the obvious advantages enumerated in

Conceptualisation Para, the an isotropic deck was considered

to be made up of 35.40 m long precast pretensioned beams,

transversely held by 200 mm thick RCC deck slab. Though the

design-wise and from aesthetical considerations, the

intermediate diaphragms could have been avoided, the same

has been provided to satisfy contractual requirement which

are in fact structurally redundant.

As there are no design criteria laid down in IRC standards

for pretensioning, invariably IRC:18 meant for post-tensioned

construction is adopted and insisted upon, for pretension

construction also. The present post-tensioned Code IRC:18

prescribes working stress method of design and permissible

stresses seem to be on highly conservative side. The

comparable AASHTO-94, the standard that is also based on

allowable stress method (ASD) design, allows at least 33 per

cent higher flexural stresses during transfer and 25 per cent

higher flexural stresses during service condition. To worsen

the matter further, the IRC stipulates 20 per cent additional

time dependent losses, 3 times 1000 h relaxation losses, minimum

80 per cent of characteristic strength at full transfer of prestress,

those perhaps are rationalised for post-tensioned construction

on the basis of past experience, where prestress transfer is

feasible in stages.

Universally, though generally there are no separate codes

for post-tensioning and pre-tensioning, the prestressing code

itself give separate design parameters such as time dependent

loss parameters, permissible stresses and transmission length

for pre-tensioning, etc. In view of this the author had suggested

to IRC Code Making Committee to make IRC: 18 a common

code for prestressed concrete road bridges common for both

pretensioned and post tensioned concrete with the separate

design parameters wherever relevant and applicable, which is

yet to be taken into cognisance.

Selection of the beam cross section for long span

pretensioned girders warrants experience in field supervision,

apart from theoretical aspects of prestressed concrete. It is

expected that the optimum concrete section that is materially

influenced by prestressing force and loading, is light for

handling and transportation, prestressing operation and

concreting friendly. The sizes of bottom and top flanges, the

depth and width of web are required to be optimised on the

basis of above constructability issues.

The pressure line (resultant of stresses) in the prestressed

concrete flexural member shifts its location within the section

upon the application of external loads. In simply supported

beams at the midspan for service condition, the stress at the

bottom-fibre is zero, i.e. no tension allowed as per codal

provision. At the midspan pressure line is above the CG of the

section, warranting the CG of the prestressing force at a

distance equivalent to moment divided by prestressing force.

Thus to cater for the compressive force by virtue of pressure

line above the CG of section at the midspan, the top flange

requirement is high, whereas nearly zero-stressed bottom fibre

DESIGN AND CONSTRUCTION OF PRE-TENSIONED SUTLEJ BRIDGE IN PUNJAB

does not require flange, apart from accommodating cables.

Towards the supports as the moments are gradually reduced to

zero, the CG of the prestressing force can be judiciously located

to be concentric to avoid any requirement of flanges.

However, at the intervening stage before the application of

imposed loads including live load, the section has to store large

prestressing force at bottom fibre, which would be neutralised

on application of external intermittent loads latter, bringing the

bottom fibre stress to zero. The above calls for widening of the

bottom flange and in fact decides the width. Thus an I section

where the pressure line can move larger distance without the

tensile stresses is chosen for pretensioned girders. While the

span to depth ratio ranges between 16 to 22, the web thickness

of 150 mm is considered to be adequate for normal I shaped

beam for honeycomb-free concreting.

However, in case of Sutlej Bridge as the vertical clearance

was not a constraint, the lavish span to depth ratio of 14 was

adopted to reduce the prestressing strands with the web

thickness of 200 mm as constrained by IRC:18, though the same

was not required by design and constructability angles.

The decision on the width of the top flange is very crucial

as the extremely narrow top flanges may buckle the precast

beams during side shifting, transportation and handling. The

Indian Codes categorise the beams as slender beams when the

span to top flange width ratio exceeds 60 or depth to flange

width ratio exceeds 4 and specifies reduction in permissible

stresses and adequate temporary restraints during handling

and erection from lateral stability considerations. Normally,

for the simply supported beams, the span to depth ratio of 15

is considered to be optimum, and when the same is related to

depth to width ratio of 4, the span to width ratio works out to

be 60. In Sutlej and Beas bridges, 35 m long beams with 2.5 m

depth was provided with 0.70 m top flange to keep the weight

of the girder to minimum with span to flange width ratio of 50

and depth to width ratio of 3.57 satisfying both the

considerations given in Indian Codes for slenderness. The

stretching the slenderness to codal limits to keep the weight

minimum, was considered to be very bold especially after the

classical beam collapses of Roop Narayan Bridge on National

Highway No.6, where the span to width ratio 50 followed the

depth to width ratio of 3 (safer than Sutlej Bridge). In his paper

A study of the failures during launching of precast prestressed

concrete beams of the Roop Narayan Bridge on National

Highway No. 6, while deliberating on Guyons contention that

for the beams depths of 5 to 8 ft., the thickness of the flanges

should never be less than 0.1 of the depth and width of the

flanges should not be less than 0.40 of the depth for

symmetrical I-beams, Mr. Seetharaman through his

investigation concludes that the span to depth ratio should

be 15 and depth to width ratio should be less than 3 for

transverse rigidity of precast beams. Thus the chosen beam

section for Sutlej called for thorough investigation and

justification vis--vis lateral stability during transfer of

149

prestress, handling and erection of the beams before the

beams are transversely rigidised by deck slab.

The lateral stability of Sutlej beams during handling and

erection was ensured by extensive investigations on the basis

of special report lateral stability of long prestressed concrete

beams by Robert F. Mait in PCI Journal Jan-Feb 1989.

The improper lifting hook placement and casting

imperfection cause the beam to be tilted at an initial angle 1

near the lifting hook location about the roll axis (Fig. 5).

Normally the casting imperfections considered 1:1920 in Sutlej

gets manifested itself by way of curvature in plan of

prestressed beam after detensioning. Lifting hook placement

tolerance was allowed to be 6.35 mm during casting. The

above tilting of beam induces the lateral deflection about

weak axis of the beam. Because of the transfer of prestress,

there is already tension at the top fibre of the beam for which

the tensile stress caused about the weak axis by the

component of the self weight due to tilt gets added which

needs to be within the permissible limits and in fact decides

the maximum tilt ( max) to which the beam can be subjected

to. After the tilting is initiated by the initial angle 1 near the

support locations, the beam achieves its equilibrium with a

uniform lift angle (shown at midspan) with CG of the mass

of the deflected beam right under the roll axis.

In the figure as Zo approaches Yr, the beam starts rotating

and becomes totally unstable even without the initial

imperfection and without improper location of lifting hook.

Thus the safety against the lateral buckling is a measure of

Yr vis--vis Zo and is called gross factor of safety (FOS = Yr/

Zo) for a perfect beam without imperfection.

If one has to account for imperfections causing the initial

angle q1 and limiting the maximum lift to max, the factor of

safety reduces to

However, it is more logical to deduce the factor of safety

against lateral stability by dividing maximum possible tilt max

with that of equilibrium rotation at midspan.

Moving the lifting position inwards improves the factor

of safety against lateral stability by virtue of reduced

deflections caused by rotations about the weak axis.

However, it has to be ensured that the stresses are within

the limits in overhang portions.

Though the very slender cross sections from lateral

stability considerations was chosen in Sutlej Bridge, the same

could be successfully executed by adhering to the specified

casting imperfections, lifting hook location tolerance, etc.

during execution. The details of the same are given in Fig. 5.

Unlike in post-tensioning, in case of pre-tensioning as the

strands are bonded during the transfer of prestress, the

HEGGADE, MEHTA & PRAKASH ON

150

Fig. 5. Laterial stability of long prestressed concrete beams with factor of safeties

beams cannot buckle which was also taken into cognisance

during lateral stability investigations.

The lateral stability guidelines for precast beams given in

Indian Codes for prestressed concrete members are similar to

that of for RCC and steel beams in terms of span to depth ratio

and depth to top flange width ratio. However, in the case of

prestressed beams, the aspect of prestressing is a new variable

and as such the same guidelines may not be applicable for

prestressed beams. In view of this the factor of safeties

enumerated above may be included for ensuring the lateral

stability of beams during shifting, transportation and erection

of prestressed, precast beams in the prestressed concrete

codes.

6.2. Design of Superstructure

The superstructure consists of six numbers of precast

pretensioned girders spaced at 2.15 m centre to centre with 250

mm thick end diaphragms to support 200 mm thick cast-in-site

RCC deck cantilevering by 1.10 m from the centre line of external

girders on either side. The pretensioned girders in the casting

yard were specified to be prestressed after 24 hours when the

strength of the concrete was 31 MPa, while the concrete grade

for the beams were M 40.

The precast girders were transported to site and placed on

bearings followed by casting of the end diaphragm. The RCC

deck slab was cast on formwork supported on girders and the

same was removed after the sufficient attainment of strength in

the deck. Thereafter, for the further loads such as weight of

crash barrier, wearing coat, railings and live load, etc. the

structure was assured to be a composite section. The effect of

differential shrinkage and temperature variation were also

considered in the design.

For finding all the longitudinal beam reaction components,

the grillage analysis (Fig. 6) was used for superimposed dead

loads and live loads, the structure was idealised as a grid of

longitudinal and transverse members. The composite girders

consisting of precast beam and deck slab was descretised to

be placed along the axis of the girder while deck slab and deck

slab with diaphragm was placed as transverse grillage members

along the line of each of end diaphragm in the structure. The

slab acts to transmit applied loads to beams by spanning

transversely between them, apart from providing means for

load sharing between longitudinal beams. Therefore transverse

members having slab properties were provided to reflect the

load sharing characteristics of the deck. For the application of

the loads due to railing, the dummy longitudinal members with

negligible section properties were provided at the edges and

transverse grillage members were continued to connect them.

The flaring properties of precast beams at the end for the

distance of 2.65 m from 200 mm to 300 mm thick has been

accounted for in the descretisation.

The grillage analysis results especially for superimposed

DESIGN AND CONSTRUCTION OF PRE-TENSIONED SUTLEJ BRIDGE IN PUNJAB

151

the prestressing moments near the simply supported ends

need to be reduced as the moments induced by self weight

and external loads gradually diminishes towards the supports

from midspan. The same is achieved by preventing the portion

of the tendons from bonding, thereby preventing from

stressing the concrete at the ends. Normally, the bond

prevention is achieved by provision of tight-fitting split plastic

tube or heavy paper or cloth tape. However, for the accurate

placement of tubes after the pre-tensioning a 20 mm dia PVC

tubes were used in Sutlej Bridge as bond prevention media at

the ends (Fig. 7).

The length of bond prevention has to be deduced after

catering for transmission length required to develop full

tension in the tendons.

Fig. 6. Grillage idealisation for deck slab with girders

dead loads and live loads were compared with Classical Little

and Morrice method for verification, which were found to be in

agreement to a large extent as illustrated in Table 1.

TABLE 1. GRILLAGE ANALYSIS

METHOD

VIA-A-VIS

LITTLE & MORRICE

The stresses in bottom and top fibres of the beam before

and after the composite action were ensured to be within the

permissible limits as specified in IRC:18 at various temporary

and service stages as tabulated in Table 2.

TABLE 2. SUMMARY OF STRESSES AT MID SPAN

When the pretensioning tendon is stressed, the diameter

of the tendon is reduced due to poisons effect and the original

diameter is regained after the release of prestress. In fact this

property is responsible for bonding pretensioned wires to

concrete. After the detensioning, the stress in the wire at the

end is zero and maximum after certain length, which is called

transmission length. The Hoyer was the first German

Engineer who developed the theory of transmission length

due to the formation of wedge shape in prestressing tendon

where the stress gradually decreases from maximum to zero

with the increase in diameter of tendon, which is popularly

referred as Hoyers effect.

The transmission length depends upon number of

variables, the most important being the strength of the concrete

at the time of transfer, the size of the tendon, friction between

the tendon and concrete and initial and effective stresses in

steel. As per the guidelines of IS:1343, 30 times the diameter of

the tendon for strands i.e. around 500 mm was considered as

transmission length in the said bridge. It is interesting to note

that the stress variation over transmission length being

parabolic, 80 per cent of the maximum prestress is developed

over half the transmission length, and as such half of the

transmission length was projected beyond bearing supports

for simply supported girders.

7. PRE-TENSIONING

The bridge of 23 spans consisted of 138 nos, 35.2 m long,

68 tonne weighing, prestressed beams with the depth of 2.50

m. Each beam consisted of 34 nos. of strands (tendons)

conforming to class-2 of IS:14268 with UTS of 1900 N/mm2.

Each strand of 15.2 mm dia was made up of 7 wires with 6 wires

surrounding the centre wire configuration resulting in

enhanced bond characteristics due to Hoyers effect, with net

strand cross sectional area of 140 mm2.

In case of the pretensioned girders with straight tendons,

The key factors in the choice and capacity of

pretensioning bed was the availability of time for precasting

girders and the economical considerations. The cost benefit

152

HEGGADE, MEHTA & PRAKASH ON

Fig. 7. Debonding arrangement for stands at the ends

analysis for various capacities of long line pre tensioning bed

was carried out as per the Table 3. Since the expenditure on

three beams casting was found to be economically optimum,

saving almost 15 months, the bed for casting three beams was

chosen, making perhaps the longest pretensioning bench in

the country with the length of 122.5 m, for stressing 115 m long

strands (Fig. 8).

TABLE. 3. COST BENEFIT ANALYSIS OF PRETENSIONING BENCH

The largest long line prestressing bed had its own share of

problems. Each strand was to be stressed to 21 tonnes,

warranting the capacity of the pretensioning bench to (2x34) =

714 tonnes. It is essential to design the pretensioning bed to

additional 20 per cent capacity as the prestressing force on

reaction abutment (Fig. 9) will increase due to long line bench

effect after casting of concrete, due to shrinkage and

temperature variation between the duration of casting of

concrete and detensioning. Prior to detensioning in the casting

yard, the strands can be stressed up to 0.80 UTS. Due to the

shrinkage of concrete clubbed with reduction in temperature,

shrinks the concrete along with the strands in the bonded length

thereby elongating and inducing further stress in the unbonded

length. If the increase in stress in unbonded length before

Fig. 8. Pre tensioning bench of 122.5 m, for stressing 15 m long strands

DESIGN AND CONSTRUCTION OF PRE-TENSIONED SUTLEJ BRIDGE IN PUNJAB

153

shuttering face, the reinforcement cages fabricated in three

pieces of 11 m each were shifted to casting bed by hydro

crane. The cages were suitably stiffened by diagonal bars

during transportation, which were removed once placed in

position in casting bed.

HT strands were cut to 115 m length and stacked over

raised platform along the line of casting bed. While opening

the coil, HT strands were passed through water tank to

remove protective coating. The cables were threaded manually

inserting through 20 mm dia PVC pipes of required length

meant for debonding. After fixing up the anchorages, the

cables were prestressed from stressing end in predetermined

sequence. The debonding pipes were positioned and sealed

with epoxy and tapes as per the drawing after the stressed

cables were anchored. The other face of the shuttering was

then lifted up and connected to already erect face by 16 mm

through bolts. The gaps were filled with foams for preventing

leakage and one end of the shuttering was provided with 50

mm wooden packing and thermo coal to facilitate easy removal

of shuttering after concreting.

Fig. 9. Cross section of Bulkhead

detensioning is beyond UTS, the strands in some cases may

even start snapping, as happened in Sutlej Bridge. The increase

in the stress of the unbonded tendon is directly proportionate

to the ratio of the length of the embedded strands to that of

total strand length. This is also affected by curing time and is

more severe when the ambient temperature during stripping is

low.

The key decisive factors in the choice of formwork for

pretensioned girders were:

(a) High resistance to damage due to rough handling.

(b) The precise dimension of the panels to fit together to

form a large unit with ease.

(c) Cleaning, setting, adjusting and handling ease.

(d) The ability of erecting one side independent of other.

(e) The ability to withstand the form and other vibrations.

(f) Rigid structural soffit form to secure and hold the side

form without movement during concreting.

(g) The minimum joints, which can be tightly sealed to

avoid leakage and bleeding.

The shuttering panels of 3 m length were erected using

8-ton capacity hydro crane, which was supported on ground

anchors by turnbuckles. After erection of one face of

shuttering the alignments to the precision could be carried out

by adjustments of turnbuckles. After the erection of one face

of shuttering the alignment to the precision could be carried

out by adjustment of turnbuckles. After the erection of one

The concrete produced by batching plant of capacity 30

m3/hr as per the design mix (Table 4.) transported through a

lead of 100 m by tractor trolley. As the concrete was to be

placed at height of 3.5 m from supply level a mechanical mode

was devised for placement. The device consisted of an

automatic conveyor designed and fabricated (Fig. 10) at site

in such way that it could move on a track line parallel to

pretensioning bed, receive concrete from trolleys up to 0.50

m3 at a time, carry the concrete through conveyor for 3.50 m

height and deliver to tremie for placement through funnel. The

device could be electrically operated by operator seated on

it, and reduced the concreting cycle to 2 hours from manual

concreting cycle of 5 hours. The concrete compaction was

achieved by poker and shutter vibrators.

TABLE 4. DESIGN MIX DETAILS

The transfer of prestress was induced by cutting strand

by acetylene torch in a pre-decided sequence after concrete

achieved the strength of 31 MPa. The best cycle time achieved

in the beam casting was 66 hours though on a average time

HEGGADE, MEHTA & PRAKASH ON

154

longitudinal trolleys.

Fig. 10. Mechanical device for concrete placement

cycle was 72 hours with the individual activity break-up as

shown in Table 5.

TABLE 5. CYCLE TIME FOR BEAM CASTING

To facilitate the movement of bed gantries and

longitudinal trolleys, the track line is laid on wooden sleepers

at 0.70 m c/c as per railway specification over well-prepared

compacted embankments. The motorised trolleys were moved

up to the span where beam was to be erected. The gantries

were used at the location to lift, side shift and lowering of

beam on pedestal as depicted in the Fig. 12 & 13. The lifting

was done with the aid of 750 mm stroke hydraulic jacks and 16

m long suspenders. The side shifting was done using the crab

assembly and winches set on top of gantries. Prior to the

lifting of the beams, the bearings were fixed at the soffit of

beams with sleeves already embedded during concreting. The

surface irregularities were dealt by application of 2 mm thick

epoxy over the bearings. The lowered beams were rested at

about 20 mm above the pedestal and the recess was grouted

using non-shrink cement grout. Till the time the recess was

grouted and end diaphragms were cast, the beams were placed

on wooden sleepers and held by temporary bracings.

On an average 5 hours cycle was comfortably achieved

as shown in the Table 6. with the progress of 3 beams per day

on a regular basis.

TABLE 6. CYCLE TIME FOR BEAM ERECTION

Despite the unforeseen impediments like non-availability

of stacking facilities, repairs of shuttering panels, maintenance

of bed alignment, and rain, etc. the casting of 138 nos. of

beams were completed in 320 days.

The pretensioning can be done either by stressing each

tendon individually or all together at a time. As the stressing

individually called for monostrand jack of 25 T capacity with

a stroke 1000 mm, the individual stressing of strands was

resorted to.

8. BEAM ERECTION

The transportation and erection of beams were

accomplished (Fig. 11) by 3 pairs of side shifting trolleys, a

pair of motorised longitudinal trolleys and a pair of 35-toon

capacity bed gantries. The side shifting trolleys were used

to shift the beams from casting bed to stacking yard and from

there to longitudinally motorised trolleys with the help of

jacks. The longitudinal trolleys being designed at lower levels,

the beams brought by side shifting trolleys were lowered to

In the water spans, between A/R to P8 and P10 to A/L, the

bed gantries and longitudinal trolleys were moved on railway

track over specially constructed embankments with the

provision of hume pipes at suitable intervals for passing the

water from u/s to d/s. However, not to constrict the water in a

too narrow passage, a temporary service bridge was made on

both sides of the piers to move the bed gantries between P8

and P10. This temporary bridge had single-line of piling on d/

s side to cater for the movement of one leg of the gantry where

as on upstream side two lines of piles were provided to move

longitudinal trolleys and transport other materials.

DESIGN AND CONSTRUCTION OF PRE-TENSIONED SUTLEJ BRIDGE IN PUNJAB

155

Fig. 11. Casting Yard Layout for Sutlej

trolley on top of the deck slab and supporting half of the gentry

(Fig. 14) on it proved to be safe, economical and fastest solution.

This method was adopted for shifting both the gantries across

P8 & P10 in seven days time without any risk and just taking

care by dropping plumbs at four locations on both sides of the

gantry to check the evenness of the movement.

Fig. 12. Showing the Erection scheme of Beam

Fig. 14. Transportation of gantry on deck

9. BEARINGS

Fig. 13. Erection, side shifting & placement

The single line of piles on downstream side was collapsed

during floods when the erection was in progress between P7 &

A/L on Nakodar side. However, on Jagraon side the gantry

was to be brought back to erect the beams on unfinished span

A/R-P22. Among the alternatives considered, providing a

POT and POT-cum-PTFE bearings were used in the Sutlej

Bridge. The typical bearing layout adopted in the bridge is

shown in the Fig. 15. Earlier, normally for the simply supported

bridges up to two lanes, fixed bearings (rocker) with a small

play provision on one end and free bearings (roller) in the

longitudinal direction having fixity in transverse direction has

been successfully used for straight superstructure like Sutlej

bridge. This arrangement for bridges with small deck width can

156

HEGGADE, MEHTA & PRAKASH ON

Fig. 15. Bearing configuration for Sutlej bridge

be still successfully adopted as expansion/contraction taking

place in pier caps and diaphragms connecting the superstructure

are same. Nevertheless, to avoid the transverse restraint likely

to be caused by thermal effects and wind force, a typical semi

classical bearing arrangement as shown in the layout was

adopted in Sutlej Bridge. As could be seen from the layout,

there were two types of bearings in span and these two types

of bearings might have different plate sizes and bolting

locations, depending upon the forces, rotations and movements.

In the precast construction like Sutlej Bridge, the grooves have

to be left in the beams at the bolting locations and as such the

manufacture of the bearings have to be approved prior to the

precasting of beams. Normally, the approval of bearing

manufacture is a very high lead-time item, which was well

synchronised in this project. At each pier location for a span,

two central bearings were fixed which were guided

longitudinally on the other side, where as two extreme girders

on either side were transversely guided while on other side left

free. This semi classical layout helped in reducing the types of

bearings to suit the precast construction.

10. LOAD TESTING OF SUPERSTRUCTURE

In line with the contract agreement, one of the spans was

to be validated by load testing to the designed IRC loading,

including impact factor. As shown in the Fig. 16 the IRC loadings

were simulated for the maximum moments in the midspan

including cycle track loadings. All the pedestals were

progressively and simultaneously loaded by progressive

increments of 25 per cent of the test load and the deflections

were recorded at the midspan of all girders

and and th

span of the third girder from left side. The maximum load was

sustained for 24 hours; during the period deflection readings

were taken at one-hour interval for the sustained loading. Then

the unloading was simultaneously carried out in 25 per cent

decrements with the readings taken during each decrement.

The deflection readings of unloaded structure continued at

one-hour interval for further 48 hours.

For each stage of loading and unloading, the observations

were made about the likely appearance of cracks, the linearity

of the load deflection curves or any other abnormalities in the

DESIGN AND CONSTRUCTION OF PRE-TENSIONED SUTLEJ BRIDGE IN PUNJAB

157

Fig. 16. Load Testing of Super Structure

load deflection behaviour. It was ensured that the bearings are

functional by measurement of rotation.

The deflection measurements were done by suspension

wire method at the required locations using dial gauges. In this

method stools were embedded in firm ground and dial gauges

of least count of 0.01mm were clamped to them. The spindles

of the dial gauges were connected by a pair of adapters in

plumb line with GI wire. To eliminate the effects of temperature,

the deflection readings were taken at fixed timings for all the

operation of loadings and unloading.

The maximum observed deflection for G3 girder at midspan

was 5.35 mm vis--vis maximum theoretical deflection of 7.3

mm, with the percentage recovery of 94.95, calculated as per

IRC: SP-51.

11. SUMMARYAND CONCLUSION

Precast pretensioning technology up to the span of 50 m

for river bridge decks can be economically exploited due to its

material efficiency. The following design and construction

aspects deserve special mention in the context of Sutlej Bridge.

1.

Design aspect

(a) Separate guidelines applicable to pretensioned

concrete in IRC:18; Universally, there are no separate

codes for post tensioning and pretensioning as the

majority of the aspects of prestressing are applicable

to both pretensioned and post tensioned concrete.

However, there is an urgent need to modify the IRC:

18 which is meant only for post tensioned concrete

bridges, to be applicable to both types of prestressing

by giving separate design parameters, such as time

dependent loss criteria, transmission length for

pretensioning, permissible stresses, etc. wherever

relevant and applicable.

(b) Lateral stability for long span prestressed, precast

beams; the guidelines for ensuring the lateral stability

given in the codes are based on steel and RCC beams.

Apart from span to depth and depth to top flange

width ratios, the three independent factor of safeties

i.e. (i) the factor of safety with respect to rotation

against tidal instability for the nearly perfect beams,

(ii) the factor of safety with respect to rotation with

casting imperfection (iii) the factor of safety vis--vis

the maximum rotation permissible has to be

established, with due recognition of prestressing

effects.

(c) Long line bench effect for pretensioning and Hoyers

effect for transmission length;

(d) Well cap at the level of LWL/GL to facilitate quality

construction; Providing well cap below the ground

level by 3 to 5 m will only enhance construction

difficulties and does not serve any aspect of good

engineering practice.

158

HEGGADE, MEHTA & PRAKASH ON

DESIGN AND CONSTRUCTION OF PRE-TENSIONED SUTLEJ BRIDGE IN PUNJAB

2. Construction aspect

(a) Provision of track-line for gantries as proper

embankment in the river bed;

(b) Provision of temporary Service Bridge across the river;

(c) Mechanisation of concreting for pretensioned beam.

(d) Use of large panel formwork for piers and beams;

(e) Bearing configuration, fixing of bearings and

stabilisation of beams after the erection till the casting

of diaphragms and deck slab;

Many of the above design and construction aspects

warrant in depth knowledge and meticulous micro planning to

suit the adoption of particular type of technology.

3. Proposal for codal guidelines for pretensioning

On the basis of designing and executing long span

pretensioned bridge spans, the authors propose the following:

(a) The minimum dimensions of the cross section shall

be

(i) Thickness of top flange: 100 mm

(ii) Thickness of bottom flange: 150 mm

(iii) Thickness of web: 150 mm

(b) The span to depth and depth to width ratios for

optimum beam cross section from lateral stability

considerations shall satisfy following Factor Of

Safeties

(i) FOS with out casting imperfections > 2

(ii) FOS with initial imperfections > 1.5

(iii) FOS with Actual angle of tilt > 1.1

(c) Provided adequate un-tensioned reinforcements are

designed for pre cast girder, the tension shall be

permitted at the top fibre of the girder which may be

restricted to 0.36(Fck)0.5.

(d) The losses due to seating and friction are not

applicable to pre tensioning. The elastic shortening

loss shall be considered for a condition that all strands

are stressed at the same time and pre stress transfer to

concrete is simultaneous. In case of pre tensioned

girders relaxation losses start as soon as pretensioning

is carried out, but the effect of which is transferred to

concrete at the time of pre stress transfer due to which

relaxation losses calculated as per IRC:18 shall be

divided by 2 for assessment of actually available pre

stressing force at transfer. It is not necessary to

consider 20 per cent additional time dependent losses

for pre-tensioned girders.

(e) Transmission length due to Hoyers effect shall be

considered to be 30 times the diameter of tendon.

(f) Pre tensioning bench for long line casting shall be

designed for 20 per cent additional capacity to

overcome Long Line Bench Effect.

ACKNOWLEDGEMENTS

The authors would like to place on record the sincere thanks

to honourable Managing Director, Joint Managing Director,

Chief Engineer and his colleagues of Punjab Infrastructure

Development Board (PIDB) without whose cooperation,

guidance and encouragement, the successful completion of

this bridge would not have been possible. The authors would

also like to thank all the engineers at H.O. and site of Gammon

India Limited for their monumental efforts to construct such a

large bridge within a very short period.

You might also like

- Drawing Title: Employer Project Design Consultant: HouseDocument5 pagesDrawing Title: Employer Project Design Consultant: HouseRoshan KejariwalNo ratings yet

- Finite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesFrom EverandFinite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesRating: 4.5 out of 5 stars4.5/5 (16)

- Mini Kin Design Book 4 The DitionDocument36 pagesMini Kin Design Book 4 The Ditionhalder_kalyan9216No ratings yet

- P8 Alok BhowmickDocument15 pagesP8 Alok BhowmickSony JsdNo ratings yet

- (Paper) - Portal Frame PierDocument23 pages(Paper) - Portal Frame PierShaileshRastogiNo ratings yet

- Draft Amendments in SP 114Document45 pagesDraft Amendments in SP 114Neeraj SharmaNo ratings yet

- ComentDocument100 pagesComentRajanNo ratings yet

- Journal of The IRC Oct-Dec14Document18 pagesJournal of The IRC Oct-Dec14Sony JsdNo ratings yet

- Bsec 1805 Op DN 01 PDFDocument227 pagesBsec 1805 Op DN 01 PDFChandan SharmaNo ratings yet

- INSDAG - SCI Publication 2012-13Document3 pagesINSDAG - SCI Publication 2012-13masteriragaNo ratings yet

- Bridge Manual Commentary PDF Complete v1.0Document160 pagesBridge Manual Commentary PDF Complete v1.0Pang Chong HengNo ratings yet

- bd10 - 97 Highway Structures - General Design PDFDocument31 pagesbd10 - 97 Highway Structures - General Design PDFSuheil BagasrawalaNo ratings yet

- Design of 24.0m PSC GirderDocument56 pagesDesign of 24.0m PSC GirderVishal SharmaNo ratings yet

- 4 Standards and Preliminary Design of Bridges 23Document26 pages4 Standards and Preliminary Design of Bridges 23Praveen BhandariNo ratings yet

- 04Jun2020100609Lecture 5 by DR Lakshmy ParameswaranDocument94 pages04Jun2020100609Lecture 5 by DR Lakshmy ParameswaranRashid Irshad AliNo ratings yet

- JournalApr Jun12Document168 pagesJournalApr Jun12Anonymous YHcvra8Xw6No ratings yet

- Prologue To Presentation: Code of Practice For Concrete Road Bridges IRC:112Document9 pagesPrologue To Presentation: Code of Practice For Concrete Road Bridges IRC:112Sony JsdNo ratings yet

- National Highways Authority of IndiaDocument17 pagesNational Highways Authority of IndiaPrabhnoor KaurNo ratings yet

- Seismic Effects On Perofrmance of Bridges PDFDocument18 pagesSeismic Effects On Perofrmance of Bridges PDFkondaNo ratings yet

- Capability Report 2022Document21 pagesCapability Report 2022Akhilendra Pratap SinghNo ratings yet

- Condition Survey and Rehabilitation of BridgeDocument11 pagesCondition Survey and Rehabilitation of BridgeManvendra NigamNo ratings yet

- Appendix H PDFDocument59 pagesAppendix H PDFarif_rubinNo ratings yet

- Bangladesh RailwayDocument12 pagesBangladesh RailwaySharmistha Talukder KhastagirNo ratings yet

- Implication of IRC 112 - 2011 On RCC Bridge DesignDocument8 pagesImplication of IRC 112 - 2011 On RCC Bridge DesignkrunalNo ratings yet

- Design of Substructure 4 PileDocument328 pagesDesign of Substructure 4 PileisurupushNo ratings yet

- DBR Rev.G 26th SeptDocument51 pagesDBR Rev.G 26th Septsudhir12345No ratings yet

- Kali Khola FinalDocument15 pagesKali Khola FinalsurendramaharjanNo ratings yet

- Abutment & Pile FDN MCW FOR MNB 43+790 - Fixed 03.09.2020 PDFDocument79 pagesAbutment & Pile FDN MCW FOR MNB 43+790 - Fixed 03.09.2020 PDFAtanu AdhiakryNo ratings yet

- Br. No.-312 ADocument99 pagesBr. No.-312 AShashibhushan SinghNo ratings yet

- Design of Precast Pier Cap - 1Document24 pagesDesign of Precast Pier Cap - 1Ankush SharmaNo ratings yet

- IrcDocument9 pagesIrcAshwani KesharwaniNo ratings yet

- Loads For Design of Sub-Structure 28.12.20Document72 pagesLoads For Design of Sub-Structure 28.12.20mayank007aggarwal100% (1)

- Installation of Large Diameter Bored Pile Socketed in Hard Rock With RCD For MTHL, MumbaiDocument10 pagesInstallation of Large Diameter Bored Pile Socketed in Hard Rock With RCD For MTHL, MumbaiAkshay SakhujaNo ratings yet

- Design Basis Report-Nh208Document19 pagesDesign Basis Report-Nh208Atanu AdhiakryNo ratings yet

- Pre-Casting, Pre-Tensioning & Launching of Full Span Super-Structure in IndiaDocument2 pagesPre-Casting, Pre-Tensioning & Launching of Full Span Super-Structure in IndiafaumijkNo ratings yet

- DWG - DGN of Elatomeric Bearing - Deharadun - r2Document16 pagesDWG - DGN of Elatomeric Bearing - Deharadun - r2RAJAT SHARMANo ratings yet

- Handouts - 21.09.2019Document158 pagesHandouts - 21.09.2019Sulabh GuptaNo ratings yet

- Lecture 1Document36 pagesLecture 1Anubhav Chaudhary100% (1)

- Touch Pile DesignDocument24 pagesTouch Pile DesignsanilNo ratings yet

- Steel Bridge Code PDFDocument139 pagesSteel Bridge Code PDFmallikarjuna rao bodduNo ratings yet

- DBR VupDocument15 pagesDBR Vuparif_rubinNo ratings yet

- AdSec Theory PDFDocument72 pagesAdSec Theory PDFPhan Anh NhậtNo ratings yet

- Trans Mainspan Updated ModifiedDocument413 pagesTrans Mainspan Updated ModifiedANKUR GHOSHNo ratings yet

- IAHE Sultanganj Presentation - 1 PDFDocument75 pagesIAHE Sultanganj Presentation - 1 PDFBalakumaran GunasekaranNo ratings yet

- Design Report-1Document23 pagesDesign Report-1kassovNo ratings yet

- DBR - Rev GDocument51 pagesDBR - Rev Gsudhir12345No ratings yet

- Irc Ih June 2018Document76 pagesIrc Ih June 2018Subhransu Sekhar Swain100% (1)

- 806 Ed MJB 01 4102 R1Document1 page806 Ed MJB 01 4102 R1ManukantShrotriyaNo ratings yet

- IRC 24 (SteelRdBrdge) Amendment 01 IRC 24 2010, JAN 2014Document2 pagesIRC 24 (SteelRdBrdge) Amendment 01 IRC 24 2010, JAN 2014msn722005No ratings yet

- Oasys Adsec: Help ManualDocument79 pagesOasys Adsec: Help ManualThomas LAiNo ratings yet

- Transverse AnalysisDocument19 pagesTransverse AnalysisSulabh GuptaNo ratings yet

- Innovations in Tied Arch BridgesDocument23 pagesInnovations in Tied Arch BridgesDhrubojyoti SenguptaNo ratings yet

- Observations On 32m RCC T BeamDocument3 pagesObservations On 32m RCC T BeamamirNo ratings yet

- Earthquake Resistant Design of Bridges-1Document42 pagesEarthquake Resistant Design of Bridges-1sanilNo ratings yet

- Design Note No. DN-P-126-002 Transverse Design of Box GirderDocument59 pagesDesign Note No. DN-P-126-002 Transverse Design of Box Girderinfra120No ratings yet

- SPH Bearing Draft (09.06.11)Document38 pagesSPH Bearing Draft (09.06.11)Dave ThompsonNo ratings yet

- Aashto - DIN Standard (In Germany) - BS 5400 (British Standard) - Indian Roads Congress (IRC) Bridge CodeDocument45 pagesAashto - DIN Standard (In Germany) - BS 5400 (British Standard) - Indian Roads Congress (IRC) Bridge CodeTeshu NigusieNo ratings yet

- T Girder My DataDocument141 pagesT Girder My DataSudip PathakNo ratings yet

- Project DetailsDocument15 pagesProject Detailsshashirajhans2140No ratings yet

- Gaja Mini ProjectDocument78 pagesGaja Mini ProjectBharath Chakravarthy100% (3)

- IJCRT2107063Document6 pagesIJCRT2107063shaik saifulla lNo ratings yet

- CE 113 CIVIL-ENGINEERING-ORIENTATION-syllabusDocument5 pagesCE 113 CIVIL-ENGINEERING-ORIENTATION-syllabusaceNo ratings yet

- Service Publication ListDocument177 pagesService Publication ListCristian m VizcainoNo ratings yet

- Concrete Durability Requirement Based On ACI-318-19Document14 pagesConcrete Durability Requirement Based On ACI-318-19MIL RABNo ratings yet

- PGHU-EH-CSPDS-000103 Rev 0 - Design Loads For StructuresDocument10 pagesPGHU-EH-CSPDS-000103 Rev 0 - Design Loads For StructuresGiovanni AlfieriNo ratings yet

- Sump Pumps: Guide For InstallationDocument4 pagesSump Pumps: Guide For InstallationMassi MateenNo ratings yet

- Aisc Asd-89 Example 001Document5 pagesAisc Asd-89 Example 001gusla7No ratings yet

- Assignment: Pile FoundationDocument17 pagesAssignment: Pile Foundationsunil khandelwalNo ratings yet

- Review of Related LiteratureDocument12 pagesReview of Related LiteratureJohn Clyde Agayao100% (1)

- DNTanks PrestressedConcreteTank PDFDocument122 pagesDNTanks PrestressedConcreteTank PDFTam AlasadiNo ratings yet

- D Scheme (Marine)Document166 pagesD Scheme (Marine)jeevaNo ratings yet

- Chapter 1: Introduction: Prestressing of ConcreteDocument5 pagesChapter 1: Introduction: Prestressing of ConcreteSamih S. BarzaniNo ratings yet

- Effect of Aggregate Size Distribution On Concrete Compressive StrengthDocument5 pagesEffect of Aggregate Size Distribution On Concrete Compressive StrengthPrakash Kumar KumarNo ratings yet

- MATS322 Fall2020 Midterm1 AnswersDocument8 pagesMATS322 Fall2020 Midterm1 AnswersWilliam Carl KistlerNo ratings yet

- GS Ep PVV 107 enDocument38 pagesGS Ep PVV 107 ensenthil muruganNo ratings yet

- Strength Calculation As Per Ibr Boiler Maker'S No.: Atpl-Rb002Document9 pagesStrength Calculation As Per Ibr Boiler Maker'S No.: Atpl-Rb002mohan babuNo ratings yet

- IPC Payment Milestones (31-Jul-2019) FinalDocument10 pagesIPC Payment Milestones (31-Jul-2019) FinalMunir HussainNo ratings yet

- Strength of Materials IiDocument48 pagesStrength of Materials IiARUNRAJH.V.GNo ratings yet

- Stabilization of Black Cotton Soil by Admixtures PDFDocument19 pagesStabilization of Black Cotton Soil by Admixtures PDFSantosh NaikNo ratings yet

- 1200 Manhole FEMA PDFDocument40 pages1200 Manhole FEMA PDFDeepak ChaubeyNo ratings yet

- Statics (KM10903) : Session 2012/2013Document10 pagesStatics (KM10903) : Session 2012/2013Alvin Tung Kwong ChoongNo ratings yet

- MADE EASY Postal Study Package Front PageDocument9 pagesMADE EASY Postal Study Package Front PagehirealchadhereNo ratings yet

- Hybrid PU Waterproofing Compound: DampflexDocument2 pagesHybrid PU Waterproofing Compound: DampflexVasanth KumarNo ratings yet

- 6 Design of Footings - AllDocument65 pages6 Design of Footings - Alldigiy40095No ratings yet

- RCC95 Continuous Beams (Tables)Document8 pagesRCC95 Continuous Beams (Tables)Felicia GhicaNo ratings yet

- Stability Analysis of Concrete StructuresDocument161 pagesStability Analysis of Concrete StructuresekaamfNo ratings yet

- Ngen 2022 V (1.1) - Release NoteDocument15 pagesNgen 2022 V (1.1) - Release NoteKwasi BempongNo ratings yet

- Ce Syllabus s-13 III - VIII SemDocument150 pagesCe Syllabus s-13 III - VIII Semapi-279049687No ratings yet

- PSC Girder Before Concreting MIPL CL 32Document2 pagesPSC Girder Before Concreting MIPL CL 32Rayudu VVS100% (1)

- PICE Presentation 060823 Akira MitoDocument40 pagesPICE Presentation 060823 Akira MitoJohn Michael AngelesNo ratings yet