Professional Documents

Culture Documents

Ventialtion CalculatiON

Uploaded by

shyam_anupCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ventialtion CalculatiON

Uploaded by

shyam_anupCopyright:

Available Formats

APPENDIX D.

12

Ventilation Calculations and Data

1. Hydration Pump Station Electrical Room Ventilation

Calculations

2. Inflow Pump Station Engine Room Ventilation

Calculations

3. JennFan Data

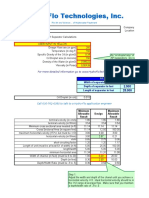

APPENDIX D.12 item 1 Calculation - Hydration Pump Station

Purpose: Ventilation for electrical room.

System Description: The electrical room shall house the electrical, instrumentation and

control, and the communication equipment. The ventilation system shall consist of an

exhaust fan that will exhaust the heated air from the room with an intake louver to permit

the cooler outside air to enter the room. The exhaust fan shall be thermostatically

controlled.

Design Criteria:

1.

2.

3.

4.

Allowable free air velocity for a intake louver = 700 fpm

Maximum 104 degrees F temperature in pump station.

Add 16 percent additional free area for bug screen.

The Outdoor design conditions shall be based on those of Fort Lauderdale,

Florida.

Assumptions:

1.

2.

3.

4.

Lighting heat gain ~ 2W/ft^2

Fan heat gain ~ 80 Btu/hr/fan

Ignore operating floor cooling effect

Assume box-like structure fully exposed. The building will have no windows and

be constructed of cast-in-place concrete and 8 fully grouted masonry units. The

roof shall be 10 hollow core slabs. The solar heating loads shall be addressed by

a 10 percent increase in the ventilation air supply. At 30% design the solar heat

load will be calculated due to the large openings required for detailing the

building design. Other building heat loads shall be assumed to be negligible.

Calculations:

Determine ventilation supply fan sizing:

Lighting heat load = 16 x 21 x 2 = 672 W = 38.2 btu/min

Fan heat load = 80 Btu/hr = 1.33 Btu/min

Heat Gain Equipment Electrical Room (preliminary estimate) 5 kW = 285 Btu/min

Total heat load = 285 + 38.2 + 1.33 = 325 Btu/min + 10% envelop heat load + 15% heat

load contingency = 406 Btu/min

q = 1.08 x Q x (Ti to) = (40.6) x (60) = 1.08Q (9 deg F)

Q = 2,500 CFM

1

Determine louver size:

2,500 CFm/700 = 3.6 sq. ft.

Add 16% for bug screen = 3.6 + 16% = 4.2 sq. ft.

Required fan rating: 2,500 CFM

JennFan model 203A: rating of 1,800 CFM, 1/3 Hp motor, requiring a 24 x 24 wall

opening. (Reference JennFan data Appendix D.12 item 3)

APPENDIX D.12 item 2 Calculation - Inflow Pump Station

Purpose: Ventilation for engine pump room at the Inflow Pump Station.

System Description: A forced air ventilation system will be provided for the operating

floor area of the pump station. The ventilation system will be available during all times of

the year to remove space heat gains and will utilize wall mounted fans for supply and for

exhaust.

INFLOW PUMP STATION VENTILATION REQUIREMENT

Design Assumption:

Remarks:

1. The equipment enclosure (pump room) is not air

conditioned

2. The operating floor inside station temperature is 100 deg.F, dry

District Standard Ventilation

bulb

3. The outdoor air temperature is 95 deg.F dry bulb

4. The safety factor is 5%.

5. 500 fpm ventilation air velocity

Min. 400 fpm by District

6. Diversity Factor is .75

Part I. Heat Gain Calculation

A. Electrical Pump Motor

Qty of 2 of 200 Hp Electrical motors

Usage factor (UF) is .5 and Load Factor (LF) is .9

And assuming the efficiency is 85%.

qep = P *

1 Eff

* UF * LF

Eff

qep = 101070

BTU

hr

Per pump motor sensible heat gain

Qep = 101070

BTU

hr

Heat Gain of 2 pumps

B. Diesel Pump Engines

INFLOW PUMP STATION VENTILATION REQUIREMENT

Design Assumption:

Remarks:

1. Qty of 3, 800 Hp Diesel Engine

Caterpillar C27DITA

q dp = 7,166

Heat Rejection to Atmosphere per

Btu

min .

Q dp = 1,289,880

Product specification at 90% load.

Total Heat Rejection by three 800

Btu

Hr..

Hp Diesel pumps(90% load)

C. Diesel Generators

Qty of two 600 KW Diesel Generators and lead/lag operated

Cummins Genset 600KW

Usage Factor = .5

Load Factor = 1

= 7790

Per manufacturer product

BTU

Min

Qg = qg * LF * UF * Qty = 467400

specification

BTU

hr

D. Total Heat Gain

Q = (Qep + Qdp + Qg)*(1+SF)*.D.F.

Q dp = 1,463,450

Total Heat Gain

Heat Gain after applying safety

Btu

Hr.

factor and diversity factor

Total heat gain including solar heating load is addressed in

Part II.A. by 10% increase in the Make up air supply

Part II. Ventilation Requirement ( H.I.)

A. Make up Air

CFM int ake =

Q

1,463,450

=

= 271,009cfm

1.08 * t 1.08 * (100 95)

Refer to design assumption

(6) Greenheck SBCS-3H72-150

Intake air velocity = 500 fpm

A=

Free area of intake louvers opening

271,009

= 542 ft 2

500

(Gravity intake)

B. Exhaust Air

INFLOW PUMP STATION VENTILATION REQUIREMENT

Design Assumption:

Remarks:

Generator 2,280 cfm

Standby

800hp engine 1650cfm

90%

Total combustion air 7,230cfm

90%

Total exhaust air 290,880cfm

(6) Greenheck SBCE-3H72-150

Part II. Ventilation Requirement ( USACE)

A. Make up Air

CFM int ake =

Q

1,463,450

=

= 150,560cfm

1.08 * t 1.08 * (104 95)

Refer to design assumption

(4) Greenheck SBCS-3L54-75

Intake air velocity = 500 fpm

A=

Free area of intake louvers opening

150,560

= 301 ft 2

500

(Gravity intake)

B. Exhaust Air

-

Generator 2,280 cfm

Standby

800hp engine 1650cfm

90%

Total combustion air 7,230cfm

90%

Total exhaust air 158,386cfm

(4) Greenheck SBCS-3L48-75

Part II. Ventilation Requirement ( USACE-Ft. Lauderdale)

A. Make up Air

CFM int ake =

Q

1,463,450

=

= 115,815cfm

1.08 * t 1.08 * (104 92.3)

Using USACE req. and Ft Laud.

climatic design ASHRAE info.

(4) Greenheck SBCS-3H54-75

Intake air velocity = 500 fpm

A=

Free area of intake louvers opening

115,815

= 232 ft 2

500

(Gravity intake)

B. Exhaust Air

-

Generator 2,280 cfm

Standby

800hp engine 1650cfm

90%

INFLOW PUMP STATION VENTILATION REQUIREMENT

Design Assumption:

-

2000hp engine 5455cfm

Total combustion air 7,230cfm

Remarks:

90%

Total exhaust air 153,750cfm

(4) Greenheck SBCE-3H48-75

Note: At 30% design the solar heat load will be calculated

due to the large openings required for detailing the building

design.

Reference fan and filter data (see Appendix D.12 item 3)

You might also like

- Back Pressure ExhaustDocument12 pagesBack Pressure ExhaustmarjukiNo ratings yet

- Cummins Engine Room Ventilation RequirementDocument3 pagesCummins Engine Room Ventilation RequirementAnonymous BJ9omONo ratings yet

- Static Pressure FansDocument35 pagesStatic Pressure FansarifkhadeerNo ratings yet

- Selection Sheet - 30XA452 Screw ChillerDocument1 pageSelection Sheet - 30XA452 Screw Chillercalvin.bloodaxe4478No ratings yet

- Noise Calculation Procedure - Simple MethodDocument7 pagesNoise Calculation Procedure - Simple MethodZiyad AwaliNo ratings yet

- All HVAC CalculationDocument52 pagesAll HVAC CalculationSlam HassanNo ratings yet

- Engine Room Ventilation - Calculation PDFDocument2 pagesEngine Room Ventilation - Calculation PDFSarawut Jae100% (1)

- Limpet Coil CalculationDocument2 pagesLimpet Coil CalculationYusuf DabhiyaNo ratings yet

- Pipe Flow Friction Factor CalculationsDocument11 pagesPipe Flow Friction Factor CalculationsVictor ValenciaNo ratings yet

- HV Room Vent CalculationsDocument1 pageHV Room Vent CalculationsChandana WanaguruNo ratings yet

- Equipment Selection & Design - 2Document5 pagesEquipment Selection & Design - 2Nabeel SiddiqueNo ratings yet

- 2.4 Static Pressure Spreadsheet 1Document4 pages2.4 Static Pressure Spreadsheet 1Swapnil Pratap SinghNo ratings yet

- Chiller Size CalculatorDocument4 pagesChiller Size CalculatormpokeNo ratings yet

- Boiler Specification 2Document3 pagesBoiler Specification 2AbdulBasitNo ratings yet

- 2.4 Static Pressure Spreadsheet 1Document4 pages2.4 Static Pressure Spreadsheet 1Jitendra KadamNo ratings yet

- GEMI Equations ToolDocument10 pagesGEMI Equations TooljnmanivannanNo ratings yet

- Design Calculation Sheet: Project No: Date: Sheet No.:1 1 Computed By: SubjectDocument1 pageDesign Calculation Sheet: Project No: Date: Sheet No.:1 1 Computed By: SubjectAbdelfatah NewishyNo ratings yet

- Pressure Drop Calculation For Fan (Exf-Bsc-02) Typical Calculation For Fan (Exf-Bsc-02)Document10 pagesPressure Drop Calculation For Fan (Exf-Bsc-02) Typical Calculation For Fan (Exf-Bsc-02)ibnrafeeqNo ratings yet

- Ejector User GuideDocument2 pagesEjector User GuidehaseebNo ratings yet

- Calculation Sheet Document No. Page No. Revision No. Date Prepared by Approved by Plant PlaceDocument22 pagesCalculation Sheet Document No. Page No. Revision No. Date Prepared by Approved by Plant PlaceSwapnil Pratap Singh100% (1)

- API SizingDocument13 pagesAPI SizingJayesh SanganiNo ratings yet

- Engine Room Ventilation - Necesar AerDocument1 pageEngine Room Ventilation - Necesar AerBirshopulosNo ratings yet

- Transformers Ventilation CalcDocument2 pagesTransformers Ventilation CalcMahmoud Khaled123No ratings yet

- Smart Duct Sizer V 3.0Document10 pagesSmart Duct Sizer V 3.0ashishNo ratings yet

- ASHRAE 90 1 Kadj Calculator Revision 5Document9 pagesASHRAE 90 1 Kadj Calculator Revision 5Basil OguakaNo ratings yet

- Engine Room AirflowDocument3 pagesEngine Room AirflowselisenNo ratings yet

- UH-60 L BookletDocument18 pagesUH-60 L Bookletcho kang ho100% (1)

- Condenser & EvaporatorDocument21 pagesCondenser & EvaporatorfitratulqadriNo ratings yet

- Heat Loss From An Insulated Pipe: ParametersDocument4 pagesHeat Loss From An Insulated Pipe: ParametersMohan BabuNo ratings yet

- Diesel Generator Tank CapacityDocument1 pageDiesel Generator Tank CapacityHamdy AdelNo ratings yet

- Yazd-System Description For Clean Drain System PDFDocument7 pagesYazd-System Description For Clean Drain System PDFace-winnieNo ratings yet

- γ γ × ∆ × × × × P 81 - 9 2 Cp A: Selected questionsDocument6 pagesγ γ × ∆ × × × × P 81 - 9 2 Cp A: Selected questionsHhaabbde SybaritzNo ratings yet

- 1-Internal Heat GainDocument15 pages1-Internal Heat GainWunNa100% (1)

- Design of Ventilation SystemsDocument5 pagesDesign of Ventilation SystemsSimon LaurentNo ratings yet

- Heat Loss Tank FarmDocument4 pagesHeat Loss Tank FarmCorrado CannellaNo ratings yet

- GDL Louvre CalculatorDocument1 pageGDL Louvre CalculatorAbraham JyothimonNo ratings yet

- Vertical Storage Tank Heat Loss Calcs - Rev.1 31.12.2010Document16 pagesVertical Storage Tank Heat Loss Calcs - Rev.1 31.12.2010jnmanivannanNo ratings yet

- PT System (2500 m3/hr) (Check The Flow) : Gravity Line CalculationsDocument7 pagesPT System (2500 m3/hr) (Check The Flow) : Gravity Line CalculationsAnshuman ChoudhuryNo ratings yet

- Generator Calculation 01Document1 pageGenerator Calculation 01Mahmoud FakhereddinNo ratings yet

- Exhaust ChimneyDocument4 pagesExhaust ChimneyDesigner ForeverNo ratings yet

- Steam Consumption and Line SizingDocument3 pagesSteam Consumption and Line SizingpavanNo ratings yet

- Double Pipe Heat Ex ChangerDocument2 pagesDouble Pipe Heat Ex ChangerSaqib RaoufNo ratings yet

- Engine Room Calc Air 2Document1 pageEngine Room Calc Air 2jack macNo ratings yet

- Pressuredrop Calculations by Kern Method SRRDocument18 pagesPressuredrop Calculations by Kern Method SRRrajeev50588No ratings yet

- L.3.1. EVAPORATOR - 01 (EV-01) : 1 o o o oDocument9 pagesL.3.1. EVAPORATOR - 01 (EV-01) : 1 o o o omedias indah monica sariNo ratings yet

- Caterpillar Proper-Engine-Room-Ventilation PDFDocument2 pagesCaterpillar Proper-Engine-Room-Ventilation PDFyadi_baeNo ratings yet

- Air Conditioning System: Pan Humidifier Load Calculation Building Room1Document1 pageAir Conditioning System: Pan Humidifier Load Calculation Building Room1psn_kylmNo ratings yet

- Engine Lubricating Oil System: Design Iv Machinery System Department of Marine EngineeringDocument20 pagesEngine Lubricating Oil System: Design Iv Machinery System Department of Marine EngineeringSean Chen GyarinoNo ratings yet

- 4.4 Heat Ex ChangersDocument7 pages4.4 Heat Ex Changersmukesh kaushikNo ratings yet

- Project Name: Doc No: Air System Name: Rev: Equipment Type: Date: Space Used For: Sheet No: Floor: Reference: ClientDocument10 pagesProject Name: Doc No: Air System Name: Rev: Equipment Type: Date: Space Used For: Sheet No: Floor: Reference: ClientMukti WibowoNo ratings yet

- Fans Static Head Calculation SheetDocument1 pageFans Static Head Calculation SheetraifaisalNo ratings yet

- Hybrid Cooling TowerDocument12 pagesHybrid Cooling TowerANIMESH JAINNo ratings yet

- Tutorial Sheet On Thermodynamics 1Document2 pagesTutorial Sheet On Thermodynamics 1Michelle Minduval100% (1)

- Fan Noise EstimateDocument5 pagesFan Noise EstimateBen ClackNo ratings yet

- LT & HT Panels RoomDocument4 pagesLT & HT Panels RoomMaxmore KarumamupiyoNo ratings yet

- VS Lab & Office - Hvac Boq 29032016Document16 pagesVS Lab & Office - Hvac Boq 29032016Ganesh RamNo ratings yet

- Room ACis.1391.2.1992Document36 pagesRoom ACis.1391.2.1992Ajay MenonNo ratings yet

- Final Energy Balance-Vizag DT 9-6-18Document6 pagesFinal Energy Balance-Vizag DT 9-6-18SUBHOMOYNo ratings yet

- Of FuelDocument11 pagesOf FuelraghbirNo ratings yet

- Energy Saving MeasuresDocument8 pagesEnergy Saving MeasuresDivyeshPSinghNo ratings yet