Professional Documents

Culture Documents

Pcb-Lab Good One

Pcb-Lab Good One

Uploaded by

Arun PeethambaranOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pcb-Lab Good One

Pcb-Lab Good One

Uploaded by

Arun PeethambaranCopyright:

Available Formats

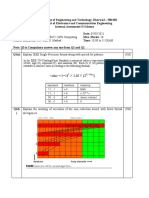

IIT Kanpur

PCB Design Guide Sheet

TheDepartmentofElectricalEngineeringatIITKanpurhasavarietyofdevicesand

machinestoproducesinglelayer,doublelayerplatedthroughprintedcircuitboards

(PCBs),multilayer(max8layers)platedthroughPCBs,forthroughpinandsurface

mounteddevices.

Printedcircuitboardsareelectroniccircuitsboardscreatedformountingelectronic

components on a nonconductive board, and for creating conductive connections

betweenthem.Thecreationofcircuitpatternsisaccomplishedusingbothadditive

and subtractive methods. The conductive circuit is generally copper, although

aluminum, nickel, chrome, and other metals are sometimes used. There are three

basic varieties of printed circuit boards: singlesided, doublesided, and multi

layered.

1.SinglesidedPCB:conductorsononlyonesurfaceofadielectricbase.

2.DoublesidedPCB:conductorsonbothsidesofadielectricbase,usuallythetwo

layersareinterconnectedbyplatedthroughholes(PTHs).

3.Multilayer:conductorson3ormorelayersseparatedbydielectricmaterialand

thelayersareinterconnectedbyPTHorpads

4layerPCBisasandwichof2doublelayeredPCBs.Likewise6layerPCBisa

sandwich of 3 double layered PCB. This sandwiching is done by placing oxidizing

materialbetweendoublelayeredPCBs.

Thespatialanddensityrequirement,andthecircuitrycomplexitydeterminethetype

ofboardtobeproduced.

Page2of26

IIT Kanpurr

PCB Design

D

Guide Sheet

S

Processstepsinvo

olvedinPCB

Bfabricatio

onareshow

wnintheffollowingblockdiagraam.

Page3of2

26

IIT Kanpur

PCB Design Guide Sheet

CADSystem

RecommendedsoftwarefortheCADsystemisAltium.Thissoftwarehasenhanced

features like improved interactive routing, user selectable track width, internal

routing loops, PCB routing completion detector, preserving track angles while

dragging,designingbottomlayerlayout(mirrorhastodone)justbyflipandediting

theboardetc.

Note: Minimum track width requirement is 0.2 mm and minimum spacing

betweentracksis0.2mm

Page4of26

IIT Kanpur

PCB Design Guide Sheet

CNCdrilling/millingmachine

A computer automated, single spindle CNC machine is used which allows direct

processing of Excellon/Sieb & Meyer drill data or HP/GL data for PCB production

(drilling,milling,isolationrouting)andmilling/drillingofholes.Selectionofdrillbitis

alsoautomated and the drill bit moves to the corresponding coordinate to makea

drill.Likewisedrillsofdifferentdiacanbemade.

Page5of26

IIT Kanpur

PCB Design Guide Sheet

Photoplotter

With the photoplotter, films are developed for various layers and for the solder

masks. Moreover, both positive and negative type films can be developed. This is

also a computer automated equipment. It plots images from a CAD database by

usingGerberdatafileonaphotographicfilm.

Here, the film is rolled over the inner drum in the plotter. On running the

softwareincomputer,thelaserdiodemovesstepbystepalongtherotatingdrumby

meansofsteppermotordrivenleadscrew.Thelaserdiodemovingspeed,resolution

canalsobeadjustedasperrequirement.

Page6of26

IIT Kanpur

PCB Design Guide Sheet

FilmDeveloper

After photoplotting, the individual PCB layers film is produced by a developer

machine. Then, under a light table, the film is manually inspected for any track

breaks,lineshortagesormissingofanytrack.

Here,thefilmsaredevelopedmanuallyinatray.

BrushingMachine

Aftercompletionofdrilling,theboardsaretobebrushedthoroughlytoensurethat

no stray particles remain on the board. Boards are brushed thoroughly, rinsed and

driedbythiswetbrushingmachine.

Page7of26

IIT Kanpur

PCB Design Guide Sheet

Laminator

Thisisusedtolaminatetheentireboardareawithphotoresistmaterial.Hereeither

positiveornegativephotoresistmaterialcanbeusedforlaminatingtheboard.We

generally use negative photo resist. Lamination is performed by rolling the

photoresistcoilunderpressureonbothsidesofthemovingboardbyheatablefeed

rollers. Howeverrotationalspeedisadjustableasperrequirement.

Page8of26

IIT Kanpur

PCB Design Guide Sheet

Platingunit

This unit is used for making printed through hole (PTH) circuit boards, where

connectivity from top to bottom layer can be made through holes. Here top and

bottom layers are connected by depositing copper in holes of the board. This unit

comprisesallthetanksandequipmentfordegreasing,rinsing,catalyzing,activating,

pickling and plating the drilled and cleaned boards. These process of degreasing,

rinsing, catalyzing, activating, pickling are used for removing grease, oil, dirt, soot

and other contaminants from surfaces. After thorough cleaning only copper is

deposited.

Page9of26

IIT Kanpur

PCB Design Guide Sheet

Exposuresystem

After fixing layoutfilms exactly on both sides of the laminated board the light

sensitivecoverisexposedbyaultravioletlightindoublesideddrawerexposureunit

with a vacuum system. After the exposure that part of the laminate, which is not

protected by the layout film becomes etchresistent (if we use negative film &

negativephotoresist).

Page10of26

IIT Kanpur

PCB Design Guide Sheet

SprayDeveloper

AfterexposingtheboardtoUVlight,thePCBisbroughtintoaspraydevelopingunit

where the board is treated with aqueous alkaline solution (like TCl alcohol)so that

thenonexposedpartmaygetsoftened.Arotarysystempresentinsidethechamber

allowsthesimultaneoustreatmentoftheentireboardsurface.

FoamEtchingCenter

Aftertreatingtheboardwithaqueousalkalinesolution,thePCBissubjectedinfoam

etching center by hanging it into a foaming fluid (usually acids) to etch out the

copper from the part of the PCB not exposed to UV. The copper part of the PCB

whichisnotexposedtoUVgetssoftensanditisetchedbyacids.Nowtheboardis

readywithprintedlayouttracks,padswhicharecoveredbyphotoresist.

Page11of26

IIT Kanpur

PCB Design Guide Sheet

Page12of26

IIT Kanpurr

PCB Design

D

Guide Sheet

S

Strippin

ngCuvette

Heretheremains ofphotoreesistmaterrialfromlaayouttrackks,padsareeremovedand

rinsedin

nliquid,usuallyanaq

queousalkaalinesolution.

Oven

After geetting the board from

m strippingg cuvette, the board

d has to bee dried. Th

his is

doneintheoven,wheretem

mperatureissadjustable.

Page13of2

26

IIT Kanpur

PCB Design Guide Sheet

MaskingandLegendprinting

The bare copper PCB is silkscreened with a solder mask (usually green)

(Sometimes the solder mask is applied by photo imaging or dry film) which is

designed to insulate and protect the copper tracks and keep them from shorting

together during the soldering process. The solder mask covers the whole board

exceptsolderablesurfacessuchasthruholeandsurfacemountpads.

Thesoldermaskisthendriedorcured.ThePCBistinnedorplated,i.e.,solder,silver

or gold is applied to exposed pads. The PCB is silkscreened with component

identificationlettering(usuallywhite).Thesilkscreenlegendisdriedorcured.Any

finaldrillingofholesthatarenottobeplatedthroughandanyextraroutingarenow

performed,andthelaminateiscutintoindividualprintedcircuitboards.

Page14of26

IIT Kanpur

PCB Design Guide Sheet

MultilayeredPCB

For fabricating multilayer PCB, we have to first fabricate corresponding number of

doublesidedPCBs.

For a 4 layered PCB, we have to first fabricate two double layered PCBs, and for 6

layered,3doublelayeredPCBs.

ThesedoublelayeredPCBsaresandwichedoneoveranotherexactlywithoxidizing

agent between them. Then the sandwiched board inserted in the multilayer press

machine.Ithasacontrolunitforallpressuresupply,pressplatesandheaters.The

largeloadingdoorthatallowsquickandeasyaccesstothepressurepartissecurity

switch protected. The unit is controlled by two digital and adjustable thermostats,

one digital timer as well as a pressure valve with pressure meter. Two strong air

ventilatorsareactivatedautomaticallyduringcoolingcycle.

Aftercompletecuringandcooling,thesandwitchedmultilayedPCBistakenoutfrom

thepressmachineissubjectedtomasking,legendprintingasperrequirement.

Page15of26

IIT Kanpur

PCB Design Guide Sheet

The PCB lab. has a variety of chemicals in the store for PCB fabrication process.

The lab. has facility for producing deionized water which is used in plating

purpose.

Page16of26

IIT Kanpur

PCB Design Guide Sheet

It has got the facility of inspection of photo films and PCBs under a table lamp

withamicroscope.

Page17of26

IIT Kanpur

PCB Design Guide Sheet

PCBManufacturingsteps

FollowingarethestepsinvolvedinfabricationofPCB.

Basematerialcutting

Drilling

Throughholeplating

Layerfilmgeneration

Solderresistfilmgeneration

Legendprintingfilm(optional)

Laminating

Exposing

Spraydeveloping

Etchingprocess

Solderresistmasking

Legendprinting(optional)

Basematerialcutting

Base material which is selected based on application, may be epoxy resin (FR4),

duroid(ofrequireddielectricconstant),iscutintotherequiredsize

Drilling

Holes are drilled through the board using an automated drilling machine. A cnc

drilling/millingmachine,whichiscontrolledbyanExcellonfilewiththeholeposition

dataandalisofthelabelsoftherequireddrillbits,isusedtodrilltheholes,tomill

certainboardcontoursandtoproducemultipleprintedpanel.Theholesareusedto

mountelectroniccomponentsontheboardandtoprovideaconductivecircuitfrom

onelayeroftheboardtoanother.

Page18of26

IIT Kanpur

PCB Design Guide Sheet

Throughholeplating

Followingdrilling,theboardisscrubbedtoremovefinecopperparticlesleftbythe

drill. After being scrubbed, the board is cleaned and etched to promote good

adhesionandthenisplatedwithanadditionallayerofcopper.Sincetheholesare

notconductive,electrolysiscopperplatingisemployedtoprovideathincontinuous

conductivelayeroverthesurfaceoftheboardandthroughtheholes.

Layerfilm

For multilayer boards films must be produced according to the number of layers.

Powerfulsoftwaretoolsgenerateaplotfile,whosedatacontrolaphotoplotter.After

developing the films, they have to be inspected under table lamp for any track

breaks,lineshortagesormissingofanytrack.

Solderresistfilm

InordertoensurenoshortingsinthePCBduetoformationofmoisture,ordueto

spreading of solder leads, the complete board except the pads are to be soldered

masked. This is done in CAD design tools and the photofilm is generated in the

photoplotter.Thenthephotofilmisdeveloped.

Legendprintingfilm(optional)

This is developed in order to ensure ease and fastness during soldering of

components. This is also designed in CAD system and the film is generated in the

photoplotter.

Laminating

Bythisprocessthedrilledandplatedthroughboardsarelaminatedbyrollingunder

pressureaphotoresistlaminateonbothsidesoftheboard.

Page19of26

IIT Kanpur

PCB Design Guide Sheet

Exposing

After properly aligning films on the photoresist laminated board, the board is

exposedbyaUVlightonbothsidesintheUVexposureunit.

Spraydeveloping

Theexposedboardisdevelopedinaspraydeveloperunit.Thedevelopersolutionis

sprayedonbothsidesoftheboardbyasprayrotatingsystem.Afterwardstherestof

the nonexposed laminate is removed by a rinsing process, whereas the exposed

laminateisetchresistantandthusprotectsthecircuitpatternagainstetching

Etchingprocess

InthatprocesstheUVnonexposedcopperisetched.Afterwardstheetchresistant

materialoverthetracks,padsofPCBisrinsedbymeansofasolventattack.

Solderresistmasking/Legendprinting(optional)

Inourlabthisisdonemanuallybyscreenprintingprocess.

Page20of26

IIT Kanpur

PCB Design Guide Sheet

A.OVERALLGUIDELINES(SUMMARY)

MaximumPCBsizewhichcanbefabricated:10inchesx12inches

MinimumPCBsizewhichcanbefabricated:3inchesx2inches

Maximumtrackwidthpossible:100mil

Minimumtrackwidthpossible:8mil

Minimumclearancerequiredforperfectplot:8mil

B.DETAILEDGUIDELINESFORPCBJOBORDER

B.1Paddimensionrequirements

Inner diameter is 33 mil minimum. Higher values will automatically be mapped to

nearestholedrillbitavailable.Mustbeatleast4milgreaterthancomponentlead

diametertoallowconsiderationsforminimumcopperplatingthicknessinthehole.

Outer diameter is 55 mil minimum and an integer values thereafter.

Differencebetweeninnerdiameterandouterdiametermustbe20milminimumto

ensure good copper area for soldering. This also applies to those footprints which

havebeenspeciallycreatedforthepurposebythedesigner.ForSMDs,thestandard

padsizespecifiedbythecomponentmanufacturermaybeused.

B.2Viarequirements

Innerdiameteris24milminimumtoensurecorrectfeedthrough.Outerdiameteris

40milminimum.

B.3Fillrequirements

Copperfillsforpowerplanesneedtobecreatedwithbasicblocksofsquaresofthe

following dimensions: blocks of sizes 10 mil to 100 mil in steps of 5 mil; blocks of

sizes100milto200milinstepsof10mil.Considerableoverlappingbetweenthese

buildingblocksisnecessarytoensurenovisiblegapsinthephotoplot.

Page21of26

IIT Kanpur

PCB Design Guide Sheet

B.4Maximumprimitivedimension

ThephotoplotteratPCBfabfacility,IITKanpurcanacceptandplotaperturesizesup

to100mil.Sothedesignermighttake thisintoconsiderationbeforedesigningthe

PCB. If any dimension higher than this is needed, he/she might have to use some

basicprimitives.Forexample,ifatrackof150milisrequired,a100miltrackanda

55miltrackcanbeplacedsidebysidewitha5miloverlaptogeta150

miltrack.

B.5Holedrillbitsavailableatthefacility

Manual Drill

78.70 mil (2.0 mm), 62.99 mil (1.6 mm), 51.18 mil (1.3 mm), 39.37 mil (1.0 mm), 35.43 mil

(0.9 mm), 31.49 mil (0.8 mm), 27.56 mil (0.7 mm), 23.62 mil (0.6 mm), 19.69 mil (0.5 mm)

CNC Mill/Drill

118.11 mil (3.0 mm), 59.06 mil (1.5 mm), 51.18 mil (1.3 mm), 43.31 mil (1.1 mm), 39.37 mil

(1.0 mm), 35.43 mil (0.9 mm), 31.49 mil (0.8 mm), 27.56 mil (0.7 mm), 23.62 mil (0.6 mm)

RF Cutters

78.70 mil (2.0 mm), 39.37 mil (1.0 mm), 15.75 mil (0.4 mm),7.87 mil (0.2 mm), 5.91 mil

(0.15 mm)

B.6SolderMasking/LegendPrintingFacility: Availableonrequest

B.7Copperthicknessonboard

Singlelayer:Optionsof1.38mil(35microns)withaboardthicknessof62.99mil(1.6

mm) and 2.76 mil (70 microns) with a board thickness of 94.49 mil (2.4 mm) are

available.BoardmaterialisGlassEpoxyorPaperPhenolic.

Doublelayer:Optionsof1.38mil(35microns)and0.67mil(17microns)bothwitha

board thickness of 62.99 mil (1.6 mm) are available. Board material is Glass Epoxy

(FR4).

C.BasicPCBDesignIssues

Page22of26

IIT Kanpur

PCB Design Guide Sheet

The designer can use autoroute tools of the PCB design software he/she is using.

Butcaremustbetakenthatalldimensionsareofintegervalues.Usuallythedesigner

canrestricttheautoroutetooltouseonlyintegerdimensionsbysettingdesignrules

for the PCB. It must also be ensured to keep outer most layer, a little larger in

dimension than the actual board. A mechanical layer called Mechanical Layer 4

showing the actual dimensions of the board must be incorporated. This helps the

fabricatortocorrectlyusetheCNCmachinefordrillingholesintothePCB.Theorigin

ofthePCBdimensionsmustalsobesetalittlefar,diagonallyfromtheleftbottom

corneroftheboard.PleaserefertothedocumentationofthePCBdesignsoftware

usedforfurtherinformation.

ThePCBdesignnamemustalsobementionedeitheronthetoplayerorthebottom

layer for a dual layered PCB. The text placement tool of the concerned PCB design

software can be used. It is a good practice to make sure that the name of the file

whichcontainsthePCBdesignrepresentsthePCBdesignveryclosely.

D.RecommendedCADSoftware

Altium Protel DXP Suite 2004

Note: IfDXP2004isbeingused,pleaseensurethatthe.PCBDOCfileisexportedto

PCB Version 4 Binary format (.PCB file) before ordering the PCB. The file which

results due to the export must be directly sent to PCB fab for processing. Opening

thisfileinDXPagaincouldresultinproblemswiththeexistingprocedure.

Note:PleasesendonlythefinalPCBfilewhileordering.

E.Ordering,FabricationandDelivery

ThefinalfilerequiredforfabricationmustbesubmittedinthePCBLabafterfillingup

thePCBjoborderformTheprocessmightresultindeliveryperiodsof23weeksfor

normalPCBsand34weeksforPCBswithgreenmaskingandlegendprinting.

Thesetimesmayvaryabitdependingonthequeuependingatthefacilityand

theprocessconditionsofthePCB.SinglelayerPCBswillbedeliveredinlessthan2

weekstime.PCBfabricationisatimeandresourceconsumingprocessandhenceis

done with utmost care. Any complaints regarding the PCB fabrication and quality

maydirectlybeaddressedtothePCBfabricationfacilityincharge.

Page23of26

IIT Kanpur

PCB Design Guide Sheet

F.Glossaryofterms

Footprint: Thepatternandspaceonaboardtakenupbyacomponent.

Clearance:ThespacingrequiredbetweentwoentitiesonaPCBtoensuresafe

operation.

Photoplotter: (also"vectorplotter",or"Gerberphotoplotter"afterGerberScientific

Co., which built the first vector photoplotters for commercial use). It plots images

fromaCADdatabaseonphotographicfilminadarkroombydrawingeachlinewitha

continuouslampshinedthroughanannularringaperture,andcreatingeachshape

(orpad)byflashingthelampthroughaspeciallysizedandshapedaperture.

GerberFile: Datafileusedtocontrolaphotoplotter.NamedafterGerberScientific

Co.,whomadetheoriginalvectorphotoplotter.

Aperture: Anindexedshapewithaspecifiedxandydimension,orlinetypewitha

specified width, used as a basic element or object by a photoplotter in plotting

geometric patterns on film. The "apertures" are thin trapezoidal pieces of plastic

whicharemostlyopaque,butwithatransparentportionthatcontrolsthesizeand

shapeofthelightpatternpassingthroughit.

Track:Besidesitsusualdefinitionofastrandofconductor,wireonaprintedboard

alsomeansarouteortrack.

Page24of26

IIT Kanpur

PCB Design Guide Sheet

Pad: ThePCBComponentfootprintshavecopperlandingareaswherethe

componentsarefixedbymeansofsolder.

ThroughHole: (Ofacomponent,alsospelled"thruhole").Havingpinsdesignedto

beinsertedintoholesandsolderedtopadsonaprintedboard.

PlatedThroughHole: AholeinaPCBwithmetalplatingaddedafteritisdrilled.Its

purposeistoserveeitherasacontactpointforathroughholecomponentoravia.

Page25of26

IIT Kanpur

PCB Design Guide Sheet

Via:AplatedthroughholeinaPCBusedtorouteatraceverticallyintheboard,that

is,fromonelayertoanother.

SMD: SurfaceMountDevice,wherethecomponentsleadsarenotfixedintoPTHs

butaresolderedtopadsdirectly.

Page26of26

You might also like

- Design Guidelines for Surface Mount TechnologyFrom EverandDesign Guidelines for Surface Mount TechnologyRating: 5 out of 5 stars5/5 (1)

- Pioneer Avh-280bt Avh-285bt Avh-289bt crt5859Document94 pagesPioneer Avh-280bt Avh-285bt Avh-289bt crt5859jonathan LacroixNo ratings yet

- Printed Circuit BoardDocument16 pagesPrinted Circuit BoardAjayChandrakarNo ratings yet

- Printed Circuit BoardsDocument31 pagesPrinted Circuit BoardsSUNNY_20_00100% (1)

- BGA Construction and ReworkDocument24 pagesBGA Construction and ReworkyogeshleostarNo ratings yet

- Printed Circuit Board DesignDocument60 pagesPrinted Circuit Board DesignUday Bhaskar100% (1)

- Industrial Training PCBDocument29 pagesIndustrial Training PCBjwndasukhraj100% (2)

- PCB Design Using Cadsoft EAGLE SoftwareDocument22 pagesPCB Design Using Cadsoft EAGLE SoftwareAmarenderNo ratings yet

- SMT Manufacturability Design GuidelinesDocument25 pagesSMT Manufacturability Design GuidelinespcbppcNo ratings yet

- PCB Book v5.0.4 e Demo WDocument56 pagesPCB Book v5.0.4 e Demo Whlgc63100% (1)

- Gerber File CreationDocument44 pagesGerber File CreationBatka Shankar100% (2)

- PCB Lab Manual Iiisem Ece PDFDocument46 pagesPCB Lab Manual Iiisem Ece PDFkathirdcnNo ratings yet

- Hdi Presentation 110913Document58 pagesHdi Presentation 110913jawsmNo ratings yet

- Report Vishal Pandey LE 06Document26 pagesReport Vishal Pandey LE 06Baikunth PandeyNo ratings yet

- Jedec Industry Standard Classifications and Peak Solder TemperatureDocument8 pagesJedec Industry Standard Classifications and Peak Solder TemperatureGuillermo VillarNo ratings yet

- Building Responsibility MatrixDocument4 pagesBuilding Responsibility Matrixmsaad2No ratings yet

- CNC Drilling Machine For Printed Circuit BoardDocument4 pagesCNC Drilling Machine For Printed Circuit BoardEditor IJTSRDNo ratings yet

- PCB Design Steps & Complete Guide - CirexxDocument10 pagesPCB Design Steps & Complete Guide - CirexxReetipragya SinghNo ratings yet

- PCB Designing Fundamentals: Compiled By: Hiren Patel (ET Dept.)Document42 pagesPCB Designing Fundamentals: Compiled By: Hiren Patel (ET Dept.)Chintaan PatelNo ratings yet

- PCB Surface Finishes Presentation by MultekDocument54 pagesPCB Surface Finishes Presentation by Multeksmtdrkd100% (1)

- Excel SolverDocument14 pagesExcel SolverJhonerValdezValdiviano100% (1)

- Chapter - 1Document46 pagesChapter - 1Vineet KumarNo ratings yet

- PCB DesignDocument26 pagesPCB DesignJomer JuanNo ratings yet

- Salvage Report: Area / Section In-Charge Date Facility Type Part Id RecommendationDocument1 pageSalvage Report: Area / Section In-Charge Date Facility Type Part Id RecommendationEddie Fernando CatapangNo ratings yet

- PCB Training PresentationDocument31 pagesPCB Training Presentationkibrom atsbhaNo ratings yet

- PCB DesignWorkshopDocument4 pagesPCB DesignWorkshopraghu0pothumudiNo ratings yet

- PCB DesignerDocument70 pagesPCB Designeram1liNo ratings yet

- Wonderful PCB (HK) Limited - UpdateDocument28 pagesWonderful PCB (HK) Limited - UpdateFercho QuezadaNo ratings yet

- PCB DesignDocument19 pagesPCB DesignGurpriksha Kaur100% (3)

- Controlled ImpedanceDocument44 pagesControlled ImpedanceMallappa Patil100% (1)

- SMT Seminar ReportDocument26 pagesSMT Seminar ReportShruthi Uppar100% (1)

- PCB Assembly Supplier IntroduceDocument19 pagesPCB Assembly Supplier IntroduceJasonlonNo ratings yet

- LED Thermal Management Basics For PCB DesignersDocument63 pagesLED Thermal Management Basics For PCB DesignersSaturn Electronics CorporationNo ratings yet

- Introduction To PCBDocument15 pagesIntroduction To PCBdileepanme100% (2)

- PCB ManufactureDocument38 pagesPCB ManufactureRajasekaran RNo ratings yet

- Steps in PCB Design and ManufacturingDocument9 pagesSteps in PCB Design and Manufacturingtinderlord akoNo ratings yet

- Comparison Education System Factory SystemDocument34 pagesComparison Education System Factory SystemWearayban MYNo ratings yet

- 7ha Constructability Pitch ExternalDocument51 pages7ha Constructability Pitch ExternalSofianeLeksir0% (1)

- Surface-Mount Technology: HistoryDocument11 pagesSurface-Mount Technology: Historyulf8014100% (2)

- PCBDocument42 pagesPCBDivyanshu Agarwal100% (3)

- PCB AssemblyDocument16 pagesPCB Assemblynirvan93100% (1)

- PCB DesignDocument45 pagesPCB DesignkesavantNo ratings yet

- Input Data: Component Code Value Description Footprint Code (Protel)Document5 pagesInput Data: Component Code Value Description Footprint Code (Protel)Alexis SanchezNo ratings yet

- Inferiority ComplexDocument16 pagesInferiority Complexsunilsm100% (1)

- Switched Capacitor FilterDocument20 pagesSwitched Capacitor FilterArijit ShawNo ratings yet

- PCBDocument18 pagesPCBjhpandiNo ratings yet

- Internship Report NewDocument12 pagesInternship Report NewSaad KhalidNo ratings yet

- Introduction To PCBDocument19 pagesIntroduction To PCBAakash VisvanathanNo ratings yet

- Bay Marshalling BoxesDocument4 pagesBay Marshalling BoxesSimbu ArasanNo ratings yet

- PCB Design in 45 MinutesDocument28 pagesPCB Design in 45 MinutesvinNo ratings yet

- Printed Circuit Board (PCB)Document14 pagesPrinted Circuit Board (PCB)Md Asadul HoqueNo ratings yet

- Electronics LAB MANUAL Exp-2Document6 pagesElectronics LAB MANUAL Exp-2Dulce DeNo ratings yet

- Preparation of A National Environmentally Sound Management Plan For Pcbs and Pcb-Contaminated EquipmentDocument103 pagesPreparation of A National Environmentally Sound Management Plan For Pcbs and Pcb-Contaminated EquipmentYaredNo ratings yet

- Thermal Design Consideration For Surface Mount LayoutsDocument16 pagesThermal Design Consideration For Surface Mount LayoutsRicardoNo ratings yet

- Printed Circuit Board PCB Thermal AnalysisDocument8 pagesPrinted Circuit Board PCB Thermal AnalysisInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Non-Idealities of Switched Capacitor Filter DesignDocument19 pagesNon-Idealities of Switched Capacitor Filter Designhariprasath_vNo ratings yet

- Thermal Management Considerations For PCBS: Measurement Techniques and Heat ConductionDocument37 pagesThermal Management Considerations For PCBS: Measurement Techniques and Heat ConductionKishore BhatNo ratings yet

- PCB Presentation DraftDocument19 pagesPCB Presentation Draftsanjay sharma100% (1)

- Strategy in (PCB) Design.Document44 pagesStrategy in (PCB) Design.Syste DesigNo ratings yet

- Assembly of Flexible Circuits With Lead - Free Solder AlloyDocument16 pagesAssembly of Flexible Circuits With Lead - Free Solder AlloyBorad AlpeshNo ratings yet

- Digital Phase Locked LoopDocument7 pagesDigital Phase Locked Loopsru_1990No ratings yet

- Wave SolderingDocument13 pagesWave Solderingle truongNo ratings yet

- Sparkfun Electronics Stenciling: Materials by Bob Hunke & Linz CraigDocument33 pagesSparkfun Electronics Stenciling: Materials by Bob Hunke & Linz Craigblooper631No ratings yet

- Types of PCB and Wave SolderingDocument4 pagesTypes of PCB and Wave Solderingpuranamravinder100% (2)

- Through Hole Via in PadDocument1 pageThrough Hole Via in PadLina GanNo ratings yet

- PCB InfoDocument19 pagesPCB InfoDarshan Iyer NNo ratings yet

- GPU CAT2 5thMAY2021 Scheme (AutoRecovered)Document5 pagesGPU CAT2 5thMAY2021 Scheme (AutoRecovered)sunilsmNo ratings yet

- Brochure - FDP - 2020 - ECEDocument2 pagesBrochure - FDP - 2020 - ECEsunilsmNo ratings yet

- More On Raga - Time AssociationDocument6 pagesMore On Raga - Time AssociationsunilsmNo ratings yet

- DLDDocument138 pagesDLDMudassar HanifNo ratings yet

- SCR Ec424 SSM Aug Dec 2013Document18 pagesSCR Ec424 SSM Aug Dec 2013sunilsmNo ratings yet

- Historical Concepts and Important Concepts in Single Subject ResearchDocument19 pagesHistorical Concepts and Important Concepts in Single Subject ResearchsunilsmNo ratings yet

- Xenomia TroubleshootingDocument14 pagesXenomia TroubleshootingsunilsmNo ratings yet

- PAR Presentation Emotional Design 2005Document24 pagesPAR Presentation Emotional Design 2005sunilsmNo ratings yet

- Wavelet TransformDocument28 pagesWavelet TransformShimaa Barakat100% (1)

- JBL Subwoofer - CS1204 (English)Document4 pagesJBL Subwoofer - CS1204 (English)pimpf1No ratings yet

- CT1000PROX - Manual Utilizare2014116121009214956Document8 pagesCT1000PROX - Manual Utilizare2014116121009214956Florin ConstantinNo ratings yet

- Gnss To Hnss Scheme Details NAME OF WORK: "Investigation and Construction of Lift Schemes To Lift Water From GNSS To HNSS"Document2 pagesGnss To Hnss Scheme Details NAME OF WORK: "Investigation and Construction of Lift Schemes To Lift Water From GNSS To HNSS"S N satyanarayanaNo ratings yet

- CarrLane Jig FixtureDocument36 pagesCarrLane Jig FixtureseminarprojectNo ratings yet

- Whats FairDocument12 pagesWhats FairfactorialthreeNo ratings yet

- En York Hvac Catalogue 2016 PDFDocument190 pagesEn York Hvac Catalogue 2016 PDFDaniel MilosevskiNo ratings yet

- PYTHONDocument19 pagesPYTHONRares AndreiNo ratings yet

- SN4500 82009 0133 D Component Maintenance ManualDocument12 pagesSN4500 82009 0133 D Component Maintenance ManualAka MonuNo ratings yet

- Apw Series: In-Process Weighing SystemsDocument3 pagesApw Series: In-Process Weighing Systemsdomin_sz100% (1)

- ASME, b31.3Document40 pagesASME, b31.3SoorajNo ratings yet

- Applications Shaft SealDocument23 pagesApplications Shaft SealMandisa Sinenhlanhla NduliNo ratings yet

- Service Management ADM 570Document3 pagesService Management ADM 570Fatimah LatiffNo ratings yet

- Lesson 1 Introduction To Media LiteracyDocument11 pagesLesson 1 Introduction To Media LiteracyRose Anne PatrimonioNo ratings yet

- College Data Analysis and Prediction SRSDocument68 pagesCollege Data Analysis and Prediction SRSsanjana100% (1)

- Sand ManufacturingDocument5 pagesSand ManufacturingJournalNX - a Multidisciplinary Peer Reviewed JournalNo ratings yet

- The Characteristics of Liquid-Phase Methanol Synthesis in An Impinging Stream ReactorDocument5 pagesThe Characteristics of Liquid-Phase Methanol Synthesis in An Impinging Stream ReactorDenny Muchammad AnwarNo ratings yet

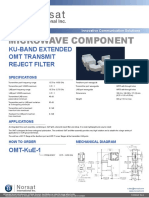

- Omt Kue 1 Spec SheetDocument1 pageOmt Kue 1 Spec Sheetappex onlineNo ratings yet

- Library Management SystemDocument28 pagesLibrary Management SystemSagar Singh50% (4)

- Xercise P S P R: Roducing Ales and Rofit EportsDocument2 pagesXercise P S P R: Roducing Ales and Rofit EportsMichael Bone-crusher PhiriNo ratings yet

- Experiments of High Voltage EngineeringDocument1 pageExperiments of High Voltage Engineeringarslan_engineerNo ratings yet

- s.95 NPT Nickel Plated: Full Port 1/4" - 4" Hot Forged Brass Ball ValveDocument2 pagess.95 NPT Nickel Plated: Full Port 1/4" - 4" Hot Forged Brass Ball ValveAditya Wibowo BasukiNo ratings yet

- Risk Assessment of Nox Gum in COLD Box of Olefin Plant Step Forward PDFDocument10 pagesRisk Assessment of Nox Gum in COLD Box of Olefin Plant Step Forward PDFIbrahimNo ratings yet

- A Diagrammatic Analysis On The SOUTH ASIAN HUMAN RIGHTS DOCUMENTATION CENTREDocument5 pagesA Diagrammatic Analysis On The SOUTH ASIAN HUMAN RIGHTS DOCUMENTATION CENTRESujay Punnoose ThomasNo ratings yet