Professional Documents

Culture Documents

MSET Engineering Corporation Work Instruction for Mechanical Testing

Uploaded by

hannanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MSET Engineering Corporation Work Instruction for Mechanical Testing

Uploaded by

hannanCopyright:

Available Formats

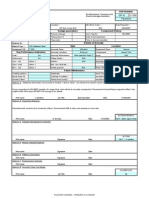

MSET ENGINEERING CORPORATION SDN. BHD.

Page 1 of 1

WORK INSTRUCTION

From: KAMARUZAMAN (kamaruzaman@mset.com.my)

To :

PTS (ptsjohor@ptspl.com)

Attn :

MS ROZANNA

Project No.

To carry-out Mechanical Testing for :-

Charpy Test

:

:

NO

Aceppt. Criteria

Hardness Test

Aceppt. Criteria

:

:

:

YES

As per ASME II Part A

Macro Etch

NO

Micro Examination:

NDT

All weld Tensile

Acceptance Criteria

Elongation

Yield strength

Bend Test

QAQC 12-002/M2-207a-02

Recertification to EN10204 3.2 (Pipe Material) - 1 no

Longitudinal (2 Nos)

Tensile Test

19th Sept 2012

Ref :

P.O No/MR No :

KENCANA_Patricia Satellite (PT-SA) / M2-207a-Recertification to EN10204 3.2 (Pipe Material)

:

:

:

:

:

:

:

Date :

NO

YES

YES

NO

(Side Bend / Face Bend / Root Bend)

Test Temperature

Method/Type

HRC

NO

:

i) RT : X-RAY

ii)

DPT

iii) MPI

: Gamma Ray

9

Chemical analysis

10

Other Testing

a) Corrosion

b) Ferrite

11

PWHT

12

Details

a)

b)

c)

d)

e)

f)

g)

h)

i)

j)

k)

l)

YES

Elements :

As per ASME II Part A

: IGC ASTM A262 Practise E

: NO

NO

Heat No

WPS No

Material Spec

Material Thk. / Dia

Welding Process

Joint Design

Weld Position

Weld Seam

Welder's Name

Welder No.

PQR No

Test Code

:

:

:

:

:

:

:

:

:

:

:

:

13

Special requirements (if any)

N/A

14

15

Witness By (if any)

Testing Date

:

:

MSET / ABS

PTS to advice readiness

REQUESTED BY

Signature

Name

Position

(HV / HB / HR)

(2- A36040)

N/A

SA 312 TP 316L

8.7mm (2)

N/A

N/A

N/A

N.A

N/A

N/A

N/A

ASME VIII DIV 1 2010 Ed 2011 Add.

RECEIVED BY

:

:

:

Kz

Kamaruzaman (Kz)

QAQC Engineer

019-928 2922

Signature

Name

Position

:

:

:

Kawasan Perindustrian Kerteh, 24300 Kerteh, Kemaman, Terengganu Darul Iman.

Tel : 609-827 1777

Fax : 609-827 1871

iv) UT

You might also like

- Design Guidelines for Surface Mount TechnologyFrom EverandDesign Guidelines for Surface Mount TechnologyRating: 5 out of 5 stars5/5 (1)

- PQR Gmaw3gDocument4 pagesPQR Gmaw3gdevendrasingh2021100% (3)

- Mechanical Properties and Performance of Engineering Ceramics and Composites XIFrom EverandMechanical Properties and Performance of Engineering Ceramics and Composites XIJonathan SalemNo ratings yet

- Weld Joint 1Document81 pagesWeld Joint 1rajibali27100% (1)

- Indcon Projects Electrode Qualification Procedure IOCL Gas PipelineDocument11 pagesIndcon Projects Electrode Qualification Procedure IOCL Gas PipelineAkhilesh Kumar67% (3)

- First Crew: Metalfab Middle East FZ LLCDocument3 pagesFirst Crew: Metalfab Middle East FZ LLCsalahuddinNo ratings yet

- PT MCGPL MCGD JP 003Document6 pagesPT MCGPL MCGD JP 003ANURAG YADAVNo ratings yet

- Concast WPS - REV-01Document28 pagesConcast WPS - REV-01meena34No ratings yet

- Tensile Test Report: CMSS/18/556 CMSS/TT/18/455 30-04-2018 03-05-2018Document12 pagesTensile Test Report: CMSS/18/556 CMSS/TT/18/455 30-04-2018 03-05-2018nareshNo ratings yet

- WPSDocument2 pagesWPSBalu SukumarNo ratings yet

- Mathan ResumeDocument5 pagesMathan ResumeSani TipareNo ratings yet

- ObjectiveDocument3 pagesObjectiveShabeer MohammedNo ratings yet

- PQR 014 (Qualified Sa 106 GR BDocument5 pagesPQR 014 (Qualified Sa 106 GR Bersenthil100% (1)

- FatDocument31 pagesFatgourishankar2No ratings yet

- G.raju Reddy Resume (PDF1) PDFDocument3 pagesG.raju Reddy Resume (PDF1) PDFanon_708469687No ratings yet

- Company Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsDocument11 pagesCompany Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsMAT-LIONNo ratings yet

- Corrosion Damage Report (CDR)Document4 pagesCorrosion Damage Report (CDR)diaccessltd_17172961No ratings yet

- New NDT Shedule-6 MethodsDocument3 pagesNew NDT Shedule-6 Methodskavas26No ratings yet

- Magnetic Test: Client: Gas Filling Company (GFC) ContractorDocument1 pageMagnetic Test: Client: Gas Filling Company (GFC) ContractorHatem RagabNo ratings yet

- Technoweld PQR Welding Procedure Single Run Fillet Joint AS3678 Gr350 GMAW 2FDocument5 pagesTechnoweld PQR Welding Procedure Single Run Fillet Joint AS3678 Gr350 GMAW 2FAdiNo ratings yet

- PQR-WPS-WPQR XXX Rev 0Document6 pagesPQR-WPS-WPQR XXX Rev 0Brett Gosselin100% (1)

- Sandeep NewDocument2 pagesSandeep Newvignesh kumarNo ratings yet

- Example CVDocument7 pagesExample CVkarthi keyanNo ratings yet

- WPS - 024Document4 pagesWPS - 024MAT-LIONNo ratings yet

- Loading Unloading Temperature Welding ProgressionDocument5 pagesLoading Unloading Temperature Welding ProgressionRajesh Owaiyar71% (7)

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document2 pagesQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNo ratings yet

- WPS - Smaw - 2Document6 pagesWPS - Smaw - 2Harkesh RajputNo ratings yet

- PQR - 152Document3 pagesPQR - 152MAT-LIONNo ratings yet

- Method Statement: Pt. Duta Graha Indah TBK Welding Procedure (Preparation)Document4 pagesMethod Statement: Pt. Duta Graha Indah TBK Welding Procedure (Preparation)Nigin Parambath50% (2)

- Curriculum Vitae: RdevanandDocument5 pagesCurriculum Vitae: RdevanandulocksystemNo ratings yet

- Pad Eye App 65 - 15 Feb 16Document1 pagePad Eye App 65 - 15 Feb 16Irnaldi Yoza WijayaNo ratings yet

- Welding Procedure Specification NO. 1-7-1: National Certified Pipe Welding BureauDocument5 pagesWelding Procedure Specification NO. 1-7-1: National Certified Pipe Welding BureauTharakeshNo ratings yet

- WPS GTAW pipe welding procedureDocument2 pagesWPS GTAW pipe welding procedureRichard PeriyanayagamNo ratings yet

- PQ7-GM-16Mo3-B1 - AWSD1.1 Rev 0Document12 pagesPQ7-GM-16Mo3-B1 - AWSD1.1 Rev 0rodwellbNo ratings yet

- 24.11.2015 EGI High Spot Dent IPPCDocument6 pages24.11.2015 EGI High Spot Dent IPPCrahul srivastavaNo ratings yet

- Mahesh K MDocument4 pagesMahesh K MulocksystemNo ratings yet

- Tensile Test ReportDocument1 pageTensile Test ReportESHWAR CHARYNo ratings yet

- Naga Resume 2Document6 pagesNaga Resume 2NikhatRizaviNo ratings yet

- WPS - 023Document10 pagesWPS - 023MAT-LION0% (1)

- L&T Log SheetDocument10 pagesL&T Log SheetSrikant GanjiNo ratings yet

- CV of Raj (Dec'23)Document3 pagesCV of Raj (Dec'23)ahiadarshNo ratings yet

- Electrode Test Record E6010Document9 pagesElectrode Test Record E6010Veeraraghavan GuruNo ratings yet

- WPS - 012Document11 pagesWPS - 012MAT-LIONNo ratings yet

- 16 MM Grade 60-70 p1g1 To p2g2Document8 pages16 MM Grade 60-70 p1g1 To p2g2John EvansNo ratings yet

- Essential welding procedure qualification recordDocument2 pagesEssential welding procedure qualification recordmainur mechanical engineer0% (1)

- 4.5-02 Test Request For Testing-NEWDocument5 pages4.5-02 Test Request For Testing-NEWearth metallurgical services pvt.ltd.No ratings yet

- Record of Welder Qualification Tests: Dodsal Pte LTD Q-Chem Project Doha, Qatar Job No: 7979Document1 pageRecord of Welder Qualification Tests: Dodsal Pte LTD Q-Chem Project Doha, Qatar Job No: 7979rohitbhat2345No ratings yet

- Prestige Engineering L.L.C: Welding Procedure Specification (WPS)Document24 pagesPrestige Engineering L.L.C: Welding Procedure Specification (WPS)Sarathiraja SekarNo ratings yet

- Corrosion Damage Report (CDR)Document4 pagesCorrosion Damage Report (CDR)diaccessltd_17172961No ratings yet

- Madina Group WPS 025 GuideDocument4 pagesMadina Group WPS 025 GuideMAT-LIONNo ratings yet

- Check List PipeDocument18 pagesCheck List PipeGeorge MadisonNo ratings yet

- New NDT Shedule-4methodsDocument2 pagesNew NDT Shedule-4methodskavas26No ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345No ratings yet

- WPS - 008Document11 pagesWPS - 008MAT-LIONNo ratings yet

- Tensile Test ReportDocument1 pageTensile Test ReportESHWAR CHARYNo ratings yet

- Test Report: Format No.: PTL/FTR-00Document7 pagesTest Report: Format No.: PTL/FTR-00qa.primetestinglabNo ratings yet

- RevisedMethodStatementforStructuralSteelWorksofCP 02Document155 pagesRevisedMethodStatementforStructuralSteelWorksofCP 02Brayand Colonia MarquinaNo ratings yet

- Corrosion Damage Report DetailsDocument4 pagesCorrosion Damage Report Detailsdiaccessltd_17172961No ratings yet

- 2021-05-21 C30 1st PassDocument1 page2021-05-21 C30 1st PassHasan al MahmudNo ratings yet

- m5-36 - Packing List - EiDocument1 pagem5-36 - Packing List - EihannanNo ratings yet

- Post Forming Heat Treatment ProposalDocument2 pagesPost Forming Heat Treatment ProposalhannanNo ratings yet

- Daily Manpower ReportDocument1 pageDaily Manpower ReporthannanNo ratings yet

- m5-36 - Packing List - DeliveryDocument16 pagesm5-36 - Packing List - DeliveryhannanNo ratings yet

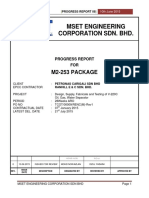

- M2-253 Contractor Progress Report 08Document7 pagesM2-253 Contractor Progress Report 08hannanNo ratings yet

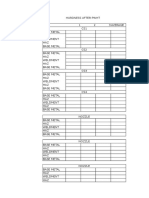

- Hardness Test Inspection Report: Weld Base MetalDocument2 pagesHardness Test Inspection Report: Weld Base MetalhannanNo ratings yet

- Book JKHFVDocument2 pagesBook JKHFVhannanNo ratings yet

- Upgrade TCOT Separation PackageDocument2 pagesUpgrade TCOT Separation PackagehannanNo ratings yet

- Round Bar 45mmDocument2 pagesRound Bar 45mmhannanNo ratings yet

- Acid Pickling Procedure Rev.c1Document6 pagesAcid Pickling Procedure Rev.c1hannanNo ratings yet

- Pressure VesselDocument8 pagesPressure VesselhannanNo ratings yet

- Rubber Lining CoverDocument1 pageRubber Lining CoverhannanNo ratings yet

- 1dimensional ReportDocument23 pages1dimensional ReporthannanNo ratings yet

- OTI 2 - 2 MUJAHIDDocument32 pagesOTI 2 - 2 MUJAHIDhannanNo ratings yet

- m2-216 Vendor Document Master ListDocument1 pagem2-216 Vendor Document Master ListhannanNo ratings yet

- Vessel Fabrication Tolerances GuideDocument1 pageVessel Fabrication Tolerances Guidehannan100% (1)

- Book 1Document12 pagesBook 1hannanNo ratings yet

- Inspection and Test Plan (ITP) (Pressure Vessel)Document1 pageInspection and Test Plan (ITP) (Pressure Vessel)hannanNo ratings yet

- 2014 Course Summary Twi SeaDocument14 pages2014 Course Summary Twi SeahannanNo ratings yet

- NO Job No 1 M4-188: Senarai Kerja-Kerja BaikpulihDocument30 pagesNO Job No 1 M4-188: Senarai Kerja-Kerja BaikpulihhannanNo ratings yet

- Pipe ScheduleDocument1 pagePipe ScheduleNad DiyaNo ratings yet