Professional Documents

Culture Documents

United States Patent (191: Andersen Et A1

United States Patent (191: Andersen Et A1

Uploaded by

khoagleOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

United States Patent (191: Andersen Et A1

United States Patent (191: Andersen Et A1

Uploaded by

khoagleCopyright:

Available Formats

United States Patent [191

[11]

4,382,561

Andersen et a1.

[45]

May 10, 1983

[54] VERTICAL ROLLER MILL

[75] Inventors: Knud T. Andersen; Erik C. P.

Christensen, both of Copenhagen,

3258 of 1915 United Kingdom .

[73] Assignee: F. L. Smidth & Co., Cresskill, NJ.

[21] Appl. No.: 231,262

[30]

Feb. 3, 1981

Denmark ............................. .. 690/80

[51]

[52]

Int. Cl.3 ............................................ .. B02C 15/00

U.S. Cl. ................................... .. 241/121; 241/290

[58]

Field of Search .............. .. 241/103, 106, 117-122,

241/ 128, 290

[56]

Primary ExaminerMark Rosenbaum

Attorney, Agent, or Firm-Pennie & Edmonds

[57]

Foreign Application Priority Data

Feb. 18, 1980 [DK]

Mehta et al. .................. .. 241/121 X

Brundiek ........................... .. 241/121

8/1980

FOREIGN PATENT DOCUMENTS

Denmark

[22] Filed:

4,127,237 11/1978

4,218,023

ABSTRACT

A vertical roller mill includes a grinding table posi

tioned for rotation around a vertical axis and two up

right grinding rollers resting on their peripheral grind

ing surfaces on the grinding table for grinding material

thereon. Each of the grinding rollers is rotatably

mounted on a respective ?xed horizontal shaft con

nected at one end to a common, central frame and at the

References Cited

other end to a draw bar. Preferably, the draw bar is

U.S. PATENT DOCUMENTS

regulated by a hydraulic cylinder secured in a bracket

which is anchored in the mill foundation.

834,387 10/1906

3,782,646

1,806,077

Little ................................. .. 241/121

5/1931

1/1974 Brundiek

McMurray........................... .. 241/121

12 Claims, 4 Drawing Figures

US. Patent

May 10, 1983

Sheet 1 of 2

4,382,561

US. Patent

May 10, 1983

Sheet 2 of2

52,51

4,382,561

VERTICAL ROLLER MILL

generally horizontal draw bars coupled to the outer

ends of the roller shafts.

The vertical roller mill according to a second pre

TECHNICAL FIELD

ferred embodiment of the present invention has at least

This invention relates to a roller mill and particularly 5 four grinding rollers comprising two frames centrally '

positioned one above the other. Each frame is common

to a vertical roller mill wherein the grinding rollers

to two of the grinding rollers. Alternatively, the verti

rotate around stationary generally horizontally

cal roller mill has at least six grinding rollers comprising

mounted shafts.

two frames centrally positioned one above the other.

Each frame is common to three of the grinding rollers.

As compared with known roller mills, the mill ac

BACKGROUND ART

In known vertical roller mills having a grinding table

capable of rotating around a vertical axis, the grinding

rollers are suspended in a pressure frame positioned

above the rollers. The frame urges the rollers against

the grinding table by means of draw bars which are

connected to the pressure frame itself.

The construction of the roller suspension in the pres

sure frame of the known mill is comparatively compli

cated and thereby vulnerable. Furthermore, such con 20

struction makes it difficult to replace worn or defective

rollers. We have invented a vertical roller mill which

cording to the present invention is distinguished in that

the roller suspension consists of few, uncomplicated and

rather robust parts. Such construction makes possible

comparatively easy replacement of the rollers, partly by

the achievement of improved control of the rollers and

reduced dynamic loads on the roller suspension.

Such replacement of the rollers is further facilitated if

the shafts are removably secured to the common, cen

tral frame.

BRIEF DESCRIPTION OF THE DRAWINGS

remedies the drawbacks of known vertical roller mill

constructions.

The present invention is described in greater detail

below in reference to the drawings wherein:

25

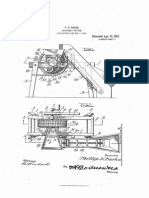

FIG. 1 is a partly diagrammatic, partially cut-away,

DISCLOSURE OF THE INVENTION

side elevational view of a roller mill according to the

The present invention relates to a roller mill compris

present invention.

ing a grinding table adapted for rotation about a vertical

FIG. 2 is a top view of the roller mill of FIG. 1.

axis, at least two grinding rollers, at least two stationary

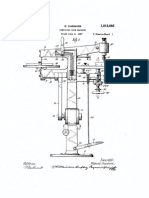

FIG. 3 is a top view of an alternative embodiment of

generally horizontally mounted roller shafts, each

grinding roller being adapted for rotation on a respec

tive shaft, means for pressing the grinding rollers

against the grinding table, a centrally positioned frame,

the roller shafts being secured to the frame at their ends

the roller mill of FIG. 1.

FIG. 4 is a side elevational view taken along the line

4-4 of FIG. 3.

DESCRIPTION OF THE BEST MODE OF THE

INVENTION

adjacent the vertical axis and the pressing means being 35

pivotally coupled to the other ends of the roller shafts.

Referring to the FIGS., a grinding table 1 is illus

In one preferred embodiment, the present invention

trated in FIG. 1 for rotating around a vertical axis and

relates to a vertical roller mill comprising a horizontal

is supported and driven by a unit 2. The preferred em

grinding table adapted for rotation about a central verti

bodiment shown in FIG. 2 includes three grinding rol

cal axis and at least two upright grinding rollers posi~

lers 3 resting and rolling on the grinding table 1. The

tioned with their peripheral grinding surfaces in en

three grinding rollers 3 grind a material layer (not

gagement with the grinding table for grinding material

shown) on the grinding table 1. Each grinding roller 3 is

thereon. Each grinding roller is positioned for rotation

pivotally mounted on a ?xed shaft 4 which together

on a respective horizontal roller shaft. A draw bar is

with the shafts of the other grinding rollers 3 are se

associated with each roller shaft. Each draw bar is an 45 cured to a common, central frame 5.

chored at one end to the mill foundation and is pivotally

The shafts 4 can be secured in various ways to the

connected at the other end to the outer end of the re

frame 5, e.g., by a ?ange 6 as shown in the drawings on

spective roller shaft. Each draw bar also has means for

each shaft 4 and similar ?anges 7 on the frame 5.

urging the respective rollers against the horizontal

The frame 5 can also be composed of several parts

grinding table. A frame, centrally positioned in relation

50 which can be clamped together and around the inner

to the grinding table, is connected to the inner end of

the associated roller shafts.

Preferably, the roller shafts are removably secured to

the central frame. According to one preferred embodi

ment, the vertical roller mill further comprises ?rst

?anges positioned on the central frame and correspond

ing second ?anges positioned on the inner end of each

ends of the shafts 4. Alternatively, the shafts 4 can be

shunk in corresponding holes in the frame 5 or may be

roller shaft, the ?rst and second ?anges adapted for

engagement for securing the roller shafts to the central

frame. Alternatively, the central frame is composed of a

plurality of members clamped together and around the

inner ends of the roller shafts. In yet another alternative

embodiment, the roller shafts are clamped in the central

frame by adjustable, conical rings.

secured on the frame 5 by adjustable conical rings.

Furthermore, the frame 5 and the shafts 4 can be cast in

one single part.

A bracket 8 is pivotally mounted at the outer end of

each shaft 4. A draw bar 9, secured to the bracket 8,

ensures that the respective grinding roller 3 is urged

against the grinding table 1 by means of a hydraulic

cylinder, 10 which is pivotally retained in a bracket 11

anchored in the mill foundation. The cylinder 10, alter

natively, can be replaced by a system of springs.

To ensure that the shafts 4 do not move in the direc

tion of rotation of the grinding table 1, they are retained

The vertical roller mill according to the present in 65 in position, e.g., by horizontal draw or tension bars 12 as

shown in the preferred embodiment of FIG. 2. The

vention further comprises means for restraining the

tension bars 12 are secured at one end to the brackets 8

roller shafts from moving in the direction of rotation of

and at the other end, e.g., to the mill housing 15 by

the grinding table. Preferably, the restraining means are

4,382,561

generally horizontally mounted shafts each having an

brackets 16 as shown in FIG. 2. Furthermore, typical

means (not shown) are positioned in the wall of the mill

housing 15 at the outer end of the shafts 4 whereby

undesired movements of the shafts 4 in the radial direc

tion of the grinding table 1 are avoided.

Material which is to be ground can be fed into the

gaps between the rollers 3. In a preferred embodiment,

inner end facing the mill axis and an outer end, the

rollers being urged against the grinding table by means

of draw bars anchored in the mill foundation, character

ized in that all the roller shafts at their inner ends are

secured to a common frame centrally positioned in

relation to said grinding table, the draw bars being piv

otally connected to the outer ends of said respective

material is fed centrally on the grinding table 1 through

an opening 13 in the middle of the frame 5 or possibly as

an overflow between the interconnecting parts of the

shafts.

4. The vertical roller mill according to claim 3, char

acterized in that the roller shafts are removably secured

to said central frame.

frame 5. A darn ring 14 determines the grinding layer

thickness on the grinding table 1.

The present invention, which is not limited to the

preferred embodiment shown in the FIGS., is also di

rected to mills having a set of only two rollers, mills 5

5. The vertical roller mill according to claim 4, fur

ther comprising ?rst ?anges positioned on said central

frame and corresponding second ?anges positioned on

having rwo or more sets each consisting of two rollers

or mills having two or more sets each consisting of

?anges adapted for engagement for securing the roller

the inner end of each roller shaft, said ?rst and second

three rollers. In the latter example, the mill comprises

several frames 5 positioned axially above each other,

shafts to said central frame.

6. The vertical roller mill according to claim 4, char

acterized in that said central frame is composed of a

each frame carrying one of the roller sets. Thus, a mill

may have four or six rollers with two frames 5 posi

plurality of members clamped together and around the

tioned above each other, each carrying every second

roller.

As illustrated in FIGS. 3 and 4, the mill in one alter

native embodiment includes two frames 5a and Sb 25

which have respective shafts 4a and 4b formed inte

grally therewith to accommodate two pairs of grinding

rollers 3a and 3b. As shown in FIG. 4, frame 5a is posi

tioned above 5b wherefore the respective grinding rol

lers 3a are larger in diameter than grinding rollers 3b.

inner ends of the roller shafts.

7. The vertical roller mill according to claim 4, char

acterized in that the roller shafts are clamped in said

central frame by adjustable, conical rings.

8. The vertical roller mill according to claim 4, fur

ther comprising means for retaining the roller shafts in

position from moving in the direction of rotation of the

grinding table.

9. The vertical roller mill according to claim 8

wherein said restraining means are generally horizontal

draw bars coupled to the outer ends of the roller shafts.

10. The vertical roller mill according to any one of

We claim:

1. A roller mill comprising a grinding table adapted

for rotation about a vertical axis, at least two grinding

rollers, at least two stationary generally horizontally

mounted roller shafts each having an inner end portion

positioned adjacent the vertical axis and an outer end

claims 3-9 having at least four grinding rollers compris

ing two frames centrally positioned one above the

other, each frame being common to two of said grinding

portion, each grinding roller being adapted for rotation

rollers.

11. The vertical roller mill according to any one of

on a respective shaft, means for pressing the grinding

rollers against the grinding table, a frame positioned

centrally of the grinding table, said roller shafts being

claims 3-9 having at least six grinding rollers compris

ing two frames centrally positioned one above the

other, each frame being common to three of said grind

secured to said frame at their inner end portions and

said pressing means being pivotally coupled to the outer

end portions of the roller shafts.

ing rollers.

12. A vertical roller mill comprising a horizontal

2. A vertical roller mill having a mill foundation

comprising a grinding table adapted for rotation about a 45 grinding table adapted for rotation about a central verti

cal axis, at least two upright grinding rollers positioned

with their peripheral grinding surfaces in engagement

with said grinding table for grinding material thereon,

vertical axis, at least two grinding rollers positioned in

engagement with said grinding table, at least two sta

tionary generally horizontally mounted roller shafts

each having an inner end portion positioned adjacent

each grinding roller being positioned for rotation on a

respective horizontal roller shaft having an inner end

the vertical axis and an outer end portion, each grinding

roller being adapted for rotation on a respective shaft,

means anchored in the mill foundation for pressing the

and an outer end, a draw bar associated with each roller

shaft, each draw bar being anchored at one end to the

mill foundation and being pivotably connected at the

other end to the outer end of the respective roller shaft,

each draw bar having means for urging the respective

rollers against said horizontal grinding table, a frame

grinding rollers against the grinding table, a frame posi

tioned centrally of the grinding table, said roller shafts

being secured to said frame at their inner end portions

and said pressing means being pivotally coupled to the

centrally positioned in relation to said grinding table,

outer end portions of the roller shafts.

said frame being connected to the inner ends of said

3. Vertical roller mill having a mill foundation, a

associated roller shafts.

grinding table which rotates around a vertical axis and

:1

*

*

$

*

at least two grinding rollers rotating around stationary 60

65

You might also like

- Micro-Lathe Plans (Popular Mechanics)Document4 pagesMicro-Lathe Plans (Popular Mechanics)sjdarkman1930100% (13)

- 507 Mechanical Movements: Mechanisms and DevicesFrom Everand507 Mechanical Movements: Mechanisms and DevicesRating: 4 out of 5 stars4/5 (28)

- Supply Chain Drivers and Metrics: Powerpoint Presentation To Accompany Powerpoint Presentation To AccompanyDocument25 pagesSupply Chain Drivers and Metrics: Powerpoint Presentation To Accompany Powerpoint Presentation To AccompanysynwithgNo ratings yet

- European Patent Application F04B 27/10: Rotor For Variable Displacement Swash Plate CompressorDocument16 pagesEuropean Patent Application F04B 27/10: Rotor For Variable Displacement Swash Plate CompressorSelvaraji MuthuNo ratings yet

- SL / y Tºš W: Feb. 2, 1965 H. R. Cowley 3,168,296Document7 pagesSL / y Tºš W: Feb. 2, 1965 H. R. Cowley 3,168,296lucasmosnaNo ratings yet

- Us 4207797Document7 pagesUs 4207797fghdfjerNo ratings yet

- April 2, 1968.: Filed Sept 26, 1966Document7 pagesApril 2, 1968.: Filed Sept 26, 1966Pedja Bekic100% (1)

- United States Patent (19) : Miiller (45) Date of PatentDocument8 pagesUnited States Patent (19) : Miiller (45) Date of PatentRodrigoPomaNo ratings yet

- Dec. 5, 1967 Hiroshi Utashiro Eta.L 3,355,922: Filed Sept. 28, 1965 2 Sheets-SheetDocument6 pagesDec. 5, 1967 Hiroshi Utashiro Eta.L 3,355,922: Filed Sept. 28, 1965 2 Sheets-SheetEstebanPortilloNo ratings yet

- Us1955360 PDFDocument8 pagesUs1955360 PDFRodrigoPomaNo ratings yet

- Tm. VC: May 13, 1969 E. F. CielaszykDocument3 pagesTm. VC: May 13, 1969 E. F. CielaszykjoycebaylonNo ratings yet

- %WWMD%WM: J. H. Vanderslig-E. Flanging MachineDocument4 pages%WWMD%WM: J. H. Vanderslig-E. Flanging MachineOO G-sus OoNo ratings yet

- WWW VMQ, I07: Feb. 12, 1963 v. C. BOWMANDocument6 pagesWWW VMQ, I07: Feb. 12, 1963 v. C. BOWMANRodrigoPomaNo ratings yet

- Description: (OCR Text May Contain Errors)Document6 pagesDescription: (OCR Text May Contain Errors)geeNo ratings yet

- Patented May 27, 1919.: S. H. GarstDocument4 pagesPatented May 27, 1919.: S. H. GarstKrozeNo ratings yet

- US2447117Document6 pagesUS2447117MahnooshNo ratings yet

- Copying LatheDocument4 pagesCopying LatheGustavoNo ratings yet

- MP-I - Lab Manual DarshanDocument159 pagesMP-I - Lab Manual DarshanNitinGothiNo ratings yet

- Lathe Machine PrinciplesDocument15 pagesLathe Machine Principlesscratch89No ratings yet

- Us2765819 PDFDocument8 pagesUs2765819 PDFAzri LunduNo ratings yet

- Us 5176330Document7 pagesUs 5176330ManivannanMudhaliarNo ratings yet

- (12 Ulllted States Patent (10) Patent No.: US 6,860,188 B2Document13 pages(12 Ulllted States Patent (10) Patent No.: US 6,860,188 B2Selvaraji MuthuNo ratings yet

- Djj10033 Chapter 3Document50 pagesDjj10033 Chapter 3YogenNo ratings yet

- Shop Made SlotterDocument4 pagesShop Made Slotternevadablue100% (4)

- "A1.h.. May,: June 4, 1929. A. B. Kerr 1,715,929Document7 pages"A1.h.. May,: June 4, 1929. A. B. Kerr 1,715,929Guillermo Avila RiveraNo ratings yet

- BY 4W1?" Mal/MM : July 4, 1957 A. Roque V 3,329,192Document2 pagesBY 4W1?" Mal/MM : July 4, 1957 A. Roque V 3,329,192Namelezz ShadowwNo ratings yet

- Us 2345069Document4 pagesUs 234506916f628aNo ratings yet

- US1685447Document5 pagesUS1685447Redirecting DecoyNo ratings yet

- Rig-E???': Gill!Document6 pagesRig-E???': Gill!luiscremaschiNo ratings yet

- Engine DesignDocument15 pagesEngine DesignAbdul-Wahab Anwar100% (10)

- Combined GearboxDocument8 pagesCombined Gearboxkats2404No ratings yet

- Title - Wood Chipper ConstructionDocument4 pagesTitle - Wood Chipper Constructionمحمد عبدالدايمNo ratings yet

- Coco Inven PDFDocument4 pagesCoco Inven PDFsushil-funNo ratings yet

- Strung de LemnDocument3 pagesStrung de LemnJohn Johnb100% (1)

- Dual Acting ShaperDocument30 pagesDual Acting ShaperAbhijeet NaikNo ratings yet

- Us1223254 PDFDocument7 pagesUs1223254 PDFRodrigoPomaNo ratings yet

- United States Patent (19) : Filed: July 27, 1976 57Document3 pagesUnited States Patent (19) : Filed: July 27, 1976 57Alexandre Magno Bernardo FontouraNo ratings yet

- Data Originating From Sources Other Than The EPO May Not Be Accurate, Complete, or Up To DateDocument3 pagesData Originating From Sources Other Than The EPO May Not Be Accurate, Complete, or Up To DateJaymar ManualNo ratings yet

- United States Patent (191: Sullivan Et A1Document21 pagesUnited States Patent (191: Sullivan Et A1fghdfjerNo ratings yet

- Shaper MachineDocument4 pagesShaper MachineNishit ParmarNo ratings yet

- Unlted States Patent (191 1111 3,736,693: Koch 1451 June 5, 1973Document4 pagesUnlted States Patent (191 1111 3,736,693: Koch 1451 June 5, 1973fgrt45No ratings yet

- Cheshire: Composing Room Machine Filed June 1927 3 Sheets-SheetDocument7 pagesCheshire: Composing Room Machine Filed June 1927 3 Sheets-SheetmephitNo ratings yet

- MD r19 - Part - B PPT NewDocument42 pagesMD r19 - Part - B PPT Newashok junapudiNo ratings yet

- H. J. Smith: Potato Cutting Machine 28 Filed 00Document3 pagesH. J. Smith: Potato Cutting Machine 28 Filed 00RodrigoPomaNo ratings yet

- Machinery's - Reference - Series - No - 15 Spur GearingDocument49 pagesMachinery's - Reference - Series - No - 15 Spur GearingJohnNo ratings yet

- Reverse Energy Bow Patent US 7743760 B2Document8 pagesReverse Energy Bow Patent US 7743760 B2DoukhoborNo ratings yet

- US2099314Document3 pagesUS2099314Jhonnatan E Avendaño Florez100% (1)

- Manufacturing Technology Ii Assignment I: Batch 10Document11 pagesManufacturing Technology Ii Assignment I: Batch 10sh_nk2010No ratings yet

- United States Patent (191: Cél 296/97 /2/70g Primary Exammer - Margaret A. FocannoDocument7 pagesUnited States Patent (191: Cél 296/97 /2/70g Primary Exammer - Margaret A. FocannoDanister GladwinNo ratings yet

- Us4522105 PDFDocument10 pagesUs4522105 PDFJin SongNo ratings yet

- United States Patent - (191: Mayeux Et AlDocument4 pagesUnited States Patent - (191: Mayeux Et AlRodrigoPomaNo ratings yet

- 4in Bench SlotterDocument4 pages4in Bench SlotterTeresa Melanathy100% (1)

- Lathe TurretDocument17 pagesLathe TurretLove ReloadedNo ratings yet

- Metalwork and Machining Hints and Tips for Home Machinists: 101 Plans and DrawingsFrom EverandMetalwork and Machining Hints and Tips for Home Machinists: 101 Plans and DrawingsNo ratings yet

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheFrom EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheRating: 4.5 out of 5 stars4.5/5 (2)

- Wood Turning - The Lathe and Its Accessories, Tools, Turning Between Centres Face-Plate Work, Boring, PolishingFrom EverandWood Turning - The Lathe and Its Accessories, Tools, Turning Between Centres Face-Plate Work, Boring, PolishingNo ratings yet

- Bearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsFrom EverandBearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsRating: 4 out of 5 stars4/5 (1)

- The Inner Workings of a Watch - A Simple Guide for Enthusiasts of Clockwork MechanismsFrom EverandThe Inner Workings of a Watch - A Simple Guide for Enthusiasts of Clockwork MechanismsNo ratings yet

- Electric Mortor For Ball MillDocument2 pagesElectric Mortor For Ball MillkhoagleNo ratings yet

- Homework 2 - SolutionDocument3 pagesHomework 2 - SolutionkhoagleNo ratings yet

- CA501Document614 pagesCA501Ignacio AntonioNo ratings yet

- Effect of Porosity On The Absorbed, Reemitted and Transmitted Light by A Geopolymer Metakaolin BaseDocument4 pagesEffect of Porosity On The Absorbed, Reemitted and Transmitted Light by A Geopolymer Metakaolin BasekhoagleNo ratings yet

- Pauling RulesDocument5 pagesPauling RuleskhoagleNo ratings yet

- Trích Dẫn Tài Liệu Theo Apa: Apa (American Psychological Association) Citation Style GuideDocument10 pagesTrích Dẫn Tài Liệu Theo Apa: Apa (American Psychological Association) Citation Style GuidekhoagleNo ratings yet

- Kich Thuoc Than TrucDocument1 pageKich Thuoc Than TruckhoagleNo ratings yet

- Hammer CrusherDocument4 pagesHammer CrusherkhoagleNo ratings yet

- Brick Wall Tiles BTCDocument1 pageBrick Wall Tiles BTCshaky1978No ratings yet

- Copper-Base Alloy Centrifugal Castings: Standard Specification ForDocument5 pagesCopper-Base Alloy Centrifugal Castings: Standard Specification Forbaher74No ratings yet

- Leeb Hardness TesterDocument4 pagesLeeb Hardness Testershanuhameed212No ratings yet

- Spare Part Philosophy - XX PDFDocument27 pagesSpare Part Philosophy - XX PDFharmlesdragon50% (2)

- Simple MachineDocument12 pagesSimple MachinemillgibsonNo ratings yet

- 5th Floor - Main Office CeilingDocument12 pages5th Floor - Main Office CeilingErick GearNo ratings yet

- EdmDocument31 pagesEdmSuvin PsNo ratings yet

- Method Statement For Painting WorksDocument2 pagesMethod Statement For Painting Worksmustafa100% (3)

- PapermakingDocument13 pagesPapermakingoyadieyeNo ratings yet

- Logistics and Transportation Industry in IndiaDocument79 pagesLogistics and Transportation Industry in Indiaabdulkhaderjeelani14No ratings yet

- DSDDocument17 pagesDSDNguyen LeNo ratings yet

- SEAL 62 ProDocument2 pagesSEAL 62 ProAlberto SundayNo ratings yet

- Csorescu BookDocument671 pagesCsorescu BookMarian CatanoiuNo ratings yet

- Le Van Sy PHD Thesis PDFDocument205 pagesLe Van Sy PHD Thesis PDFNhan LeNo ratings yet

- Rotary Seal GuideDocument22 pagesRotary Seal Guideallrounder_mannNo ratings yet

- Faurecia Cae PDFDocument43 pagesFaurecia Cae PDFVimal MenonNo ratings yet

- A Ac SpecificationsDocument12 pagesA Ac SpecificationswinsonecNo ratings yet

- Resume of R. Naveen KumarDocument5 pagesResume of R. Naveen Kumarajin ekkishowNo ratings yet

- Yamabiko Corporation - Wikipedia, The Free EncyclopediaDocument2 pagesYamabiko Corporation - Wikipedia, The Free EncyclopediabmxengineeringNo ratings yet

- Paper MakingDocument1 pagePaper MakingBurak KucukkelesNo ratings yet

- Steel Castings, Martensitic Stainless and Alloy, For Pressure-Containing Parts, Suitable For High-Temperature ServiceDocument5 pagesSteel Castings, Martensitic Stainless and Alloy, For Pressure-Containing Parts, Suitable For High-Temperature ServiceJoelCristobalNo ratings yet

- Bernekon DMCC ProfileDocument6 pagesBernekon DMCC ProfileOsman TariNo ratings yet

- A 744Document5 pagesA 744Carlos JuárezNo ratings yet

- Soup To Nuts 2Document10 pagesSoup To Nuts 2mtang45No ratings yet

- New Products Management: Merle Crawford Anthony Di Benedetto 10 EditionDocument18 pagesNew Products Management: Merle Crawford Anthony Di Benedetto 10 EditionmzumziNo ratings yet

- Phase Diagrams in Liquid PhaseDocument4 pagesPhase Diagrams in Liquid PhaseRed GuyNo ratings yet

- Plant Operations Director Manager in Dallas FT Worth TX Resume Kevin HuurmanDocument2 pagesPlant Operations Director Manager in Dallas FT Worth TX Resume Kevin HuurmanKevinHuurmanNo ratings yet

- Ac Solve PaperDocument59 pagesAc Solve PaperHaseeb ShadNo ratings yet

- Data SheetDocument8 pagesData SheettomychalilNo ratings yet