Professional Documents

Culture Documents

Sec 8. Squeeze Cementing

Sec 8. Squeeze Cementing

Uploaded by

Ivan Josten DancessCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sec 8. Squeeze Cementing

Sec 8. Squeeze Cementing

Uploaded by

Ivan Josten DancessCopyright:

Available Formats

Section 8

Squeeze Cementing

Table of Contents

Introduction................................................................................................................................................8-3

Topic Areas ............................................................................................................................................8-3

Learning Objectives ...............................................................................................................................8-3

Unit A: Squeeze Cementing Background ..................................................................................................8-3

Purposes of Squeeze Cementing ............................................................................................................8-3

Squeeze Cementing Terminology ..........................................................................................................8-4

Hesitation ...............................................................................................................................................8-5

Planning Squeeze Cementing Jobs.........................................................................................................8-5

Unit A Quiz ............................................................................................................................................8-6

Unit B: Squeeze Cementing Calculations..................................................................................................8-7

Squeeze Problem One ............................................................................................................................8-9

Squeeze Problem Two..........................................................................................................................8-17

Unit B Quiz ..........................................................................................................................................8-22

Answers to Unit Quizzes .........................................................................................................................8-23

81

Cementing 1

Squeeze Cementing

Use for Section Notes

82

Cementing 1

Squeeze Cementing

Introduction

this process. The bottom of casing strings (shoe)

and liner tops may also require squeezing to

correct problems. These types of jobs may not

require perforating prior to squeezing.

If all primary cementing jobs were completely

successful, there would rarely be a need for

squeeze cementing. However, if drilling mud

has been bypassed (channeling) during the

primary job, squeeze cementing may be required

to correct or remediate the problem.

Topic Areas

Squeeze cementing is the process by which

cement is forced into the casing-hole annulus.

Fluid returns are not normally expected at the

surface. Perforations in the pipe are often

required to obtain a flow path to the annulus.

The channel or area of poor bond, as well as the

perforations, are filled with cement. Pump

pressure is allowed to rise in order to "squeeze"

cement slurry into the desired area. The cement

is allowed to harden into a plug which blocks

fluid movement. Drill-out of set cement inside

the casing is normally required.

In this section, these units will be included:

A. Squeeze Cementing Background

B. Squeeze Cementing Calculations

Learning Objectives

Upon completion of this section, you should be

familiar with:

Existing production perforations may be

abandoned by squeeze cementing. Also, casing

leaks due to pipe corrosion may be sealed with

The purposes of squeeze cementing

How to calculate a basic squeeze cementing

job

Unit A: Squeeze Cementing Background

To perform a successful squeeze job, it is first

necessary to become familiar with

the purposes of squeeze cementing

terminology associated with squeeze

cementing

planning considerations for squeeze jobs.

Purposes of Squeeze

Cementing

Some of the more common reasons for

performing a squeeze job are

to correct a defective primary cementing job

caused by channeling or insufficient fill-up

83

to provide a seal for places purposely not

cemented during primary cementing for

example, squeezing liner tops

to reduce the gas/oil ratio by shutting off

some of the gas-producing perforation

(isolating the gas and oil zones)

to improve the oil/water ratio by shutting off

some of the water-producing formation

(isolating the oil and water zones)

to close-off an unproductive formation from

the wellbore

to prevent fluid migration

to repair casing holes caused by corrosion,

perforation, etc. (Fig. 8.1)

Cementing 1

Squeeze Cementing

Figure 8.2 Whole cement slurry does not

enter the formation

In squeeze jobs, forcing the formation to fracture

is not the objective. If the formation fractures, it

will break down. Then whole cement slurry (not

just the filtrate) will be displaced into the

formation. Therefore, care must be taken so that

the pump pressure and the pressure exerted by

the weight of the fluid are not sufficient to force

a fracture of the formation. The pressure

required to force filtrate into the formation

without fracturing it is called the pump-in

pressure.

Figure 8.1 Squeezing to repair casing.

Squeeze Cementing

Terminology

In order to understand the different methods

used in squeeze cementing, it is necessary to

first be familiar with the following terms:

Cement dehydration

Pump-in pressure and injection rate

Low- and high-pressure squeeze

Block squeezing

The volume per minute at which the fluid will be

pumped during the squeeze job is called the

injection rate. Both the pressure and rate should

be established by performing an injection test in

which well fluid is pumped into the formation to

determine at what rate and pressure the fluid will

be absorbed into the formation.

Cement slurry is composed of cement, additives

and water. When slurry reaches a permeable

formation, only the water (filtrate) will pass into

the cracks of the formation (Figure 8.2). Cement

dehydration is the process by which the cement

forms a cake and hardens on the face of the

formation.

During a low-pressure squeeze job, enough

pressure is applied to form a filter cake of

dehydrated cement on the formation. In other

words, the pump-in pressure or the pressure

necessary to place cement against the formation

will not cause the formation to fracture.

However, if the formation will not absorb filtrate

at the pump-in pressure, (because of blocked

perforations or low formation permeability),

more pressure may be applied. This will result in

a fractured formation - whole slurry will fill the

fractures. This is considered a high-pressure

squeeze job.

84

Cementing 1

Squeeze Cementing

the necessity of using a spacer (in case of

fluid incompatibility)

Block squeezing requires that perforations be

made at the interval to be squeezed. Then,

cement is forced into this interval (Figure 8.3).

Block squeezing is generally used to isolate the

producing zone before completing a well.

Figure 8.3 Block Squeeze

the bottomhole static temperature, which

affects the setting time of the cement

the difference between the depths of the

perforations and the packer (if used), which

should from 100 to 150 ft to allow enough

volume to continue the squeeze after the

cement has cleared the workstring

the maximum pressure to be used, which

cannot exceed the pressure limitations of the

workstring, casing, BOPs, and other

equipment to be used

the type of cement to be used, in that fluidloss additives are used to ensure that a small

amount of cement filter cake will form

against the formation, while the slurry in the

casing remains fluid enough to reverse out

the amount of cement to be used, which

depends on the volume of the workstring

(volume of cement should not exceed the

capacity of the tubular goods) and the length

of the interval to be squeezed (a rule of

thumb is to use 2 sk/ft).

testing all wellhead equipment and annulus

to the pressure required to reverse out the

maximum height of cementing the

workstring.

Hesitation Squeeze

At some point during a squeeze job, you will

have attained the pressure planned for the job.

That pressure is then held. If it drops off (that is,

bleed off is occurring), you know that your

cement is continuing to dehydrate.

In this case, a hesitation squeeze may be

conducted. Time is allowed for the cement to

begin to set. The pressure is applied again. If

bleed off continues, more time is allowed. This

is repeated as many times as is necessary; the

only limitation is the thickening time of the

cement. If too long a period is allowed, the

workstring may be cemented up.

Planning Squeeze Cementing

Jobs

Before any type of squeeze job is undertaken,

information must be obtained and choices must

be made, including

the types of well fluids to be used, which

will affect the pressure to reverse out, and

85

Cementing 1

Squeeze Cementing

Unit A Quiz

Fill in the blanks with one or more words to check your progress in Unit A.

1. Common reasons for performing a squeeze job are to ___________ a defective primary cementing

job or to __________ holes in casing caused by corrosion. In addition, the ______________ ratio is

improved.

2. When the filtrate enters the formation, cement ____________ to form a cake on the formation.

3. The pressure required to force filtrate into the formation without ___________ it is called the

___________ pressure. This pressure is established by pumping _________________ into the

formation to be squeezed.

4. If the formation fractures during a squeeze job, then a _________ pressure squeeze job is being

performed.

5. If the pressure drops off during a squeeze job, this is called ______________. To correct this

condition, a _______________ squeeze may be performed.

6. The ____________ pressure to be used during a squeeze job cannot exceed the limitations of the

equipment being used.

7. Cement used for squeeze job usually contains ______________ additives.

86

Cementing 1

Squeeze Cementing

Unit B: Squeeze Cementing Calculations

Before beginning a squeeze cementing job,

several calculations must be performed. The

types of calculations to make depend on the

nature of the job. Following are the basic

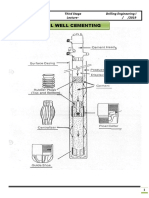

squeeze problem calculations (Fig. 8.3,4):

8 Pressure to reverse out at the completion of

the job.

1 Volume of cement (bbl).

Following are the well parameters needed for the

calculations (Fig. 8.3):

9 Amount of cement pumped though the

perforations.

2 Pressure to reverse one barrel of slurry from

workstring.

A Drillpipe/tubing size

3 Minimum water requirements.

B Packer depth

4 Displacement volume to spot cement one

barrel above packer.

C Top of perforations

D Bottom of perforations

5 Pressure to reverse cement when spotted.

E Casing size

6 Pressure to reverse cement from workstring

when cement reaches top perforation.

7 Pressure to reverse cement from workstring

when cement reaches bottom perforation.

A

Well Fluid

5

Cement

Well Fluid

B

C

D

E

Figure 8.3 Well schematic showing squeeze calculations and parameters.

87

Cementing 1

Cement

Well Fluid

Well Fluid

Well Fluid

Squeeze Cementing

8

9

Figure 8.4 - Well schematic showing squeeze calculations and parameters.

The remainder of this section presents two

sample squeeze problems and shows, step by

step, how to calculate all the needed data. You

will need a copy of the Halliburton Cementing

Tables (the Red Book) to use during the

samples.

88

Cementing 1

Squeeze Cementing

Squeeze Problem One

Well Parameters

A

2 7/8 in., 6.5 lb/ft

EUE Tubing

Drillpipe/tubing size

2 7/8 in., 6.5 lb/ft

EUE

Packer Depth

5000 ft

Top of perforations

5094 ft

Bottom of perforations

5136 ft

Casing size

7 in., 20 lb/ft

Cement type

Class G

Cement volume

Displacement/well fluid

75 sk

Fresh water (8.33

lb/gal)

1 Volume of Cement (bbl)

B

Packer at 5000 ft

Perf top at 5094 ft

Perf bottom at

5094 ft

7 in., 20 lb/ft

Casing

To convert the given volume of cement from

sacks to barrels, you must determine the yield of

the slurry.

1. Using the Technical Data section of the

Red Book, determine the yield of a neat

Class G slurry, given its weight of 15.8

lb/gal. The table shown in Fig. 8.6 (extracted

from the Class G section of the Red Book)

shows this to be 1.15 cu.ft/sk.

Figure 8.5 Parameters for Sample

Problem A.

2. Multiply the volume of cement in sacks by

the slurry yield to determine the volume in

cubic feet.

75 sk 1.15 cu.ft/sk = 86.25 cu.ft

Now, convert cubic feet to barrels using the

conversion constant found in the Technical

Data section of the Red Book:

86.25 cu.ft 0.1781 bbl/cu.ft = 15.36 bbl

Figure 8.6 Class G data from Red Book.

89

Cementing 1

Squeeze Cementing

the number of feet that one barrel will fill

inside the tubing, which is 172.76 ft/bbl.

2 Pressure to Reverse One Barrel of

Slurry from Workstring

3. Multiply the differential pressure found in

Step 1 by the value found in Step 2 to obtain

the pressure required to reverse out one

barrel of slurry from the workstring:

0.3878 psi/ft 172.76 ft/bbl = 67.00 psi/bbl

Well Fluid

Later on, you will be calculating different values

of cement left in the tubing, according to where

you are in your job. You will then use the value

determined in the step above to calculate the

total pressure required to reverse out the cement.

Figure 8.7 Determining pressure to

reverse on barrel of slurry from drillpipe.

The following is a quick way to calculate the

pressure required to reverse out the slurry from

the workstring. These calculations will be based

on a column equal in height to one barrel of

fluid in the workstring. (Your answer will be in

psi/bbl.)

Figure 8.8 Hydrostatic pressure data from

Red Book.

1. Referring to the Calculations and

Formulae section of the Red Book (shown

in Fig. 8.8), look up the psi/ft (hydrostatic

pressure gradient) of the 15.8 lb/gal cement

and the 8.33 lb/gal water. Then find the

difference between these two values: 0.8208

psi/ft and 0.4330 psi/ft:

0.8208 psi/ft 0.4330 psi/ft = 0.3878 psi/ft

2. Then, using the Capacity section (Table

211) for 2 7/8 in., 6.5 lb/ft EUE tubing, find

8 10

Cementing 1

Squeeze Cementing

First, determine the capacity of the tubing. It

extends from the surface to the packer, a

total of 5000 ft. Look up the capacity factor

for the 2 7/8 in., 6.5 lb/ft EUE tubing in the

Capacity section (Fig 8.9). This factor is

0.00579 bbl/ft. Multiply the length of the

tubing by its capacity factor to obtain the

capacity of the tubing:

3 Minimum Water Requirements

The minimum fluid (water) requirements for a

squeeze job include the volumes needed for the

following:

Cement mixing water (always fresh water

unless the slurry is otherwise designed)

Displacement fluid (the capacities of the

tubing and the casing)

5000 ft 0.00579 bbl/ft = 28.95 bbl

3. Then figure the capacity of the 7 in., 20 lb/ft

casing (Table 214) from the packer to the

lowest perforation (5136 ft 5000 ft = 136

ft).

Reversing fluid

Therefore, each of these volumes needs to be

calculated and then added together.

136 ft 0.0404 bbl/ft = 5.49 bbl

Note: This volume does not include both primeup and wash-up volumes, which would also

need to be accounted for.

4. You may have to reverse out the excess

cement remaining in the tubing (after

unsetting the packer). This reverse

circulation occurs around the setting depth

of the packer (5000 ft). So the volume in the

tubing to reverse out is the same as the

displacement volume you have already

calculated for the tubing (Step 2), which is

28.95 bbl.

1. With the help of the Technical Data

section of the Red Book, you can calculate

how much mixing water you will need (see

Fig. 8.6). Because you are using Class G

cement with a weight of 15.8 lb/gal, the

water requirement is 5.0 gal/sk. Multiplying

the amount of cement needed, in sacks, by

the water requirement gives you your total

mixing water:

Keep in mind that you should use the type

and weight of fluid in the annulus for

reversing fluid.

5.0 gal/sk 75 sk = 375 gal

5. Now, the minimum amount of fluid required

for this job can be calculated by adding the

cement mixing water (Step 1), the two

displacement fluid volumes (tubing and

casing- Steps 2 and 3), and the reversing

volume (Step 4):

To convert to barrels:

375 gal 42 gal/bbl = 8.93 bbl

2. As for the fluid needed for displacement,

you will need to calculate the capacities of

the appropriate parts of both the tubing and

casing. Since there is no way of knowing

when a well will squeeze (pressure will not

bleed off), you must have enough fluid to

displace all of the slurry to the lowest

perforation.

8.93 bbl + 28.95 bbl + 5.49 bbl + 28.95 bbl

= 72.32 bbl

NOTE: As a good practice, we recommend that

you have double the volumes needed to reverse.

8 11

Cementing 1

Squeeze Cementing

Figure 8.9 Tubing capacity data from Red Book.

Figure 8.10 Casing capacity data from Red Book.

8 12

Cementing 1

Squeeze Cementing

4 Displacement Volume to Spot

Cement One Barrel Above Packer

5 Pressure to Reverse when Cement

Spotted

After the cement is spotted one barrel above the

packer, the packer will be set to avoid

circulating any cement behind the packer. When

the packer is set and you attempt to begin

pumping fluid into the perforations, you may

experience problems establishing an injection

rate, in which case you would unset the packer

and reverse all the cement out of the tubing.

Therefore, you need to calculate how much

pressure is required to do this.

The pressure needed to reverse out this cement

in the tubing can be calculated by multiplying

the barrels of cement in the tubing, which in this

case is the total cement volume, by the

differential pressure per barrel of fluid (as

calculated in Calculation 2 , 67.00 psi/bbl):

Cement

Well Fluid

15.36 bbl 67.00 psi/bbl = 1029 psi

Figure 8.10 Displacement Volume.

To avoid damaging the formation that can be

caused by pumping all the well fluid ahead of

the cement into the perforations, the packer is

left unset while the cement is spotted one barrel

above it. This allows well fluid to circulate out

of the well.

To determine the volume of displacement to

pump behind the slurry to spot it one barrel from

the packer, you subtract the total cement volume

plus one barrel from the tubing capacity

(determined during Calculation 3 ):

Tubing Capacity

28.95 bbl

Cement Volume

- 15.36 bbl

Volume Above Packer

- 1.00 bbl

Displacement Volume

12.59 bbl

8 13

Cementing 1

Squeeze Cementing

Use your Red Book to find the capacity

factor (bbl/ft) of the 7 in., 20 lb/ft casing,

then multiply this value by the length of

casing between the packer and the top

perforation (5094 ft 5000 ft = 94 ft).

6 Pressure to Reverse Cement from

Workstring when Cement Reaches

the Top Perforation

94 ft 0.0404 bbl/ft = 3.80 bbl

2. Now, subtract this volume from the total

volume of cement to determine how much

slurry remains in the tubing:

15.36 bbl 3.80 bbl = 11.56 bbl

Well Fluid

3. The final step in this calculation is to

multiply the volume of cement remaining in

the tubing by the differential pressure per

barrel of fluid (as calculated in Calculation

2 , 67.00 psi/bbl):

Cement

11.56 bbl 67.00 psi/bbl = 775 psi

Figure 8.11 Pressure to reverse when

cement reaches the top perforation.

As with the previous question, problems with

injection rates may occur when cement reaches

the top perforation. In this case, we can only

reverse out the cement that is left inside the

tubing, and not the cement that has exited below

the packer and is now inside the casing.

The first calculation we need to make, therefore,

is the volume of cement remaining in the tubing.

1. To do this, you calculate the volume of

cement in the casing and subtract that

volume from the total volume of cement.

Determining the volume of cement in the

casing requires you to calculate the capacity

of the casing from the packer depth (5000 ft)

to the depth of the top perforation (5049 ft).

8 14

Cementing 1

Squeeze Cementing

(Step 2) by the differential pressure per

barrel of fluid (as calculated previously in

Step 3 of the calculation for pressure to

reverse out one barrel, 67.00 psi/bbl):

7 Pressure to Reverse Cement from

Workstring when Cement Reaches

Bottom Perforation

9.87 bbl 67.00 psi/bbl = 661 psi

Well Fluid

Note: The effects of friction have been

disregarded in all these calculations.

Figure 8.12 Pressure to reverse when

cement reaches bottom perforation.

Related to the calculation just completed, this

calculation will be based on the fact that cement

has made it to the bottom perforation, but no

cement has entered the perforations. Therefore,

we need to once again calculate the volume of

cement that remains in the tubing.

1. First, find the volume of cement that is in

the casing. This calculation has already been

performed in Calculation 3 (5.49 bbl).

2. Now subtract this volume from the total

volume of cement:

15.36 bbl 5.49 bbl = 9.87 bbl

3. The pressure needed to reverse out this

cement in the tubing can now be calculated

by multiplying the barrels in the tubing

8 15

Cementing 1

Squeeze Cementing

8 Pressure to Reverse Out at the

Completion of the Job

9 Amount of Cement Pumped

Through the Perforations

Using information obtained from previous

calculations, you can calculate the amount of

cement pumped through the perforation during

this squeeze job.

Well Fluid

1. The total volume of slurry (15.36 bbl) minus

the volume of slurry in the casing (5.49 bbl)

minus the volume of slurry now in the

tubing is the volume of cement in the

formation:

15.36 bbl 5.49 bbl 4.95 bbl = 4.92 bbl

2. Divide this by the yield of the cement, 1.15

cu.ft/sk, to obtain the amount of cement in

the formation:

27.62 ft3 1.15 ft3/sk = 24 sk

8

9

Results of Calculations

The following table presents the results of the

nine calculations for Squeeze Problem One:

Squeeze Cementing Calculation Results

Description

1 Volume of cement (bbl).

Figure 8.13 Pressure to reverse out at the

completion of the job.

2 Pressure to reverse one

barrel of slurry from workstring.

For the following calculations, you have to

assume that some arbitrary volume of

displacement fluid was pumped behind the

cement at the time squeeze pressure is reached.

The volume chosen here is 24 bbl.

1. Find out how much cement is in the tubing

now, given that 24 bbl of displacement fluid

were pumped behind it:

28.95 bbl 24 bbl = 4.95 bbl

2. Now multiply the amount of cement in the

tubing by the pressure required to reverse

one barrel out of the tubing (67.00 psi/bbl)

4.95 bbl 67.00 psi/bbl = 332 psi

8 16

Result

15.36 bbl

67.00 psi/bbl

3 Minimum water

requirements.

72.32 bbl

4 Displacement volume to

spot cement one barrel above

packer.

12.59 bbl

5 Pressure to reverse cement

when spotted.

1029 psi

6 Pressure to reverse cement

from workstring when cement

reaches top perforation.

775 psi

7 Pressure to reverse cement

from workstring when cement

reaches bottom perforation.

661 psi

8 Pressure to reverse out at

the completion of the job.

332 psi

9 Amount of cement pumped

though the perforations.

24 sk

Cementing 1

Squeeze Cementing

Squeeze Problem Two

In this job, you are to squeeze off a channel that

runs from perforations below a packer to a point

above the packer. Note that the first seven

questions you will answer are based on the same

calculations as in Squeeze Problem One, with

two additional calculations (8 and 11):

1 Volume of cement

2

3

4

5

6

7

8

9

10

11

Pressure to reverse one barrel of slurry from

workstring

Minimum water requirements

Displacement volume to spot cement one

barrel above packer

Pressure to reverse cement when spotted

Pressure to reverse cement from workstring

when cement reaches top perforation

Pressure to reverse cement from workstring

when cement reaches bottom perforation

Maximum pump pressure when cement slurry

has reached the bottom perforation

Pressure to reverse out at the completion of

the job

Amount of cement pumped through the

perforations

Maximum pump pressure if the channel is full

of cement

Well Parameters

Packer Depth

2 7/8 in., 6.516 lb/ft EUE

Tubing

6200 ft

Top of Perfs

6240 ft

Drillpipe Size

Bottom of Perfs

Casing Size

Cement Type

Cement Additives

Cement Volume

Displacement/ Well

Fluid

2 7/8 in., 6.5 lb/ft

EUE Tubing

Packer at 6200 ft

Perf top at 6240 ft

Perf bottom at

6250 ft

7 in., 20 lb/ft J-55

Casing

Figure 8.14 Parameters for Squeeze

Problem B.

6250 ft

7 in., 20 lb/ft, J-55

Class H

0.4% Halad-413

150 sk

Fresh Water (8.33 lb/gal)

8 17

Cementing 1

Squeeze Cementing

1 Volume of Cement

Class H

Cement

0.4% Halad413

Water

Totals

Mixing

Water

Required

(gal)

94

0.0382 =

3.5908

0.376

0.0811 =

0.0305

0 +

4.3 gal

7.92

+

4.3 gal

35.819 =

130.20

8.33

4.3

Well Fluid

Factor

(gal/lb)

Material

(lb)

Material

Name

Absolute

Volume

(gal)

Total mixing water must be entered under absolute gallons

before totaling.

Find the weight of the mixed cement by using this formula:

Total Pounds/Total Absolute gallons = pounds/gallons

Find the cement yield in cubic feet per sack by using this

formula:

Total Absolute gallons / 7.4805 gal/cu.ft. (constant) = cu.ft./sack

The mixing water per sack is the sum of the gallons in the far

right column

Cement Density

(lb/gal)

Cement Yield

(ft3/sk)

Mixing Water

required

130.20 /

7.92 =

16.4

lb/gal

7.92 /

4.4805 =

1.06

ft3/sk

4.3

Gal/sk

Figure 8.15 Determining pressure to

reverse one barrel of slurry from workstring.

Based on the worksheet,

150 sk 1.06 cu ft/sk = 159 cu ft

159 cu. ft 0.1781 bbl/cu. ft = 28.32 bbl

3 Minimum Water Requirements

2 Pressure to Reverse One Barrel of

Slurry From Workstring

1. Cement Mix Water:

Hydrostatic pressure gradients (from

Calculations and Formulae section of Red

Book)

16.4 lb/gal cement

8.33 lb/gal water

150 sk 4.3 gal/sk = 645 gal

645 gal 42 gal/bbl = 15.36 bbl

2. Displacement Fluid:

0.8519 psi/ft

0.4330 psi/ft

Tubing: 6200 ft 0.00579 bbl/ft = 35.90 bbl

Casing: 6250 ft 6200 ft = 50 ft

50 ft 0.0404 bbl/ft = 2.20 bbl

Differential Hydrostatic Pressure Gradient =

3. Reversing Fluid: 35.90 bbl

0.8519 psi/ft 0.4330 psi/ft = 0.4189 psi/ft

Feet/Barrel Factor For Workstring = 172.76 lb/ft

0.4189 psi/ft 172.76 ft/bbl = 72.37 psi/bbl

Minimum water required:

15.36 bbl + 35.90 bbl + 2.02 bbl + 35.90 bbl

= 89.18 bbl

NOTE: Always plan to reverse with 2 times the

tubing capacity. Therefore in this problem plan

for an additional 35.9 bbls.

8 18

Cementing 1

Squeeze Cementing

4 Displacement Volume to Spot

Cement One Barrel Above Packer

Tubing Capacity

Cement Volume

Volume Above Packer

Displacement Volume

6 Pressure to Reverse Cement from

Workstring when Cement Reaches

Top Perforation

35.90 bbl

- 28.32 bbl

- 1.00 bbl

6.58 bbl

Capacity of casing from packer (6200 ft) top

perforation (6240 ft):

6240 ft 6200 ft = 40 ft

40 ft 0.0404 bbl/ft = 1.62 bbl

5 Pressure to Reverse Cement

When Spotted

28.32 bbl 1.62 bbl = 26.70 bbl remaining in

tubing

26.70 bbl 72.37 psi/bbl = 1932 psi

28.32 bbl 72.37 psi/bbl = 2050 psi

Well Fluid

Cement

Cement

Well Fluid

Figure 8.17 Pressure to reverse cement.

Figure 8.16 Calculations 4 and 5.

8 19

Cementing 1

Squeeze Cementing

(1903 psi) from the collapse resistance of

the casing being used. This value can be

found in the Dimensions and Strengths

section of the Red Book. Refer to the correct

table for the 7 in, 20 lb/ft, J-55 casing being

used (Fig 8.20). The collapse resistance is

2270 psi.

7 Pressure to Reverse Cement from

Workstring when Cement Reaches

Bottom Perforation

Capacity of casing from packer to bottom

perforation = 2.02 bbl (from Calculation 3 )

2270 psi 1903 psi = 367 psi

26.30 bbl 72.32 psi/bbl = 1903 psi

2. Since there is a differential pressure from

the packer to the perforation (no cement is in

the channel), you must also subtract this. To

calculate the differential, multiply the

distance from the packer to the lowest

perforation (6250 ft 6200 ft = 50 ft) by the

difference in the psi/ft for the cement and

well fluid (0.8519 psi/ft - 0.4330 psi/ft =

0.4189 psi/ft):

Well Fluid

28.32 bbl 2.02 bbl = 26.30 bbl

50 ft 0.4189 psi/ft = 21 psi

3. Now, subtract the differential pressure from

Step 1 to obtain the maximum pump

pressure:

7

368 psi 21 psi = 347 psi

Remember, this is the maximum pressure that

can be applied at the surface if the cement has

reached the perforations.

Figure 8.18 Pressure to reverse cement.

Well Fluid

8 Maximum Pump Pressure when

Cement Slurry Has Reached the

Bottom Perforation

It is necessary to determine the maximum

pressure that can be applied at the surface for

this squeeze job. The pressure applied at the

surface may be transmitted through the channel

to the outside of the casing above the packer. If

the pressure applied is high enough, it may

collapse the casing.

1. This calculation is done by first subtracting

the pressure to reverse out cement to lowest

perforation and no cement in the formation

Figure 8.19 Maximum pump pressure.

8 20

Cementing 1

Squeeze Cementing

Figure 8.20 Casing data from Red Book.

Subtract the pressure to reverse the remaining

cement slurry from the tubing from the collapse

resistance of the casing to find the maximum

pump pressure at surface:

9 Calculation of Pressure to

Reverse Out at the Completion of the

Job

2270 psi 789 psi = 14812 psi

Final Displacement Volume = 25 bbl

Cement Volume Remaining in Tubing:

35.90 bbl 25 bbl = 10.9 bbl

11

Reverse Pressure:

10.9 bbl 72.37 psi/bbl = 789 psi

Well Fluid

10 Amount of Cement Pumped

Through the Perforations

Volume of Cement in Perforations:

28.32 bbl 10.9 bbl 2.02 bbl = 15.4 bbl

15.4 bbl 5.6146 cu ft/bbl= 86.46 cu ft

86.46 cu ft 1.06 cu ft/sk = 82 sk

11 Maximum Pump Pressure if the

Channel is Full of Cement

10

Assuming that 25 bbl of displacement fluid have

been pumped behind the volume of slurry, and

that the channel is full of cement, you know

there is no differential pressure from the packer

to the perforations in this case. What is the

maximum pump pressure before the casing

collapses?

Figure 8.21 Calculations for 9, 10, and 11.

8 21

Cementing 1

Squeeze Cementing

Results of Calculations

The following table presents the results of the

nine calculations for Squeeze Problem Two:

Squeeze Cementing Calculation Results

Description

1 Volume of cement (bbl).

2 Pressure to reverse one

barrel of slurry from workstring.

Result

28.32 bbl

89.18 bbl

4 Displacement volume to

spot cement one barrel above

packer.

6.58 bbl

5 Pressure to reverse cement

when spotted.

2050 psi

6 Pressure to reverse cement

from workstring when cement

reaches top perforation.

1932 psi

1903 psi

8 Maximum pump pressure

when cement slurry has

reached the bottom perforation

347 psi

9 Pressure to reverse out at

the completion of the job

789 psi

10 Amount of cement

pumped through the

perforations

72.37 psi/bbl

3 Minimum water

requirements.

7 Pressure to reverse cement

from workstring when cement

reaches bottom perforation.

11 Maximum pump pressure

if the channel is full of cement

82 sk

1481 psi

Unit B Quiz

Fill in the blanks with one or more words to check your progress in Unit B.

1. The well parameters needed for squeeze calculations include:

____________________________________

____________________________________

____________________________________

____________________________________

____________________________________

2. To convert a given volume of cement from sacks to barrels, you must determine the

____________________________________________.

Now check your answers in the Answer Key at the back of this section.

8 22

Cementing 1

Squeeze Cementing

Answers to Unit Quizzes

Items from Unit A Quiz

Refer to

Page

1. correct, fill, oil/water

8-3

2. dehydrates

8-4

3. fracturing, pump-in, fluid

8-4

4. high

8-5

5. bleed-off, hesitation

8-5

6. maximum

8-5

7. fluid-loss

8-5

Items from Unit B Quiz

1. Drillpipe size

Refer to

Page

8-7

Packer depth

Top of perforations

Bottom of perforations

Casing size

2. yield of the slurry

8-9

8 23

Cementing 1

You might also like

- The Guide to Oilwell Fishing Operations: Tools, Techniques, and Rules of ThumbFrom EverandThe Guide to Oilwell Fishing Operations: Tools, Techniques, and Rules of ThumbRating: 4.5 out of 5 stars4.5/5 (11)

- Well Integrity for Workovers and RecompletionsFrom EverandWell Integrity for Workovers and RecompletionsRating: 5 out of 5 stars5/5 (3)

- Cementing CalculationsDocument39 pagesCementing CalculationsJohnSmith100% (6)

- Halliburton Sand Control MCS Closing SleeveDocument41 pagesHalliburton Sand Control MCS Closing SleevePither ZuritaNo ratings yet

- CL-4.Cement AdditivesDocument59 pagesCL-4.Cement AdditivesAli Aliiev100% (3)

- Drillsim 20 ManualDocument290 pagesDrillsim 20 Manualfabrizzio100% (1)

- Completion String ComponentsDocument12 pagesCompletion String Componentshameddriller100% (3)

- 5 4 Primary Cementing Calculations PDFDocument38 pages5 4 Primary Cementing Calculations PDFAbrarhassan100% (1)

- Squeeze Cement With Coiled TubingDocument60 pagesSqueeze Cement With Coiled TubingJose Leonardo Materano Perozo100% (1)

- Cementing Squeeze Program Braden Head MethodDocument20 pagesCementing Squeeze Program Braden Head Methodfauzanhaq1602No ratings yet

- Two Stage CementingDocument28 pagesTwo Stage CementingTariq100% (3)

- List of Asteroids in AstrologyDocument4 pagesList of Asteroids in Astrologymehta_chintan60% (5)

- Primary Cementing CalculationsDocument38 pagesPrimary Cementing CalculationsAli Aliiev33% (3)

- Squeeze CMTG With CTDocument60 pagesSqueeze CMTG With CTLuis Fernando Quiroz Ibañez100% (1)

- Cementing Best Practice Jorge SierraDocument60 pagesCementing Best Practice Jorge Sierrahamora3392% (13)

- Reverse Circulation Cementing: The Complete PictureDocument104 pagesReverse Circulation Cementing: The Complete PictureJoan Corso100% (1)

- Cementing CalculationDocument68 pagesCementing CalculationWanto Supriyo75% (4)

- 09 Bit Balling Summary GuidelinesDocument1 page09 Bit Balling Summary GuidelinesCerón Niño SantiagoNo ratings yet

- Cementing CalculationsDocument2 pagesCementing CalculationszapspazNo ratings yet

- Drillstring Design ManualDocument23 pagesDrillstring Design ManualAdil Aytekin93% (15)

- Squeeze Cementing PresentationDocument15 pagesSqueeze Cementing PresentationAhmed Ali AlsubaihNo ratings yet

- Liner CementingDocument18 pagesLiner CementingAli Aliiev100% (2)

- Vol 6 Remedial Cementing PracticesDocument127 pagesVol 6 Remedial Cementing PracticesdenywahyuNo ratings yet

- Guía para Tapones de CementoDocument15 pagesGuía para Tapones de CementoJunnior López PintadoNo ratings yet

- Cementing Manual - Macondo FindingsDocument44 pagesCementing Manual - Macondo FindingsEmilyDean100% (5)

- Squeeze Remedial CementingDocument4 pagesSqueeze Remedial CementingMahesh MahajanNo ratings yet

- Halliburton Cementing TablesDocument545 pagesHalliburton Cementing TablesOswal Agusto Cabrera Pantoja100% (1)

- Alaska Wells Group Recommended Practice: CT Operations - Squeeze CementingDocument29 pagesAlaska Wells Group Recommended Practice: CT Operations - Squeeze CementingMuhammad Shahrukh100% (1)

- Primary and Remedial CementingDocument108 pagesPrimary and Remedial CementingPablo Santo100% (2)

- Well Cement Integrity and Cementing PracticesDocument62 pagesWell Cement Integrity and Cementing PracticesMarwa Alqutt100% (5)

- Well CementingDocument8 pagesWell CementingNima MoradiNo ratings yet

- Cement Plug Balanced GuideDocument9 pagesCement Plug Balanced GuideemiljuchiacNo ratings yet

- Cementing Best PracticesDocument67 pagesCementing Best PracticesRobert Beddingfield100% (10)

- 2-Criteria For Successful CementingDocument36 pages2-Criteria For Successful CementingAry Rachman100% (2)

- Well Control BPDocument498 pagesWell Control BPcristianoclem100% (1)

- Cementing Lectures 2019Document24 pagesCementing Lectures 2019Uthman Mohammed100% (1)

- BJ SqueezecementingDocument77 pagesBJ SqueezecementingAbdullahAliNo ratings yet

- Coil Tubing ApplicationDocument40 pagesCoil Tubing ApplicationPratimaNo ratings yet

- Completions and Workovers 1.9Document46 pagesCompletions and Workovers 1.9Maqbool Ahmad67% (3)

- IDPT - 13 - Cementing TechnologyDocument41 pagesIDPT - 13 - Cementing TechnologyMas KuncritNo ratings yet

- Pipe Sticking PDFDocument5 pagesPipe Sticking PDFAnimeshNo ratings yet

- Tie Back Liner RunDocument3 pagesTie Back Liner RunkangrassNo ratings yet

- Squeeze Cement Complete Ver 2006Document22 pagesSqueeze Cement Complete Ver 2006Doni KurniawanNo ratings yet

- Casing and Casing Design 1Document60 pagesCasing and Casing Design 1Albert Wilson DavidNo ratings yet

- Coiled Tubing Cleanout, Diagnosis, and Remediation of Sand Control FailuresDocument43 pagesCoiled Tubing Cleanout, Diagnosis, and Remediation of Sand Control FailuresDavide Boreaneze100% (1)

- 06 - Liner CementingDocument18 pages06 - Liner CementingangelacanchonNo ratings yet

- Liner Running, Setting & Cementing ProceduresDocument43 pagesLiner Running, Setting & Cementing Proceduresarez muhammedNo ratings yet

- 12 CL-6.Liner CementingDocument19 pages12 CL-6.Liner CementingEslam Atif AzkolNo ratings yet

- Fracturing Engineering Manual - 4243456 - 02Document903 pagesFracturing Engineering Manual - 4243456 - 02Pablo Antezana100% (2)

- Cementing ServicesDocument110 pagesCementing ServicesReeder Pat Price100% (4)

- Downhole Cementing EquipmentDocument22 pagesDownhole Cementing EquipmentAli Aliiev100% (1)

- Sand Control and Gravel Packing Techniques: It Never Rains in the Oil Field!From EverandSand Control and Gravel Packing Techniques: It Never Rains in the Oil Field!Rating: 5 out of 5 stars5/5 (1)

- Casing and Liners for Drilling and Completion: Design and ApplicationFrom EverandCasing and Liners for Drilling and Completion: Design and ApplicationRating: 5 out of 5 stars5/5 (3)

- Model 3500 Bearing Maintenance ProcedureDocument2 pagesModel 3500 Bearing Maintenance ProcedureAli AliievNo ratings yet

- Model 7200 ManualDocument84 pagesModel 7200 ManualAli AliievNo ratings yet

- 4216 Mud Balance ManualDocument2 pages4216 Mud Balance ManualAli AliievNo ratings yet

- CL-8.Squeeze CementingDocument43 pagesCL-8.Squeeze CementingAli Aliiev100% (1)

- Model 3500 ManualDocument1 pageModel 3500 ManualAli AliievNo ratings yet

- Chemicals and ConsolidationDocument15 pagesChemicals and ConsolidationAli AliievNo ratings yet

- 5270 Technical ManualDocument24 pages5270 Technical ManualAli AliievNo ratings yet

- Dr. Randall Seright New Mexico TechDocument40 pagesDr. Randall Seright New Mexico TechAli AliievNo ratings yet

- CL-7.Liner CementingDocument15 pagesCL-7.Liner CementingAli AliievNo ratings yet

- B.suleimanovSelection Methodology For Screening Evaluation of EOR MethodsDocument11 pagesB.suleimanovSelection Methodology For Screening Evaluation of EOR MethodsAli AliievNo ratings yet

- Iptc 12145 MS PDocument22 pagesIptc 12145 MS PAli Aliiev100% (1)

- Spe 198351 MSDocument9 pagesSpe 198351 MSAli AliievNo ratings yet

- Rao CBM 96 (2015) 508-517Document11 pagesRao CBM 96 (2015) 508-517Ali AliievNo ratings yet

- Fiveland AnnbjørgDocument131 pagesFiveland AnnbjørgAli AliievNo ratings yet

- 32 PA New Experiments Models Conformance Control Microgels Goudarzi 05-07-14Document17 pages32 PA New Experiments Models Conformance Control Microgels Goudarzi 05-07-14Ali AliievNo ratings yet

- Gas MigrationDocument39 pagesGas MigrationAli AliievNo ratings yet

- Instruction Manual MODEL 3060 Constant Speed Mixer: Revision E.8 - February 2008 P/N: 30-060-0 S/NDocument20 pagesInstruction Manual MODEL 3060 Constant Speed Mixer: Revision E.8 - February 2008 P/N: 30-060-0 S/NAli AliievNo ratings yet

- Center For Petroleum & Minerals: Service Code Service Description Price, SR Sample PreparationDocument8 pagesCenter For Petroleum & Minerals: Service Code Service Description Price, SR Sample PreparationAli AliievNo ratings yet

- Active Land Growing MachinesDocument3 pagesActive Land Growing MachinesAli AliievNo ratings yet

- Instruction Manual MODEL 1200 Atmospheric Consistometer: Revision B.5 - March 2008 P/N: 12-0185 S/NDocument25 pagesInstruction Manual MODEL 1200 Atmospheric Consistometer: Revision B.5 - March 2008 P/N: 12-0185 S/NAli AliievNo ratings yet

- Model 7150 Fluid Migration Analyzer (FMA) : Part Number 7150-0089 Revision P.3 - January 2008Document76 pagesModel 7150 Fluid Migration Analyzer (FMA) : Part Number 7150-0089 Revision P.3 - January 2008Ali AliievNo ratings yet

- ISO10426 Calibration RequirementsDocument1 pageISO10426 Calibration RequirementsAli AliievNo ratings yet

- Amoco - Directional Survey HandbookDocument260 pagesAmoco - Directional Survey Handbookmsm2550% (2)

- Effects of Averrhoa Carambola Fruit Aqueous Extract On Some Aspects of Glucose MetabolismDocument5 pagesEffects of Averrhoa Carambola Fruit Aqueous Extract On Some Aspects of Glucose MetabolismHerald Scholarly Open AccessNo ratings yet

- Uptake of Carbon Dioxide and Evolution of OxygenDocument5 pagesUptake of Carbon Dioxide and Evolution of OxygenBeatrice Lianne Francisco EstacioNo ratings yet

- Fire Apparatus Turn Around DetailDocument1 pageFire Apparatus Turn Around DetailvitruviuzNo ratings yet

- Majstrovic Electricity-Transmission-And-Distribution Power Oman 2020Document113 pagesMajstrovic Electricity-Transmission-And-Distribution Power Oman 2020Abdul HaseebNo ratings yet

- CRE - Fluid-Particle ReactionDocument42 pagesCRE - Fluid-Particle Reactionandono kusuma jatiNo ratings yet

- Ascorbic Acid Drug StudyDocument2 pagesAscorbic Acid Drug StudyJam Mohammad100% (5)

- Manual HDF12 & 16 & 20 & 24 EN 150815 EMAILDocument36 pagesManual HDF12 & 16 & 20 & 24 EN 150815 EMAILAyman Hammodeh100% (1)

- 21.9L LuvegiDocument3 pages21.9L LuvegiJonathan CastilloNo ratings yet

- NGP TS 1100uDocument2 pagesNGP TS 1100uxxxfarahxxxNo ratings yet

- Ziess Lang Zeiss Information 70 114 120 1968 PDFDocument8 pagesZiess Lang Zeiss Information 70 114 120 1968 PDFAnonymous e6wKru5tnNo ratings yet

- Reproduction AND Development: (In Plants and Animals)Document29 pagesReproduction AND Development: (In Plants and Animals)Samarra LouisseNo ratings yet

- Hank Kolb CaseDocument2 pagesHank Kolb Caseafif12No ratings yet

- Sillicon 7225.1100Document49 pagesSillicon 7225.1100Mohammed ShoaibNo ratings yet

- Experiment No. 1 Physical Process: Name: Ariane Mamada Date: August 11, 2022 Yr & Section: 2 - V2A ScoreDocument17 pagesExperiment No. 1 Physical Process: Name: Ariane Mamada Date: August 11, 2022 Yr & Section: 2 - V2A ScoreAriane MamadaNo ratings yet

- Circulatory Pathway Through The Heart: Biology - CirculationDocument34 pagesCirculatory Pathway Through The Heart: Biology - CirculationLejNo ratings yet

- Chapter 1Document23 pagesChapter 1s26j22137No ratings yet

- Report On Jamshoro Thermal Power PlantDocument24 pagesReport On Jamshoro Thermal Power PlantSuresh Kumar100% (2)

- A2 MilkDocument16 pagesA2 MilkJesus Arturo Ramos ArticaNo ratings yet

- Cooling Towers Are Heat Removal Devices Used To Transfer Process Waste Heat To The AtmosphereDocument26 pagesCooling Towers Are Heat Removal Devices Used To Transfer Process Waste Heat To The AtmosphereAIYODOT DOTNo ratings yet

- Troubleshooting: 5.1 Troubleshooting For Circuit-Breaker Proper (MCCB/ELCB)Document6 pagesTroubleshooting: 5.1 Troubleshooting For Circuit-Breaker Proper (MCCB/ELCB)ARUNPRASADEEENo ratings yet

- Sabg Schools Phase III - Uge01 - Monthly Progress Report - April-24 Rev-00Document23 pagesSabg Schools Phase III - Uge01 - Monthly Progress Report - April-24 Rev-00Hamed JunaidNo ratings yet

- ESI (Tronic) 2.0: Diagnostic SolutionsDocument9 pagesESI (Tronic) 2.0: Diagnostic SolutionsMessi EmetievNo ratings yet

- Department of The Army Pyrotechnics Branch Aberdeen Proving Ground, Maryland 21020-5423Document5 pagesDepartment of The Army Pyrotechnics Branch Aberdeen Proving Ground, Maryland 21020-5423freemedicNo ratings yet

- RubberDocument29 pagesRubberabdullah2110154No ratings yet

- CSRL-NRL-Class - XI (MT - 02)Document14 pagesCSRL-NRL-Class - XI (MT - 02)Tarun SoniNo ratings yet

- AI - Class 9 HY MSDocument7 pagesAI - Class 9 HY MSBhavya RanaNo ratings yet

- The Fire Assay of Gold Silver and Lead in Ores and Metallurgical Products - Leonard Austin 1907Document100 pagesThe Fire Assay of Gold Silver and Lead in Ores and Metallurgical Products - Leonard Austin 1907Ferudun Akyol100% (2)

- Comparison Acces Point 20 Unit Cikarang 1Document22 pagesComparison Acces Point 20 Unit Cikarang 1Awaludin NurNo ratings yet

- Nickel 3Document227 pagesNickel 3AngelikRuiz100% (1)