Professional Documents

Culture Documents

Wall Thickness Calculation ASME B31!8!2007 Template

Uploaded by

MubarizCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wall Thickness Calculation ASME B31!8!2007 Template

Uploaded by

MubarizCopyright:

Available Formats

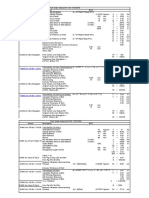

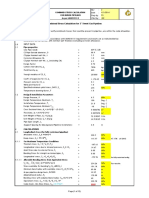

ATTACHMENT - X

Document No. X

Wall Thickness Calculation of 36in Gas Pipeline (Location Class-3, D.F.=0.5, Corr. Allow.=1.5mm)

1

2

3

DESIGN INPUT

Design Code

4

5

Pipeline Size / Nominal O.D

Corrosion Allowance

Location Class

7

8

Design Factor

0.5

9

10

Steel Coefficient of Expansion,

Modulus of Elasticity

0.0000117

2.07E+05

per deg C 6.50E-06 in/in/ oC

Mpa

3.05E+07 Psi

P

Td

Ti

63.5

bar g

921.0

psi g

C

o

C

149.0

55.4

65

13

1

ASME B31.8

D

A

36

1.5

in

mm

914

mm

11

12

13

Pressure and Temperature Data

Design Pressure

14

15

16

Design Temperature (Underground)

Installation (backfill) Temp

Weld joint factor

17

18

Temperature Derating Factor

19

20

21

A. WALL THICKNESS

Grade

SMYS of Line Pipe

22

23

Wall Thickness Calculated

tmin = P x D / (2x Sx Fx E x T) + A

24

25

26

Next higher API wall thickness

D/t Check ( Should be < 96)

27

28

29

30

31

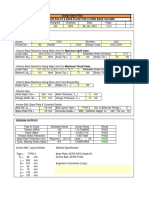

B. EQUIVALENT STRESS CHECK FOR CORRODED PIPE CONDITION

Wall thickness (t)

Hoop Stress = Sh = PD/2t

B.1 Restrained Pipe (Underground)

Thermal Stress = ST = a (Ti - Td) E

Longitudinal Stress due to pressure = SP = 0.3 Sh

-125.9

60.5

MPa

MPa

-65.5

OK

MPa

267.1

241.1

267.1

OK

MPa

MPa

MPa

B.2 Unrestrained Pipe (Aboveground)

Longitudinal Stress due to pressure = SP = 0.5 Sh

100.8

MPa

Longitudinal Stress, SL

SL = SP +SB + SX

0.75 x SMYS = 312 MPa

Without considering SB (Bending stress) and SX (Axial stress due to external loading):

SL = SP

SL 0.75 x SMYS

Longitudinal Stress check :

hence

100.8

OK

MPa

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

Longitudinal Stress, SL

SL = SP + ST + SB + SX

Equivalent Stress check :

F

F

X60

S

tmin

t

0.9 x SMYS = 374 MPa

SE 0.9 x SMYS

SE1

SE2

SE

hence

psi

15.5

mm

0.610 inch

15.9

58

mm

0.626 inch

14.4

mm

201.6

MPa

C. MINIMUM BENDING RADIUS

Minimum bending radius for underground section is calculated from maximum margin of bending stress,

based on Max (SE1, SE2) = 0.9 x SMYS. Hence, bending stress SB =

-106.5 MPa

R (Minimum Bend Radius) = E D / (2 |Sb|)

889 m

D. CHECK ON THINNING DUE TO COLD BENDS: BEND RADIUS = 40 D

Inner bend radius divided by diameter, (n)

As per PD 8010-1:2004, % of Wall thinning = 50 / (n+1)

Pipe thk. before bending = cal thk/(1-thinning %)

Available thickness for bending (= Selected thk)

Adequacy Check (Pipe thk before bending < Available thk)

Page 1 of 1

415 MPa

60200

0.9 x SMYS = 374 MPa

Without considering SB (Bending stress) and SX (Axial stress due to external loading):

SL = SP + ST

SL 0.9 x SMYS

Longitudinal Stress check :

hence

Equivalent Stress, SE

SE1 = | Sh - SL |

SE2 = [ Sh2 + SL2 - Sh SL ]1/2

SE = Max (SE1, SE2)

39.5

1.23

15.7

15.9

OK

%

mm

mm

You might also like

- Wall THK Calculation Asme b31.4Document5 pagesWall THK Calculation Asme b31.4Dwi Hermawan100% (2)

- Wall Thickness Calculation - ASME B31.8 2007 (Template)Document1 pageWall Thickness Calculation - ASME B31.8 2007 (Template)LU1228100% (3)

- Reinforcement CheckDocument2 pagesReinforcement Checkviv0102No ratings yet

- Wall Thickness Calculation ASME B31!8!2007Document1 pageWall Thickness Calculation ASME B31!8!2007shafeeqm3086No ratings yet

- ASME B31.3 Pipe Wall ThicknessDocument33 pagesASME B31.3 Pipe Wall Thicknessaike_5No ratings yet

- Wall THK Calculation Asme b31.4Document7 pagesWall THK Calculation Asme b31.4Luis Jose Duran100% (1)

- Permissible Elastic Bend Limit CalculationDocument4 pagesPermissible Elastic Bend Limit Calculationheldermanuel100No ratings yet

- YoussefDocument1 pageYoussefhhgjdfNo ratings yet

- Area Reinforcement CalculatorDocument5 pagesArea Reinforcement CalculatorAnonymous Iev5ggSR100% (1)

- Trunnion Calcualtion SheetDocument22 pagesTrunnion Calcualtion SheetAbhijit50% (2)

- Pipe Wall Thickness Calculation ASME B31.8Document16 pagesPipe Wall Thickness Calculation ASME B31.8DikaAnindyajati100% (2)

- ASME B31.3.4.8 Wall Thickness CalculatorDocument26 pagesASME B31.3.4.8 Wall Thickness Calculatoreko123100% (1)

- ASME B31 8 Riser CalcDocument12 pagesASME B31 8 Riser CalcEmmanuel LawrenceNo ratings yet

- Wall Thickness CalDocument6 pagesWall Thickness CalNorazlan Shah MahadiNo ratings yet

- Pipíng & Stress Analysis Ref - Sofware Caesar II. 06-09-2017 Autor - Ing R L Morard - U T N 1Document9 pagesPipíng & Stress Analysis Ref - Sofware Caesar II. 06-09-2017 Autor - Ing R L Morard - U T N 1Oswaldo GuerraNo ratings yet

- Calc Asme Viii Div-1 2007 Ed - Rev1Document32 pagesCalc Asme Viii Div-1 2007 Ed - Rev1AndiWSutomoNo ratings yet

- 2654 - Pipe Wall Thickness Calculation As Per ASME B31.3Document20 pages2654 - Pipe Wall Thickness Calculation As Per ASME B31.3Sridhar Vijayan100% (3)

- Design Data: 4" Weldolet CalculationDocument2 pagesDesign Data: 4" Weldolet Calculationgrabetty100% (2)

- Nozzle Design CalculationDocument1 pageNozzle Design CalculationSachin55860% (1)

- Blind Flange Design Calculation As Per Asme Section Vii Division - 1Document4 pagesBlind Flange Design Calculation As Per Asme Section Vii Division - 1mukesh100% (2)

- TBE-Pressure Vessel Standard TemplateDocument4 pagesTBE-Pressure Vessel Standard TemplateSiva baalanNo ratings yet

- B31 G Level 1 EvaluationDocument5 pagesB31 G Level 1 EvaluationmmNo ratings yet

- EIL Nozzle LoadsDocument5 pagesEIL Nozzle LoadsAniket GaikwadNo ratings yet

- Thickness Calculation of Pressure Vessel ShellDocument17 pagesThickness Calculation of Pressure Vessel ShellVishnuGK100% (1)

- ASME PipingOffice - Piping CalculatorsDocument5 pagesASME PipingOffice - Piping CalculatorsJohn PaulNo ratings yet

- Pipe Wall Thickness (Complete)Document40 pagesPipe Wall Thickness (Complete)Andri PutraNo ratings yet

- Retirement ThicknessDocument7 pagesRetirement ThicknessKamal UddinNo ratings yet

- B31G 1991Document3 pagesB31G 1991Ahmed MahjoubNo ratings yet

- Wall Thickness Pipeline (Gas) B31Document25 pagesWall Thickness Pipeline (Gas) B31Rais Brian Abdurahman100% (6)

- Lethal Service - Quick Guide - Pressure Vessel EngineeringDocument4 pagesLethal Service - Quick Guide - Pressure Vessel EngineeringVilas AndhaleNo ratings yet

- Calculation For Reinforced PadDocument4 pagesCalculation For Reinforced Padjsridhar_34750% (2)

- Asme b31g Level 2 A1Document27 pagesAsme b31g Level 2 A1finiteinjustice75% (8)

- ASME B16.5 2013 FlangeRating 1.0Document4 pagesASME B16.5 2013 FlangeRating 1.0sanjaysyNo ratings yet

- Pressure Vessel Calculations ASME SectioDocument11 pagesPressure Vessel Calculations ASME Sectioivan chirinosNo ratings yet

- Design Sheet As Per ASME 31.8 2012 For 12inch TeeDocument3 pagesDesign Sheet As Per ASME 31.8 2012 For 12inch TeechethanNo ratings yet

- ASME VIII CalculationDocument15 pagesASME VIII CalculationJoao Osmar Correa100% (1)

- ASME 31 - 8mDocument1 pageASME 31 - 8mMarcoAlbaNo ratings yet

- Flange Asmeviii Div.1 App.2 Rev0Document10 pagesFlange Asmeviii Div.1 App.2 Rev0lk700615100% (1)

- ASME B31.8 Riser CalcDocument23 pagesASME B31.8 Riser Calcisrar khan100% (2)

- MDMT Calculations For A Pressure Vessel - Abdel Halim GalalaDocument12 pagesMDMT Calculations For A Pressure Vessel - Abdel Halim Galalabego00No ratings yet

- ASME B31.4 Riser CalcDocument14 pagesASME B31.4 Riser CalcCastorNoroñoNo ratings yet

- Above Ground Piping Wall Thickness CalculationsDocument7 pagesAbove Ground Piping Wall Thickness Calculationslutfi awn100% (1)

- PIPECALC ASME B31.4 - Rev 2Document24 pagesPIPECALC ASME B31.4 - Rev 2Mohsin RazaNo ratings yet

- Steel Pipe Design Calculation For SeamlessDocument4 pagesSteel Pipe Design Calculation For SeamlessA SubinNo ratings yet

- Hydrostatic Test Pressure Calculation: Pipe DataDocument2 pagesHydrostatic Test Pressure Calculation: Pipe DataAkram AlhaddadNo ratings yet

- Extreme Fiber Elongation To UCS-79Document1 pageExtreme Fiber Elongation To UCS-79Azwan Shah100% (2)

- Minimum Pipe Thickness - B31.1 - PG1Document10 pagesMinimum Pipe Thickness - B31.1 - PG1ravivarmadatla2011No ratings yet

- Pipe Bend Againts Coating 3LPE AnalisisDocument25 pagesPipe Bend Againts Coating 3LPE Analisisraditia2205100% (1)

- Miter B1 ADocument55 pagesMiter B1 AFarid TataNo ratings yet

- Design Input:: Design Sheet Title: Design of Anchor Bolts & Base Plate For A Fixed Base Column Ameya STDDocument4 pagesDesign Input:: Design Sheet Title: Design of Anchor Bolts & Base Plate For A Fixed Base Column Ameya STDSuryaSinghNo ratings yet

- 31barg CalculationDocument10 pages31barg Calculationshani5573No ratings yet

- AD2000 (31barg) CalculationDocument10 pagesAD2000 (31barg) CalculationMagdaline Matabang100% (1)

- FinalDocument12 pagesFinalchompink6900No ratings yet

- Weight CalculatorDocument12 pagesWeight CalculatorShafqat AfridiNo ratings yet

- SPAN Calc.Document48 pagesSPAN Calc.yoi_123No ratings yet

- Wall-Thickness-Calculation-ASME B31.8-2016-API5LGRBDocument1 pageWall-Thickness-Calculation-ASME B31.8-2016-API5LGRBtitir bagchiNo ratings yet

- Combined Stress Calc Rev. 2Document12 pagesCombined Stress Calc Rev. 2babu75% (4)

- Steam Drum, Water Wall & Evaporator - VWHA054Document36 pagesSteam Drum, Water Wall & Evaporator - VWHA054Mani SunNo ratings yet

- Pipe Wall Thickness Calculation (As Per Asme B31.3 Section 304.1.2)Document1 pagePipe Wall Thickness Calculation (As Per Asme B31.3 Section 304.1.2)farhadNo ratings yet

- 05 CalDocument53 pages05 Calnatarajan RavisankarNo ratings yet

- General Inspection CraneDocument12 pagesGeneral Inspection CraneHendra YudistiraNo ratings yet

- Pipe Drafting and Design Third Edition PDFDocument475 pagesPipe Drafting and Design Third Edition PDFHendra Yudistira91% (34)

- Thermodynamic and Thermochemical Characteristics of Holmium SilicidesDocument10 pagesThermodynamic and Thermochemical Characteristics of Holmium SilicidesHendra YudistiraNo ratings yet

- Integrity Evaluation of Small Bore Connections (Branch Connections) PDFDocument9 pagesIntegrity Evaluation of Small Bore Connections (Branch Connections) PDFHendra YudistiraNo ratings yet

- Form 610 - Daily Field Coating Inspection ReportDocument8 pagesForm 610 - Daily Field Coating Inspection ReportHendra Yudistira100% (1)

- D.G Size Calculation (22.8.12)Document1 pageD.G Size Calculation (22.8.12)Waleed Mohammed FekryNo ratings yet

- ISO 6520 Defects Overview PDFDocument27 pagesISO 6520 Defects Overview PDFalinor_tn100% (4)

- Crossing Calculation API RP1102 (TEMPLATE)Document1 pageCrossing Calculation API RP1102 (TEMPLATE)Hendra Yudistira100% (1)

- Fabrication - Assembly & ErectionDocument83 pagesFabrication - Assembly & ErectionRengga Andryastama100% (2)

- B31G CalculatorDocument3 pagesB31G CalculatorHendra Yudistira100% (6)

- Steam TurbinesDocument198 pagesSteam TurbinesHendra Yudistira100% (1)

- Cost Engineering TerminologyDocument120 pagesCost Engineering TerminologyHendra YudistiraNo ratings yet

- Radiography Calculations: Ir-192 Exposure Calculator (Fe)Document2 pagesRadiography Calculations: Ir-192 Exposure Calculator (Fe)Ali AlhaikNo ratings yet

- Weld Cracking PDFDocument5 pagesWeld Cracking PDFjuanNo ratings yet

- Draft ISO 21457Document21 pagesDraft ISO 21457Hendra YudistiraNo ratings yet

- Determing Calculation For Repair of Storage TankDocument4 pagesDeterming Calculation For Repair of Storage TankHendra Yudistira100% (2)

- Design Pressure PSVDocument8 pagesDesign Pressure PSVHendra YudistiraNo ratings yet

- B31GDocument3 pagesB31GHendra YudistiraNo ratings yet

- Cathodic Protection of Aboveground Petroleum Storage Tanks: Api Recommended Practice 651 Second Edition, December 1997Document23 pagesCathodic Protection of Aboveground Petroleum Storage Tanks: Api Recommended Practice 651 Second Edition, December 1997Hendra Yudistira100% (2)

- Crude Oil Pipeline CalculationDocument104 pagesCrude Oil Pipeline CalculationHendra Yudistira100% (3)