Professional Documents

Culture Documents

Neles NA Seat Leakage Guide

Neles NA Seat Leakage Guide

Uploaded by

fahimshah1301Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Neles NA Seat Leakage Guide

Neles NA Seat Leakage Guide

Uploaded by

fahimshah1301Copyright:

Available Formats

Neles North America

Seat Leakage Guide

August 28, 2009

Neles North America Seat Leakage Guide

Leakage testing of metal seated valves can be a subject of much confusion and conflicting

expectations. This booklet presents summaries of three common leakage testing standards as

well as comparisons between them and actual product examples.

Important Notes:

1) The information in this booklet is not intended as a replacement for the official leakage

standards referenced on these pages.

2) Examples are for demonstration purposes only. All leakage rates are not available for all

valves. Please consult with the factory to determine the available leakage rates for a

specific valve model.

3) Leakage rates are measured for new valves on the bench after assembly. The

standards referenced in this booklet do not set any requirements for leakage

performance for valves once in service. Long term leakage rate performance is

dependent on the valve and application and cannot be guaranteed.

Table of Contents

Guide To ANSI/FCI 70-2-2006.. Page 1

Guide To ISO 5208 Third edition... Page 2

Guide To API 598 Eighth edition... Page 3

Comparison of Leakage Rates.. Page 4

Examples... Page 5

Leakage Rates in Context.. Page 7

Leakage Rates Available for Standard Products Page 8

Guide To ANSI/FCI 70-2-2006

Class I Modified class II, III or IV valves. No test required by agreement between user and

supplier

Classes II, III and IV

Media Clean air or water

Temperature 50 to 125 F

Pressure 45 to 60 psig or within +/- 5% of max operating dP, whichever is less

Acceptable Leakage for Class II 0.5% of rated valve capacity (12,100 ml/min for a 2RE)

Acceptable Leakage for Class III 0.1% of rated valve capacity (2,420 ml/min for a 2RE)

Acceptable Leakage for Class IV 0.01% of rated valve capacity (242 ml/min for a 2RE)

Class V

Media Clean water

Temperature 50 to 125 F

Pressure Within +/- 5% of max operating dP, not to exceed max pressure rating of valve body

at ambient temperature per ASME B16.34 and B16.5

Acceptable Leakage 0.0005 ml/min of water per inch of seat diameter per psi dP

-orMedia Air or Nitrogen Gas

Temperature 50 to 125 F

Pressure 50psig

Acceptable Leakage 4.7 standard ml/min of air per inch of seat diameter

Class VI

Media Air or Nitrogen Gas

Temperature 50 to 125 F

Pressure Maximum rated valve dP or 50 psig, whichever is less

Acceptable Leakage per ANSI Class VI

Seat Diameter

Leakage

Leakage (ml/min)

(inches)

(bubbles/min)*

1

0.15

1.5

0.30

2

0.45

2.5

0.60

3

0.90

4

1.70

6

4.00

8

6.75

10

11.1

12

16.0

14

21.6

16

28.4

* 1 bubble is equivalent to 0.15 ml

1

2

3

4

6

11

27

45

Notes for all leakage classes:

1) Leakage rates shall be measured once flow is stabilized

2) Seat diameter is measured at the point of seating contact to the nearest 1/16inch (2mm).

Neles North America Seat Leakage Guide Page 1 Aug 28, 2009

Guide To ISO 5208 Third edition

Closure Test

Low Pressure

Gas

High Pressure

Liquid

Sizes

4"

> 4"

4"

> 4"

Required Closure Tests

Seat Supported Trunnion Mounted

ASME Class

Ball Valve

Ball Valve

1500

> 1500

600

> 600

1500

> 1500

600

> 600

Required

Required

Required

Required

Optional

Optional

Optional

Optional

Butterfly Valve

Required

Optional

Required

Optional

Optional

Required

Optional

Required

Required

Optional

Required

Optional

Optional

Required

Optional

Required

Minimum Test Duration

Valve Size

Time (sec)

2"

2.5" to 6"

8" to 12"

14"

15

60

120

120

Low Pressure Gas Test

Media Air or other suitable gas

Temperature 5C to 40C (41F to 104F)

Pressure 6bar +/- 1bar (87psi +/- 14.5psi)

High Pressure Liquid Test

Media - Water with optional corrosion inhibitor, kerosene or other appropriate liquid having a

viscosity not greater than that of water. If the valve shell is an austenitic stainless steel, water

chloride content is not to exceed 100ppm.

Temperature 5C to 40C (41F to 104F)

Pressure 1.1 x CWP of full rated valves or 1.1 x rated differential pressure of reduced rated

valves.

Maximum Acceptable Leakage Rates

(mm3/second x DN number)*

Test Media

Rate A

Liquid

0

Gas

0

* 1000 mm3 = 1 ml

DN numbers

Valve Size 1/2" 3/4"

DN

15

20

Rate B

Rate C

Rate D

0.01

0.3

0.03

3.0

0.1

30.0

1"

25

1.5"

40

2"

50

2.5"

65

3"

80

4"

100

6"

150

Neles North America Seat Leakage Guide Page 2 Aug 28, 2009

8"

200

10"

250

12"

300

14"

350

16"

400

Guide To API 598 Eighth edition

Closure Test

Sizes

4"

Low Pressure

> 4"

4"

High Pressure

> 4"

Required Closure Tests

Seat Supported Trunnion Mounted

ASME Class

Ball Valve

Ball Valve

1500

> 1500

600

> 600

1500

> 1500

600

> 600

Required

Required

Required

Required

Optional

Optional

Optional

Optional

Required

Optional

Required

Optional

Optional

Required

Optional

Required

Butterfly Valve

Required

Optional

Required

Optional

Optional

Required

Optional

Required

Minimum Test Duration

Valve Size

Time (sec)

2"

2.5" to 6"

8" to 12"

14"

15

60

120

120

Low Pressure Test

Media Air or inert gas

Temperature 41F to 122F (5C to 50C)

Pressure 60 to 100psig (4 to 7barg)

High Pressure Test

Media Air, inert gas, kerosene, water with optional corrosion inhibitor, or a non-corrosive liquid

having a viscosity not greater than that of water. If the valve shell is an austenitic stainless

steel, water chloride content is not to exceed 100ppm.

Temperature 41F to 122F (5C to 50C)

Pressure 110% of maximum rated pressure at 100F for ball valves, and 110% of design

differential pressure at 100F for butterfly valves

Maximum Acceptable Leakage Rates

Liquid Test

Gas Test

Valve Size

(drops/min)*

(bubbles/min)**

2"

2.5" to 6"

8" to 12"

0

0

12

24

20

40

2 drops/min per

4 bubbles/min per

14"

inch of valve size

inch of valve size

* 1 milliliter is considered equivalent to 16 drops

** 1 bubble is considered equivalent to 0.15 ml

Neles North America Seat Leakage Guide Page 3 Aug 28, 2009

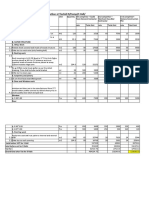

Comparison of Leakage Rates using gas test media (Air, Nitrogen)

ANSI/FCI 70-2-2006

Test Pressure (psig)

class V

class VI

50

50

4.7

7.05

9.4

11.75

14.1

18.8

28.2

37.6

47

56.4

65.8

75.2

0.15

0.30

0.45

0.60

0.90

1.70

4.00

6.75

11.1

16.0

21.6

28.4

Valve Size (inches)*

1

1.5

2

2.5

3

4

6

8

10

12

14

16

ISO 5208 Third edition

rate A

rate B

rate C

API 598 Eighth edition

rate D

Low Pressure Test

73 to 102

60 to 100

Maximum Acceptable Leakage (ml/min)

0

0

0

0

0

0

0

0

0

0

0

0

0.45

0.72

0.9

1.17

1.44

1.8

2.7

3.6

4.5

5.4

6.3

7.2

4.5

7.2

9

11.7

14.4

18

27

36

45

54

63

72

45

72

90

117

144

180

270

360

450

540

630

720

0

0

0

3.6

3.6

3.6

3.6

6

6

6

8.4

9.6

* Seat diameter for ANSI/FCI 70-2-2006

Comparison of Leakage Rates using liquid test media (Water)

Pressures based on ASME class 300 carbon steel test valve - body rating 740psig per ASME B16.34

ANSI/FCI 70-2-2006

class V

Test Pressure (psig)

rate A

rate B

740

Valve Size (inches)*

1

1.5

2

2.5

3

4

6

8

10

12

14

16

ISO 5208 Third edition

rate C

API 598 Eighth edition

rate D

814

High Pressure Test

814

Maximum Acceptable Leakage (ml/min)

0.37

0.56

0.74

0.93

1.11

1.48

2.22

2.96

3.70

4.44

5.18

5.92

0

0

0

0

0

0

0

0

0

0

0

0

0.015

0.024

0.03

0.039

0.048

0.06

0.09

0.12

0.15

0.18

0.21

0.24

0.045

0.072

0.09

0.117

0.144

0.18

0.27

0.36

0.45

0.54

0.63

0.72

0.15

0.24

0.3

0.39

0.48

0.6

0.9

1.2

1.5

1.8

2.1

2.4

* Seat diameter for ANSI/FCI 70-2-2006

Neles North America Seat Leakage Guide Page 4 Aug 28, 2009

0

0

0

0.75

0.75

0.75

0.75

1.25

1.25

1.25

1.75

2

Valve Test Example - XT04CWTAS6SJHADD

ANSI/FCI 70-2-2006

Class V water test

Test pressure = 275 psig based on CF8M body rating from ASME B16.34 class 150

Seat diameter = 4

Acceptable Leakage = 0.0005 ml/min x 4x 275 psi = 0.55 ml/min

Class V air test

Test pressure = 50 psig

Seat diameter = 4

Acceptable Leakage = 4.7 ml/min x 4= 18.8 ml/min

Class VI air test

Test pressure = 50 psig

Seat diameter = 4

Acceptable Leakage = 1.70 ml/min

ISO 5208 Third edition

Low Pressure air test

Test pressure = 87 psig

DN number = 100 for a 4valve

Rate A = 0 ml/min

Rate B = 0.3 mm3/sec x 100 x 1 ml/1000 mm3 x 60 sec/min = 1.8 ml/min

Rate C = 3.0 mm3/sec x 100 x 1 ml/1000 mm3 x 60 sec/min = 18 ml/min

Rate D = 30.0 mm3/sec x 100 x 1 ml/1000 mm3 x 60 sec/min = 180 ml/min

High Pressure water test

Test pressure = 302 psig based on 1.1 x CF8M body rating from ASME B16.34 class 150

DN number = 100 for a 4valve

Rate A = 0 ml/min

Rate B = 0.01 mm3/sec x 100 x 1 ml/1000 mm3 x 60 sec/min = 0.06 ml/min

Rate C = 0.03 mm3/sec x 100 x 1 ml/1000 mm3 x 60 sec/min = 0.18 ml/min

Rate D = 0.1 mm3/sec x 100 x 1 ml/1000 mm3 x 60 sec/min = 0.6 ml/min

API 598 Eighth edition

Low Pressure air test

Test pressure = 60 to 100 psig

Acceptable Leakage = 24 bubbles/min x 0.15 ml/bubble = 3.6 ml/min

High Pressure air and water tests

Test pressure = 302 psig based on 1.1 x CF8M body rating from ASME B16.34 class 150

Acceptable Leakage (air test) = 24 bubbles/min x 0.15 ml/bubble = 3.6 ml/min

Acceptable Leakage (water test) = 12 drops/min x 1 ml/ 16 drops = 0.75 ml/min

Neles North America Seat Leakage Guide Page 5 Aug 28, 2009

Valve Test Example D5FA16DAS02

ANSI/FCI 70-2-2006

Class V water test

Test pressure = 1480 psig based on WCB body rating from ASME B16.34 class 600

Seat diameter = 14, this is a reduced bore valve

Acceptable Leakage = 0.0005 ml/min x 14x 1480 psi = 10.36 ml/min

Class V air test

Test pressure = 50 psig

Seat diameter = 14, this is a reduced bore valve

Acceptable Leakage = 4.7 ml/min x 14= 65.8 ml/min

Class VI air test

Test pressure = 50 psig

Seat diameter = 14, this is a reduced bore valve

Acceptable Leakage = 21.6 ml/min

ISO 5208 Third edition

Low Pressure air test

Test pressure = 87 psig

DN number = 400 for a 16valve

Rate A = 0 ml/min

Rate B = 0.3 mm3/sec x 400 x 1 ml/1000 mm3 x 60 sec/min = 7.2 ml/min

Rate C = 3.0 mm3/sec x 400 x 1 ml/1000 mm3 x 60 sec/min = 72 ml/min

Rate D = 30.0 mm3/sec x 400 x 1 ml/1000 mm3 x 60 sec/min = 720 ml/min

High Pressure water test

Test pressure = 1628 psig based on 1.1 x WCB body rating from ASME B16.34 class 600

DN number = 400 for a 16valve

Rate A = 0 ml/min

Rate B = 0.01 mm3/sec x 400 x 1 ml/1000 mm3 x 60 sec/min = 0.24 ml/min

Rate C = 0.03 mm3/sec x 400 x 1 ml/1000 mm3 x 60 sec/min = 0.72 ml/min

Rate D = 0.1 mm3/sec x 400 x 1 ml/1000 mm3 x 60 sec/min = 2.4 ml/min

API 598 Eighth edition

Low Pressure air test

Test pressure = 60 to 100 psig

Acceptable Leakage = 4 bubbles/min x 16x 0.15 ml/bubble = 9.6 ml/min

High Pressure air and water tests

Test pressure = 1628 psig based on 1.1 x WCB body rating from ASME B16.34 class 600

Acceptable Leakage (air test) = 4 bubbles/min x 16x 0.15 ml/bubble = 9.6 ml/min

Acceptable Leakage (water test) = 2 drops/min x 16x 1 ml/ 16 drops = 2 ml/min

Neles North America Seat Leakage Guide Page 6 Aug 28, 2009

Leakage Rates in Context

It is often easier to understand the comparisons between different leakage rates if they are put

in the context of everyday values.

Here are some real world examples to illustrate the leakage rates for our 4valve example.

Valve Test Example - XT04CWTAS6SJHADD

Leakage

Gas Test

Rate

(ml/min)

ISO 5208 Third edition Rate A

0

ANSI/FCI 70-2-2006 class VI

1.7

ISO 5208 Third edition Rate B

1.8

API 598 Eighth edition

3.6

ISO 5208 Third edition Rate C

18.0

ANSI/FCI 70-2-2006 class V

18.8

ISO 5208 Third edition Rate D

180

Valve Test Example - XT04CWTAS6SJHADD

Leakage

Liquid Test

Rate

(ml/min)

ISO 5208 Third edition Rate A

0

ISO 5208 Third edition Rate B

0.06

ISO 5208 Third edition Rate C

0.18

ANSI/FCI 70-2-2006 class V

0.55

ISO 5208 Third edition Rate D

0.60

API 598 Eighth edition

0.75

Time to fill the volume

of a basketball

about 3 days

a little less than 3 days

about a day and a half

6.6 hours

6.3 hours

40 minutes

Time to fill a medium

cup of coffee (14oz)

a little less than 5 days

about a day and a half

12.5 hours

11.5 hours

9 hours

Neles North America Seat Leakage Guide Page 7 Aug 28, 2009

Leakage Rates Available for Standard Products

ANSI/FCI 70-2-2006

Valve Series Seat Style

X-MBV seat

supported

M2 seat

supported

S6

X-MBV

trunnion

M2 trunnion

LG/LW

L1/L2

L6

R-series

Finetrol

ZX

H

S (1)

K (1)

G

J (2)

S (1)

P (1)

E

H,X,K

J (2)

H

S

B

L

S

H

S

E

B

C

K

all (3)

all (3)

all (3)

S

T

all

all

class IV

(water)

class V

(water)

standard

standard

standard

standard

ISO 5208 Third edition

Low Press. Air Test High Press. Water

class V class VI

Rate C

Rate D

(air)

(air)

optional

optional

optional

optional

optional

optional

optional

optional

optional

optional

optional

optional

optional

standard

standard optional

optional

optional

standard optional

optional

optional

standard optional

optional

optional

standard optional

optional

optional

optional

standard

standard optional

optional

standard optional

optional

optional

standard optional

optional

optional

standard optional

optional

optional

standard optional

optional

optional

standard optional

optional

standard optional

optional

optional

standard optional

optional

optional

standard optional

optional

optional

standard optional

optional

standard optional

optional

optional

standard optional

optional

optional

standard optional

optional

optional

standard optional

optional

optional

class IV (water) standard, optional test to 1/10 class IV (air)

standard

standard

standard

Rate C

Rate D

standard

standard

standard

standard

optional

optional

optional

standard

standard

standard

standard

standard

standard

standard

standard

standard

standard

standard

standard

standard

standard

standard

standard

standard

standard

API 598 Eighth edition

(Only for valves larger than 2")

Low Pressure

Air Test

optional

optional

optional

optional

High Pressure

Water Test

optional

optional

optional

optional

optional

optional

optional

optional

optional

optional

optional

optional

optional

optional

optional

optional

optional

optional

optional

optional

optional

optional

optional

optional

optional

optional

optional

optional

optional

optional

optional

optional

optional

optional

Notes:

1) Seat supported ball valves with locked seat designs require a minimum dP of 30psi to meet required leakage rates

2) J-seated valves with UOP construction "UU" are tested with helium per customer specification UOP-671

3) Optional leakage rates are for the preferred direction with shaft on high pressure side. Non preferred direction is tested to ISO 5208 rate C (water)

or ANSI class V (water)

Neles North America Seat Leakage Guide Page 8 Aug 28, 2009

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Tutorials QuestionsDocument3 pagesTutorials Questionskarri100% (1)

- Suitability of Stabilized Copper Slag-Fly Ash and Rice Husk Ash Mix As Road Construction MaterialsDocument52 pagesSuitability of Stabilized Copper Slag-Fly Ash and Rice Husk Ash Mix As Road Construction MaterialsB VAMSI KRISHNANo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Uk Truss BrochureDocument104 pagesUk Truss BrochureJFAFPNo ratings yet

- B7 Butterfly Valve - Wafer Style - : Spec SheetDocument1 pageB7 Butterfly Valve - Wafer Style - : Spec SheetParthibanNo ratings yet

- Datasheet ActuatorDocument1 pageDatasheet ActuatorParthibanNo ratings yet

- API Torque Receptacle Tech Note 2016-05-31Document2 pagesAPI Torque Receptacle Tech Note 2016-05-31ParthibanNo ratings yet

- W100 Multi TurnDocument2 pagesW100 Multi TurnParthibanNo ratings yet

- 3/2 Way Ball Valves Khb3K: Model CodeDocument6 pages3/2 Way Ball Valves Khb3K: Model CodeParthibanNo ratings yet

- Complete Guide: How To Order Velan ValvesDocument12 pagesComplete Guide: How To Order Velan ValvesParthiban100% (1)

- Brochure Manifold 2 Valves Rev.00Document12 pagesBrochure Manifold 2 Valves Rev.00ParthibanNo ratings yet

- Surface FinishDocument1 pageSurface FinishRay Faiers100% (3)

- Weld Prep PDFDocument1 pageWeld Prep PDFParthibanNo ratings yet

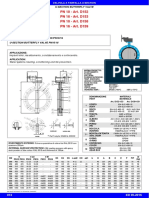

- PN 10 - Art. D152 PN 16 - Art. D153 PN 10 - Art. D158 PN 16 - Art. D159Document1 pagePN 10 - Art. D152 PN 16 - Art. D153 PN 10 - Art. D158 PN 16 - Art. D159ParthibanNo ratings yet

- IG 76 MESC 14d - 2021Document3 pagesIG 76 MESC 14d - 2021bmanojkumar16No ratings yet

- 1247EDocument2 pages1247EschumonNo ratings yet

- Atlas Copco AccessoriesDocument48 pagesAtlas Copco AccessoriesSumit Bhasin100% (1)

- Com Kitchen Plumbing Indirect Waste Fact Sheet 2205Document3 pagesCom Kitchen Plumbing Indirect Waste Fact Sheet 2205parelkidNo ratings yet

- Zertifikat ISO 14001 Umweltmanagement enDocument2 pagesZertifikat ISO 14001 Umweltmanagement enwahbyNo ratings yet

- Frey Ss I Bar Eta 090169Document34 pagesFrey Ss I Bar Eta 090169Amal HajarNo ratings yet

- Assignment DQS154Document17 pagesAssignment DQS154Irfan AimanNo ratings yet

- Toyota Genuine Motor Oil 5w30 PDFDocument3 pagesToyota Genuine Motor Oil 5w30 PDFRadinal AkbarNo ratings yet

- Seleccion de Filtros de PiedraDocument1 pageSeleccion de Filtros de PiedraCristhian ParragaNo ratings yet

- Kinetics of Wet Oxidation of Formic Acid and Acetic AcidDocument6 pagesKinetics of Wet Oxidation of Formic Acid and Acetic AcidVerónica ArévaloNo ratings yet

- Series Air-Handling Unit: AIR VDLUME: 2209 57766 M /H (2.5m/s)Document23 pagesSeries Air-Handling Unit: AIR VDLUME: 2209 57766 M /H (2.5m/s)Erwin MaldoNo ratings yet

- MODEL G0484 Gearhead Mill/Drill With Stand: Owner'S ManualDocument48 pagesMODEL G0484 Gearhead Mill/Drill With Stand: Owner'S Manualcmperes49No ratings yet

- Zest BarDocument2 pagesZest Barrita.baharian2663No ratings yet

- High Performance ConcreteDocument116 pagesHigh Performance ConcretealfredoNo ratings yet

- NTC Thermistors:: Type CLDocument3 pagesNTC Thermistors:: Type CLErnesto Moya-AlborNo ratings yet

- IM Fused Alumina Article - Dec 20071 PDFDocument5 pagesIM Fused Alumina Article - Dec 20071 PDFMrutunjay Patra100% (1)

- Artimetic Cheeking StationaryDocument242 pagesArtimetic Cheeking Stationarymolla aleneNo ratings yet

- Raychem: MIL-STD-1553B Data Bus MicrocouplersDocument11 pagesRaychem: MIL-STD-1553B Data Bus MicrocouplersVolkan SezginNo ratings yet

- Data Sheet - Accelerator Buildshot AflDocument2 pagesData Sheet - Accelerator Buildshot AflRajesh GiriNo ratings yet

- Agiecharmilles Cut e 350 600 - enDocument28 pagesAgiecharmilles Cut e 350 600 - enrachid HachhoucheNo ratings yet

- Model Textbook of Chemistry For Senior Secodary Schools: January 2006Document499 pagesModel Textbook of Chemistry For Senior Secodary Schools: January 2006I am SheldonNo ratings yet

- Air Compressor SeminarDocument15 pagesAir Compressor SeminarAshish Deotale75% (4)

- FDA Componentes Empaques AlimentosDocument153 pagesFDA Componentes Empaques AlimentosPatricia RodriguezNo ratings yet

- Manara Plast PDFDocument2 pagesManara Plast PDFfarjana khatunNo ratings yet

- Structural Stainless Steel PDFDocument5 pagesStructural Stainless Steel PDFGiri DharanNo ratings yet

- Welding MCQSDocument46 pagesWelding MCQSchin22222222No ratings yet

- Checklist For Water ProofingDocument1 pageChecklist For Water ProofingShivam PandeyNo ratings yet