Professional Documents

Culture Documents

TECASTVEKTON

Uploaded by

Jonathan CruzCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TECASTVEKTON

Uploaded by

Jonathan CruzCopyright:

Available Formats

(Cast nylon)

TECAST VEKTON cast nylon,

available in a variety of grades,

offers a combination of good

mechanical properties,

excellent bearing and wear

characteristics, and the largesize capabilities of the casting

process. Its fatigue resistance,

noise damping ability, corrosion

resistance, and light weight

make TECAST VEKTON ideal

for metal replacement

applications, such as bearings,

gears, sheaves, and sprockets.

At one-eighth the weight of

bronze, TECAST VEKTON is

easier to handle and maintain

than metals such as iron,

aluminum, brass, and bronze,

which it typically replaces in

industrial wear applications.

Other materials that TECAST

VEKTON commonly replaces

because of its superior

performance are laminated

phenolics, elastomers, and

wood.

TECAST VEKTON has

excellent wear and abrasion

resistance, resulting in

extended component life and

lower maintenance cost. Its

formulations are readily available in rod, plate, and tube.

Nonstandard shapes, such as

rings, discs, and blocks can be

economically produced in small

quantities with short lead

times. Custom parts can be

cast-to-size or near-net-shape

with relatively inexpensive

tooling.

TECAST VEKTON 6PA NATURAL

TECAST VEKTON 6PA BLACK

TECAST VEKTON 6PA BLUE

TECAST VEKTON 6PAM

TECAST VEKTON 6PAG

TECAST VEKTON 6XAU

TECAST VEKTON 6PAL

TECAST VEKTON

TECAST VEKTON

An FDA-compliant cast type 6 nylon used in applications requiring cast nylon

advantages without fillers.

A black cast type 6 nylon that is more UV resistant than 6PA natural.

A blue cast type 6 nylon with properties similar to 6PA natural.

A molybdenum disulfide-filled cast type 6 nylon used for general bearings and wear

applications because of its superior strength and hardness.

A graphite powder-filled cast type 6 nylon with properties similar to 6PAM but better

suited to wet applications.

A high heat (up to 260F continuous), weather resistant cast type 6 nylon with

superior fatigue-resistance and bearing properties.

An oil-filled cast type 6 nylon used in applications requiring excellent bearing and

wear properties where external lubrication is difficult or impractical.

Its unique combination of strength, wear resistance, toughness, machinability, and corrosion resistance make TECAST VEKTON cast nylon ideal for bearings, thrust washers, bushings, wear pads, sheaves, rollers, gears, sprockets, and wheels. TECAST VEKTON is commonly used in construction equipment, material handling systems,

amusement park rides, pulp and paper processing equipment, steel mills and industrial

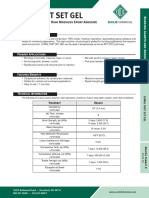

TYPICAL PROPERTY VALUES

ASTM

Test

Method

Units

Density

Specific Gravity

Water Absorption, @ 24 hours, 73F

@ Saturation, 73F

D792

D792

D570

D570

lbs/in3

g/cc

%

%

Tensile Strength @ Yield, 73F

Tensile Modulus

Elongation @ Break, 73F

Flexural Strength, 73F

Flexural Modulus, 73F

Compressive Strength

Izod Impact Strength, 73F

Rockwell Hardness, 73F

Shure Hardness

Wear Factor Against Steel, 40 psi, 50 fpm

D638

D639

D638

D790

D790

D695

D256

D785

D3702

D3702

D3702

MECHANICAL

PHYSICAL

PROPERTIES

THERMAL

Heat Deflection Temperature @ 66 psi

D648

@ 264 psi

D648

Coefficient of Linear Thermal Expansion

D696

Maximum Servicing Temperature, Intermittent

Long Term UL746B

Specific Heat

Thermal Conductivity

Vicate Softening Point

Melting Point

D2133

Flammability

UL94

ELECTRICAL

Static Coefficient of Friction

Dynamic Coefficient of Friction, 40 psi, 50 fpm

Surface Resistivity

Volume Resistivity

Dielectric Strength

Dielectric Constant, @ 60 Hz, 73F, 50% RH

@ 1 MHz

@ 20 GHz

@ 30 GHz

Dissipation Factor, @ 60 HZ, 73F

D257

D257

D149

D150

D150

D150

D150

D150

Tecast

Vekton

6PA

Tecast

Vekton

6XAU

Tecast

Vekton

6PAM

6PAG

Tecast

Vekton

6PAL

.0416-.0419 .0416-.0419 .0416-.0423 .0412-.0416

1.15 - 1.16 1.15 - 1.16 1.15 - 1.17 1.14 - 1.15

1.2

1.2

1.2

.75

-

10,000

350,000

25

12,500

350,000

.6

115

200 x 10-10

.26

11,000

350,000

20

12,500

350,000

.7

115

-

11,000

350,000

20

12,500

350,000

.6

115

-

8,800

350,000

25

12,500

325,000

1.2

100

-

F

F

in/in/F

F

F

BTU/lb-F

F

F

-

370

200

4.0 x 10-5

300

200

.40

1.67

428

HB

370

200

4.0 x 10-5

350

260

428

-

370

200

4.0 x 10-5

300

200

428

-

4.0 x 10-5

330

200

428

-

ohm/square

ohm-cm

V/mil

-

1014

500

3.7

-

1014

500

3.7

-

500

3.7

-

psi

psi

%

psi

psi

psi

ft-lbs/in

R Scale

D Scale

in3 x 1

hr

PV

-

This information is only to assist and advise you on current technical knowledge and is given without obligation or liability.

All trade and patent rights should be observed. All rights reserved. Data obtained from extruded shapes material.

MATERIAL AVAILABILITY

Rods: Diameters: 2 - 8 diameter, 4 length

9 to 20 diameter, 12 length

Plates: 1/4 to 4 thickness inclusive are 2 x 4, 4 x 4 and 4 x 8

3/8 and greater also available in 4 x 8

Primary Specification (Typical)

6PA: L-P-410a

6PAM: L-P-410a Wear Resistant

Shapes Specification (Typical)

6PA: ASTM-D-5989 S-PA0211

6PAL: ASTM-D-5989 S-PA0251

6PAM: ASTM-D-5989 S-PA0221

P

A

EN

IN

0 0 CER

01:20

TI F

I

ED

ISO

Profiles, tubes, and special sizes are custom-produced on request.

90

GE

R WA S H I N G T O

DISTRIBUTED BY

Division of Ensinger, Inc.

HEADQUARTERS

365 Meadowlands Boulevard

Washington, Pennsylvania 15301

Telephone: 800-243-3221 Sales

800-869-4029 Technical

Fax: 724-746-9209

e-mail: sales@ensinger-ind.com

CANADA

Ensinger-Plastifab

8115 Lafrenaie Street

Montreal, Quebec H1P 2B1

Telephone: 514-325-9840

Fax: 514-325-5222

Web site: www.plastifab.ca

e-mail: infoprod@plastifab.ca

VE501/0604

You might also like

- Terex Jaques - ST JawDocument12 pagesTerex Jaques - ST Jawjonathandyson100% (2)

- Aluminum HoneycombDocument8 pagesAluminum HoneycombManoj ManoharanNo ratings yet

- VCS Flange SealDocument2 pagesVCS Flange SealBaskar KannaiahNo ratings yet

- RT Duroid 6006 6010 Laminate Data SheetDocument2 pagesRT Duroid 6006 6010 Laminate Data SheetdrhammoudaNo ratings yet

- Catalog PACKINGDocument24 pagesCatalog PACKINGAnton FransiscusNo ratings yet

- PREPRUFE 300R Plus & 160R Plus Membranes Data Sheet (US Version)Document2 pagesPREPRUFE 300R Plus & 160R Plus Membranes Data Sheet (US Version)Joyce Agustine Glory LNo ratings yet

- Ficha Tecnica PikotekDocument2 pagesFicha Tecnica Pikoteking_arriagaNo ratings yet

- Atlas Copco TEX Breakers BrochureDocument16 pagesAtlas Copco TEX Breakers BrochureSumit BhasinNo ratings yet

- Nylon Screws Test DataDocument6 pagesNylon Screws Test DatadineshNo ratings yet

- Vinyl Sheet Pile Datasheet (Id)Document1 pageVinyl Sheet Pile Datasheet (Id)dedyNo ratings yet

- Waterstop PVC BalbeckDocument7 pagesWaterstop PVC BalbeckLuis Carlos EsquivelNo ratings yet

- Gas & Steam Turbine GeneratorsDocument2 pagesGas & Steam Turbine GeneratorsJuan Carlos Vivas GuioNo ratings yet

- ALS7501 01 Sucker Rods Brochure PDFDocument8 pagesALS7501 01 Sucker Rods Brochure PDFedinson saenzNo ratings yet

- AVT Ball & Butterfly Brochure 05 Latest 12 PageDocument12 pagesAVT Ball & Butterfly Brochure 05 Latest 12 PageshalbyNo ratings yet

- SafariDocument20 pagesSafarizahiruddinNo ratings yet

- Belting Correia de BorrachaDocument54 pagesBelting Correia de BorrachaFilype NascimentoNo ratings yet

- Arc Insulations BrochureDocument5 pagesArc Insulations BrochureacompositesNo ratings yet

- Kiswire - NeptuneDocument8 pagesKiswire - NeptunealphadingNo ratings yet

- RT Duroid 6006 6010 Laminate Data SheetDocument2 pagesRT Duroid 6006 6010 Laminate Data SheetSaravanakumar SermarajaNo ratings yet

- Steel Pad Catalog PageDocument1 pageSteel Pad Catalog PageTang Hong ChiangNo ratings yet

- Black Knight 1000 BrochureDocument2 pagesBlack Knight 1000 BrochureAdamMitchellNo ratings yet

- FLYER ROTOCLEAN and Mobile Dust Collectors ECO 2CDocument2 pagesFLYER ROTOCLEAN and Mobile Dust Collectors ECO 2CDaniel AustinNo ratings yet

- Arrester GEDocument26 pagesArrester GEDionisio Guzman100% (1)

- Polyken 930: Product Data SheetDocument2 pagesPolyken 930: Product Data SheetEdwin Bustamante Cabrera100% (1)

- WaboElastoFlex Park 0408Document4 pagesWaboElastoFlex Park 0408Cristhian Alfonso Mandujano PérezNo ratings yet

- J CreteDocument8 pagesJ CreteWilber Rojas PilcoNo ratings yet

- TEX 10 Pneumatic Pick Hammer: Long Stroke. Hard Hitting. Low WeightDocument4 pagesTEX 10 Pneumatic Pick Hammer: Long Stroke. Hard Hitting. Low Weightalexander_1985No ratings yet

- Polyken 936 TapeDocument2 pagesPolyken 936 TapeKyaw Kyaw AungNo ratings yet

- TICO Structural BearingsDocument14 pagesTICO Structural BearingsTheoniusNo ratings yet

- Fabrication of Large GRP Storage TanksDocument60 pagesFabrication of Large GRP Storage TanksjoekaledaNo ratings yet

- GPT 1-3 PGE Tech SpecificationsDocument4 pagesGPT 1-3 PGE Tech SpecificationsEhtisham AndrAbiNo ratings yet

- Description Features and CharacteristicsDocument2 pagesDescription Features and CharacteristicsPranpath NarupantawartNo ratings yet

- Pipe CatalogueDocument6 pagesPipe CatalogueirfanNo ratings yet

- Fibretron BrochureDocument13 pagesFibretron Brochureravi kumarNo ratings yet

- Materials Selection Guide AluminiaDocument3 pagesMaterials Selection Guide AluminiaHardik AcharyaNo ratings yet

- Aslan100 GFRPDocument20 pagesAslan100 GFRPzsomborusNo ratings yet

- RO3000 Pour Rogers 3006 PDFDocument4 pagesRO3000 Pour Rogers 3006 PDFTeddy112No ratings yet

- LA AN NY YA AR RD D P PU UL LLR LRO OP PE E: Lanyard Pull RopeDocument2 pagesLA AN NY YA AR RD D P PU UL LLR LRO OP PE E: Lanyard Pull Ropemathan_aeNo ratings yet

- Fabrock 30: Board Insulation For OEM ApplicationsDocument2 pagesFabrock 30: Board Insulation For OEM ApplicationsCristhian RangelNo ratings yet

- Web ProductSheet DiamondWrap 2018 PDFDocument2 pagesWeb ProductSheet DiamondWrap 2018 PDFRiankwnNo ratings yet

- Polyken 930: Product Data SheetDocument2 pagesPolyken 930: Product Data SheetAgustina De Winne100% (1)

- Clock Spring Diamond Wrap BrochureDocument2 pagesClock Spring Diamond Wrap BrochuremuhammadxpNo ratings yet

- ECL Sanilec Supplier CatalogueDocument3 pagesECL Sanilec Supplier CatalogueIsabelle LoNo ratings yet

- Mining Hose - Hard Wall Range (808) : Excellent Minerals SolutionsDocument2 pagesMining Hose - Hard Wall Range (808) : Excellent Minerals Solutionshiram89No ratings yet

- Canada - 2015 - Fiberglass Rods For Modern Composite InsulatorsDocument6 pagesCanada - 2015 - Fiberglass Rods For Modern Composite InsulatorsgdssgdNo ratings yet

- Surface Belt Structure: Cema C & D SeriesDocument8 pagesSurface Belt Structure: Cema C & D SeriesSari Ully SibaraniNo ratings yet

- Mobil DTE 10 Excel SeriesDocument3 pagesMobil DTE 10 Excel SeriesSuprastowo Bin SarinoNo ratings yet

- Dural Fast Epoxy Gel EuclidDocument3 pagesDural Fast Epoxy Gel Euclidpayaso1973No ratings yet

- Gearresters Fullcatalog PDFDocument26 pagesGearresters Fullcatalog PDFRatilal M JadavNo ratings yet

- Locked SeamDocument8 pagesLocked SeamTony DuignanNo ratings yet

- TEX Pneumatic Breakers: When Quality CountsDocument16 pagesTEX Pneumatic Breakers: When Quality Countsalexander_1985No ratings yet

- CHAD Tech Manual AAC EcoPanel V3.outputDocument68 pagesCHAD Tech Manual AAC EcoPanel V3.outputbadar_tsaniNo ratings yet

- Large Generators WEBDocument16 pagesLarge Generators WEBHiep NguyenNo ratings yet

- HV Juice Apr-May2015 WebDocument8 pagesHV Juice Apr-May2015 WebFerran MunyósNo ratings yet

- CRDocument8 pagesCRErfan EffendyNo ratings yet

- WaboCrete SiliconeSeal 0321 DataSheet-2.2023Document4 pagesWaboCrete SiliconeSeal 0321 DataSheet-2.2023marketing.avaneeshNo ratings yet

- SPE 78705 Development of Composite Progressing Cavity PumpsDocument4 pagesSPE 78705 Development of Composite Progressing Cavity PumpsRonald LlerenaNo ratings yet

- TERA Joint BrochureDocument16 pagesTERA Joint BrochureraigoukiNo ratings yet

- Load-Bearing Fibre Composites: International Series on the Strength and Fracture of Materials and StructuresFrom EverandLoad-Bearing Fibre Composites: International Series on the Strength and Fracture of Materials and StructuresNo ratings yet

- Geotextiles and Geomembranes HandbookFrom EverandGeotextiles and Geomembranes HandbookT.S. IngoldRating: 5 out of 5 stars5/5 (1)

- Inox 316Document2 pagesInox 316Jonathan CruzNo ratings yet

- BW140E Welding in Tool Making PDFDocument24 pagesBW140E Welding in Tool Making PDFJonathan CruzNo ratings yet

- HZ Tecaflon Ptfe Natural in de 201501Document1 pageHZ Tecaflon Ptfe Natural in de 201501Jonathan CruzNo ratings yet

- Tivar 1000 PDS e 31052011Document1 pageTivar 1000 PDS e 31052011Jonathan CruzNo ratings yet